In the fuel systems of many automobile engines, due to their design aspects and the principle of their operation, injection pumps are used. We are talking about high pressure fuel pumps.

Many have heard about them, some have encountered them personally. But for some reason they talk about low-pressure pumps much less often. Although in reality it is also an important component of the internal combustion engine fuel system. It is also called pumper.

Low Pressure Fuel Pump Definition

To create a diesel fuel injection system, a low pressure fuel pump is installed. Its main purpose is to supply fuel from the tank to the high pressure pump. Stepped operation allows you to achieve higher efficiency from the equipment. The unit in question performs several functions:

- Supply of the required amount of fuel.

- Creation of sufficient excess pressure at the inlet to the injection pump. Otherwise, the entire system will not be able to function correctly.

- Creation of the required vacuum pressure in the suction pipe, which is sufficient to take fuel from the tank, taking into account the installed filter element.

- Providing pressure sufficient to overcome the resistance created by the fine filter.

- Preventing the effect associated with the release of bubbles of light volatile components during the movement of fuel in the system. A similar phenomenon occurs when transporting fuel in a system at high ambient temperatures.

Today, TNND is performed as a separate component, which is mounted together with other components. The main application is to power a diesel engine. It is worth considering that the failure of the node in question leads to the inoperability of the entire system.

The device of the booster pump and various types of low-pressure pumps

If we talk about design, the low pressure fuel pump has the following components:

- Drive shaft

- Rotor with blades

- Stator

- Distribution disk

- Drive gear regulator

- Couplings

The principle of operation is that the rotor begins to move first, as a result of which its blades move closer to the stator. As a result, under the influence of centrifugal force, “chambers” and a certain voltage are created. Then the fuel flows from the chambers to the fuel injection pump. To supply fuel, channels are made in the distribution disk. If the pressure exceeds the norm, part of the fuel is redirected to the pressure reducing valve.

Given that the booster pump and the high pressure pump are connected, a fuel drain choke is provided to maintain the required conditions. The specified throttle is a jet that is screwed into the injection pump.

This solution allows you to maintain the desired conditions in the chambers, while taking into account the dependence on the speed at which the drive shaft moves. This scheme is well suited for diesel engines, but there are other types of booster pumps.

Types of low pressure fuel pumps

Let's start with the fact that a low-pressure fuel pump is installed on any car, gasoline (carburetor, injector), and on many diesel ones, but not on all. This device “pulls” fuel from the fuel tank, after which the fuel passes through filters, enters the metering systems and is supplied to the engine.

Currently reading

How to maintain and charge a maintenance-free type of battery for...

ZIL 130 engine: a legend of the Soviet automobile industry

In this case, booster pumps are mechanical and electric. On gasoline carburetor internal combustion engines there is a mechanical pump, on injection engines there is an electric fuel pump. However, if in gasoline analogues, regardless of the type of engine, such a pump is the main one, in diesel engines the booster pump supplies fuel to the injection pump.

- A mechanical booster pump is usually installed on the cylinder block. This device is powered by the engine itself. Simply put, while the engine is rotating, a special cam of the pump is pressed, as a result the device begins to pump fuel into the carburetor. The mechanical pump also has a special lever, which allows you to manually pump gasoline before starting the engine.

We also recommend reading the article about how a diesel injection nozzle works and works. From this article you will learn about the design and operating principles, as well as the design features of diesel injectors.

- An electric booster pump became a necessity after injection engines appeared. The fact is that for normal operation of the injector, fuel must be supplied to the injectors at a higher pressure compared to carburetor internal combustion engines.

Naturally, a mechanical pump with weak performance is not able to cope with such a task. It was replaced by an electric fuel pump. Such a pump is actually an electric motor and a pumping chamber, which are combined in a common housing. The supercharger is located directly in the gas tank and is immersed in fuel. Also integrated into the pump housing is a fuel level sensor and a special mesh filter for cleaning fuel.

This solution has a number of advantages, since the device is more productive and also does not overheat from excess heat in the engine compartment. Also, before starting the engine, there is no need to pump fuel manually, since after turning the ignition key, the booster pump immediately starts working, raising the pressure in the power system.

It should also be noted that in a circuit with an electric pump, fuel constantly moves through the lines, which allows maintaining a normal temperature of the fuel and avoiding overheating.

Classification of TNND

There are quite a large number of different low pressure pumps on sale. The power supply system of diesel engines is equipped with the following designs:

- Oral.

- Geared.

- Piston.

In addition, classification is carried out according to the type of drive. Based on this feature, the following devices can be distinguished:

- Mechanical. In this case, rotation is transmitted from the injection pump shaft or the camshaft or camshaft.

- Electric. In some systems and cars, an additional electric motor is installed, from which rotation is transmitted to the device in question.

