A little about the carburetor

This type of carburetor is installed on a car that contains non-contact ignition systems. This device has 2 cameras. The throttle valves open in sequential order.

The carburetor contains a number of specific systems:

- Two chambers go through the dosing stage.

- The feather chamber is equipped with an idle speed.

- Both cameras make the transition.

- Starting occurs semi-automatically.

- Availability of a special accelerator pump. The type of this pump is diaphragm.

- Availability of various economizer modes.

Model 21083 series contains the smallest diffusers in diameter. This model is only suitable for an engine with a volume of no more than one and a half liters. This type of carburetor allows you to install absolutely any improvement in the power plant, if you subject it to certain modifications. The modification will consist in the fact that you will need to machine the diffusers to the cross section you need. This quality makes the carburetor quite versatile.

Note: If your engine has a volume of more than one and a half liters, then installing this type of carburetor is not recommended. This is due to the fact that at a high number of revolutions it will have a bad effect on the engine. Due to the fact that model 21083 produces a rather lean mixture, in order to increase the level of dynamics on the UZAM engine, it is recommended to replace the nozzles.

What are the features of a Solex carburetor?

The features of the design under consideration, called Solex, include the following points:

- The design belongs to the group of emulsion structures.

- This type of carburetor has a rather complex system for non-contact ignition of the mixture. This moment determines the characteristics of the carburetor.

- The design has two chambers that can be opened sequentially using a throttle valve.

- The carburetor is also equipped with two chamber metering systems and an idle speed system.

- The design is equipped with a semi-automatic starting device, a diaphragm pump accelerator, and an economizer for adjusting power in various operating modes.

The above points should be taken into account when considering how to perform carburetor tuning on a VAZ 2108.

Briefly about the Solex 21083 carburetor

The carburetor does not cause any glaring problems, it is quite up to date with its time, there are just some reasons to make changes to its settings and calibration to adapt to driving style. Solex is not very flexible in settings. All that can be done without removing the carburetor is adjusting the idle speed and replacing the jets. Why do tuning the Solex 21083 carburetor, let's figure it out together.

Solex for a one and a half liter engine of eights and nines differs from the same model for a 1.3 liter engine almost only in jets and some calibration dimensions. This is where he doesn’t always show good results. Let’s make a reservation right away - there can be no talk of any fuel savings when making changes to the carburetor design.

Consumption may change for the better, but this will inevitably lead to failures in transient engine operation, unstable idle and inefficient high speeds due to a lean mixture. In order to save fuel and spend 3 liters per hundred, you need to change the car, not the jets. Therefore, with your permission, we will not talk about savings. In any case, it will lead to unstable operation of the engine, and we value our eight or nine for stability.

Important little things

Any Solex (except 21073) has jets with very thin holes. It should be noted that because of this, the jets are very sensitive to debris in the fuel, and the carburetor itself often becomes clogged with dirt. For this reason, fuel filters should be changed regularly. To increase reliability, you can install an injection fuel filter. It will be a little more expensive, but you can increase the interval between inspections of the unit.

If the decision to install a Solex carburetor on a classic is made, then in addition to the carburetor, additional spare parts may be needed. The unit can be installed with or without recreating the EPH system - only the unconnected solenoid valve will remain. The easiest way is to get by with this system. But experts say that although the EPHH allows for 5% fuel savings, the system is unreliable and often fails. And this significantly reduces the reliability of the entire unit.

To prevent the solenoid valve from cutting off the fuel supply to the Solex idle channel (after all, the EPHH unit is not installed as standard), it is necessary to remove the valve needle from the housing. But the easiest way is to connect the valve from the ignition switch.

When installing Solex on rear-wheel drive VAZs, you need to plug the return flow with a plug or connect it through a check valve to the fuel supply system to the fuel filter.

Solex tuning

There are a number of tuning methods to increase the power and throttle response of the 2109.21083 engine by tuning the Solex carburetor. One of the most common types of VAZ tuning is the installation of a turbine on the carburetor. The use of turbocharging allows you to increase the power of the VAZ power unit (without using an injector), due to an increase in the amount of air and fuel supplied to the cylinders. In this case, an increased volume of the air-fuel mixture is burned, which increases the energy released. Accordingly, in the working cylinders there is an increase in gas pressure on the pistons, which ensures an increase in the power of the VAZ 2109.21083 engine to the power of an engine with an injector.

The use of turbines has gained popularity on engines with direct fuel injection (gasoline and diesel). Installing a turbocharger on VAZ 2109.21083 carburetor power units causes a number of problems associated with the distribution of air flows when operating in different modes.

- The turbine increases the air density in the intake manifold, which leads to a lean mixture. The solution to this problem is fuel jets with a greater degree of performance achieved by increasing the cross-section of the bore diameter. New Solex carburetor jets will allow the engine to operate stably both at low speeds and at medium and high speeds (as on engines with an injector).

