We adjust the valves of the VAZ 2106, sequence table + adjustment video

Car owners of “classics” designed during the Soviet period often have to deal with the issue of repairing and tuning their car. Due to the high popularity and fairly strong density of cars on the roads of that time, some repair procedures and tuning operations remain quite relevant.

The design difference between classic cars and products of the modern automotive industry is the need to manually adjust many parameters.

Work order:

The valve adjustment procedure on the VAZ 2106 is necessary for a number of specific reasons. The main reason is the significant heating of the power unit during operation. The laws of physics state that during heating there is a linear increase in the size of solids.

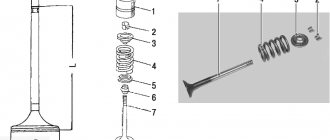

One of the most important elements that require adjustment under operating conditions is the gas distribution mechanism. The key element of this mechanism is the valve.

Valves are usually divided into intake and exhaust; they are responsible for opening access for the penetration of the air-fuel mixture into the working combustion chamber through special windows in the cylinder head. They are also responsible for the release of exhaust gases.

At the point of contact of the valve, a gap is formed, which is usually called thermal. It is this gap that is subject to careful adjustment.

Valve adjustment gauges

The result of incorrect valve adjustment is an increase in fuel consumption and a noticeable decrease in the power characteristics of the power unit.

What is the procedure for adjusting valves on a VAZ-2106

When the Zhiguli reaches its mileage of 10 thousand kilometers, it becomes necessary to adjust the valves, regardless of whether the car shows this failure.

For the VAZ-2106, the consequences can be terrible, which will entail not only loss of strength, but also the unnecessary waste of a large amount of money. You will learn from this article what the procedure for adjusting the valves on the VAZ-2106 is, it will be interesting. Neglecting the recommendations for adjusting valves after every 10 thousand kilometers can cause an increase in fuel consumption, a decrease in engine power and other problems that will interfere with the normal operation of the vehicle. If valve knocking occurs while the engine is idling, then this is the cry of the car’s soul; the valves urgently need to be adjusted. This sound has specificity, it is difficult to confuse it with any other. In order to make adjustments, it is not necessary to spend money on service stations; this can easily be done at home.

Preparation for work and disassembly

I would like to immediately note that this procedure requires time and is conditioned by an understanding of the process. There is a certain algorithm for implementing this task. To begin with, place your car on a level surface and provide free and well-lit access to the engine compartment.

The engine must be cooled and at ambient temperature.

Before starting the adjustment process, you need to prepare:

- a set of different wrenches in sizes “10”, “13”, “14”, “17”;

- 0.15 mm feeler gauge;

- key for turning the crankshaft;

- screwdrivers;

- spare valve cover gasket.

The disassembly process includes removing the air filter, disconnecting all pipes from the air filter cover, removing the choke cable, accelerator linkage and cylinder head cover.

It is advisable to remove the distributor cover so that it does not cause inconvenience during the adjustment process. There will be marks on the pulley and oil seal cover. The crankshaft must be turned until they coincide.

This position indicates that in the 4th cylinder the piston is on the compression stroke.

The procedure for adjusting valves VAZ 2101-2107

First we prepare the car:

- wait until the engine cools down if it was running;

- park the car on level ground;

Valve adjustment procedure:

- Remove the air filter cover and the filter itself.

- Disconnect the filter mounting tubes and remove the mount.

- Remove the air damper control cable (choke).

- Remove the throttle linkage.

- Unscrew the nuts securing the valve cover and remove it.

- Before adjusting the valves, immediately check how the chain is tensioned. If the tension is not normal, you will have to do the work again.

- Remove the distributor cover.

- We install the piston in the 4th cylinder at top dead center (TDC). TDCs are set using marks on the internal combustion engine crankshaft pulley and the camshaft drive cover, and marks are also applied to the camshaft gears and camshaft cover. The mark is set with a special key for the internal combustion engine crankshaft pulley bolt. If you don’t have a key, you can set the 4th piston to TDC by rotating one of the rear wheels. Raise one side with a jack and place the gear shift lever in 4th gear to make it easier to turn and turn the wheel slowly. When setting marks without a key, you will need an assistant to look at the marks.

- When the marks on the camshaft and the camshaft cover are aligned, check that the marks on the crankshaft are also aligned. You can also check whether the marks on the distributor slider match. The contact terminal should be directed to the high voltage wire terminal of the fourth cylinder. We have already discussed how to determine whether ignition is early or late in another article.

