08/21/2021 15,382 VAZ 2106

Author: Ivan Baranov

After a certain mileage, oil consumption increases and compression in the cylinders decreases. This indicates wear of the piston group. In this case, the piston will need to be replaced. When replacing pistons, it is necessary to take into account the dimensions of the piston group of the VAZ 2106. The article describes how to correctly select and change all the components of the piston group on the VAZ 2106.

[Hide]

Replacing Piston Rings for VAZ 2107 ~ VESKO-TRANS.RU

Replacing pistons and piston rings VAZ 2107

Replacing piston rings and pistons on a VAZ 2107 is done in cases where the gap between the surface of the ring, piston and the working surface of the cylinder increases, which in turn is accompanied by an increase in oil consumption, a decrease in engine power, and also an increase in fuel consumption.

Typically, wear of the pistons is accompanied by wear of the compression rings, and it may also be necessary to bore the cylinder block.

Major repairs with block boring must be carried out in a special workshop, because it is unrealistic to carry out such work without special abilities and experience; the most that can be done is to remove and replace the pistons and piston rings.

To replace piston rings and pistons, you need to drive the car into a pit; you will need a standard set of tools. The order of repair work is as follows:

- Drain the engine oil from the engine crankcase by unscrewing the drain plug on the pan. Also remove the pan by unscrewing the bolts securing it with a 10mm socket wrench.

- Remove the cylinder head, having previously removed the air filter, the cylinder head cover and unscrewing the nuts securing the head, remove it from the block.

- We remove the pistons alternately, starting from the first cylinder. We unscrew the nuts securing the connecting rod caps, remove the steel-aluminum liner from the cap and push the piston assembly with the connecting rod upward.

- We remove the piston and connecting rod assembly and secure it in a vice. Using a screwdriver, we remove two compression rings and one oil scraper ring (if the pistons are removed to replace the rings, if the pistons themselves need to be replaced, then there is no need to remove the rings). Using an iron mandrel of suitable diameter, knock out the pin and remove the piston.

Replacing the piston after overheating of a VAZ (classic). Do it yourself!

It turned out very long! Anyone who wants to find out a lot from what is not written in more than one book,

Read also: Replacing the Passat B4 Heater Radiator With Air Conditioning

Part 5 Lada Overhaul of VAZ 2107 (1600) Preparation of piston rings for installation

Showed how you can remove and disassemble the engine at home from a VAZ

classic, without winch. I tried

This completes the disassembly process. Now we need to pick up new pistons. Take the new piston and stick it into the cylinder, the regular piston should slowly lower under its own weight. If the piston fails or does not move, then it does not fit. Also, when selecting, keep in mind that the internal diameter of the cylinder will initially be somewhat smaller, so make the assessment here and there in the middle part of the cylinder.

The next step is to select the rings. Insert the ring into the cylinder and lower it slightly downward, slightly above its middle part. The gap between the ends should be less than 0.2mm or two blades wide.

Next, you need to select a pin for the new piston. Lubricate your finger with engine oil and insert it into the piston. It should be inserted with the usual pressure of a huge finger and should not fall out when positioned vertically. The finger should not fit freely into the connecting rod head; it will have to be seated on the hot side.

Once all the elements have been selected, you can begin assembly. First we assemble the piston and connecting rod with a pin. To press the pin, you will need a special mandrel and a gas burner to heat the connecting rod head. The assembly order looks like this:

- Insert the retaining ring into the piston boss on one side.

- Clamp the connecting rod in a vice, heat its head to 240V°, put on the piston and insert a pin using a mandrel, which will simply fit into the heated head. Push your finger until it rests against the locking ring . Install the second stopper.

At the final stage of assembly, install two compression rings and an oil scraper ring. Lubricate the rings, their grooves and the connecting rod with engine oil. Push the piston into the cylinder from above and secure the connecting rod to the crankshaft. At this point, the repair work on removing and replacing pistons and piston rings of the VAZ 2107 has been completed.

