What versions of DSG are there?

DQ250 (Wet clutch)

In mid-2003, a 6-speed gearbox was released, developed jointly with Borg Warner. Generation DSG DQ250 . It is worth immediately noting that the clutch (double clutch discs) operated in an oil bath. This gearbox is recognized as the most successful, it transmits good torque (up to 350 HM), switches gears smoothly, saves fuel, and, at the same time, is also quite wear-resistant.

On the technical side, there is one nuance, because... a “wet” clutch is used - oil is a “gasket” between the rubbing surfaces, which ensures large losses. Of course, problems did not escape her, but over 12 years the designers have rid the box of most of its shortcomings. DSG6 was designed to work in tandem with more powerful engines (2.0 TSI, 2.0 TDI, etc.) than DSG7 - DQ200, which we will talk about below.

DQ200 (Dry clutch)

So we got to DSG7, the reliability of which, if not everyone, then certainly every second car enthusiast has heard about. Is everything so sad? Let's figure it out.

What cars are equipped with DSG?

VAG uses all versions of its gearboxes (S-Tronic, DSG and PDK). But which cars were equipped with dry DSG7?

You can determine it yourself by using our service by clicking on the LINK .

In short, the problematic DSG was installed on almost all VAG cars. These are Skoda, Seat, Volkswagen, Audi. You will find it on cars with engines up to 1.8 liters. You can also determine by the torque in the technical characteristics, if the torque is above 250Hm, then with a 99% probability there is the good old DSG6, or even a classic hydraulic automatic transmission.

There are exceptions, for example, on the Skoda Octavia (until 2012) 1.8, both the dq250 and the classic automatic transmission were installed, as well as on the Skoda Fabia 1.6, VW Polo 1.6 and some other models. For front-wheel drive VW Tiguan 1.4TSI and 150 hp. We installed DSG6, and on the 2.0TSI 4motion - a regular hydraulic automatic transmission.

DSG 7 problems (DQ200)

Why so capricious?

DSG refers to robotic transmissions, as most (but not all) robots have a bad reputation. Chat with owners of Toyota Auris and Opel cars equipped with robotic transmissions, they will probably tell you about the round sums left in services.

Weaknesses of DSG 7 mechatronics

From the outside it seems that there is nothing simpler than robotic gearboxes, because it is practically a mechanical gearbox controlled by electronics. Note that despite its apparent simplicity, almost no one has managed to achieve reliable operation of the unit. If in a conventional automatic transmission, for example, jerks at start are dampened by a donut (aka torque converter), then in a robotic transmission everything depends on the quality of the program and hydraulics. As for preselective robots, and this is DSG, they are even more complex, they have 2 clutches, which means that both the “software” itself and the hydraulics are more complex. For example, for DSG gearboxes, the coordinated operation of the clutch actuators is important. After all, in order for a gear change to be perceived by the driver as rapid-fire, the gearbox must have time to open one clutch and close the other without interrupting the flow of power and as quickly as possible.

| The worst thing for DSG is traffic jams |

To summarize, DSG does not like constant clutch operation and frequent gear changes. This applies to driving in traffic jams; frequent starts and accelerations lead to overheating and further wear of the clutch. Quite strange, don't you think? After all, cars with automatic transmission are bought for the sake of comfortable movement, incl. in traffic jams, and this mode, especially in megacities, is the most popular. It should also be noted that the “launch” technique (spinning the engine with the gear in gear with the brake pressed and a sharp start) will not work either; it will most likely lead to the death of the box. Hence the resource declared by the manufacturer of 300,000 km, somewhere on the autobahns in Germany is real, at a monotonous speed, when the driver does not need to pedal in traffic jams. During city use, we get a clutch life of 50,000-80,000 in the best case. Mechatronics up to 100,000 km.

What problems does the owner face?

Harmless according to VW:

- Sounds;

- Grinding;

- Metallic clang.

As statistics show, dealers refuse to consider such cases under warranty if there is no vibration or kicking, arguing that this is a feature of the box, so with such problems you should not go for diagnostics, with a high degree of probability you will lose time.

Unpleasant:

- Pinky;

- Jerks;

- Vibration;

- Loss of traction during acceleration.

