What is soot

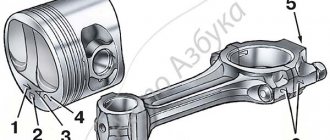

Since the piston is the first part that takes the load from the ignition of the combustible mixture (takes the blow), it is constantly exposed to temperature, mechanical and chemical influences.

Soot is the formation of a layer as a result of burnt chemicals contained in the supplied fuel. Fuel contains various additives and impurities. When decomposed fuel substances come into contact with hot internal combustion engine parts (pistons, cylinders, valves, connecting rods), these substances stick to the hot metal and settle. Carbon deposits form especially quickly on the pistons due to incomplete combustion of the fuel-air mixture and the breakdown (decomposition) of engine oil. In other words, carbon deposits are deposits that interfere with the normal operation of the internal combustion engine, so it must be removed. Carbon removal is also called decarbonization.

The formation of carbon deposits on intake valves, piston heads, and walls of combustion chambers is the most common occurrence.

The composition of carbon deposits includes ash and carbon compounds. Solid deposits of ash + impurities and particles of unburned fuel and motor oil, also called coke. If there is a lot of coke on several parts, this is already coking of the engine.

What is carbon deposits on pistons?

Looking inside the power plant, we will definitely see that many parts are covered with deposits of various types. Experienced drivers divide them into sludge, carbon deposits and varnish formations. One of the reasons for the formation of deposits is the breakdown of engine oil in the engine. It oxidizes and decomposes over time, so breakdown products can settle on the elements, forming a deposit. Therefore, every driver should know how to clean the piston from carbon deposits.

We remove carbon deposits from the engine without disassembling it

Over time, deposits begin to accumulate in the car engine, preventing it from working properly. Dealing with carbon deposits is not difficult, this is required.

No matter how often car enthusiasts change the engine oil and no matter how high-quality fuel they select, carbon deposits still appear over time in one way or another. Moreover, it forms almost everywhere: on pistons, valves. Its presence on the rings significantly reduces their mobility.

The reasons for the large amount of soot are primarily due to low-quality fuel, which does not burn completely. They may also consist of incorrectly selected oil or low quality oil.

It is very harmful to immediately load a cold internal combustion engine. It is important to warm it up.

How can you tell if your internal combustion engine is heavily polluted?

In this case, the car begins to constantly overheat for no apparent reason. That is, there is no leak, the antifreeze is normal, but the car overheats, the cooling fan works all the time. The reason for this is the deterioration of heat transfer.

When starting the internal combustion engine after a long stop (about 5 - 6 hours in summer and more than 3 hours in winter), black smoke comes out of the exhaust pipe for about half a minute or less. The internal combustion engine does not operate quite smoothly after it is started. After warming up, engine performance immediately improves. The interior may feel burnt. The “traction” becomes worse - the car takes longer to gain speed. Fuel is consumed more than usual by about 1/5. When the ignition is turned off, detonation may occur. As a result, a noticeable vibration is felt. This is due to the combustion of the remaining fuel. It ignites from heated carbon deposits.

Is it possible to remove carbon deposits without disassembling the engine?

So, you need to buy compressed air (it is sold in cans), a syringe with a tube and a liquid intended for decarbonization. The pistons will need to be set to the same level. Use the key to turn the crankshaft pulley, or lift the front wheel, then engage fifth gear, then start turning the wheel. A tube and syringe are useful for pouring liquid. Decarbonization will take time, about 2 hours, but more is better. Then the liquid should be removed from the wells. After this, you need to blow out the spark plug wells with compressed air. Then you should get into the car, turn on the ignition, press the gas and turn the starter for 5 seconds. After this, put the spark plugs back and start the car engine. It should work for about ten minutes. Initially, black smoke will be observed, which means that the product remaining in the engine is burning through.

To clean the rest of the internal combustion engine, flushing oil is required. It requires driving approximately 100 kilometers. When traveling, there is no need to put any load on the engine. Then the oil should be washed off, fill with regular oil and drive the car quietly, the washing is completed.

Liked? Give it a class! Subscribe to the channel if you like cars

!

Source

What to do if the chainsaw still won’t start

If the initial inspection did not yield anything or the defects were eliminated during the search process, but the chainsaw still does not start, then you need to look for more serious reasons. It is best to identify and repair such breakdowns at a service center. However, if you have experience, you can find and eliminate them yourself. What to diagnose and check?

- Compression in the cylinder;

- Compression in the crankcase;

- Carburetor operation.

In the first case, checking the compression in the cylinder will allow you to find out the condition of the cylinder-piston group (CPG) of a chainsaw that does not want to start when cold. To do this you need a compression gauge. The device is screwed into place of the spark plug and the engine is started idle. Measuring the readings allows you to judge the condition of the CPG. In the absence of a compression gauge, you can determine the compression in the cylinder offhand as follows:

- Place your finger on the spark plug hole;

- Try to start the chainsaw engine.

By placing your finger on the spark plug hole and pulling the starter, you can check the compression in the cylinder

If you feel that your finger is being pulled strongly into the spark plug channel, then everything is in order with compression. The absence of vacuum in the chamber indicates a malfunction. The cylinder-piston group needs a more detailed inspection, which will give an idea of the condition of the piston and cylinder, piston rings and bearings.