- The amount of charge air pressure in different modes is different, and is directly proportional to the crankshaft speed. Since oversaturation of the manifold air reduces the speed of flow through the carburetor diffusers, and this leads to a decrease in fuel supply (in some cases, cessation).

- On engines with a turbine, the operating compression ratio is lower (gasoline with an injector) compared to atmospheric ones. If a regular engine with a carburetor has a coefficient of 10-11, then in a turbocharged engine it is 8.7-9.6. This characteristic is dictated by operational safety measures, since during the compression stroke at a high coefficient the likelihood of fuel detonation increases. This problem on the VAZ can be solved by increasing the volume of the chamber by installing an additional gasket under the head. It will give an increase in volume with the remaining piston stroke, therefore, the compression ratio will decrease slightly.

Tuning a Solex carburetor by installing a turbine requires changing the design of the carburetor itself, but if you correctly work out all the important aspects of installation and tuning, you can achieve good performance and dynamics from your VAZ car (2109,21083). In general, full-fledged tuning of the Solex carburetor consists of increasing the elasticity of the power unit at medium and high speeds, while not forgetting to achieve full filling at the bottom.

Carburetor tuning consists of changing the established calibrations, adding structural elements of the metering system, for which additional metering channels are mounted in the body. Cutting and subsequent grinding of small diffusers and increasing the diametrical cross-section of the main diffusers reduces the aerodynamic resistance to air flow.

Licking and polishing the fairly thick throttle shaft, air dams, and exposed mounting screws reduces resistance to air flow. The use of accelerator pump nozzles with increased capacity will add several horses to your VAZ.

Solex tuning

Classic tuning

VAZ 21093 carburetor tuning

To tune a Solex carburetor, you need to carry out the following operations:

- Remove the carburetor itself from the car;

- It is good to clean it from dirt;

- Remove the jets and throttle valves (this is done to bore the diffusers);

- Both chambers must be enlarged in size using a special machine;

- Grind the carburetor to reduce incoming air resistance;

- We select the ones needed for the now modernized carburetor.

Selection of jets

VAZ 21093 carburetor tuning

Selecting jets is the most difficult process. They must be selected taking into account not only coincidence, but also high accuracy. Thus, the VJ must be selected so as to allow a certain amount of air to pass through, which would be equal to the amount of fuel passed through the TJ. Otherwise, the fuel mixture will not be properly balanced, which will inevitably lead to poor acceleration and other problems. In addition, the jets must be properly balanced. This issue must be approached with all responsibility, understanding that instability of the fuel level will lead to a lean mixture.

Carburetor jets

Note. As you know, the ideal level is 1 mm. Other levels lead to malfunctions and loss of power.

In the process of tuning the carburetor, it is also recommended by experts to install a rubber shut-off needle, which ensures a more reliable level during heavy loads. In addition, such a needle is durable and can eliminate freezes when the accelerator pedal is pressed sharply.

Rubber locking needle

Tuning the Solex 21083 carburetor to improve technical characteristics

Many car enthusiasts prefer to increase the efficiency of the factory carburetor, thereby making a number of modifications.

Tuning the Solex 21083 carburetor is an excellent opportunity to most optimally customize the fuel supply system to suit your preferences and driving style. Thus making your car more responsive and playful, the technical characteristics in this case are improved, but, as a rule, you have to sacrifice efficiency.

This carburetor can also be installed on the nine, so when tuning the VAZ 2109 engine, you can at the same time take care of tuning the carburetor, because one complements the other. And in the end you will get a very fast car that can compete with foreign cars. And in general, do-it-yourself tuning is a good thing and very useful for the car and its owner.

Why is carburetor tuning done on a VAZ 2109?

The answer is obvious. This gives a serious increase in the dynamics of the car and its power. Typically, not everyone does tuning a VAZ 2109 carburetor with their own hands. For this, there are special workshops that seriously engage in tuning the VAZ 2109.

Work on the carburetor is carried out as part of a set of measures to improve the power unit and ignition system. But not everyone has the means to do this.

Let's describe the simplest methods. So, you have started tuning the VAZ 2109 whose carburetor you are planning to “pump”. What is needed first for this?

Of course, setting up a VAZ 2109 carburetor is not the easiest task in the world. But the simplest actions to increase power are available to everyone.

- We get to the second chamber of your carburetor. There you need to remove the spring from the throttle valve vacuum drive. What will it give? With a slight increase in fuel consumption, you get a guaranteed “plus” in the car’s dynamics. Cheap and cheerful.

- The second thing that can be done to improve it is to slightly modify the same vacuum drive. To do this, you will need to insert a ring of wire under the nut that secures the damper drive levers in the second chamber. What is the result? And this is what we get - we now have a protrusion located between the wire and the other lever. After this, you just need to tighten the nut. Again, we get an increase in dynamics, and an increase in consumption to a minimum.