With these symptoms, there is a 90-95% chance that the clutch will wear out. At the same time, unfortunately, the problem will progress. If we are talking about vibration, then it is usually of this nature:

- Vibration when accelerating in 2nd gear for 1-2 seconds (when driving around an obstacle or resuming acceleration between 5 and 10 km/h)

Emergency mode - problems with mechatronics:

- Lack of gears, and this happens both while driving and when starting the engine. The error can be cured briefly by turning off/on the ignition. In most cases, the verdict is the same - replacement or repair of mechatronics. On average 50,000-90,000 rubles. The mechatronics unit is essentially a complex unit that controls the operation of the box.

Replacing synthetic oil with mineral oil:

- In countries with warm climates, synthetics can interact with copper parts of the transmission, leading to a short circuit, which leads to an electronic problem. Because Mineral oil has a narrow temperature range; the solution is not very suitable for Russia.

Replacement of faulty parts under warranty - the case may repeat:

- Many car owners have had to replace the clutch and then the mechatronics under warranty. But even this did not always help, and the problem arose again. Since 2013, the concern has released a modified clutch for the DQ200, which is more wear-resistant than the first versions. There is no confirmation of this yet.

Horror stories about DSG: real and imaginary robot problems, and what to do about them

On the vicissitudes of public opinion

About five to ten years ago, Volkswagen models were considered exemplary reliable.

This, however, is all thanks to the experience of the 90s and early 2000s with the massive import of truly reliable Golf, Jetta and Passat. They were not “indestructible” at all, but in general the stereotypes of reality more or less corresponded. The situation has changed noticeably with the appearance of TSI motors (which we recently wrote about in detail ) and preselective DSG “robots” in the company’s lineup. The scale of public opinion gradually began to tilt in the opposite direction. This opinion is an inertial thing, and at first the problems of new power units and transmissions were simply not recognized, especially since a fair portion of the “fans” drove cars of previous generations without these troubles. The unfortunate owner of the problem car was faced not only with very harsh accusations from “warranty engineers” and other official structures of “improper operation”, but also with public censure on specialized resources on the Internet.

In general, the arguments of the officials and the “social activists” were approximately the same: the owner poured the wrong oil and the wrong gasoline and drove incorrectly. In those rare cases when the oil was always strictly “original”, gasoline was always from an ideal supplier, and the driver’s moral qualities and Nordic character were beyond suspicion, public opinion was inclined to believe that this was an accidental marriage and that it “happens” in general.

Articles / Practice This terrible downsize: problems with Volkswagen 1.4 TSI engines, and what to do with them Even if you are not a car guru, you have probably heard that all these small-volume engines with direct injection and turbocharging are a complete disaster. What did they do exceptionally... 284446 23 24 10/03/2017

Meanwhile, the number of cases increased. More and more owners of new cars with new engines and low mileage found themselves in a situation where engine or transmission repairs were required. It has become impossible to keep silent, let alone blame the car owners themselves for the problems.

By the beginning of the 10s, public opinion had collapsed. Of all the configurations, the simplest ones were declared to be the only correct ones, with classic Aisin hydromechanical automatic transmissions and naturally aspirated engines, without direct injection and turbocharging. Prices for cars with DSG and TSI engines on the secondary market have become noticeably behind not only the prices of cars with “regular” automatic transmissions, but also cars with manual transmissions and simple 1.6 MPI. The fear of “downsize” gave rise to a funny effect: they bought Skoda Octavia with a 1.8 TSI engine in large quantities from us, fortunately the price difference with the 1.4 TSI was small, and in addition they gave an Aisin automatic transmission.

Analysis of prices on the secondary market clearly shows that DSG is unnecessarily demonized, cars with such automatic transmission sometimes cost 100-150 thousand rubles cheaper than similar cars with Aisin TF60SC, and even cars with a fairly reliable six-speed DSQ DQ250 are not more expensive than cars with manual transmission .

But enough digressions. Let's take a closer look at the breakdown features of the most popular and cheapest DSG gearbox of the DQ200 series and try to answer a simple question - is it possible to buy a car with it now?

Patient portrait

First, about the subject of conversation. As practice shows, most of the participants in discussions simply do not know what the unit is called, and even more so, how it works. The automatic transmission of the DQ200 series, also known as 0AM/0CW and the related 0CG gearbox for hybrids, includes quite a lot of transmissions for engines with a transverse engine with different gear ratios and housings.

