“Bagel” in a machine box: what is it?

So, in everyday life it is customary to call a torque converter a “donut”.

The device received this name due to its shape. As a rule, gas turbine engines are installed in conjunction with “classic” hydromechanical automatic transmissions and CVT variators. Also, occasionally this element is paired with preselective boxes. To be clear, the torque converter is actually the clutch of the automatic transmission. Its main task is to convert and transmit torque from the engine to the gearbox. At the same time, the device does not have clutch discs (by analogy with a manual transmission), which interact with each other by closure and direct contact.

Simply put, the “donut” automatic transmission works like a hydraulic gearbox. The HDT (fluid coupling) reduces the speed and increases the torque with a transformation ratio of up to 2.4. In this case, energy is transmitted through the flow of ATF transmission fluid (automatic transmission oil). The result is soft gear shifting and no shock loads.

In a nutshell, the engine crankshaft is connected to the pump wheel. This wheel inside the gas turbine engine accelerates the transmission oil, after which it is redirected to the turbine wheel. The turbine wheel is connected to the automatic transmission. The oil spins the turbine wheel and is then redirected back to the pump wheel.

The liquid also falls on the blades of the guide wheel-reactor. This wheel accelerates the flow of fluid and redirects it in the direction of rotation. As a result, the fluid flow accelerates until the speed of rotation of the pump and turbine wheels is equalized.

At this moment, the torque converter begins to operate in fluid coupling mode, when the torque is no longer converted, the reactor wheel rotates freely without affecting the fluid flow.

The greater the difference in the speed of rotation of the pump and turbine wheels, the greater the acceleration of the ATF fluid flow. However, the downside is the high heat. When heated, the efficiency of the donut decreases. If the speed of rotation of the wheels is equalized, there is no longer an urgent need to transmit torque through the liquid (taking into account losses).

For this reason, gas turbine engines received friction clutch elements, that is, torque transmission is based on friction. This mode is called torque converter locking, when the input and output shafts are connected, that is, torque is transmitted directly.

At the initial stage, the blocking was triggered automatically (the pressure of the working fluid led to the triggering). Later, automatic transmissions received electronic control, and a separate valve became responsible for blocking the gas turbine engine.

In any case, the main task was the decision to connect the shafts directly, eliminating the transmission of torque through oil. The functions of the friction locking linings have also changed somewhat. Like the clutch of a manual transmission, when accelerating a car with an automatic transmission, the locking clutches of the gas turbine engine close slightly and slip slightly, while the torque is transmitted to the transmission more efficiently, without significant losses.

At the same time, the torque converter locks in modern automatic transmissions as early as possible in order to increase efficiency. It turns out that the “donut” today effectively combines the functions of a hydraulic gearbox and a conventional mechanical clutch.

As it may seem at first glance, the solution is optimal. However, it is quite obvious that the high heating of ATF fluid has not gone away (especially when paired with powerful internal combustion engines), and the presence of friction (rubbing) locking elements in the design indicates that they are subject to wear.

It is for this reason that a hydraulic unit, which seems very reliable, actually experiences significant loads, wears out quickly and may well fail under certain conditions.

In other words, the torque converter may well experience premature and unexpected failures. Experts also, not without reason, consider the “donut” to be the weak link in the automatic transmission design.

Why do you need a torque converter (donut) in an automatic transmission?

The hydraulic transformer is one of the most important units of the car, providing communication between the engine and transmission, essentially performing the functions of the clutch and some others.

Due to its external resemblance to a bakery product, it received the name “bagel” among auto mechanics.

Main functions of the torque converter:

- transmission of torque with its double conversion in the direction of increase;

- partial performance of the clutch function as in a manual transmission; when changing gears, the donut breaks the direct connection between the internal combustion engine and the transmission;

- automatic transmission protection during rapid acceleration and engine braking;

- When changing gears, the hydraulic transformer partially takes over the torque, ensuring a smooth change of gears.

What is the torque converter responsible for in an automatic transmission?

The torque converter is typical for two types of transmissions: automatic transmission and CVT. In fact, the automatic transmission torque converter is the clutch, connecting the transmission and the engine. At the same time, the gas turbine engine converts torque, ensuring smooth gear shifting.

Modern torque converters, controlled by an ECU, “monitor” the pressure of the working fluid, the frequency and correct rotation of the blades, as well as other parameters.