In general, when it comes to tuning, always expect higher fuel consumption. And the more you modify the carburetor, the higher the final figure will be. If this doesn’t scare you, then let’s continue.

The following are the methods:

- Replacing the diffuser. If the standard diffuser of the primary chamber is marked 3.5, then, without hesitation, set it to 4.5. You will be happy. Or rather, growth.

- Further more. You need to change the pump nozzle. The usual one costs 30. Throw it away and set it to 40. Progress will be noticeable.

A separate conversation is tuning the VAZ 2109 Solex carburetor. Precise adjustment of the Solex VAZ 2109 carburetor in workshops is quite expensive, but it will pay off with interest.

Here, some fans of “pumping” even manage to install two carburetors at once. Experts, taking a repair kit and an adapter manifold, manage to quite successfully synchronize the opening of the dampers. I think there is no need to explain what kind of increase you will get with two carburetors.

You can also read on this topic:

Share on social networks

Alex S December 2, 2013

Published in: Russian cars

Tags: Our cars, Tuning, Tuning VAZ

How does Solex differ from Ozone and Weber?

The main difference between Solex carburetors and devices of previous families is the possibility of installing it on transversely located power units with the float chamber forward. This installation option made it possible to eliminate the leanness of the fuel mixture when the car enters a turn, climbs, or during sudden acceleration.

In addition, Solex has a completely different float chamber design. It has a two-section design, which allows the device to be used both on front-wheel drive cars and on classic cars.

Solex carburetors are reliable and maintainable

Is it necessary to modify the carburetor at all?

We have already told you that if, for example, you take a regular carburetor from a classic model, then the power of a standard engine in a car directly increases. Well, the forced one, in turn, will add more rigidity to the main power system. Now a little about the calculations. For example, tuning an engine with more than 2 thousand revolutions, its filling coefficient will directly be from 1.35 to 1.5.

Calculating diffusers is of course difficult, especially for beginners. Therefore, you should know that at low speeds, the fuel fluid in a car deteriorates significantly, unlike at high speeds. What does this have to do with?

In turn, this is related to the main parameter, namely the diameter of the diffuser. They, in turn, reduce the degree of vacuum, so there is a negative effect on the spray of fuel fluid in the car.

Camshaft 2108

Engines 2108, 21081, 21083 have a camshaft installed in the cylinder head. The engine camshaft (2108, 21081, 21083) is part of its gas distribution mechanism (GRM). It performs the function of driving the valves, since with its cams, when rotating, it alternately (in a certain sequence) presses on their pushers. In addition, the camshaft drives the ignition distributor (distributor) and the fuel pump.

Camshaft device 2108

The engine camshaft is a high-precision part cast from cast iron. Cams, journals and the surface under the shaft seal are bleached to a depth of 0.2 mm to increase strength.

The camshaft has five journals for installation in the engine block head supports. It is secured on top by a camshaft bearing housing, consisting of two halves and mounted on studs.

In addition, to prevent axial displacement, the camshaft has a thrust collar located between the end of the rear shaft support and the housing of the auxiliary units. There is also an eccentric for driving the fuel pump on the shaft. There is a groove at the end of the shaft for connection with the distributor shaft. At the other end, a timing gear is mounted on a key, secured with a bolt.

The camshaft is lubricated under pressure through holes in the cylinder head supports.

Camshaft dimensions

The height of the cams (intake and exhaust) at the camshaft 2108 is 9.0±0.1 mm. The diameter of the necks is 24.915-24.931 mm.

How does a camshaft work?

The camshaft rotates due to the drive on its pulley by the timing belt from a pulley on the crankshaft. At the same time, he presses the valve tappets with his cams in a certain sequence, forcing them to open. The position of the camshaft and crankshaft relative to each other is determined by special marks. As a result, timely opening and closing of valves is achieved at certain phases during engine operation (intake-compression-stroke-exhaust). At the same time, this work is synchronized with the work of the ignition distributor (distributor) since it is also driven by the camshaft. Accordingly, a spark jumps to the spark plugs at the right moment.

In addition, the camshaft drives the fuel pump (gasoline pump) of the engine power supply system. The eccentric on the shaft acts on the pusher rod.

Camshaft faults

Camshaft journal wear

Wear of the surface under the oil seal

Wear of camshaft bearings in the cylinder head and housing

As a result of wear of the camshaft supports (in the body and head of the block), its beating occurs, which negatively affects the operation of the valve mechanism. The permissible runout of the camshaft journals is 0.02 mm.

As a result, increased noise from under the engine valve cover and unstable engine idle speed.

Applicability of camshaft 2108

On carburetor engines 2108, 21081, 21083 of VAZ cars 2108, 21081, 21083, 2109, 21091, 21093, 21099, a camshaft 2108-1006015 is installed.

