Adjusting the idle speed of carburetors is most often in demand for domestic cars.

In this article we will look at how adjustments are made correctly and what tools are needed for this. At the end of the article we tell you how to find a good specialist in carburetor engines to carry out adjustments. Find out the cost of idle air adjustment online in 3 minutes

Don't waste your time - use the Uremont search and get offers from nearby services with specific prices!

Get prices

Why do you need to adjust carburetor idle speed?

According to the factory's requirements, the crankshaft of our car must rotate at idle (that is, when the car's engine is running, but you do not press the gas pedal) at a speed of no more than 900 and no less than 850 revolutions per minute. With an unadjusted carburetor, the engine:

- There will be three.

- It will stall.

- Gasoline consumption will increase.

It will not work correctly while driving and accelerating (with dips).

Features of setting up the carburetor of a 2-stroke scooter

The carburetor on the 2t scooter is slightly different in design and does not fit the 4t motor. The question of how to set up such a device worries all owners of two-stroke machines.

Most Chinese models have a fairly simple carburetor without unnecessary adjustments. The enrichment here is mechanical, although if you are tuning a scooter or you have a Japanese model, the enrichment can also be electric. In order to use the mechanical option, you must first pull the trigger on it, and then try to start the equipment.

Adjusting the carburetor of a 2T scooter is not difficult, but it does require some patience. In order to do this, you will need to disassemble the carburetor: first you will need to unscrew the top cover. The needle in it is fixed with a staple; it needs to be pulled out. The quality of the mixture is adjusted in the same way as described above. A feature of the push-pull system is that the needle affects the quality of the mixture only in a certain position. If the throttle valve is raised to its maximum, only the main fuel jet will be responsible for the fuel mixture. Sometimes the idle speed system interferes with it. Depending on what carburetor you have installed.

For a cold start, you need to use a starting enrichment, which must be closed after the engine warms up; Simply put, it's a suction. In such carburetors, the fuel level plays an important role. It is also regulated by mechanical intervention in the operation of the float chamber. It is configured in the same way as in the four-stroke version. In fact, the carburetor for 2t engines differs from models for engines on a 4-stroke scooter only in jets and some other parameters, but it is designed similarly, and therefore is regulated in the same way.

What do you need to know before adjusting your engine carburetor?

First, we should consider the simplest rules that we will need before proceeding with the operation of setting up this engine unit.

Adjusting the idle speed should only be done when the engine is warmed up to operating temperature. This is an elementary and fairly understandable rule, which can be explained very simply - when an engine adjusted in a cold state heats up, it will work differently. In general, the quality of any carburetor and its reliability are determined by how long it has been in operation. The new reliable carburetor does not require intervention in its operation. Adjustments are made only after the crankcase tube has been completely disconnected. This is the only way to get rid of the influence of crater gases when making adjustments. For precise tuning, you need to use a gas analyzer. This is a desirable but mandatory requirement; however, with the device, the results will definitely be more accurate. The method of regulating the stroke of carburetors is the same for all VAZ cars. You will need one tool - a slotted screwdriver.

The essence of the adjustment procedure is simple and clear. There are two screws on the engine carburetor - they are called the “quality” screw and the “quantity” screw. The first screw changes the area of the hole, through which a mixture of gasoline and air is supplied to the engine. And the quantity screw regulates the crankshaft speed.

There are imported carburetors that use a “quality” screw to change the cross-section of the jet, what is called “by air”. You can tell them apart by looking at the “quality” screw at the top of the carburetor. On domestic fuel supply systems, this screw is located at the bottom of the unit - the usual “gasoline” setting.

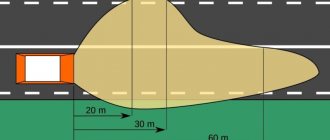

To finish with the theory and start talking about how the engine idle speed is adjusted, let’s just say that when tuning “by air,” the air-fuel mixture is enriched with gasoline, and when tuning “by gasoline,” on the contrary, it becomes leaner. Also, those interested can look at the picture explaining the principle of operation of the carburetor.

How to clean a VAZ 2106 carburetor without removing it

The first cleaning method is to do it without disassembling the mechanism. The fact is that not every car enthusiast is able to disassemble and reassemble the unit. A special technique was developed for its washing. For this purpose, a special aerosol product in cans is used. Common cleaners include “ABRO”, “Mannol”, here I made an overview table of carburetor cleaners, perhaps it will be useful to you when choosing.

To clean, you will need to perform the following steps sequentially:

- Warm up the engine and turn it off.

- Remove the filter and its housing.

- To effectively flush, remove the solenoid valve by unscrewing it from the housing.

- Special nozzles are sold with the cans, which effectively distribute a powerful stream of product. All visible parts are treated with the substance.

- Afterwards, process the external parts of the device.

- Next, you need to wait from 5 to 8 minutes, which depends on the manufacturer. During this time, the product dissolves carbon deposits, after which it is easily washed out with gasoline and the dirt burns in the cylinders along with the fuel.

Cleaning a VAZ 2106 carburetor is usually accompanied by replacing the gasket, which is located between the carburetor body and the manifold. The manufacturer produced several types of gaskets made of paronite, metal and heat-resistant special cardboard. If you are not sure about modifying your carburetor, then take it to the market with a real material example.