Photo: volkswagen-media-services.com

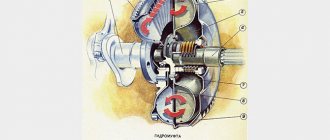

All these gearboxes are seven-speed, with dry normally open clutches in a single unit. The complex design of the coaxial clutches was developed in collaboration with the Luk company: in fact, the original set was supplied by them. The design uses a purely mechanical system to compensate for clutch wear, but it is not the main one. The box works with a dual-mass flywheel, which itself is a part with a limited resource.

Operating pressure of the accumulator

50-75 bar

The mechanical part of the box has a separate oil bath in which the differential operates. The mechatronics unit is located in the front of the box and can be replaced without removing the entire unit. The system has a hydraulic drive of all four gear shift rods and both clutch release rods. The oil pump is electrically driven. The mechatronics also includes a hydraulic accumulator with a working pressure of 50-75 bar. The DQ200 is almost completely independent from the rest of the car's electrical system; it even has its own crankshaft speed sensor.

The design is designed for engines with a torque of up to 250 Nm, but in practice it can withstand as much as 350 Nm and even a little higher. The unit is designed specifically for use with low-power engines as a transmission with maximum efficiency and a large dynamic range.

In practice, this means that the box works perfectly with 80 hp engines. and 125 Nm of torque, as well as with 1.4 and 1.8 TSI engines, which produce 250 Nm at peak. Of course, with more powerful engines, the load on the mechanical part of the automatic transmission is somewhat higher, but unlike classic hydromechanical automatic transmissions, the load on the mechatronics does not directly depend on the transmitted torque.

The gearbox is essentially mechanical, but has a composite input shaft and two secondary ones. The gears are engaged using clutches, like conventional manual transmissions. In such a design, it seems that everything should be reliable if the bearings can withstand it, but...

The list of possible problems turned out to be quite large, and mechanical problems are not in last place. Let's start with them.

Typical breakdowns

If the diagnostic shows errors 21096 P073A, 21097 P073B, 21094 P072C or 21095 P073D, then this indicates problems in the mechanical part.

First of all, the gear forks fail. Here they move using a ball bearing bushing. And, as it turned out, it cannot withstand the load, because the hydraulics perform shifts very quickly and harshly. Once the bushing is damaged, its inner plate is sent floating around the box, causing damage to the gears and creating metal debris. The latter not only acts as an abrasive, but also clogs the Hall sensors, which are needed by the mechatronics to control the box. In case of serious damage, balls may fall out. They are more difficult to grind, but the box can handle it. But there will be even more losses.

It is not only the first and second gear shift forks that are damaged, as many people think. The sixth-rear fork breaks just as often. The design of the bushing bearings is fundamentally the same. After 2013, and on repair forks, the design of the bushings was completely replaced, they became solid. Nominally, the service life of such a design without a ball bearing is shorter, but it does not break, and purely resource problems have not yet manifested themselves. This is exactly the design installed on 0CW.

The remaining failures of the mechanical part of the box are in most cases considered secondary, associated with oil contamination due to broken rods. Thus, failure of the differential, chipping of gears, complete destruction of the seventh gear and overheating of the bearings in most cases are caused precisely by the presence of metal dust in the oil, a product of the destruction of the forks. By themselves, they rarely happen, and are usually associated with engine tuning or missed oil levels. Well, or unsuccessful assembly of the box: like any manual transmission, the DQ200 is sensitive to the accuracy of assembly and tuning.

Breakage of the differential can be a completely independent problem: the satellites are welded to the axle under increased load due to an unsuccessful design, and not due to any other problems.

Fault numbers P175 21062/21184 and P176E 21063/21185 indicate problems with clutches and their wear.

Failures of the clutch block and dual-mass flywheel are considered by many to be beyond the list of failures of the DSG itself, but in fact, these are its integral parts. The flywheel wears out during serious torsional vibrations, during starts, slipping of clutches and wheels, when driving over uneven surfaces under traction, and similar situations. Wear accelerates overheating and contamination of the structure.

Articles / Practice What's wrong with the DSG gearbox? There are many different horror stories circulating among motorists. One of the most popular today is about DSG robotic gearboxes on Volkswagen cars. Jerks, failures in traction and... 319690 9 45 08/13/2014

The clutch block also does not like dirt, but the complex design has many more vulnerable points. But the main thing for us is that with a replacement price of about 50 thousand rubles, new versions of this unit are simply more reliable and better maintain gaps during operation. Since 2012, installing a shield on the hole for the release rods has made it possible to significantly reduce contamination of the clutch housing and their wear. Adjustment of the working gap is the responsibility of the master, and the general list of typical violations during assembly is almost a dozen items.