In some cases, the injection engine 2111 of VAZ 21083, 21093, 21099 cars is equipped with a camshaft 2110-1006015 or 2111-1006015, which has a pin at the end for a phase sensor (in an ECM with two oxygen sensors for Euro-3 standards).

Camshaft tuning 2108

The simplest is to replace it with a camshaft 2110 with large cams (intake - 9.6 ± 0.1 mm, exhaust - 9.3 ± 0.1 mm) and other cam angles and lift heights that allow increasing the dynamic characteristics of the car (improved acceleration and increased movement speed). In this case, the engine's throttle response at the “lower” range is lost, and it has to be cranked to high speeds. which reduces the resource.

More complex is the installation of a split gear, which allows you to independently change the valve timing and achieve from the engine either speed or throttle response at the “bottoms”, as desired.

Notes and additions

What is camshaft journal and lobe whitening? Bleaching is the process of imparting increased hardness to the elements of a cast iron part by heating and subsequent rapid cooling. The part acquires increased hardness (white cast iron cementite is formed in the bleached areas), but at the same time brittleness.

More articles on the gas distribution mechanism of engine 21083 (2108, 21081)

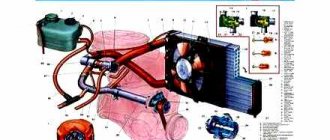

Fuel injection systems

Fuel injection systems are currently used much more often than carburetor systems, especially on gasoline engines of passenger cars. Gasoline is injected into the intake manifold of an injection engine using special electromagnetic injectors (injectors) installed in the cylinder head and controlled by a signal from the electronic unit. This eliminates the need for a carburetor, since the combustible mixture is formed directly in the intake manifold.

There are single-point and multi-point injection systems. In the first case, only one injector is used to supply fuel (with its help, the working mixture is prepared for all engine cylinders). In the second case, the number of injectors corresponds to the number of engine cylinders. The injectors are installed in close proximity to the intake valves. The fuel is injected in a fine spray onto the outer surfaces of the valve heads. Atmospheric air, entrained into the cylinders due to rarefaction in them during intake, washes fuel particles from the valve heads and promotes their evaporation. Thus, the air-fuel mixture is prepared directly at each cylinder.

In an engine with multipoint injection, when power is supplied to the electric fuel pump 7 through the ignition switch 6, gasoline from the fuel tank 8 through filter 5 is supplied to fuel rail 1 (injector rail), common to all electromagnetic injectors. The pressure in this ramp is regulated using regulator 3, which, depending on the vacuum in the inlet pipe 4 of the engine, directs part of the fuel from the ramp back to the tank. It is clear that all injectors are under the same pressure, equal to the fuel pressure in the rail.

When it is necessary to supply (inject) fuel, an electric current is supplied to the winding of the electromagnet of injector 2 from the electronic unit of the injection system for a strictly defined period of time. The electromagnet core, connected to the injector needle, is retracted, opening the way for fuel into the intake manifold. The duration of the electrical current supply, i.e. the duration of fuel injection, is regulated by the electronic unit. The electronic unit program at each engine operating mode ensures optimal fuel supply to the cylinders.

In order to identify the engine operating mode and calculate the injection duration in accordance with it, signals from various sensors are sent to the electronic unit. They measure and convert the following engine operating parameters into electrical impulses:

- throttle angle

- degree of vacuum in the intake manifold

- crankshaft speed

- intake air and coolant temperature

- oxygen concentration in exhaust gases

- Atmosphere pressure

- battery voltage

- and etc.

Engines with gasoline injection into the intake manifold have a number of undeniable advantages over carburetor engines:

- fuel is distributed more evenly among the cylinders, which increases engine efficiency and reduces engine vibration; due to the absence of a carburetor, the resistance of the intake system is reduced and cylinder filling is improved

- it becomes possible to slightly increase the degree of compression of the working mixture, since its composition in the cylinders is more homogeneous

- optimal correction of the mixture composition is achieved when switching from one mode to another

- provides better engine response

- exhaust gases contain less harmful substances

However, power systems with gasoline injection into the intake manifold have a number of disadvantages. They are complex and therefore relatively expensive. Servicing such systems requires special diagnostic instruments and devices.

The most promising fuel supply system for gasoline engines is currently considered to be a rather complex system with direct injection of gasoline into the combustion chamber, which allows the engine to operate for a long time on a very lean mixture, which increases its efficiency and environmental performance. At the same time, due to the existence of a number of problems, direct injection systems have not yet become widespread.

How to properly adjust the quality of the mixture?

In order to change the driving characteristics of the car, you can fine-tune the quality of the mixture. Considering this question, we note:

1. We completely line up the carburetor.

2. Install the necessary jets.

3. If the spark plugs flicker or are white due to a slight enrichment of the mixture, this is a sign of a problem with the quality of the mixture.

4. Adjustment should be made using a special screw.

5. Adjustment using a screw is only possible when the EAC system is turned off, since fuel is added from the idle system, and this has a strong influence on the behavior of the engine.