To replace the gasket, the seating area should be thoroughly cleaned of dirt and wiped with a rag. Lay the new one in the same way as the old one was laid, install the mechanism on it and tighten the fastening nuts.

How to clean the carburetor on a VAZ 2106 using a solvent

One of the most accessible ways to flush the carburetor on a VAZ 2106 is to flush the carburetor with a solvent. The washing process is clearly shown in this video:

How to quickly blow out a carburetor with your own hands

If you do not have a compressor or any other specialized equipment for purging, you will need a regular car compressor, which can be bought in a store for pennies. How to blow through a carburetor on a VAZ 2106 with a car compressor in this video:

How to carry out regulation using the example of a domestic carburetor

The domestic “Zhiguli” carburetor “Ozone” is regulated by the supply of gasoline. At the same time, in the middle part of the designer they installed an “over-the-air” adjustment screw, this greatly expanded the range for settings of the machine unit. Before you begin the carburetor adjustment procedure, you need to make sure that the throttle adjustment drive is working properly and is not sticking. To do this, simply press the gas pedal. Then you need to set the ignition timing and adjust the gas distribution. These are complex engine tuning operations; each deserves its own article. Carburetor adjustment, so to speak, is the “finishing touch” to the final tuning of your car’s engine.

How is the idle speed of a VAZ adjusted?

- First screw in the “quality” screw all the way to the limit.

- Then carefully turn it back one and a half or 2 turns. This way your fuel mixture will be as enriched as possible with gasoline.

- Now turn the “quantity” screw. It must be turned 2 turns from the point where the throttle valve turns. This will be enough to start the engine.

- Then get into the car and start it.

- After this, start turning the screw so that the amount of gasoline-air mixture with the throttle closed is sufficient for stable operation of the engine.

- Using the same quality screw, achieve the composition of the mixture when the engine, when idling, begins to show the maximum number of revolutions. Carefully turn the adjusting screw and slowly reduce the speed to 900 rpm.

Experienced drivers perform this operation by ear. If the damper drive is adjusted properly, then at idle it will be completely closed, and when the gas pedal is pressed to the floor, it will open as much as possible. When the “quality” screw is screwed in as much as possible, the engine should stall. If this does not happen, you need to adjust the throttle valve (it is too open).

These are actually all the operations that are performed when adjusting the carburetor. If you were unable to do this the first time and the engine stalled, simply repeat the operation. You can check the setting this way: press the gas pedal all the way and lower it sharply. If the engine does not stall after this, but still produces the required speed, then everything is in order.

When adjusting using a gas analyzer, you need to rotate the mixture quality screw, observing the amount of CO. This is a rather complicated setting and is usually done in workshops, because it is necessary to ensure that the carbon monoxide content complies with GOST standards. However, it should be noted that in this way it is possible to adjust CO only at idle speed - the first measurement when passing a technical inspection at the traffic police. The second measurement, which is performed at engine speeds of 2000-3000 per minute, is slightly affected by this adjustment. The CO content at high speeds is determined not by the carburetor setting, but by the general condition of the engine and the quality of the fuel.

As you can see from the text above, adjusting the idle speed is not difficult, but it will require time, special tools and some skill if you want the carburetor to work really well.

At a minimum, you will have to open the hood and get your hands dirty. If you don't want to do this, then a great option is Uremont.com. This is a special aggregator of car services where you can place a request for the required operation, namely “carburetor idle adjustment.” Within a few minutes, you will begin to receive offers from service stations registered on this site, which received your application. All you have to do is choose the most profitable and convenient offer and take the car. All services of the Uremont.com website are free.

Jets and accelerator pump

Owners of carburetor cars know that jets change, but they do not always understand why jets are needed and how their size affects the operation of the carburetor. Let's start with the fact that the engine sucks in air through a special hole made in a large diffuser. At the same time, a certain amount of fuel is drawn through the fuel nozzle. The engine displacement directly affects how much air the engine will draw through the diffuser in a certain time, as well as the amount of gasoline sucked in parallel with the air.

It is for this reason that large-volume engines have carburetors with small jets. Installing such a carburetor on an engine with a smaller volume will mean that the “original” jets in this carburetor will produce a mixture that is too lean for normal engine operation. To solve this problem, you should find jets from a carburetor, which was initially designed for a specific internal combustion engine volume or as close as possible to it. You need to select jets starting with the fuel jet, then select the air jet under the fuel jet. The selection is made from a group of jets for the first chamber, the second chamber is adjusted only after the first.

Now let's talk about the accelerator pump. The accelerator pump delivers additional fuel when the throttle valve opens, allowing for more efficient acceleration. The pump is activated using a special cam. On engines with a Solex carburetor installed, the indicated accelerator pump cam must be set to the largest one.

You should also pay attention to the so-called “spout” of the accelerator pump. When the valves are opened, fuel should flow in a clear stream and not drip even with a slight throttle opening. It is also important what position the nose occupies. The stream of gasoline must fall exactly into the area between the diffuser wall and the throttle valve, that is, the fuel is jetted directly into the manifold. The jet must not hit the diffuser or damper. If this happens, then after sharply pressing the accelerator pedal the car will not accelerate immediately, and a failure will occur. Self-refinement of the carburetor involves installing two spouts in the chambers to obtain better performance from the engine, or only one spout in the first chamber of the carburetor for a more economical mode.