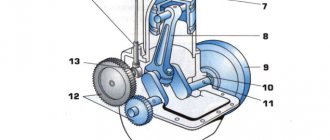

As for the torque converter design, the gas turbine housing is mounted in the hydromechanical transmission housing and receives drive via the gears of the matching gearbox. The torque converter includes four main elements.

- A pump wheel connected to a gear and driven by a matching gearbox and torque converter housing.

- Turbine wheel, rigidly mounted on the turbine shaft flange, which is also the leading element of the planetary gearbox.

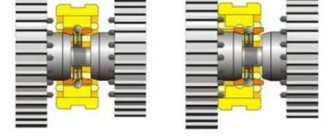

- The stator, also known as the reactor, is connected to an axis fixedly fixed to the crankcase through an overrunning freewheel. The coupling has an outer cage with shaped jamming grooves, to which the rollers are pressed by springs. The outer race of the coupling is rigidly connected to the reactor and rotates with it as one whole. The inner race of the coupling is installed on the splines of the axle and is movably fixed in the hydromechanical transmission housing.

- Locking mechanism (friction locking of gas turbine engines). This unit consists of a housing, a piston with sealing rings, a cover that together with the piston forms a cavity filled with oil, a hub rigidly connected to the wheel and shaft, two driving steel and three driven metal-ceramic disks and a housing rigidly bolted on one side to the pump wheel, and on the other with a lid. The housing has internal teeth for installing drive discs. In a friction clutch, the driving and driven disks are placed one after another, with a disk with a metal-ceramic coating having internal teeth being placed first on the supporting surface.

When the torque converter operates, the blade system of the pump and turbine wheel reactor forms an internal circulation circle, which is filled with oil (ATF fluid).

The gas turbine engine operates in three modes:

- torque transformation mode;

- fluid coupling mode;

- blocking mode;

The transformation mode is used when starting the car from a standstill, when accelerating or climbing, as well as when driving off-road. In this operating mode of the gas turbine engine, the reactor is stationary. The pump wheel, with its blades, directs flows of oil onto the blades of the turbine wheel and sets it in motion, but at a relatively lower speed.

Why do you need a torque converter (donut) in an automatic transmission?

The torque converter replaces the clutch system and avoids turning off the engine when stopping. A system of two turbines transmits torque to the automatic transmission with a conversion value of 2-3.5 times.

Torque converter device.

During the transition between gears, the hydraulic converter takes away part of the torque, which makes shifting smooth and safe for the transmission. During rapid acceleration or sudden braking, the transformer serves as an additional barrier that protects the automatic transmission from overheating and failure.

Automatic transmission torque converter design

What is a torque converter in an automatic transmission or a “donut”, as mechanics call it? A gas turbine engine is a hydraulic drive that connects the engine and the automatic transmission without a rigid connection. Plays the role of a clutch in analogy with a manual transmission.

There are two types of hydraulic drives: fluid coupling and torque converter. The difference between them lies in the transformer's ability to convert torque. While a fluid coupling can only transmit. The “donut” automatic transmission operates in both modes with automatic switching, so it can be called a hybrid unit.

Why is a torque converter needed in an automatic transmission? The node has several purposes:

- ensures stepless gear shifting and smooth vehicle movement;

- dampens vibrations and shocks from engine and transmission operation, extending their service life;

- allows the engine to idle;

- promotes engine braking;

- increases the vehicle's cross-country ability in difficult conditions by continuously transmitting torque from the engine to the wheels.

The design of the automatic transmission torque converter is based on the laws of hydraulics. The mechanical force of the engine goes into the “donut” and is converted into hydraulic energy due to the movement of the fluid flow in the cavity of the gas turbine engine. Pressure and kinetic energy arise, which cause the transmission shaft to rotate. And from it the torque goes into the planetary gear shift mechanism.

In theory, an automatic transmission could consist only of a torque converter. But at high speeds its efficiency decreases greatly. The donut gear ratio is limited. It cannot provide reverse driving or a sufficient number of gears. Therefore, in an automatic transmission, a planetary gearbox is installed behind the torque converter, which is capable of obtaining any gear ratio in a given range.

One of the leading developers of eight-speed torque converter gearboxes is the German company ZF. High-tech transmissions from this manufacturer are installed in Jeep, BMW, Volkswagen, Audi, Jaguar, Cadillac, and Infinity cars.