Rotor and gear versions are installed on passenger cars and commercial trucks. On trucks there is a diesel engine with an already built-in injection system.

Advantages of installing TNND

The use of modern, highly efficient, low-pressure fuel pumps as part of the fuel system of various vehicles and engines provides a number of objective and important advantages.

It is worth focusing on the most significant points.

- This is the most important component of the entire ICE power supply system. With its help, fuel is effectively supplied to the injection pump, and the fuel is additionally driven through the installed coarse and final fine filters. This minimizes the damage caused to the engine from low-quality fuel.

- Due to the booster pump used, the operation of the car engine is stabilized in various modes and at different engine speed parameters.

- This eliminates the situation where the engine may run out of fuel when operating under high load conditions that require an increased volume of fuel for stable operation.

- TNND can be installed on a car if it is not normally available. They mount it directly into the tank, or cut it into the fuel line after leaving the tank.

- Using a booster pump, you can partially or completely solve the problem of slight airing of the supply system due to long-term parking of the car.

- The use of such a device makes it possible to simplify and facilitate starting the engine during frosts and during long periods of parking. This is especially true for diesel internal combustion engines.

Cars with high-quality and efficient fuel injection pumps, as car owners themselves note, start easier and require less starter speed to start. In various modes, engines operate more stable. In certain situations, there is a slight increase in power, since the pump continues to provide the engine with the required volume of fuel, even when the internal combustion engine is operating at high speeds.

TNND is truly an important, and sometimes irreplaceable, component of an automobile fuel system. It does not fail very often, so car owners do not have any special problems with it.

Design features of rotary injection pumps

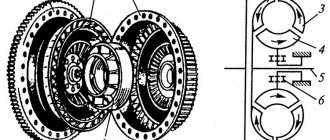

Rotary pump designs are widely used and may differ in design features. The main difference lies in the method of forming a closed chamber for the supplied fuel. Design Features:

- The basis of the design is the body, which is often made in a cylindrical shape. The body has slots of variable cross-section.

- The rotation is transmitted to a slotted rotor, into which rollers and flat blades are inserted.

- At the moment of rotation, the blades come into contact with the surface of the housing. This creates separate chambers that capture the fuel and discharge it through the outlets.

It is worth considering that this design has a fairly large number of disadvantages. The main one is the need to create a complex drive from a crankshaft or other drive. This point significantly increases the cost of the unit and reduces its reliability. To increase the reliability of the unit, an electric drive is installed, which ensures a reliable supply of fuel to the high-pressure pump.

Single acting fuel priming pump

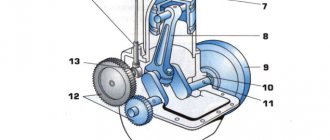

A single-acting fuel priming pump consists of a housing that houses a rod, piston and valves.

At the fuel inlet and outlet, inlet 5 and outlet 1 valves with springs are installed in the pump housing. The pump is driven by the eccentric 3 of the injection pump cam shaft. The force is transmitted through the pusher to the piston drive of the fuel priming pump. The reverse stroke of the piston is carried out under the action of spring 6. The operating principle of such a pump is as follows. When the eccentric 3 escapes from the pusher 2, the pressure on the piston 4 from the pusher side disappears and under the action of the spring 6 the piston moves upward. At the same time, inlet valve 5 closes, and outlet 1 opens and fuel flows to the injection pump. When the eccentric 3 of the cam shaft runs up against the rod 2, the piston 4 moves down. Fuel under pressure opens the inlet valve 5 and enters through the slots in the piston into the cavity located above the piston.

Gear TNND

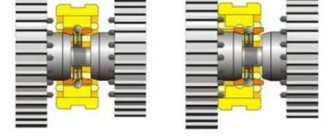

Gear injection pumps resemble the design of oil pumps. This design is also quite common. Key points:

- The body serves as the basis of the structure. It has a high degree of tightness and strength.

- Inside the housing there are two gears that are meshed. Both gears are sized for the teeth to contact the surface of the housing. This ensures the creation of sealed chambers.

- At the moment of rotation, the gears capture fuel, after which they throw it into the outlet holes.

The mechanism under consideration has all the advantages and disadvantages that are characteristic of rotary versions. However, gear ones are characterized by a simpler and more reliable design, they are cheaper to maintain, due to which they have become very widespread. Piston version of the pump

Piston designs have also become very widespread. Low pressure pumps come in two types:

- Single action. In this case, the maximum amount of fuel is removed in one cycle.

- Double action. Such a device is characterized by the fact that two fuel pumps are performed in one working cycle.

A single-acting pump has a simpler design. Its features:

- A cast body is used as the basis.

- The housing has an inlet chamber, a discharge chamber, and a central area for the piston to move.

- A single design is created by a piston, a rod, a cylindrical pusher, a roller with an eccentric cam shaft.

