Classification of engines by type

The operating principle of the power unit is based on the conversion of thermal energy into mechanical energy. Repeated processes in the motor represent the operating cycle of the engine. Depending on how many strokes the piston makes, engines are divided into four-stroke and two-stroke. Internal combustion engines used in cars operate on a 4-stroke cycle. This includes fuel inlet, power stroke (back and forth) and exhaust gas outlet.

In a two-stroke engine, only 2 piston strokes occur in one cycle: the power stroke and compression. Filling of the cylinders and cleaning occurs during these 2 strokes. Engines of this type have significant disadvantages, such as high exhaust emissions. The main disadvantage is high fuel consumption, which is why two-stroke engines are not used in modern cars.

Engine operating principle

The operating principle of classical internal combustion engines is based on the conversion of fuel flash energy - thermal energy released from fuel combustion - into mechanical energy.

However, the process of energy conversion itself may differ.

The most common option is this:

- The piston in the cylinder moves down.

- The inlet valve opens.

- Air or a fuel-air mixture enters the cylinder. (under the influence of the piston or piston and turbocharging system).

- The piston rises.

- The exhaust valve closes.

- The piston compresses the air.

- The piston reaches top dead center.

- The spark plug fires.

- The exhaust valve opens.

- The piston begins to move upward.

- Exhaust gases are forced into the exhaust manifold.

Important!

If diesel fuel is used, then the spark does not take part in starting the engine; diesel fuel ignites itself during compression.

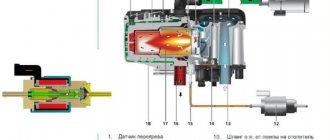

At the same time, to understand the operating principle, it is important not just to take into account the physical sequence, but to keep the entire control system under control. The diagram of the ELECTUDE training module helps to understand it clearly.

Please note that in distance learning courses on the ELECTUDE platform, when studying the diesel engine control system, it is deliberately analyzed separately from the fuel injection control system. A very smart approach. It is really difficult for many students to immediately understand both the control system and the injection system. And in order to master the material well, it is necessary to move competently step by step.

But let's return to the operation of the engine itself. The considered operating principle is relevant for most internal combustion engines, and it is reliable for any vehicle, including trucks.

In fact, devices operating on this principle operate on 4 strokes (which is why most motors are called four-stroke):

- Release stroke.

- Air compression stroke.

- The actual working stroke is the very moment when the energy from fuel combustion is converted into mechanical energy (to start the crankshaft).

- The opening stroke of the exhaust valve is necessary to ensure that the exhaust gases leave the cylinder and make room for a new portion of the mixture of fuel and air

4 strokes form a duty cycle.

In this case, three beats are auxiliary and one is directly giving impetus to the movement. Visually, the operation of the four-stroke model is presented in the diagram.

Injection engine type

The injection engine works a little differently: fuel is supplied into the air using a fine injection method. A flammable liquid is sprayed under pressure through a nozzle, which significantly reduces fuel consumption, because the quantity is dosed by special devices. For this reason injection engines are more economical, and the optimal proportion of the combustible mixture makes it possible to increase the purity of the exhaust and increase the efficiency of the power unit.

Injection engines are divided into mechanical and electronic. In a mechanical engine, the fuel dosage is set using levers, and in the electronic power unit, a special fuel dosage control system is used. When using such systems, fuel burns more thoroughly and harmful emissions are reduced.

Internal combustion engine structure

The first piston internal combustion engines had only one cylinder of small diameter. Subsequently, to increase power, the cylinder diameter was first increased, and then their number. Gradually, internal combustion engines took on the form we are familiar with. The “heart” of a modern car can have up to 12 cylinders.

The simplest is the engine with an in-line cylinder arrangement. However, as the number of cylinders increases, the linear size of the engine also increases. Therefore, a more compact arrangement option appeared - V-shaped. With this option, the cylinders are located at an angle to each other (within 180 degrees). Typically used for 6 cylinder engines and larger.