Modes

When the internal combustion engine is started, working fluid is supplied to the donut using a special pump and the pressure increases. The centrifugal wheel begins to spin, the stator and centripetal turbine are still motionless.

Bagel operating modes:

- Transformation . When changing the position of the selector and increasing the supply of the fuel mixture when pressing the gas pedal, the speed of the pump wheel increases due to the movement of the crankshaft. The increasing movement of the transmission fluid causes the turbine wheel to rotate. The vortex flows of the transmission fluid either transfer to the stationary reactor wheel or return to the turbine wheel, increasing its efficiency. The torque is transmitted to the drive wheels, and the car begins to move. The reactor contains an overrunning clutch, which, if there is a significant difference in the rotation of the pump and turbine, blocks the rotational movement of the stator and direct transmission of engine torque to the automatic transmission occurs; special reactor wheel blades increase the flow speed from the centripetal turbine and return it to the centrifugal pump, increasing the torque. If the resistance to movement increases (climbing a hill), the stator stops the rotational movement and increases the transmission of torque to the pump wheel. Upon reaching certain parameters (required speed and torque), the gear in the automatic transmission is changed.

- Fluid coupling. At a certain speed, the rotation of the centrifugal pump and turbine wheel is synchronized, and the flow of working fluid enters the stator from the reverse side, at which movement occurs in only one direction. The device switches to fluid coupling mode.

- Blocking . When certain parameters are reached, the electronics blocks the hydraulic transformer using a friction disk and direct rigid transmission of torque is carried out without loss of power.

When changing stages, the donut switches off to ensure smoothness, then starts working again. Using this process, the possibility of “slippage” is eliminated, the life of the torque converter is increased, power loss is reduced and fuel mixture consumption is reduced.

The electronic control unit instantly changes the operating mode of the donut, adapting its operation to changing conditions.

Torque converter operating modes

- Slipping – the lock-up clutch is open. By means of the control valve, the working fluid is supplied through channel “B”, thereby pressing the valve away from the wall of the rear cover of the gas turbine casing. Oil through channel “B” is discharged through the cavity inside the shaft. Used when starting from a standstill and accelerating. By opening the torque converter lock-up clutch in higher gears, it allows the car to accelerate dynamically without moving to a lower gear.

- Engagement mode – clutch is locked. Oil flows through channel “A” into the cavity behind the clutch, forcing the piston to press against the rear cover of the casing. The friction force between the friction linings leads to the engagement of the gas turbine housing with the turbine wheel. The clutch closes advantageously when driving in higher gears. On most automatic transmissions, the torque converter lockup is activated after 3rd gear. But due to stricter environmental standards on modern cars, the clutch can be blocked in any gear at engine speeds above 1000 rpm.

- Controlled slip mode - the clutch operates with a slight slip. In design options not equipped with a damper, the mode is used to dampen torsional vibrations. In this case, a small amount of slippage is allowed between the turbine section and the pumping section. This improves switching smoothness and efficiency.

Description of the torque converter design

The torque converter is located in the automatic transmission housing and is connected to the oil pump through the transmission input shaft. On the opposite side, the “donut” is attached to the engine flywheel through threaded bosses.

The automatic transmission torque converter parts are located in a sealed casing, where they are immersed in ATF fluid. Due to the toroidal shape of the torque converter housing, it was nicknamed the “donut”. To get to the filling, you need to carefully cut the weld along the equator of the casing.

In cross-section, the automatic transmission torque converter is a set of bladed wheels and couplings mounted on one axis:

- pump wheel;

- turbine wheel;

- reactor wheel;

- overrunning clutch;

- locking clutch.

The pump wheel is welded to the housing cover, which is connected to the engine crankshaft. The turbine wheel is structurally similar to the pump wheel and is installed opposite with a small gap. The turbine is rigidly connected to the transmission input shaft.

Between the pump and the turbine there is a reactor. It is fixed to the freewheel, which is mounted on the input shaft bushing. The lock-up clutch is located behind the turbine.

The kinematic diagram shows how the main parts of the torque converter are located and shows the trajectory of the fluid flow. Structurally, the automatic transmission torque converter is a direct drive device, when the blade wheels force the fluid to circulate in the following order: pump - turbine - reactor - pump.

Torque converters with an overrunning clutch are called complex ones.