- In the suction cavity there is an inlet valve through which fuel is drawn from the tank. The outlet is located in the discharge section.

At the time of operation, the piston creates a reciprocating motion. This design is less practical, but is also quite common due to its high efficiency. The double-action version has a more complex design, but this significantly increases the efficiency of the mechanism.

Fuel tank

The fuel tank must be protected against corrosion and must withstand twice the operating pressure of the fuel supply system, at least 0.3 bar. Excess pressure should be automatically released through special openings and safety valves located in the tank. When driving over rough terrain, tilting the tank or hitting it, fuel should not leak from the filler neck or pressure equalization devices. The tank must be located separately from the engine so that in the event of any malfunction the fuel can be prevented from igniting.

Selection and measurement of TNND

The type of pump in question operates under high loads for a long period. Due to this, rapid wear of the main elements occurs. Excessive wear and tear may cause the device to break. In most cases, to restore the structure, the main elements are replaced.

If the damage is serious, then you have to completely replace the unit. Serious defects include the following:

- Cracks and other defects in the body. The chambers of the housing must be characterized by high tightness, since pressure is created during operation of the device. As a result, liquid may be forced out through the housing.

- Fracture and destruction of main parts. Improper operation and untimely maintenance, too much load can cause destruction of the main elements.

- Deformation of key non-separable parts. This occurs due to the operation of the device with obvious defects.

It is worth considering that when replacing a pump, attention should be paid to the corresponding models. All work on replacing the device and setting it up should be entrusted exclusively to professionals, since mistakes made can lead to very serious consequences.

Principle of operation

The operating scheme of the low-pressure automobile pump used provides for the presence of 2 operating modes:

- preparation mode;

- Work mode.

Taking into account the purpose, as well as having disassembled the very device of the automobile fuel injection pump, it would not be superfluous to analyze its operating principle in more detail.

The preparation stage is observed at the moment when the piston begins to move in the upward direction. At this time, an eccentric acts on it, the spring contracts. Then the movement of fuel in the chambers between the coarse and fine filtration elements starts.

If we talk about the operating mode, then it occurs during the reverse movement of the piston when it moves down.

The low pressure fuel pump constantly delivers a larger volume of fuel than the internal combustion engine requires for stable operation.

Due to this, under different operating modes, it is possible to create the most optimal conditions within the automobile fuel system for the operation of the engine installed in the car. After all, if the piston constantly moves, the load will be very high, and all this will end in quite expected malfunctions, breakdowns of the unit.

If fuel is supplied in less quantity, then the voltage will increase, the piston will not be able to cope with it and cope with it. The result will be a stuck piston. This indicates that the fuel mechanism is supplying less working fluid. If fuel is supplied in large volumes, the piston actively makes its movements, and the high-pressure pump distils more fuel.

Having figured out how the low-pressure pump works in the engine and how it is connected to the injection pump, it is definitely worth talking about the existing types of injection pumps used.

Mechanical fuel pump design

A mechanical fuel pump, used in engines with a carburetor injection system, is attached to the cylinder block or cylinder head with screws. In most cases, a diaphragm pump is used to supply fuel. The pump attached to the block is driven by a crankshaft on which a special eccentric cam is provided. This cam presses on the rod, which compresses the membrane located inside the housing.

Mechanical fuel pumps had a manual fuel pumping system in case the system “dryed out” after a long stay.

When the cam is pressed, the volume of the pump's internal chamber decreases, and when it increases again, gasoline is sucked into the chamber. To prevent fuel from flowing back into the pipeline, the supply pipe is equipped with a check valve. When the next press occurs, fuel exits through the discharge pipe and is supplied to the carburetor, and a new portion from the pipeline enters the chamber. The pressure in the supply line can be regulated by installing a more or less stiff spring, but for design reasons it cannot be high (this is due to the fact that the stiffness limits of the spring are limited by the elasticity of the metal from which it is made).

Such different TNND

Let's move on to the varieties of TNND. There are two main types:

Electrical

Electric low pressure fuel pump

Electric, in turn, can be divided into several more subgroups depending on the design, namely:

- roller;

- gear;

- centrifugal.

Now let's try to understand each of the above types.

So, let's start with the classics that can be found on cars with carburetor engines - these are mechanical pumps. As we already mentioned above, this type of injection pump is located directly on the engine and this is not accidental. The fact is that the drive of this pump is provided by the crankshaft through a special eccentric cam.

During rotation, this cam presses on the rod, which, in turn, compresses the membrane inside the pump, reducing its internal volume. Due to the compression and expansion of the membrane, fuel is pumped into the carburetor. The flow of fuel back into the tank is blocked by a check valve.