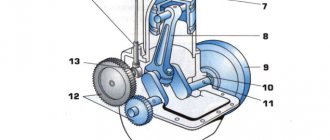

One of the main parts of the engine is the cylinder (6), which contains a piston (7) connected through a connecting rod (9) to the crankshaft (12). The straight up and down movement of the piston in the cylinder is converted by the connecting rod and crank into rotational movement of the crankshaft.

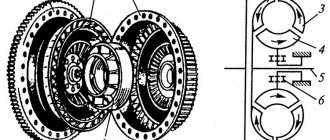

A flywheel (10) is attached to the end of the shaft, the purpose of which is to ensure uniform rotation of the shaft during engine operation. The top of the cylinder is tightly closed by the cylinder head (cylinder head), in which there are inlet (5) and outlet (4) valves that close the corresponding channels.

The valves open under the action of the camshaft cams (14) through transmission mechanisms (15). The camshaft is driven by gears (13) from the crankshaft. To reduce losses due to overcoming friction, removing heat, preventing scuffing and rapid wear, rubbing parts are lubricated with oil. In order to create normal thermal conditions in the cylinders, the engine must be cooled.

But the main task is to make the piston work, because it is the main driving force. To do this, the cylinders must be supplied with a combustible mixture in a certain proportion (for gasoline engines) or measured portions of fuel at a strictly defined moment under high pressure (for diesel engines). The fuel ignites in the combustion chamber, throwing the piston down with great force, thereby setting it in motion.

Engine type carburetor

Gasoline that passes through the fuel system ends up in the carburetor or intake manifold. Air enters it, which is then mixed with fuel to form the finished mixture. It is supplied to the cylinders and there it is ignited by a spark provided by the spark plugs.

Cars with carburetor engines are currently considered obsolete. Nowadays, injection-type engines are widely used. Fuel is atomized by injectors or through the intake manifold.

Supply system

The supply systems for spark-ignition and compression-ignition internal combustion engines differ from each other, although they have a number of common elements. The common ones are:

- Fuel tank.

- Fuel level sensor.

- Fuel purification filters - coarse and fine.

- Fuel pipelines.

- Intake manifold.

- Air pipes.

- Air filter.

Both systems have fuel pumps, fuel rails, and fuel injectors, but due to the different physical properties of gasoline and diesel fuel, their design has significant differences. The supply principle itself is the same: fuel from the tank is supplied by a pump through filters to the fuel rail, from which it enters the injectors. But if in most gasoline internal combustion engines the injectors supply it to the intake manifold of the car engine, then in diesel engines it is supplied directly to the cylinder, and there it is mixed with air. The parts that ensure air purification and flow into the cylinders - the air filter and pipes - also belong to the fuel system.

Diesel engine type

Diesel engines deserve special attention . Their operating principle is based on the ignition of the working mixture during compression. When air is drawn in, the process occurs under high pressure, causing the mixture to spontaneously ignite. After ignition, the piston stroke occurs, which then displaces the exhaust gases.

This type of engine has lower fuel consumption and a small amount of harmful substances in emissions. The efficiency of this power unit is also much higher. Diesel engines now continue to improve and even frost is no longer an obstacle to starting the engine.

Different types of diesel engines have different characteristics that depend on the time of year. These power units do not have an ignition system, because the fuel ignites due to high pressure, which causes the piston to move.

By application

Description and classification

These mechanisms also differ in application. They can drive not only vehicles, but also various mechanisms and devices. Today there are several main types of engines. Each of them is designed to work on the basis of one or another type of fuel and according to its own principle.

Injection

The principle of operation in an injection engine is as follows: fuel is supplied using finely dispersed spray into a hollow combustion chamber. Thanks to this supply method, it is possible to significantly save fuel consumption, as well as reduce the amount of exhaust gases when the vehicle is moving.

Injection engines are divided into:

- Electric - the amount of fuel supplied is regulated by a special electrical system. Thanks to this, the dosage is calculated so correctly that it allows you to significantly reduce the amount of exhaust gases, as well as use the fuel as fully and efficiently as possible.

- Mechanical - the system for adjusting the injection intensity is organized using special levers.