Components of the torque converter

The basis of the pump and turbine wheels of the torque converter is a bowl cast from a light alloy. Grooves are cut out on the inner and outer surfaces of the bowl, between which the blades are located. The blades are made by stamping and connected to each other by a toric disk using bending tendrils. Additionally, the blades on the bowl are secured with a ring.

The curvature of the bowl and the complex shape of the blades are designed to meet the requirement to increase the efficiency of liquid circulation. Thus, the design of the wheels provides the necessary speed and direction of oil movement.

The turbine wheel rests on the shaft by means of a hub and plain or rolling bearings. The bearing absorbs radial and axial loads.

The pump hub is typically used to drive the oil pump located behind the torque converter. The drive is activated when the end splines of the hub enter the corresponding grooves of the pump drive gear.

Torque converter malfunctions

- Support bearing wear. Characteristic symptoms are a slight metallic sound when switching.

- The increase in engine speed does not correspond to the acceleration dynamics. The problem is in the overrunning clutch. If the malfunction appears only in one or several stages, the problem is burnt clutch packs.

- A rustling noise when the engine is running at idle and low speeds (may disappear while driving). Malfunction of the needle thrust bearing between the turbine/reactor wheel and the rear cover of the gas turbine casing.

- Loud metallic sound when switching. The reason is damaged blades (this happens extremely rarely).

- Loss of dynamics in higher gears. Wear of the friction linings of the torque converter lock-up clutch. Without proper experience, it can be difficult to notice the difference in dynamics on a car with a malfunctioning clutch. Therefore, most often owners are faced with the consequences of this malfunction. Friction dust and the adhesive layer of the lining contaminate the oil and clog the oil circulation channels. Constant slippage overheats the donut itself, the oil, and with it the mechatronics electronics. All this over time leads to shocks, kicks when changing gears, and an increase in shift time. Therefore, it is so important to understand the operating principle of the torque converter and promptly change the oil in the automatic transmission.

What are the risks of driving without locking the torque converter?

The service life of torque converters on automatic transmissions is calculated by the manufacturer from 200 thousand to 300 thousand kilometers. For example, on older Mercedes models, torque converter malfunctions may not appear for 500 thousand kilometers. The Toyota Mark 2 automatic transmission is also not prone to breakdown quickly.

Experts advise: “If the car begins to twitch during acceleration and does not shift gears smoothly, it must be immediately taken for a technical inspection.” The linings on it are worn out. This means that the blocking will no longer turn on on time.

If the torque converter lock-up solenoid, which is responsible for the clamping force, is clogged, the automatic transmission will push and kick. The vehicle will consume a large amount of fuel.

Wear products will continue to spread throughout the automatic transmission. This will lead to contamination of the pump and lubricant. As a result, wear products will act as an abrasive agent on the clutch teeth. Accordingly, the oil will overheat due to strong friction. As a result, the automatic transmission will need to be replaced.

It happens that the pump wheel or turbine in the torque converter wears out faster. How to check what is damaged in the torque converter, and whether a malfunction in the gas turbine engine is the cause of all problems is in the next block.

Table of signs and causes of automatic transmission malfunction

Signs of malfunction of various types and types of automatic transmissions are largely similar, since the design of these components is similar. The automatic transmission is one of the main mechanisms of the car, the malfunction of which can create serious costs for the driver’s family budget. Therefore, even an inexperienced driver should know what automatic transmission malfunctions exist and how to detect them.

Basic malfunctions and repairs of the automatic transmission torque converter

So, automatic transmission torque converter problems can arise for various reasons. The first signs of a torque converter malfunction:

- slight slipping at start;

- feeling of vibrations when the car is moving;

- jerking while shifting gears;

- impossibility of turning on the blocking mode.

As for the causes of malfunction of the automatic transmission torque converter and methods for solving them, the main list should include:

- Wear of bearings (support or intermediate, between the turbine and the pump). When the vehicle's transmission operates without load, a slight mechanical noise is heard, which disappears as the vehicle speed increases. The problem is eliminated by disassembling, troubleshooting or replacing worn bearings.

- Loss of transmission oil properties, oil filter contamination. When driving a car at high speeds, vibrations appear, which increase over time in almost all modes of vehicle movement. The malfunction is eliminated by replacing the oil filter and transmission oil. Overrunning clutch wear. The torque converter reactor stops working, as a result of which the increase in torque does not occur and, accordingly, the speed gain dynamics decrease. The malfunction is eliminated by replacing the overrunning clutch.