Read also: Opel Astra H Low Beam Lamp Replacement

Source: https://vesko-trans.ru/zamena-porshnevyh-kolec-vaz-2107/

How to replace piston rings in an engine yourself

Decrease in vehicle performance can be due to many factors. Therefore, the “treatment” for such a disease must be selected correctly. A significant factor is the level of compression in the combustion chambers of the cylinder block. For such a diagnosis, replacing the piston rings is suitable.

THIS IS INTERESTING: How to disassemble a VAZ 2107 generator

Additional signs include loss of engine oil and decreased fuel efficiency of the vehicle. A more accurate picture will be obtained by measuring compression using special instruments.

Carrying out compression measurements in cylinders

Let's look at an example of working on classic VAZ models. It is necessary to measure compression on a warm engine. Readings from a cold engine can distort the picture. For measurements, you will need a special pressure gauge equipped with a threaded tip. It can be bought at any auto store.

Compressometer appearance

The check begins by unscrewing all the candles from their sockets. Then the central cable from the ignition coil is disconnected. We set the gear to neutral and turn the throttle valve to the maximum opening. After this, screw the compression gauge into one of the spark plug holes. At this time, an assistant must turn the starter handle. Two or three pumps will be enough.

The readings are considered normal if the data on the device is 12-13 ks/cm2.

Level 10 to 12 is also acceptable. But if the numbers are below 10 kg/cm2, then this indicates low compression. If compression still reaches a satisfactory level, but a little late, then the valves may be responsible.

To clarify, you can pour about 20 ml of oil into the disputed chamber and crank the starter again, taking a measurement. When normal compression is established at 12 kg/cm2, the reason lies in the rings. Correct installation of the piston rings can solve this problem. If the pressure remains low, then the valves are the cause of the decrease.

Installation using a mandrel

Disassembling the engine to replace rings

Before replacement, it is necessary to perform a number of preparatory work:

- it is necessary to drain the used engine oil, because after installing new rings you need to fill in fresh working fluid;

- We loosen the exhaust pipe of the muffler;

- you need to remove the valve mechanism cover and align the engine to the marks;

- we dismantle the camshaft star, and for front-wheel drive VAZs we remove the bolt securing the belt drive pulley, and then the timing belt itself with the pulley;

- in the classics, we loosen the tensioner, and then also dismantle the chain and sprocket mounted on the camshaft;

- then we dismantle the rocker with springs, laying everything out in the correct order to assemble the parts into place;

- remove the block head, before this you need to disconnect the manifold;

- unscrew and get rid of the pan and oil pump;

- remove the connecting rod caps, and then push the connecting rods up so that they can be pulled out along with the piston.

Source: https://ktonaavto.ru/remont-i-obsluzhivanie/dvigatel/kak-samomu-zamenit-porshnevye-kolca-v-dvigatele.html

VAZ 2106 engine design - Do-it-yourself car repair

The VAZ-2109 was equipped with three power units with a volume of 1.1, 1.3 or 1.5 liters. With the exception of displacement and, accordingly, height, the Nine engines are otherwise no different from each other.

Initially, all installed engines were carburetor, and only at the beginning of the 2000s the manufacturer began to equip cars with injection engines.

Below we will consider the design of the “nine” engine using the example of the 1.5-liter VAZ-2111 injection engine; it was also installed on the VAZ-2110 and 2114 of early years of production.

So, the “heart” of the VAZ-2109 car is a four-stroke, four-cylinder, eight-valve “aspirated” engine running on gasoline, with an overhead camshaft. Unlike the rear-wheel drive VAZ-2106 and VAZ-2103, the front-wheel drive models 2109, 2110, 2114 and others have a transverse engine. The cylinders are numbered from the crankshaft pulley, their operating order is 1-3-4-2. Electronic control is carried out by a “January” controller, Bosch or GM.

Engine crank mechanism

The design of the cylinder block of the VAZ-2111 engine is identical to block 21083. It is cast from cast iron, the cylinder diameter is 82 mm, and if the piston group is replaced, it can be increased by:

- 0.4 for the first repair;

- 0.8 at the second.