- After the marks match, we proceed to adjusting the valve clearances.

The correct procedure for adjusting the valve mechanism of the VAZ “Classic” 2101-2107. Crank angle Adjustable valves 8 and 6 180 4 and 7 360 1 and 3 540 5 and 2

The procedure for carrying out the valve adjustment process

Table of the sequence of adjusting valve clearances on a VAZ 2106 car:

| Crank angle | Camshaft angle | Cylinder numbers | Adjustable valve numbers |

| 0° 180° 360° 540° | 0° 90° 180° 270° | 4 and 3 2 and 4 1 and 2 3 and 1 | 8 and 6 4 and 7 1 and 3 5 and 2 |

The valves must be adjusted according to a strictly defined sequence. The following data indicates the degree of rotation of the crankshaft to adjust one valve or the other:

- The initial position, when the marks coincide, makes it possible to adjust valves 6 and 8.

- Having turned the crankshaft 180 degrees, we adjust valves 4 and 7.

- Rotation 360 degrees provides access to work with valves 1 and 3.

- A 540 degree rotation allows you to adjust valves 5 and 2.

For convenience, car enthusiasts and craftsmen apply their own marks to the crankshaft pulley. Most often it is divided into two parts, leaving a mark opposite the one made at the factory.

The process of adjusting valves on a VAZ 2106, list and video

From this video, you will learn how to adjust valves for a VAZ 2106. Enjoy watching!

During the adjustment process, you should adhere to this algorithm:

- Having maintained the position set according to the marks, we check the gap on cams 8 and 6 of the camshaft. An important fact is that the gaps are calculated starting from the star mark, which is located closer to the windshield. From this cam we begin counting. Next, under the camshaft, slightly above the rocker itself, we place the dipstick. If the probe penetrates freely, then it is necessary to loosen the nut 17 of the rocker where the measurements take place. To avoid any problems with scrolling, you need to loosen the nut by 13. Next, tighten the nut by 17 and the gap is measured again. It is necessary to ensure that the probe, penetrating into the gap, does not bend, but at the same time fits into it quite tightly with a certain force. After achieving the desired result, you can begin adjusting the next cam.

- For approximately 6 strokes, use the key to rotate the engine shaft. The mark on the sprocket should be in the 9 o'clock position and aligned with the mark on the pulley. Next, we adjust cams 4 and 7. The adjustment process is identical to that described above.

- Then we rotate the shaft 180 degrees. The mark on the star is at the 6 o'clock position. The mark on the pulley must strictly coincide with it. In this position, cams 1 and 3 are adjusted.

- By turning the shaft so that the mark is at the 3 o'clock position, we will be able to adjust the 2nd and 5th cams.

- The last step is to crank the crankshaft with the starter, then check all adjustments and tighten the nuts. We reassemble all dismantled elements in the reverse order. If necessary, we replace the valve cover gasket during the assembly process.

The process of adjusting the VAZ 2106 engine valves

The regulation procedure itself consists of several important stages:

- We set the position in accordance with the marks, check the gaps on camshaft cams No. 8 and 6. The gap should be fixed from the asterisk-shaped mark, which is located next to the windshield. We place a feeler gauge under the shaft, above the rocker. If it gets into the gap easily, you should loosen the size 17 nut on that rocker. Don't forget to loosen the nut to 13, otherwise scrolling will occur. Next, tighten the nut again and repeat the measurement. We need the feeler gauge to fit tightly into the gap, but not bend.

- Using a key, rotate the motor shaft 6 strokes so that the mark is at the 9 o’clock position and coincides with the notch on the pulley. After this, we adjust cams 4 and 7 in exactly the same way.

- By rotating the shaft 180 degrees, we gain access to valves 1 and 3. The mark is in position at “6” and clearly coincides with the cutoff on the pulley.

- We turn the shaft until the mark coincides with the “3 o’clock” position, and adjust valves 2 and 5.

- At the last stage, you should turn the crankshaft using the starter, finally check all the gaps and tighten the nuts. The assembly procedure is the reverse of the disassembly step. If necessary, you can replace the valve cover gasket.

Useful tips

Particular attention should be paid to the timing chain before adjusting the valves. The chain must be installed correctly. The degree of tension should be carefully checked.