- Broken spline connection between the turbine wheel and the automatic transmission shaft. The car stops moving because the torque from the internal combustion engine is simply not transmitted to the gearbox. The problem is solved by restoring the spline connection or replacing the torque converter. We also recommend reading the article about which automatic transmission is better to choose: automatic, robot or CVT. In this article, you will learn about the advantages and disadvantages of different types of automatic transmissions.

- Destruction of wheel blades or reactor. While the car is moving, a loud metallic grinding and knocking noise is typical. In this case, the problem is solved by replacing the damaged components or the entire assembly.

- Overheat. This problem may arise due to the so-called “oil starvation”, or due to clogging of the automatic transmission cooling system. In this case, cleaning the radiator and filters is required. A complete replacement of the transmission fluid is also necessary.

Signs of problems with the automatic transmission torque converter

As a rule, problems with the gas turbine engine are indicated by the condition of the oil in the automatic transmission. It is recommended to check the condition of the lubricant at least once a month. Often this allows you to promptly identify problems with the automatic transmission or torque converter and immediately begin to fix them.

- If the color of the ATF changes quickly after replacement (the initially clear oil becomes cloudy, darkens and becomes opaque), this is often a sign of problems with the friction linings.

- Also, problems with the gas turbine engine are indicated by signs when the car pulls worse, acceleration dynamics are lost, fuel consumption has increased, jerks are noticeable when driving quietly or during engine braking, vibrations have appeared, a howl is heard when decelerating, the car begins to roll back when starting uphill.

One way or another, the above signs and symptoms are the basis for checking the donut. Often, timely measures can avoid serious damage to both the gas turbine engine and the automatic transmission itself.

How does the malfunction manifest itself?

- Wear of the lock is often expressed as follows: when the car accelerates smoothly to 60-80 km/h, the car begins to twitch. The point is that when the gas turbine engine is properly blocked at such speeds, it turns on. The engine speed drops, but the switching to the next stage does not occur. In the event of a malfunction, the lock does not engage with the engine, but begins to slip. The torque from the engine is transmitted jerkily, which causes this behavior of the car.

- The next sign of a faulty torque converter lockup often appears on Mercedes automatic transmissions. When starting to move, when the transmission is switched to Drive mode, the car itself tries to pull forward with the brake pressed. This happens until the engine stalls, because the torque converter locks up and suffocates it.

With a faulty torque converter, the car can still be driven for some time. But it is also worth considering that such a GTR has a negative impact on the rest of the transmission. In particular, the wear products of the locking we just talked about add to the problems. This debris, along with the oil, spreads throughout the box and damages living units. The adhesive layer on which the locking pad is held is especially destructive. It is “fierce”, and therefore, even if it gets loose, then this glue sticks tightly where it is not needed. So, dear car enthusiasts, if you notice that some of these signs appear on your iron horse, it is better not to put off repairing the torque converter. Until this box became the coffin for the entire automatic transmission, followed by a major overhaul of the automatic transmission.

Symptoms of a problem

There may be several signs of serious malfunctions of the automatic transmission torque converter. All of them indicate an imminent breakdown of the gas turbine engine and failure.

Sign. A noise resembling the beating of a metal object is heard. It disappears under load.

Problem and solution. Wear of the bearings located between the turbine and the pump. To remove these symptoms and fix the breakdown, you need to disassemble the torque converter and replace the bearings.

Sign. Vibration of the automatic transmission when accelerating above 60 km/h or driving the car on a flat surface at high speed.

Problem and solution. Filter device is dirty. Loss of functional properties of the lubricant. It is necessary to completely replace the ATF in the automatic transmission and install a new filter. It is quite possible that oil starvation has occurred. It is necessary to check the automatic transmission pan for leaks.

Sign. There is no movement back or forward.

Problem and solution. The connection between the turbine and the automatic transmission shaft has broken. To solve this problem, you will need to replace the torque converter. In rare cases, you can get by simply replacing the spline connection.

Sign. The car cannot accelerate and gain the required speed in a short time.

Problem and solution. The overrunning clutch has failed. It is necessary to disassemble the torque converter and replace it.

Sign. Oil overheating. The automatic transmission jerks and kicks.

Problem and solution. For example, if there are problems with wear on the friction lining of the torque converter brake locking piston, it is very difficult to notice the incorrect operation of the device. Because of this, the oil often overheats to 140 degrees Celsius. Overheated lubricant destroys the rubber of gas turbine engine oil seals. Oil begins to flow.