Crankshaft

The crankshaft is located at the bottom of the block and rotates on five main bearings that have removable covers, which are secured to the block with bolts. The covers are not interchangeable and are marked with marks on the outside.

The middle support of the main bearing has slots into which support half-rings are installed, eliminating axial displacement of the crankshaft. The front half-ring is made of an alloy of steel and aluminum, the rear half-ring is made of cermet.

If play in the crankshaft appears, the half rings must be replaced.

THIS IS INTERESTING: Ford Focus 2 repair

The bearing shells - support and connecting rod - are thin-walled, made of steel-aluminum alloy. There are grooves on the inside of all the upper main bearings, with the exception of the third bearing bearing.

The design of the crank (engine crankshaft) is as follows: it is cast iron, has four connecting rods and five main journals. Eight counterweights are cast together with the shaft. Channels are drilled inside the shaft, closed with plugs and having a dual purpose:

- they supply oil to the connecting rod journals from the main ones;

- they clean the oil, since centrifugal force throws all mechanical impurities that are not retained by the filter towards the plugs.

The latter circumstance must be taken into account when overhauling the engine, and when removing the crankshaft, and especially when balancing, it is necessary to clean the channels from accumulated deposits. After cleaning, the plugs are replaced with new ones.

The camshaft drive pulley is attached to the front part of the crankshaft, and to it is the generator drive pulley, which also works as a damping device, thanks to the elastic element between the outer and inner parts of the pulley.

A cast iron flywheel is attached to the rear end using six bolts. It has a ring gear designed to start the engine using a starter.

In addition, there is a conical mark on its surface, designed to determine TDC after the engine is assembled.

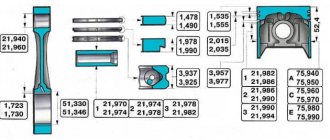

Piston group

The connecting rods are made of steel and have an I-section. The covers are processed together with the connecting rods, and therefore are not interchangeable. The cylinder number is stamped on them and on the connecting rods.

Piston pins are steel tubes. They float freely in the piston bosses, in which they are fixed using retaining rings.

Piston design: the pistons are made of aluminum alloy and have three grooves in the upper part for piston rings. The set of rings for each piston consists of two compression rings and one oil scraper ring. Compression rings prevent gases from entering the crankcase, and the oil scraper removes oil from the cylinder walls and carries it to the bosses to lubricate the piston pin.

Slightly lower are the holes for the piston pin (boss). There is a recess in the bottom of the piston designed to prevent bending of the valves in the event of a break in the timing belt. In the VAZ-2109 with an engine capacity of 1.3 liters, it is flat, so a broken belt inevitably led to failure of the entire piston group and gas distribution mechanism, and as a result, to expensive repairs.

Block head and timing device

All front-wheel drive cars of the VAZ family, be it 2109, 2110 or 2114, have one cylinder head, common to all cylinders. They are mounted to the block using ten screws. During installation, a metal gasket is placed under it. This gasket is for single use and cannot be reused. There are five camshaft bearings at the top of the cylinder head.

The camshaft of the engine of the VAZ-2109 car has the index 21083. Some engines are equipped with 2110 or 2111 shafts; their design is slightly different from 21083, which allows for an increase in engine power.

The shaft is cast from cast iron, there are five supports and eight cams on it that open the valves. It is driven by a toothed belt from the crankshaft pulley.

The shafts can be correctly installed relative to each other using the alignment lug on the rear timing belt cover and the marks on the drive gears and flywheel.

Seats are pressed into the cylinder head, as well as valve guides. On the inside of the bushings there are grooves for supplying lubricant; the bushings are closed on top with oil deflector caps.

The valves are made of steel, and the intake head is made of heat-resistant steel. They are mounted obliquely in one row. The inlet valve has a larger diameter than the outlet valve. The gaps between the valves and camshaft cams are adjusted using shims that have increased wear resistance.