Also, the clutch unit suffers greatly if the driver does not work properly with traction in traffic jams and on rough terrain. By the way, both clutches are normally open, so there is absolutely no need to put the box in neutral to reduce the load on the mechatronics and clutch in traffic jams. But the knot still remains quite complex and expensive. And very vulnerable to driver and technician errors.

However, the service life of even the first versions of the unit can be a very respectable 150-250 thousand kilometers or more. And in terms of service life stability, the latest versions have greatly improved: after 2012, there are almost no cases of clutch block wear before a mileage of 100 thousand.

Major mechatronics failures

The remaining breakdowns of the DQ200 are associated with the mechatronics unit - the electro-hydraulic transmission control unit. Its problems may well harm the mechanical part, because the gears are engaged independently, and the clutches are not connected to each other. The list of typical block failures is quite extensive. So you'll have to execute it as a list.

- Pump motor failure

- Failure of control solenoids

- Failure of the pressure accumulator

- Damage to the electronic board or its sensors

- Failure of the mechatronics housing due to cracked channels or breakage of the accumulator cup

- Leaks and loss of tightness

Just three or four years ago, the prevailing opinion was that any breakdown of mechatronics required its replacement. There were plenty of arguments, ranging from the complexity of the design to the lack of spare parts.

The block itself was not very well executed. What caused this is unknown: either the Romanian assembly, or the quality of the work of German engineers. It is important that the replacement was expensive, and besides, there were no guarantees regarding his subsequent happy life. Fortunately, the situation has now changed. Repair documentation and standard troubleshooting cases have appeared.

The situation is complicated by the fact that since 2015, electronics units are flashed once and cannot be installed on another machine. This “killed” the nascent market for refurbished blocks, but, apparently, craftsmen will soon solve the problem.

Electrical faults (fuses blow in the automatic transmission power circuit) are mainly associated with the valve body.

Typical errors - 21148 P0562, 21065 P177F and 21247 P189C - are mainly associated with damage to the conductors of the electronic board and failure of the mechatronics electric pump.

The board's conductors literally burn out, damaging its body, and the motor simply stops due to pump failures or its own problems. Often the pump windings burn out.

Surprisingly, they were among the first to learn how to repair burnt circuit boards. The power buses are simply soldered; fortunately, no special equipment is required for this. The motors are changed or simply rewound; now such restoration is available in the factory. The price of “used” electric motors and those restored by factory methods ranges from one to five thousand rubles.

Faults 18156 P1748 and 05636 P1604 are also related to the electronic board, but in that case the control module is damaged.

Articles / Hatchback Choosing a used VW Golf VI: grief of turbo engines, problems with DSG If you don’t like to read long articles, then here’s a summary in one sentence. The only problem-free VW Golf VI is with a naturally aspirated 1.6 and a manual transmission. Everything else -... 89404 11 0 11/30/2016

The ceramic board is afraid of vibrations and temperature changes, as well as overheating. Electronics are more difficult to restore. But, like other automotive electronic components on a ceramic substrate, they can be repaired. All you need is skill and special equipment. And also – the availability of documentation. All this is now available in specialized service centers, and such a malfunction is far from a death sentence for the board.

Failures of individual sensors, except for the clutch position sensor, can be eliminated by replacing them. Buying them now is no longer difficult.

The solenoids also fail. There are eight of them here, they are combined into two blocks 0AM325473. Washing doesn't always help them. But there are a sufficient number of used, refurbished and even new parts at a reasonable price. The typical price for a set of two factory remanufactured units is around $90.

The mechatronics control board 927769D, which includes all sensors, conductors, “brains” and connectors, is available at a price of about 40 thousand rubles. Replacing the board assembly is a good repair option if partial repair is not possible or conditions do not allow it. Moreover, you will receive the most modern version of the board, with improved characteristics. If you want to further reduce costs, you can order the board on AliExpress or eBay for $200 to $300.