An uneven knocking sound in the area of the upper part of the valve cover is evidence that the thermal clearances of the valves are increased and their adjustment is necessary. To adjust and measure the gap, it is necessary to use special feeler gauges aimed at adjusting classic VAZ engines.

These probes are wider. Standard feeler gauges are quite narrow and are not able to cover the entire width of the gap in the area of the pressure arms and camshaft cams. This makes it impossible to determine the correct gap size.

In most cases, the cover accompanying the dipstick contains a valve adjustment diagram. It is presented and designed in the form of a table. A well-tuned engine on a VAZ model 2106 is a fairly reliable design.

Adjusted valves reduce engine noise, ensure maximum performance and fuel efficiency. To achieve and maintain the maximum performance indicators specified by the manufacturer, adjustments must be made at a preferable frequency of 15 thousand kilometers traveled.

Traffic warning signs. You can find out what these signs are on our website.

This article contains a rating of DVRs with two cameras.

Here you can read how to make panel tuning for a VAZ 2114.

Source

Purpose of VAZ 2106 engine valves

One of the most important systems that require adjustment during operation is the gas distribution mechanism (GDM). The design of this mechanism allows the fuel-air mixture to be supplied to the combustion chamber in a timely manner and exhaust gases to be removed from the engine cylinders.

The timing belt includes the camshaft and crankshaft and the chain connecting them. Due to the timing mechanism, synchronous rotation of two shafts occurs, which, in turn, makes it possible to strictly observe the sequence of opening and closing valves in all cylinders.

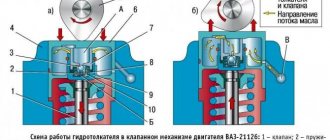

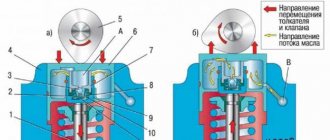

The camshaft lobes act on special levers that push the valve stems. As a result, the valves open. As the camshaft rotates further, the cams return to their original position and the valves close.

Thus, the result of the operation of the gas distribution mechanism is the consistent and timely opening and closing of the valves.

There are two types of valves:

- Intake (open the fuel supply to the combustion chamber).

- Exhaust (provide removal of exhaust gases).

Adjusting valve clearances on VAZ 2106

You can adjust the valve clearances of the VAZ 2106 yourself. To do this, you only need a standard set of plumbing tools and a few simple devices.

Reasons for adjusting clearances

The engine constantly operates at high temperatures. This leads to wear of its elements and a change in the size of the thermal clearances of the valves. External signs of incorrectly installed gaps are:

- the appearance of characteristic noise (knock) at idle;

- reduction in engine power and loss of dynamics during acceleration;

- increased fuel consumption;

- long-term operation of the vehicle without carrying out the clearance adjustment procedure.

Frequency of adjustment and size of gaps

The manufacturer recommends adjusting the thermal clearances of the VAZ 2106 valves every 30 thousand km, and checking their values every 10 thousand km. In addition, experts advise adjusting the gaps every time when dismantling the cylinder head (cylinder head) and replacing its gasket. If this is not done, the clearances of some valves will be reduced, while others will be increased. As a result, engine noise will increase, its power will decrease and fuel consumption will increase.

The gap size regulated by the automaker for intake and exhaust valves is 0.15 mm.

Required Tools

To adjust valve clearances, you will need the following tools and accessories:

- set of socket wrenches;

The dipstick cover usually shows the diagram and sequence of valve adjustment. However, a standard 0.15 mm thick feeler gauge cannot cover the entire width of the gap, so precise valve adjustment is not possible when using this tool. Moreover, the gap width gradually changes during operation due to wear of valves, cylinder head seats and other elements of the power unit. As a result, the adjustment accuracy is further reduced.

To more accurately set gaps, it is recommended to use a micrometer. In this case, the measurement results are practically independent of the condition and wear of engine elements.

Procedure for adjusting valve clearances

A special key is used to gradually rotate the crankshaft to a certain angle in order to sequentially adjust all valves. The numbering of valves, like cylinders, starts from the front of the engine, that is, from left to right.

The procedure for adjusting the valves is as follows:

- when the crankshaft is stationary, valves 8 and 6 are adjusted;

- when the crankshaft is turned 180 o, valves 7 and 4 are adjusted;

- when the crankshaft is turned 360 o, valves 3 and 1 are adjusted;

- When the crankshaft is turned by 540 o, valves 2 and 5 are adjusted.