Carburetor

The carburetor type of engine is considered obsolete. Its main method of operation is that fuel is supplied to a special chamber (injector) where it is mixed with air, and only then this mixture enters the engine cylinders, where ignition occurs using a spark.

Diesel

It is immediately worth noting that this type of engine has the following advantages:

- Greater efficiency.

- Less fuel consumption.

- Minor release of harmful substances into the surrounding atmosphere.

The principle of operation is that a diesel engine ignites spontaneously when it is significantly compressed under the pressure of drawn-in air. The forward and reverse stroke of the piston is caused first by flammable diesel, and then by exhaust gases.

Hybrid

This type is combined. Its operation is partially driven by electricity generated by the battery. A vehicle or machine moves partly by burning fuel.

Important! If we talk about the advantages of this type, they are undeniable - low speed, reduced fuel consumption, and a high level of environmental friendliness.

The development of the industry now allows a variety of mechanisms to develop more and more quickly. Today, thanks to the environmental movement, only those types that run on electricity or operate on hydrogen are increasingly being used.

Source

Advantages of internal combustion engines

- Convenience

. It is enough to have a gas station on the road or a can of gasoline in the trunk - and the problem of refueling the engine is easily solved. If the car has an electric motor, charging is not yet available in all places. - High engine refueling speed

. - Long service life

. Modern internal combustion engines easily operate within the period declared by the manufacturer (on average 100-150 thousand kilometers), and some even 300-350 thousand kilometers. However, the world record holder is a mileage of ~4,800,000 km. And there are no extra zeros here. This record was set on the Volvo P1800 engine. The only thing is that during its operation the engine underwent major overhauls twice. - Compactness

. Internal combustion engines are much more compact than external combustion engines.

Tuning

Those who like to increase the power of internal combustion engines often install (if this is not provided by the manufacturer) various types of turbines or compressors.

The compressor produces little power at idle speed, but maintains a stable speed. The turbine, on the contrary, squeezes out maximum power when it is turned on.

The installation of certain units requires consultation with specialists who have experience in a narrow field, since repair, replacement of units, or addition of additional options to an internal combustion engine is a deviation from the purpose of the engine and reduces the life of the internal combustion engine, and incorrect actions can lead to irreversible consequences, that is, the operation of the internal combustion engine may be permanently terminated.

Classification of internal combustion engines

In the process of internal combustion engine evolution, the following types of these motors, which have proven their effectiveness, have emerged:

- Piston internal combustion engines. In them, the working chamber is located inside the cylinders, and thermal energy is converted into mechanical work through a crank mechanism that transmits motion energy to the crankshaft. Piston engines are divided, in turn, into

- carburetor , in which the air-fuel mixture is formed in the carburetor, injected into the cylinder and ignited there by a spark from the spark plug;

- injection , in which the mixture is supplied directly to the intake manifold, through special nozzles, under the control of an electronic control unit, and is also ignited by a spark plug;

- diesel engines , in which the air-fuel mixture is ignited without a spark plug, by compressing air, which is heated by pressure at a temperature exceeding the combustion temperature, and fuel is injected into the cylinders through injectors.

- Rotary piston internal combustion engines. In motors of this type, thermal energy is converted into mechanical work through the rotation of a rotor of a special shape and profile by working gases. The rotor moves along a “planetary trajectory” inside the figure-of-eight-shaped working chamber and performs the functions of both a piston, a timing mechanism (gas distribution mechanism), and a crankshaft.

- Gas turbine internal combustion engines. In these motors, the conversion of thermal energy into mechanical work is carried out by rotating a rotor with special wedge-shaped blades, which drives the turbine shaft.

The most reliable, unpretentious, economical in terms of fuel consumption and the need for regular maintenance are piston engines.

Equipment with other types of internal combustion engines can be included in the Red Book. Nowadays, only Mazda makes cars with rotary piston engines. Chrysler produced an experimental series of cars with a gas turbine engine, but this was in the 60s, and none of the automakers returned to this issue. In the USSR, T-80 tanks and Zubr landing ships were equipped with gas turbine engines, but later it was decided to abandon this type of engine. In this regard, we will dwell in detail on the piston internal combustion engines that have “gained world domination”.