Troubles can also be expected from the main aluminum board-body of the unit and the hydraulic accumulator. The hydraulic accumulator can be torn out of the block with damaged threads, and it will bend the housing cover. At the same time, the liquid will disappear. The housing often leaks near the “glass” of the accumulator. The crack can be welded, fortunately there is enough space, but it will require very high-quality work with milling the leak cavity. In extreme cases, the entire housing can be replaced. The price of the part on Amazon is about 40 dollars, which is not so much, but in Moscow it will cost you 150.

The average cost of repairing a mechatronics assembly will be about 35-50 thousand rubles. Usually, the price of repairing a unit from various specialized companies that install the units they have restored instead of yours is within the same range.

Average cost of mechatronics repair

35,000 - 50,000 rubles

Progress in mechatronics design has affected literally all elements. The control board has changed dramatically; in newer versions it is noticeably more powerful and more resistant to temperature and overcurrent. The housing of the mechatronics unit has become stronger. But the hydraulic accumulator, apparently, has not changed, nor has the electric motor of the pump. The solenoids have also changed minimally. But the company replaced the oil in mechatronics with a less chemically active one. This is expected to extend the life of the control board solenoids and plastic.

Among the mechatronics malfunctions, there are almost none that will require its complete replacement with a new one. So the price of the assembled unit at 300 thousand rubles should not scare you. It will be much cheaper to restore. But breakdowns of the mechanical part can be expensive, but now there is a good selection of “used” units in which the mechanical part is guaranteed to be in good condition.

It is believed that the main problems of the DQ200 series boxes were solved with the release of the updated 0CW in 2013. Yes, there are quite a lot of changes compared to the 0AM series. And almost all affected nodes could be found in the list of “main problems” of the old version of the box.

To take or not to take?

Does it make sense to buy a car on the secondary market with such a gearbox now? What about the new one? The answer will be more likely “yes” than “no”. But only if you are not one of the “riders” and will not let any minor malfunction lead to a complete breakdown. If you are not one of them, then making a decision in favor of choosing a car with a DSG DQ200 is quite a lot.

Firstly, at the current price of fuel, an extra liter and a half of consumption is already a significant help, and the DSG is more economical than even a manual transmission. Secondly, a car on the secondary market will almost certainly turn out to be much cheaper than the same car with a “classic” automatic transmission. If only simply due to the fact that they are too afraid of “robots”, and the difference in the price of cars is even higher than the price of replacing the complete unit with a “contract” one.

Mechatronics control board 927769D

40,000 rubles

Another reason is the ease of diagnosing the DQ200 using a scanner. This is no longer a “pig in a poke” purchase. You can find out not only the approximate wear of the clutches, but also understand how the car was operated, what troubles can be expected in the near future, and the like. Knownly problematic copies can be discarded.

Classic automatic transmissions received such rich diagnostic capabilities only on the latest generations of six- and eight-speed gearboxes, and Aisin, which usually acts as an alternative to DSG, is not one of them.

The cost of repairing most DSG breakdowns has dropped dramatically over the past five to six years. If you pay attention to the incorrect behavior of the box in time, then the chances of inexpensive repairs are very good. The design of this “robot” is simple and extremely repairable, and now there is no longer any doubt about it.

In severe cases where the mechanical components of the box are irreversibly damaged, a good selection of used components is available. It turned out that cars often have a shorter service life than this very troublesome unit.

And the last argument in favor of DSG is purely ideological. Cars with a classic automatic transmission are often purchased by people who use the car harshly, without regard to manuals. Such cars may quite naturally have a high mileage, and the loads they endure during operation can be very high. After a few years, it becomes unknown which car will be a more profitable purchase: the one that was initially more reliable, but has gone through “thick and thin,” or the one that required much more gentle handling and received it in full.

Survey

How is your DSG transmission doing?

Your voice

Total votes:

How to operate DSG to avoid problems?

Although these tips cannot protect you from DSG malfunctions with a 100% guarantee, they will help extend the service life.

- The box does not tolerate “jerking”; jumping from row to row at a total flow speed of up to 40-50 km/h, for example, is unacceptable.

- If you are driving in a traffic jam, we recommend turning on the S or Manual mode, which will prevent constant shifting 1-2-3-2-1-2-3, and this is in most cases the main problem of clutch wear.

- Avoid slipping at start. The TSI engine in tandem with the DSG demonstrates amazing dynamics, one way or another, try not to skid at traffic lights, this is detrimental to the gearbox.