You can also control the angle of rotation of the crankshaft by observing the movement of the distributor slider or camshaft. The only difference is that valves 7 and 4 are adjusted by turning by 90 o, and not by 180 o, as indicated above. The angle of subsequent turns should also be half as large - 180° instead of 360° and 270° instead of 540°. For convenience, marks can be applied to the distributor body.

Checking timing chain tension

Before setting valve clearances, you should check the timing chain tension and adjust it if necessary. As the vehicle is used, the chain gradually stretches. As a result:

- an unpleasant knock occurs when the engine is running;

- the chain wears out quickly;

- the chain jumps on the teeth of the camshaft sprocket, which leads to disruption of the timing phases.

Checking chain tension can be done in two ways:

- Open the hood and listen to the running engine. If there are extraneous noises that disappear when you briefly press the accelerator pedal, it can be stated that the chain is weakened.

- Remove the protective casing from the engine. We insert a screwdriver into the chain like a lever and try to bend the chain in at least two places where there is free space under it. The chain should not bend. A similar operation can be performed by hand. At the same time, it is not recommended to press hard on the chain to avoid damaging it.

When the chain is loosened, its tension is adjusted using a special tensioner.

Video: procedure for checking timing chain tension

The procedure for adjusting valve clearances on a VAZ 2106 with a micrometer

The algorithm for adjusting valve clearances with a micrometer is as follows:

- Place the car on a level surface and open the hood.

- Turn off the on-board power supply. To do this, disconnect the negative terminal of the battery.

Procedure for adjusting valve clearances with a feeler gauge

Adjusting the gaps with a feeler gauge is carried out similarly in the following order:

- By turning the crankshaft flywheel, we ensure that the marks of the camshaft sprocket and its bearing cap coincide. As a result, the piston of the fourth cylinder will rise to TDC, and it will be possible to adjust valves 6 and 8.

- We install a standard feeler gauge (0.15 mm) between the camshaft and valve rocker 8.

Video: adjusting valve clearances on a VAZ 2106

Adjusting valves on the VAZ-2106

The gaps between the camshaft cams and valve levers on the Classic need to be adjusted every ten thousand kilometers. This procedure is simple and can be done on your own without contacting a service center.

The gaps that need to be adjusted are also called “thermal”. They received this name because they are able to change as the engine warms up. When engine parts heat up during operation, they expand by fractions of a millimeter, but this expansion is enough to change the gap. If the thermal clearances are not measured and returned to the specified values, the camshaft lobes will begin to break and, eventually, the entire shaft will require replacement. This is a much more expensive and complex operation than adjusting the valves.

To adjust the thermal clearances of valves on a VAZ-2106, you will need wrenches 10, 13 and 17, a flat-head screwdriver, a spark plug wrench, a crankshaft wrench and a 0.15 mm thick dipstick.

Before removing the engine valve cover, you need to remove the air filter housing.

Work begins with removing the valve cover of the cylinder head

. For this:

1. Remove the negative terminal of the battery

2. Unscrew the three nuts of the air filter housing cover

3. Pull out the filter element and unscrew the fasteners of the lower part of the filter housing from the carburetor

4. Disconnect the crankcase ventilation hose from the air filter housing and remove the housing. Carefully close the carburetor hole with a cardboard lid or a lint-free cloth.

5. Using a screwdriver, loosen the bolt securing the carburetor air damper rod (“choke”) and move it to the side.

6. Remove the retaining ring on the triangular lever of the carburetor rods and remove the lever. If the lever cannot be removed, disconnect the carburetor linkage system from the main linkage of the gas pedal by removing the lock.

7. Unscrew all the nuts securing the valve roof (along the perimeter), remove the profile washers

8. Remove the valve cover by first lifting its rear edge (closer to the interior), and then moving it towards the front of the car and up.

The valve cover has been removed. Now you can start placing marks on the shafts

This will give you access to the camshaft and valves. On the VAZ-2106, as on all classic AvtoVAZ models, the valves have a lever drive and are adjusted with nuts. Each valve has two nuts - a locking one and an adjusting one. By turning the adjusting nut, the amount of lift of the valve lever changes and thereby adjusts the gap between it and the corresponding cam on the camshaft.

The valve adjustment bolts are located on the left in the direction of travel of the vehicle.

The clearances are adjusted at a certain relative position of the crankshaft and camshaft. To understand what position they are in, you need to set the piston of the first cylinder to the highest possible position (top dead center, TDC).