Pushers are metal cups moving in the cylinder head holes. To improve wear resistance, the surface in contact with the ends of the valve stems is cemented.

Lubricating parts

Combined engine lubrication device for the VAZ-2109 (2110). Oil is supplied to the main and connecting rod bearings, as well as to the camshaft supports under pressure; the cylinders, pistons, pins and rings, camshaft cams and pushers are lubricated by splashing; all other associated parts are lubricated by gravity.

A gear-type oil pump with a bypass valve is installed at the front of the block. The oil receiver is mounted using bolts on the cover of the second main bearing and the pump housing. The oil filter is non-separable and has bypass and anti-drainage valves. The design of the lubrication system and other engine systems is discussed in detail in separate articles.

THIS IS INTERESTING: Lada Granta speed floats

Crankcase ventilation is forced, gases are removed through the oil separator.

Source: https://avto-voshod.ru/ekspluatatsiya/ustrojstvo-dvigatelya-vaz-2106.html

Piston pin VAZ 21213, 2101-07, 2121, 2123 (blue, green, red)

Dear customers, in order to avoid mistakes when sending a set of piston pins, in the “Comment” line indicate the model and year of manufacture of your car, the class of the piston pin (blue color - 1st class, green color - 2nd class, red color - 3rd class th class).

The clouds of bluish smoke escaping from the exhaust pipe give the driver many unpleasant thoughts. This most often indicates an unpleasant, but inevitable moment in the life of a car - engine repair.

When the car has traveled approximately 150 thousand kilometers, noticeable wear of the piston group occurs.

By diameter, piston pins are divided into three classes at 0.004 mm intervals.

Source

How to replace piston rings without removing the engine?

The service life of piston rings is not tied to scheduled maintenance. Although under ideal operating conditions this should be the case. In reality, they are replaced when compression decreases.

If a major overhaul of the engine is not planned, a replacement can be carried out without removing the power unit. It is quite “comfortable” to change the piston rings without removing the engine on in-line fours with a transverse arrangement.

The press release was prepared by specialists from the mileage adjustment website Krutilka-spidometra.ru. We always have a professional speedometer twister in stock - which will increase your mileage without any trace of intervention in the system and at the time you need. Quality guarantee for all devices, fast delivery in Moscow and throughout Russia.

As an example - vase. replacing the piston on a classic without removing the engine

No special equipment is required for this, except perhaps a crimping mandrel. It is advisable to install the car on an overpass, or use a garage pit. You can change the piston rings without removing the engine by placing the front end on supports, but it is inconvenient to work this way.

The order of work is as follows:

- Drain the engine oil and coolant.

- We remove the cylinder head.

- Remove the engine sump.

- Unscrew the lower connecting rod clamps.

- We push out the pistons with connecting rods.

Then we change the rings in the usual way, driving the pistons into the cylinder head. We install the head in place, screw the lower clamps of the connecting rods.

Any garage mechanic knows how to remove the piston on a classic VAZ without removing the engine. But with foreign cars everything is somewhat more complicated.

What engines was equipped with the VAZ 2103

The VAZ 2103 power plant is a classic model, part of the AvtoVAZ OJSC engine line. This is a modernized version of the FIAT-124 unit, developed by domestic engineers back in the second half of the last century. The changes affected the camshaft and the inter-cylinder distance.

The tuning of the FIAT-124 engine was carried out with high quality, because in the future its mass production did not stop for decades. Of course, restylings were carried out, but the core of the engine remained the same. The peculiarity of the VAZ 2103 engine is that its timing shaft is driven by a chain and not a belt.

The 1.5-liter power unit represents the third of four generations of the classic. This is the heir to the 1.2 liter VAZ 2101 and 1.3 liter VAZ 21011 engines. It preceded the creation of the powerful 1.6 liter VAZ 2106 unit and more modern injection engines for front-wheel drive cars. All modifications of the VAZ 2103 engine were distinguished by improved technical capabilities.