6. If the screw is tightened tightly, then the mixture is lean.

7. To obtain the required quality, a small unscrewing is carried out when the ratio becomes 14.7 air to one part gasoline.

If you need to save money, you can tighten it a little; if you need a fast car, you can unscrew it slightly. Note that you also cannot overdo it with unscrewing.

Tuning the exhaust system of VAZ 2107

Some car owners make the engine sound louder so that it resembles the growl of sports cars. To do this, the catalyst is replaced with a special flame arrester. Other VAZ 2107 owners believe that tuning the exhaust system is justified if the result is an increase in engine power. When assessing the feasibility of such measures, it should be borne in mind that improper installation will lead to increased fuel consumption and deterioration in vehicle performance. Therefore, work on tuning the exhaust system should be entrusted to professionals.

Tuning the exhaust manifold and exhaust pipe

For better purging of exhaust gases, extreme sports enthusiasts replace the standard exhaust manifold with a StinGer spider complete with a double exhaust pipe (pants) made of stainless steel. This allows you to increase power at high speeds by about 9 hp. With. At the same time, the exhaust gas output formula “4–2-1” does not change.

Since the internal walls of the StinGer are smoother, installing such a manifold will increase the efficiency of exhaust gases and increase power at maximum speed by 9 hp. With

The smooth surfaces of the StinGer manifold flanges ensure a tight fit to the cylinder head and to the pants. However, the new exhaust pipe does not have a threaded seat for the oxygen sensor. Therefore, if necessary, a nut is welded on this pipe in front of the catalyst, into which the sensor is installed.

The oxygen sensor in the VAZ 2107 is located on the exhaust pipe in front of the catalyst - this is where the nut for its installation is welded

Since the pants end with a flange, the resonator of the injection model is attached without problems. However, on carburetor VAZ 2107 this unit is designed differently, so it is better to immediately install a resonator from an injection engine on such a car.

Installation of a straight-through muffler

The standard VAZ 2107 muffler consists of two pipes, welded at different angles and lined with a non-flammable mineral wool filler, which reduces the speed of exhaust gases and softens the exhaust. To increase the volume of the exhaust and make the flow of exhaust gases straight, audio tuning of the exhaust system is carried out. Instead of a conventional muffler, a direct-flow muffler made by yourself is installed.

In a direct-flow muffler, the exhaust gases do not make turns, which dampen the speed, and act as additional resistance, reducing engine power

There are two ways to make a direct-flow muffler:

- remake the old muffler, which will not cause problems even for inexperienced owners and will be very cheap;

- weld a new muffler, which will be quite difficult to secure under the bottom of the car.

The work is performed in the following order:

- The old muffler is removed.

- A window is cut out along the entire length of the oval body using a grinder.

- The filler is removed and the metal insides are cut out.

- Using a drill or grinder, perforate a piece of pipe equal to the length of the muffler (52 cm). A large number of holes or slots will disperse the flow of exhaust gases, reducing temperature and noise.

- A perforated pipe is carefully welded inside the body, connecting the inlet and outlet pipes.

- An exhaust pipe is welded to the rear side of the muffler - it can be double and chrome-plated. The part of the pipe that goes inside the muffler is also perforated using a drill.

- The oval body is filled with mineral wool, fiberglass, asbestos or other non-combustible material.

- The window in the housing is welded.

Video: manufacturing and installation of an adjustable exhaust with a damper for a VAZ 2107

Thus, with the help of tuning you can turn a VAZ 2107 into a completely new car. In accordance with the wishes of the car owner, almost any components and parts are modified, including the engine. Elements for tuning are available for sale, and most of the work is quite simple to complete, carefully following the instructions of professionals.

The process of setting up a Solex carburetor

To adjust the 21083 carburetor for the UZAM engine, you should start by setting a specific level in the float chamber. Level adjustment must be made relative to the lid. To perform this operation, you need to use a special template suitable for your type of carburetor. Such a template is usually found in a special user manual. Without it, you will not be able to complete this task yourself.

After adjusting the float level, you need to make an adjustment for the idle speed.

To do this, you need to perform a number of sequential operations:

- Remove the fully tightened quality screw. It is in the position of approximately 6 turns. When the vacuum in the vacuum hose disappears, you need to stop rotating. This hose is directed to the distributor.

- Check the power plant, which is in a warm state. The test is to see if the engine can maintain idle speed from a thousand to 1500 per minute. If the number of revolutions reaches 800 per minute, then this number should be reduced. To achieve this, you need to additionally unscrew the screw.

- In order to achieve stable operation of your engine, provided that the mixture is as lean as possible, you need to turn the screw more gradually. It is worth understanding that the more the screw is tightened, the leaner the mixture, and therefore CO2 emissions will be minimal.