For this:

1. Unscrew the spark plug of the first cylinder.

2. Remove the ignition (distributor) cover.

3. Using a crankshaft pulley wrench, rotate this shaft to such a position that the mark on the camshaft sprocket (recess) coincides with the boss (protrusion at the top) on the camshaft bearing housing.

4. The outer contact of the ignition distributor rotor (distributor slider) should be under the contact of the spark plug of the first cylinder on the distributor cover. If this is not the case, rotate the shaft again until the marks match and the contact should fit as it should.

It is convenient to determine the top dead center in the first cylinder by the position of the distributor slider.

If the marks match and the contact of the distributor rotor is in the spark position on the spark plug of the first cylinder, it means that the piston of this cylinder is set to top dead center. You can verify this not only by the marks. When there is very little left until the marks on the camshaft sprocket and on the bearing housing coincide, you can insert a screwdriver into the spark plug hole of the first cylinder and very carefully turn the crankshaft with a wrench. The screwdriver will begin to be clamped by the piston. If this happens, it means that it is moving upward, and during the coincidence of the marks it will actually remain at TDC. Before bringing the piston to TDC, the screwdriver must be pulled back.

This position of the shafts and pistons is the beginning for adjusting the valves. Next, you will need to periodically rotate the crankshaft and check the clearances at the corresponding valves. When and where to check, we learn from the thematic infographics prepared for adjusting the valves of carburetor engines of classic VAZs. The zero position of the crankshaft (0 degrees) is the piston of the first cylinder set at TDC; we begin the adjustment from this position.

The procedure for adjusting valves on a VAZ-2106

Checking the gap using a feeler gauge is carried out as follows. After aligning the shafts according to the table, insert a feeler gauge under the camshaft bearing housing above the valves of the cylinder corresponding to the table. The feeler gauge will fall into the gap and should move in it with slight pinching. If the probe moves freely or, conversely, almost does not fit through, this valve needs adjustment.

To adjust the valve you need:

1. Hold the adjusting nut with a 13mm wrench and loosen the locking nut with a 17mm wrench.

2. If the probe went through freely, slightly tighten the adjusting nut (to the left); if the probe did not fit through, move the nut to the right.

3. Try inserting the dipstick again.

4. Make sure that the feeler gauge begins to enter the gap with slight pinching and, again holding the adjusting nut from turning, tighten the lock nut.

Perform this operation on all valves according to the table. And when all adjustments are completed, turn the crankshaft one revolution. Set the marks again and repeat the check. If the clearances remain normal, you can install the valve cover and reassemble all the attachments.

Valve stem seals

Oil seals (valve seals) are designed to seal the valve. They trap excess lubricant (motor oil), preventing it from entering the combustion chamber.

The mechanical pair in the cylinder head is the valve stem and its guide sleeve. Technologically, it is almost impossible to join these parts without a gap. Valve seals are used to seal the connection. A high-quality and serviceable cap should fit tightly on the valve stem and allow only the amount of oil to pass through that is necessary for normal operation of the system.

If earlier the caps were made of fluoroplastic, now their production uses special reinforced and oil-resistant rubber. The upper part of the cap is pressed against the valve stem by a special spring.

The market offers valve stem seals from various manufacturers and brands, differing in quality, reliability and durability.

After long-term operation of the engine, the oil seal may collapse due to:

- physical aging of the material from which it is made;

- loss of the original elasticity of rubber under the influence of oil and high temperature;

- material delamination.

This causes excess lubricant to enter the combustion chamber and increases oil consumption. Oil seals on domestic cars are usually replaced every 80 thousand kilometers. The last figure may increase significantly as a result of:

- use of caps made of modern high-quality materials;

- using high-quality original motor oil;

- preventing engine overheating;

- constant monitoring of the engine oil level.

Signs of failure of valve stem seals

The main signs of malfunction of valve seals on the VAZ 2106 are:

- increased oil consumption (more than one liter per thousand kilometers);

- light-colored exhaust gases;

- oil deposits on spark plugs;

- significant reduction in the dynamic characteristics of the engine;

- increase in fuel consumption.

Such problems can be solved by replacing the caps. It's quite easy to do it yourself.

Selection of valve stem seals

Until the end of the 80s, caps produced by the Kursk plant were installed on all domestic cars. They were not of high quality, since they could not withstand high temperatures, and they had to be changed every 30 thousand kilometers. Then a new rubber-like material (fluorine rubber) was developed, from which leading manufacturers began to make caps. The material from which they are made may differ in color, but its basis should be rubber (recycled or acrylate), which ensures the durability of the part.