This malfunction continues with complete wear of the clutch lining. Its glued part comes off and travels through the automatic transmission. Then it settles and sticks in the wrong places, causing a blockage. The blockage prevents the free circulation of oil. The pressure drops.

Therefore, both experts and experienced mechanics at service stations ask car owners to carry out regular maintenance. When the clutch wears out, the malfunction is invisible. But subsequently it leads to a complete replacement of the automatic transmission. Although at the initial stages it was possible to get by only by changing the clutch lining.

Infrequent failures of gas turbine engines include the following problems:

- destruction of turbine blades and pump wheel. Leads to breakdown of the gas turbine engine. It needs to be completely replaced. The problem is determined only after opening;

- overrunning clutch wedge;

- unlocking the overrunning clutch;

- overheating with destruction of the hub.

Read

Replacing the automatic transmission torque converter oil seal with your own hands

Overheating of the transmission fluid can cause rapid loss of functionality.

Sign. The smell of burnt plastic spreading into the cabin. A common problem on Toyota Camry 50.

Problem and solution . A clogged radiator is the problem in this case. It is recommended to remove and clean it. Changing the oil and filter device is a must.

Sign. Kicks, delays when switching gears in winter.

Reason and solution . This can be facilitated by cold starting. To avoid these symptoms, the automatic transmission needs to be warmed up in winter. At temperatures below 0, the car owner must warm up the automatic transmission to an operating temperature of 70 degrees Celsius and only then start driving.

Attention! Unresolved problems and left for later, symptoms of torque converter malfunctions on the DSG can lead to destruction of the pulleys and broken belt or chain. We will have to restore the CVT box completely.

On cars of an older year of manufacture, the rocker itself fails. It locks in one position. Here you will need to replace the selector and gear shift knob. This can be done without removing the automatic transmission.

Replacement or repair

The torque converter is easy to repair. All its parts, including blades and rings of the pump, turbine and reactor, are available on the aftermarket.

Transformer repair takes place in several stages:

- cutting off the weld and disassembling the device;

- cleaning the torque converter parts from dirt and oil with a special solution (solvent);

- diagnostics of parts (inspection, defect detection using various methods);

- removing worn parts, drilling or cutting off their fastenings;

- attaching, welding or gluing new parts;

- checking the tightness of the locking piston, replacing oil seals and seals;

- transformer assembly, balancing (runout alignment) on the machine;

- body welding;

- checking the quality of welds, internal clearance, locking functionality;

- rebalancing the torque converter;

- checking the serviceability of the repaired device.

If several parts are damaged, the transformer is severely worn, or a combination of these factors, a complete replacement of the device may be recommended. The cost of replacement can be an order of magnitude higher than the average cost of repair. Refurbished and used devices may cost less, but their service life will be 20-40% less than that of new ones.

Do-it-yourself automatic transmission torque converter repair

Repairing an automatic transmission torque converter will not be more expensive than buying a used gearbox. To carry it out you will need:

- pit or overpass;

- wrenches and repair kits;

- valve for removing automatic transmission;

- test equipment;

- lift;

- oil;

- new filter device.

To repair the torque converter, you need to remove the automatic transmission from the car and completely dismantle it. Pull out the torque converter and install it on a special machine, on which you carefully cut the housing along the seam and separate it into two parts.

Experts do not recommend repairing the torque converter yourself. It is also not recommended to pour various cleaning liquids into it. Since, in addition to caked oil and carbon deposits, they destroy seals, oil seals and other rubber gaskets. Read Replacing the automatic transmission torque converter oil seal with your own hands

Experienced mechanics prohibit the use of old oil seals and O-rings. Although they have not been used, their lifespan has expired. Since rubber dries out over time, it bursts. Unnoticeable microcracks on such an installed oil seal can lead to a complete replacement of the device in the future.

After completing all repair work on the automatic transmission torque converter, it is recommended to install it in the box and carry out balancing. Otherwise, the disturbed balance will kill all mechanical parts of the automatic transmission.

Welding of the body is required. This is done to ensure the tightness of the device.

Attention! The solvent will not be able to wash away the adhesive from the clutches that has spread throughout the automatic transmission.