- For a warm engine, you need to set the idle speed to around 900 per minute. This number is suitable for the summer period of the year. And in winter it will require approximately 1000 rpm.

Depending on the size of your engine, the choice of jet is made. Remember that the larger the engine volume in your car, the less jets are needed.

For the first chamber, a fuel and then an air nozzle are initially selected. After this, jets are selected for another chamber.

1 Technical changes in the VAZ 2108 engine system

First of all, the owners of the VAZ 2108 car are trying to increase the engine capacity, which will increase its power. To do this, it is necessary to increase the piston stroke by 3-3.8 millimeters. As a rule, this is achieved by replacing the crankshaft and pistons, however, depending on the specific engine modification, you can proceed in several ways:

- install forged pistons of increased size and shape,

- mechanically modify standard pistons,

- install pistons from model 21213 and replace the system connecting rods.

For a standard production VAZ 2108 engine with a volume of 1.6 liters, it is best to use a crankshaft measuring 75.6 millimeters; on 1.5 liter engines, a crankshaft measuring 71 millimeters is best.

Similar articles

The diameter of the standard pipe in the injection-type VAZ 2108 engine system is 46 millimeters. To improve the supply of the fuel mixture to the cylinders during tuning, it is necessary to increase the throttle diameter by 5-8 millimeters. If you increase it to a larger size, there is a risk of damaging the throttle pipe. In addition, when installing a throttle valve with a larger diameter, you must ensure that there is a thermal gap between the pipe body and the valve. As the diameter increases, more air will enter the cylinders even when the unit is opened slightly.

Tuning a VAZ 2108 carburetor with your own hands comes down to grinding, sharpening and smoothing the corners in the system.

All this will improve air circulation and carburetor performance. First of all, the carburetor must be disassembled and divided into two halves, which can be washed with a special solution. Next, using a file, the screws of the air damper axis are ground down, which create unnecessary resistance to air flows; in addition, the air damper itself can be sharpened. After this, you can bore the throttle valves in diameter and replace the “cam” drive from the pump booster with a sports version.

Tuning Solex and its feasibility

There is no need to immediately begin drastic measures to modify the carburetor - it will be enough to perform the simplest operations, and the characteristics of the Solex can be changed beyond recognition and congenital diseases can be eliminated. Minimum things to do:

- selection and replacement of fuel jets;

- selection and replacement of air jets;

- changing the size of the primary chamber diffuser;

- polishing and grinding of small diffusers;

- adjustment and polishing of throttle valve axles.

Improvements to the VAZ 2107

Almost every car owner strives to get the maximum result from his car. However, the carburetors installed on the “classic” with a volume of 1.5 or 1.6 liters, which have a standard distributor, muffle the engine. In this case, it will be possible to increase the speed to the level of 4000...4500 rpm. Due to the design features, in a higher operating range, a slower increase in vehicle speed and speed occurs.

Experts say that the VAZ engine needs periodic cranking at high settings.

A positive result in such a situation is the burning of soot (carbon deposits) from the cylinder walls. The valves also rotate in the bushings when entering the mode from 4000 rpm, which ensures uniform wear and does not form holes at the ends . Although the engine life is slightly reduced with such loads.

Modernization begins with the removal of the vacuum drive springs in the “seven” carburetor. It is located in the primary chamber. You need to understand that this will increase fuel consumption by about 0.5...0.6 liters. However, the dynamics will noticeably improve.

The same operation is allowed for the mechanical drive of the secondary chamber. To do this, a spring is selected from the vacuum drive, straightened, and later bent in front of the last ring. This must be done so that the protrusion of the outer lever is located between the spring and the second drive lever. This will ensure increased dynamics at high speeds, as well as acceleration of the car without significant drops in power.

At the next stage, we get rid of the small diffuser mounted in the main one above the throttle valve. As a rule, it is marked 3.5. In the vacant seat we place the same element, but marked “4.5”. At the same time, it is possible to replace the accelerator pump nozzle. It is better to change it to a more powerful one, which is marked “40”; similar parts are installed on “Weber”.

What is the difference between modifications 21081 and 21083

If you compare the two main modifications of Solex carburetors (21081 and 21083), used on front-wheel drive Sputniks and Samaras, then visually you will not find any differences between them. The difference exists only in the operating parameters of some of their elements.