- When stopping for a long time (traffic lights), move the selector to the “N” position.

These tips are advisory in nature, it is up to everyone to follow them.

How to understand that mechatronics repair is needed

Mechatronics can fail after a mileage of up to 40 thousand km, and can function normally up to 200 thousand km. It is difficult to make any predictions about its service life. But in practice, most often problems arise after a 100,000 mileage. Failures may be associated with faulty sensors, hydraulics, or boards.

The most common signs of DSG 7 mechatronics problems

- When accelerating the car there are jerks.

- Shocks, grinding noises, vibration when changing gears.

- No reverse.

- Difficulty switching to modes “R” and “D”.

- The box goes into emergency mode and then restores the function after a restart.

- The car does not start or move away; in this case, the electronic board is most likely burned out.

- A malfunction of the DSG 7 mechatronics can also be indicated by extraneous noise, difficult acceleration, jolts at the start of movement, gear skipping, power loss and other manifestations of control discomfort.

When to contact a car repair shop? Straightaway. The scheme is simple - the sooner you respond to problems, the cheaper it will be to repair the DSG 7 mechatronics, and the less damage other components of the machine will suffer.

Is it worth buying a car with DSG?

Again, let's talk about the DQ200 modification. First of all, before purchasing, diagnostics, both computer and visual, are necessary. If the mileage exceeds 50,000 km, and the previous owner did not change the clutch or mechatronics, you should expect possible costs associated with replacing the clutch (turnkey ~45,000 rubles) and/or mechatronics (~55,000 rubles).

As for other modifications (wet clutch), everything is much simpler here. Ask the owner for documents confirming at least an oil change every 60,000 km, this will be a definite plus and proof that the person monitored the technical condition of the robot.

Let's sum it up?

DSG problems are a collection of problems with complex gearshift technology. We must pay tribute, its rate of fire and smooth shifting are currently, if not ideal, then at least among the best civilian cars with automatic transmission. In addition, fuel savings reach up to 10%. However, the concern underestimated the wear of components in typical conditions, for us this is traffic jams.

According to the manufacturer, in 2013 DSG 7 received an upgraded version, and there should be fewer problems (in any case, this is what is connected with the cancellation of the 5-year warranty on the gearbox for cars produced in 2014).

On the other hand, almost all manufacturers have problems with automatic transmissions to one degree or another. For example, 4-speed Japanese dinosaur automatic transmissions are considered indestructible, so if first of all you value reliability and durability, you should pay attention to them. But you won’t have to wait for dynamics and delights, unlike cars equipped with DSG. Only you can decide, the law of the market is simple - the buyer votes with rubles.

If you have questions, ask them in the comments, we will definitely answer!

Top 5 exact symptoms of breakdown

Extraneous noises (constantly or periodically) If you notice that new sounds have appeared in the checkpoint area, this is a reason to be wary. Typically, the wear of components makes itself felt in the form of metallic grinding, tapping, and creaking. Even if the car is still under warranty, you can’t count on much help from dealers in this case. Very often, after a “harmless” crackling sound, other problems appear.

Body vibration Vibration can be constant or pulsating (1-2 seconds each). It is felt most strongly during acceleration or at idle. To notice vibrations, just put your hand on the body. But sometimes the vibration is so strong that it can be felt even in the cabin.

Shocks when starting off One of the most common symptoms of a DSG failure. Most often, jerking occurs when trying to accelerate, especially on an uphill slope. Sometimes shocks also occur when the selector is moved to the “R” or “D” position, after which the car starts moving normally. Hard impacts can also be observed when moving to lower levels (in particular from 3-2 and 5-4).

Clutch slipping It is easy to notice DSG clutch slipping by reducing acceleration dynamics. The car's power is not enough for quick maneuvers, and there is a lack of traction. Another sure sign is delayed gear shifting. The next stage switches on at too high engine speeds.

Partial or complete failure of the manual transmission In case of critical breakdowns or failure of the mechatronics, the car will simply refuse to start moving. The gearbox goes into emergency mode, and error information is stored in the logbook. Sometimes the problem goes away after restarting the engine, but it is important to understand that this is only a temporary measure. All these symptoms for DSG are quite dangerous.

By ignoring them, you risk aggravating the breakdown and cannot be sure of safety on the road. Remember that the sooner you arrive at the workshop, the simpler and less expensive the repair will be.