The presence of impurities in the material of the caps leads to their rapid failure. This applies primarily to fakes. Therefore, when purchasing, you should first of all pay attention to the manufacturer and be able to identify original products. The cost and service life of caps from leading brands are approximately the same.

When replacing VAZ 2106 caps, we can recommend the products of the following companies:

- Elring is a German company that produces not only rubber caps, but also a number of other parts, and supplies its products to more than 140 countries.

- Glazer is a Spanish company with a rich history, producing caps that are certified and comply with ISO9001/QS9000 requirements.

- Reinz is a German company whose products experts recommend installing on an unworn valve-guide bushing pair.

- Goetze is a German company recognized by automakers around the world. Since 1987, Goetze has been a supplier of quality spare parts for cars and boats, including valve stem seals, manufactured using innovative technology.

- Payen and other manufacturers.

The quality of original domestic products is significantly inferior to foreign analogues. In any case, the choice remains with the car owner, his wishes and capabilities.

Replacing valve stem seals for VAZ 2106

To replace the caps you will need:

- special desiccant for valve crackers (fasteners);

The procedure for replacing valve stem seals is as follows:

- Remove the valve cover from the cylinder head.

- Remove the camshaft and rocker.

Video: replacing valve stem seals on a VAZ 2106

Replacing the valve cover gasket

The need to dismantle the cylinder head cover arises in the following situations:

- when tensioning the chain in the engine;

- when replacing the valve cover gasket;

- when adjusting valves;

- when replacing other engine parts.

The process is simple and will not take much time with minimal plumbing skills. To do this you will need:

- heads for 8 and 10;

- extension for keys;

- crank or ratchet;

- pliers.

Valve cover gasket replacement procedure

The valve cover gasket is changed as follows:

- Unscrew the three nuts and remove the cover from the metal air filter housing.

- Remove the air filter from the housing.

- Unscrew the four nuts securing the filter housing to the top of the carburetor.

After replacing the gasket, assembly is performed in the reverse order.

Video: replacing the valve cover gasket

Procedure for tightening the nuts on the valve cover

The nuts on the valve cover should be tightened very carefully in a strictly defined sequence, as excessive force can strip the threads on the studs. First you need to tighten the nuts in the middle of the cover, and then gradually move to its edges.

Correctly and timely adjusted valves will allow the owner of a VAZ 2106 to avoid much more serious problems. You can do this yourself, having a standard set of tools and devices and carefully studying the recommendations of professionals.

Source

The procedure for adjusting valves VAZ 2101-2107

First we prepare the car:

- wait until the engine cools down if it was running;

- park the car on level ground;

Valve adjustment procedure:

- Remove the air filter cover and the filter itself.

- Remove the air damper control cable (choke).

- Remove the throttle linkage.

- Unscrew the nuts securing the valve cover and remove it.

- Before adjusting the valves, immediately check how the chain is tensioned. If the tension is not normal, you will have to do the work again.

- Remove the distributor cover.

- We install the piston in the 4th cylinder at top dead center (TDC). TDCs are set using marks on the internal combustion engine crankshaft pulley and the camshaft drive cover, and marks are also applied to the camshaft gears and camshaft cover. The mark is set with a special key for the internal combustion engine crankshaft pulley bolt. If you don’t have a key, you can set the 4th piston to TDC by rotating one of the rear wheels. Raise one side with a jack and place the gear shift lever in 4th gear to make it easier to turn and turn the wheel slowly. When setting marks without a key, you will need an assistant to look at the marks.

- When the marks on the camshaft and the camshaft cover are aligned, check that the marks on the crankshaft are also aligned. You can also check whether the marks on the distributor slider match. The contact terminal should be directed to the high voltage wire terminal of the fourth cylinder. We have already discussed how to determine whether ignition is early or late in another article.

- After the marks match, we proceed to adjusting the valve clearances.

The correct procedure for adjusting the valve mechanism of the VAZ “Classic” 2101-2107. Crank angle Adjustable valves 8 and 6 180 4 and 7 360 1 and 3 540 5 and 2

Disconnect the filter mounting tubes and remove the mount.

From the table we see that if the 4th piston is set to top dead center, then we measure and adjust the 6th and 8th valves.

vote

Article rating