It seems that a mechanical injection pump has a simple and reliable design, but it cannot be used in modern cars with injection or distributed injection - it pumps up too little pressure, and even then with pulsations, which negatively affects the stability of operation.

Because of this, the auto industry has massively switched to electric pumps. With the introduction of this type, there was no need to install it near the engine, so in most cases you can find it in the gas tank.

It would seem that the place was chosen strangely, but this is, in fact, a subtle engineering calculation - in a tank filled with fuel, the high pressure fuel pump cools best, and the noise from its operation does not irritate our nerves.

The key design elements of this type of gasoline pump are the electric motor and the pump part. Roller and gear devices use the physical effect of vacuum, which occurs when the position of the rollers or gears changes relative to the stationary parts of the pump.

It should be noted that these two types are currently considered not the most successful, since they create pulsations in the system, and their performance sometimes does not meet the demands of the motors.

The centrifugal low pressure fuel pump is free from the listed disadvantages. The basis of its design is an impeller, which, rotating at high speed, creates turbulence in the fuel, as a result of which the pressure at the pump outlet increases.

Probably, car experts will be able to correct us and supplement the story with other types of gas pumps. This is true, there are a large number of designs, but we tried to remember the most common ones. We hope, our dear readers, that after reading the article, there are fewer dark horses among the numerous components and assemblies of the car for you.

Subscribe to the blog, share links to it with friends, and I, in turn, will continue to delight everyone with new publications.

Current types

Do-it-yourself all-terrain vehicle on low-pressure tires

A low-pressure fuel pump used in automotive internal combustion engine systems can exhibit different characteristics and design features at its output. All TNND can be divided into 2 main groups:

- mechanical;

- electric.

It is impossible to imagine a modern car, be it gasoline or diesel, without a fuel injection pump. After all, it is with the help of this device that fuel is pumped out of the tank and supplied for further operation of the internal combustion engine.

Let's look at mechanical devices first.

If we talk about the mechanical type, then such fuel injection pumps are mainly found on old carburetor engines. Mounted on the cylinder block, fixed with a simple screw connection. The work is performed by a crankshaft with an eccentric cam. When this cam is pressed, contractions occur and gasoline is pumped into the chamber.

To prevent fuel from pouring back into the tank, a special non-return valve is additionally used in this unit. Subsequent active presses contribute to the flow of fuel into the carburetor for subsequent combustion.

An electric type of device has become a more advanced and modern solution.

It is relevant for injection car engines, since the injector entails the use of a large number of various electrical equipment. As a result, it became impossible to pump fuel mechanically. He could not carry out his tasks and, accordingly, no longer created the necessary pressure, taking into account the requirements of the new system.

If we consider an electric pump in a simplified version, then it is the pump component itself and the electric drive (electric motor) enclosed in a housing. There is also a filter, a fuel intake and a flow sensor inside. The operating principle resembles a mechanical analogue. But the difference is that an electric motor is responsible for moving the fuel.

TNND are mounted inside the fuel tank. It is a mistake to think that this is wrong from a security standpoint. In the case of a mechanical type of device, heating of the fuel occurred under the influence of the operation of the internal combustion engine. In electrical systems, this problem is completely eliminated. The fuel continuously moves through a system of special tubes, which does not allow the working fluid to heat up to dangerous temperatures, or at least approach these values.

That is, we can safely say that installing a high pressure fuel pump in a gas tank is the most correct and rational solution from the standpoint of maintaining the optimal temperature. After all, the distance between the pump and the heat source is impressive.

It is also important to note that the electric pump design components are in constant contact with gasoline. They're immersed in it

As a result, it makes no sense to talk about any short circuits or ignitions. In principle, they cannot happen.

Advantages of installing a booster pump on a diesel engine

If we return to the main topic, in many cases the booster pump for a diesel engine is electric. Such a pump becomes an important element in the power system, as it allows not only to quickly and efficiently supply diesel fuel to the injection pump, but also to pass diesel fuel through the filters.

Also, the presence of a booster pump allows you to achieve stable operation of the diesel engine in all modes and at any speed, that is, there is no shortage of fuel under load. We also note that many owners of diesel cars that do not have an additional pump as standard decide to install it themselves.

This need can be dictated by various reasons, ranging from slight airing of the power system after parking and ending with the desire to make starting a diesel engine easier. The pump can be installed either in the fuel tank or integrated in certain sections of the diesel fuel supply lines after the tank.

We also recommend reading the article about what a fuel injection pump (high pressure fuel pump) is. From this article you will learn about the purpose, principles of operation, as well as design features of pumps of this type.

As a rule, after installation, owners note that the diesel engine starts easier (you need to make fewer revolutions with the starter). There is also more stable operation of the internal combustion engine in different modes (transient modes, idle, operation under load). In some cases, an increase in power is also possible, since fuel is stably supplied to the injection pump even at high speeds.