Table: comparison of basic calibration data for Solex carburetors 21081 and 21083

| 21081 | 21083 | |||

| For 1st camera | For 2nd camera | For 1st camera | For 2nd camera | |

| Mixing chamber diameter, mm | 32 | 32 | ||

| Diffuser diameter, mm | 21 | 23 | 21 | 23 |

| Air jet of the main dosing system | 165 | 135 | 155 | 125 |

| Fuel jet of the main metering system | 95 | 97,5 | 95 | 97,5 |

| Idle air jet | 170 | 170 | ||

| Idle fuel jet | 39–44 | 39–44 | ||

| Air jet of the second chamber transition system | 120 | 120 | ||

| Fuel nozzle of the second chamber transition system | 50 | 50 | ||

| Economizer fuel jet | 40 | 40 | ||

| Accelerator pump cam number (size) | 4 | 7 | ||

| Throttle valve starting gap, mm | 1,0 | 1,1 | ||

| Air damper starting gap, mm | 2,7±0,2 | 2,5±0,2 | ||

| Needle valve hole diameter, mm | 1,8 | 1,8 | ||

| Vacuum regulator hole diameter, mm | 1,2 | 1,2 |

Device

VAZ 2109 tuning Solex carburetor

Before tuning, you need to know how the Solex carburetor works. It was produced in several modifications and on the VAZ 2109 it was installed either DAAZ-2108 or DAAZ-2183. The first of the carburetor modifications was installed on a 1.3 liter engine, the second on a 1.5 liter engine. These carburetors are devices that are designed to accurately meter fuel into the air stream. The Solex carburetor also has the following features:

- It is in the carburetor that the process of forming a combustible mixture from fuel and air takes place, with its subsequent supply to the engine cylinders (see When replacing a VAZ cylinder is not necessary);

- Note that the Solex carburetor has two vertical channels called chambers.

Solex carburetor design

Note. A throttle valve is provided at the bottom of each chamber to allow air to pass through.

- Due to the fact that there are two chambers, and the damper drive is designed in such a way that as you press the gas pedal, one and then another channel opens, such a carburetor is called a two-chamber carburetor.

Note. The chamber that opens earlier is called primary, and the one that opens later is called secondary.

- Among the main features of the carburetor, we also note cone-shaped narrowings, called diffusers. They are needed to create the vacuum necessary to suck fuel from the float chamber (a special container in the carburetor body).

Note. The fuel level in the float chamber is constantly maintained to ensure normal carburetor operation.

- The Solex carburetor consists of two main parts: upper and lower. The flange housing, air filter fixing studs and fuel fittings are what the upper part consists of. The lower part consists of the housing, diffusers, float chamber and throttle valves.

VAZ 2109 carburetor tuning

Technical parameters of DAAZ-2108/2183 carburetors

| Diffuser and its diameter, mm | 21-23 |

| Performance of the main fuel jet TZh | 97,5-97,5/95-97,5 |

| Performance of the main air jet or VJ | 165-125/165-125 |

| Mixing chamber diameter, mm | 32 |

| Diameter of pump nozzles, cubic cm for 10 strokes | 14,5/14,5 |

Do-it-yourself Solex carburetor tuning

There are several methods for modifying this carburetor. Most often, tuning is done by boring and grinding various surfaces, as well as smoothing corners. Before the finalization process, it is worth preparing some tools. Such as screwdrivers of various types, items for grinding, a compressor, as well as a special liquid for washing parts.

After you have removed the carburetor and disassembled it, you need to carry out a number of operations:

- Clean carburetor parts.

- Use a file to file off the protruding parts of the screws that are located on the throttle valve.

- Grind off the damper shaft as much as possible.

- The lower part of the carburetor must be thoroughly washed.

- The dampers and their axles need to be pulled out.

- Use a file to round off the B3 axis. After this, you need to tighten the bolts with a cone-shaped head.

- After assembling the entire throttle mechanism, various errors in the initial stamping should be smoothed out.

- Accelerator pump tubes need to be installed in 2 chambers.

- If the mixing chamber has any irregularities, they need to be smoothed out.

Let's summarize: Such carburetor tuning can increase its performance several times.

It will also be interesting

13.12.2020

Doing the work yourself

Sidebar: Important: Conventionally, all modernizations can be divided into global improvements and alterations, as well as fine-tuning and adjustment. Some work can improve the performance of the device: boring, smoothing corners, surface grinding, and so on.

The features of the work on modernizing the carburetor include the following points:

1. First you need to dismantle the carburetor. The design is quite simple, so the process will not take much time. For disassembly you will need simple tools. 2. The next step can be called dividing the structure into two halves: for this, the upper part is separated from the lower. In order to significantly increase the efficiency of the structure, the structure should be flushed using a special liquid. Cleaning is also often done using compressed air. When air is supplied under high pressure, the internal surface is cleaned. 3. When examining the carburetor structure, you can immediately notice that the screws used in assembling the structure protrude greatly. This moment determines a significant increase in resistance. It is air resistance that causes a decrease in power. Using a file and sandpaper, you can smooth out all the screws, which will cause a decrease in resistance, which means increased efficiency and engine power.