How to check the automatic transmission gas turbine engine

Car owners are interested in how to check the operation of the torque converter. Experts say that without disassembling the gas turbine engine, checking the “donut” is impossible. Error codes about malfunctions and emergency mode may appear on the dashboard monitor, but the final verdict can only be made after disassembling the gas turbine engine.

This is because most failures occur at the mechanical level. This requires disassembling each component separately and inspecting it visually.

At home or in the garage, the car owner will be able to disassemble the torque converter only if he well understands the principle of operation and structure of the device. You need to have a special machine on which you can clamp the donut and carefully cut it to get to the inside. You will also need specialized tools to identify the fault and remove it.

Read

Reasons why a car with an automatic transmission does not move forward or backward

If the car owner is not good at this or is not an experienced mechanic, then at the first sign of trouble, it is better to contact experienced mechanics at a service station. What are the external manifestations of a breakdown of the gas turbine engine of the automatic transmission in the next block.

Recommendations for maintenance and operation of gas turbine engines

The use of a “donut” in the transmission simplifies and facilitates driving even in difficult conditions. However, an automatic transmission with a torque converter, when compared with a manual transmission, loses in terms of parameters:

- low efficiency without blocking;

- fuel consumption is 10% higher;

- small range of change of donut torque and the need to install a planetary gearbox;

- complexity of design and maintenance;

- high price.

To become a regular customer of an automatic transmission torque converter repair shop, you need to follow two rules:

- press the gas and brake pedals to the floor as often as possible in order to quickly wear the locking clutch friction into abrasive powder, contaminate the oil and accelerate the wear of the machine;

- never change the fluid, especially if it is black, hot, and the level is above or below normal.

Seriously, the gas turbine engine fails slowly and unnoticed by the driver. A clear signal of malfunction is an oil leak at the junction of the torque converter and the engine. Other signs of a problem may appear already at the stage of the “disease” spreading throughout the automatic transmission. Therefore, if the car behaves strangely: it accelerates slowly, the fuel consumption has increased, vibration appears when driving, you need to send the car for inspection.

Before independently inspecting the box, you need to study the structure and features of a specific automatic transmission model. To get to the torque converter, you will have to remove the entire box. It will not be possible to repair the donut without cutting and disassembling. Flushing the torque converter with solvents can damage the wheels and “corrode” the seals.

After repair and assembly of the automatic transmission, balancing of the torque converter is necessary. Not all services carry out this operation, as it is labor-intensive and problematic. The gas turbine engine operates at high speeds - an imbalance or misalignment of the shafts will damage not only the donut, but also the entire automatic transmission.

How to extend the life of an automatic transmission fluid coupling

To extend the life of a hydromechanical transformer, you must follow the following recommendations:

- regularly check the color and transparency of the oil in the automatic transmission and replace ATF and filters at least once every 40-60 thousand kilometers;

- fill in the fluid recommended by the car manufacturer;

- change seals and seals during each major overhaul and overhaul of the transformer, be sure to replace all gaskets when the mileage exceeds 150 thousand km without repair;

- avoid sudden acceleration and deceleration; when driving aggressively, change consumables and oil more often;

- after starting the engine, turn on all gears and modes one by one, holding the brake and holding each for 2-3 seconds;

- avoid towing both in the driven position (with the engine turned off) and in the driving position;

- at low temperatures, warm up the car for at least 10 minutes at idle, in the warm season - 2-3 minutes (the transmission and fluid coupling are warmed up separately, with the engine running).

The service life of an automatic transmission with a torque converter, with timely oil and filter changes, can be more than 300 thousand km. With a mileage of more than 150 thousand km, in most cases, repair or replacement of the main parts of the device is required - housing, couplings, turbines, etc.

If used carelessly or if there are defects in the design, major repairs may be needed much earlier.

What role does the torque converter play?

To ensure smooth gear shifting and continuous transmission of torque (for a CVT), a completely different type of clutch is used.

In cars with a variator and automatic transmission, a torque converter acts as a clutch - an element that transmits torque from the power plant to the gearbox.

The peculiarity of this element, which is part of the transmission design, is that force is transmitted through liquid, that is, there is no rigid connection between the engine and the gearbox (although this is not entirely true).

The torque converter allows for stepless power transmission, with the ability to change torque and rotation speed.

Also, at the moment of changing the stage (in an automatic transmission), the torque converter allows you to disconnect the engine and transmission from each other, and then smoothly resume power transmission.

Essentially, the device acts as a clutch, but with some additional functions.