4. The axle and air damper must be dismantled. In order to significantly improve the performance of the carburetor, the damper should be sharpened. 5. After completing the above work, you can move on to the bottom of the structure. The lower part can be disassembled in the same way as the upper part. 6. Next, the throttle valves are taken out along with the axles for more thorough cleaning and modification. 7. Using a fine-grain file, you can round the axes. Only when the caps are hidden inside the axles can unnecessary resistance be avoided. The problem under consideration can be solved by using screws that have conical heads. The caps can be sunk fairly quickly by using a drill of the appropriate diameter. 8. Having completed the above work, you can assemble the structure. 9. When assembling, you should pay attention to the fact that in small diffusers there is an error in the casting of the body. In order to also significantly reduce resistance, the legs of the small diffuser are modified so that they resemble wings. As the results of the studies show, it is this form that is more adynamic, that is, the resistance is reduced to zero. 10. Attention should also be paid to the design of the accelerator pump. Experiments conducted indicate that the ideal design is a combination of two tubes and two chambers. A rather important point is that the efficiency of the entire structure depends on the correctness of the set gaps. 11. The drive cam, due to its design features, is recommended to be completely changed.

His Majesty diffuser

As you can see, the diffuser occupies not the last place in this hierarchy, and here’s why. The main problem with Solex DAAZ 21083 is that the standard mixture is too lean. The engineers deliberately took this step in order to strangle the engine in favor of efficiency, depriving it of its dynamic potential. But even without resorting to complex and subtle calculations, it is clear that first of all it is necessary to eliminate aerodynamic errors, which are full of any DAAZ carburetor.

If you pick up a diffuser, large or small, pay attention to the quality of the casting and show all this happiness to an engineer at least from Ford Europe, he will go crazy. A standard diffuser creates so many turbulences and parasitic flows in the intake tract that the efficiency of the carburetor is reduced by 20 percent. What kind of tuning can we talk about with such diffusers! Therefore, first of all, they need to be sanded, removing all the seams that create swirls.

Setting up the VAZ-2109 carburetor

In cases where the ignition system is adjusted correctly, but the car still accelerates poorly, the engine does not pull, “sneezes,” “twitches,” stalls when the gas pedal is released, consumes a lot of fuel, and so on, then you need to pay attention to the carburetor.

Unfortunately, in the car’s operating manual and in other sources, of which there are a huge number on the Internet today, there are no specific recommendations on how to properly configure the VAZ-2109 carburetor. Basically, all the advice boils down to the typical method of adjusting the carburetor by rotating two adjusting screws. It has been passed down from generation to generation by car enthusiasts since the appearance of the first VAZ carburetors. Therefore, we will not repeat ourselves, but will consider in detail the typical malfunctions of the Solex carburetor with practical recommendations for eliminating them.

Eliminating air leaks

One of the most common problems is excess air sucking under the carburetor. You can also handle this on your own. To do this, it is necessary to increase the pressing area of the carburetor flange (provided that there is no deformation of the carburetor cover). You will need corner pads (VAZ 2101–2107), in which we drill holes up to 8.2 mm in diameter. Now all that remains is to replace the factory washers with these pads and tighten the nuts.

If the cause of air leaks is a deformed cover, you can replace the factory gasket by making a new one yourself. It can be made from thicker cardboard or other suitable material. Lay a fabric thread along the contour of the gasket and along the contour of the holes and secure it with any gasoline-resistant glue. Grinding the bottom plane of the carburetor cover can also give a good result.

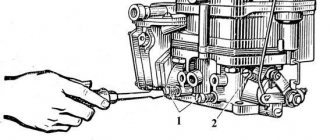

How to remove a Solex carburetor

To remove the carburetor from the car for the purpose of repair, maintenance or replacement, it is necessary to disconnect the mechanical, pneumatic, electrical and fuel fittings from it, and then unscrew the nuts securing it to the manifold flange:

- Remove the air filter housing by unscrewing the center cover nut and the four flange nuts on the carburetor top studs.

- Disconnect the electrical connectors of the limit switch and solenoid valve.

- Remove the return spring and disconnect the throttle cable.

- Disconnect the choke actuator.

- Loosen the clamps and remove the fuel supply and return hoses.

- Disconnect the hoses of the distributor vacuum regulator, crankcase ventilation and throttle heating unit.

- After unscrewing the four nuts of the intake manifold studs, remove the carburetor.

When reinstalling, special attention must be paid to the tightening of these nuts, since the lower plate of the housing is very easily deformed from excessive force, after which air begins to leak into the manifold.

What should a modified carburetor provide?

- First of all, it must directly provide a normal volume of air at high speed.

- There should be an excellent degree of vacuum at low speed.

Now let's look at the tuning Solex. Having read the information described above, we can make a simple conclusion that the modified Solex carburetor, namely with a 24/27 diffuser, tuning will, in turn, also consist of boring the second chamber itself. As a rule, with such parameters, a car has a large mixing chamber. Therefore, drivers can set the throttle to approximately 34 ml. Probably everyone has the following question: is it possible to make the motor even more powerful? Of course you can, but only if you have a carburetor with a mixture chamber diameter of no less than 33.5 and no more than 35 ml.