A chainsaw may not start when cold due to a lack of compression in the engine crankcase. The main reason for this is damage to the gasket located between the cylinder and the crankcase. It is quite easy to detect a lack of compression:

- Disconnect the upper tube from the carburetor;

- Pour gasoline into a regular cork;

- We immerse the removed tube in the fuel;

- We pull the starter several times.

If fuel is sucked out of the cap when the chainsaw starter starts, then everything is fine with compression. If not, look at the gasket.

If the fuel is drawn in, then everything is fine - the gasket is intact. Otherwise, you will have to purchase a repair kit and make a replacement. How to do this, watch the video why a Chinese chainsaw won’t start:

Starting the tool may be complicated by improper operation of the carburetor or its breakdown. It often happens that during the sawing process the fastening screws become loose and air is sucked into the cylinder. Check that the carburetor is securely fastened. Inspect it for fuel leaks. There can be many reasons for the malfunction. It is possible to accurately determine the malfunction, eliminate it and fine-tune the carburetor only at a service center.

After going through a step-by-step troubleshooting of the chainsaw engine, you will be able to find the malfunction, fix it yourself and successfully start your working tool. Do not take on types of work that you are not confident in. Entrust troubleshooting and troubleshooting to specialists from the service center.

This product will help clean the piston from carbon deposits.

Don't know how to clean the engine piston from carbon deposits?

Schumann to the rescue! The stove and oven cleaner not only copes with grease in the kitchen, but also perfectly removes fossilized carbon deposits on pistons. It is true that in some cases this is contraindicated.

Often car enthusiasts who disassemble and repair engines wonder how to clean carbon deposits on pistons? There are quite a lot of proposals - from special means to banal soaking in gasoline, diesel fuel, kerosene or some kind of solvents, but this is often ineffective.

The product for cleaning ovens and stoves contains alkali, which is why it is very caustic and quickly and easily dissolves carbon deposits (both at the top and in the hard-to-reach grooves of the piston rings). Therefore, if you need to clean the oil channel on the piston, you can take a plate cleaner, but you need to apply it for a short time and on the pistons without special spraying, otherwise there will be trouble!

The main disadvantages of the product: excessive causticity

and something that can

only be used if the engine is disassembled

and the part is already in hand.

To clean pistons from carbon deposits without disassembling the engine, dimexide is used in the same budgetary way, but there are a number of reasons why this should not be done, they are described here

.

Indisputable advantages: completely removes any carbon deposits

, you can

clean both the piston and the valves

; the best tool

for decoking the oil channels

in the piston is always

available in the kitchen

.

To clean the piston, the best option would be to use a gel-like product or spray, but cream or powder ones are less effective. Therefore, if you have a difficult case, then it is better not to use any of the cleaning products for stoves and ovens, but only: Schumanite, Amway Oven Cleaner or the like, which contains surfactants, solvents, sodium hydroxide, or better yet, organic acid (then it will also be safe for aluminum parts).

Products containing alkali (caustic soda) damage the protective oxide film on the aluminum piston, causing it to darken and succumb to oxidation. Therefore, it is strictly not recommended to keep this composition for longer than 5 minutes.

When one treatment does not bring the desired result, the procedure can be repeated again, and it is better to wrap the coated piston in cellophane so that the product does not dry out but remains on the surface and continues to act until washed off with water.

Yes, this is a dangerous drug

, but very effective and cheap, because a good housewife or owner can always find it in the kitchen. Well, if it’s still a little scary, you’ll have to spend money and buy a special cleaner. Motorists recognized Profoam 1000 as one of the best in this category.

Are you interested in this idea? Give it a thumbs up!

And if you have something to say about this, then don’t hold back and speak up in the comments.

Video about cleaning pistons and valves from carbon deposits

By the way, still not subscribed to the channel? Be sure to subscribe right now if you don’t want to miss another good tip on car maintenance or repair!

Source

White carbon deposits on the piston

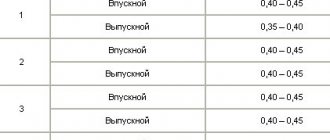

Hello everyone, for what reason could there be a white coating on the valves and piston? Cylinders 2 and 3 and valves are perfect, no carbon deposits at all. And cylinders 1 and 4 and valves have a white coating. And when I measured the compression, it was like this: 1 - 25 bar 2 - 30 bar 3 - 20 bar 4 - 15 bar From the 4th cylinder, the cylinder head bolts and so on stink very much. Probably burnt oil. What could be the problem with white plaque?

In the evening I’ll try to post some pictures, I just lost the engine and had to urgently leave for another city; I haven’t studied my problem in detail yet.

I also took the injectors to Bosch service, they said everything was fine with them, within normal limits, the return flow was a little too high. But I don’t know for sure, maybe they deceived me, but what’s the point.

Car e46 320Cd with m47n engine

I asked him to spray it with wd-40, wipe it and take better pictures, there didn’t seem to be any cracks.

Well, the intake valves only let in air. Does excess air cause a white coating to form?

In general, I scattered the block. As a result, the pistons were removed from the block, but they stuck out 2mm and got stuck, there was such a ringing sound, the rings rest against the step. The step is elliptical, the honk at 9 and 3 o'clock remained in other places, erased and the step there is awesome. I haven’t been able to measure the step yet, I’ll probably take it to Mechanics tomorrow, they’ll immediately tell you what to do and how to do it. There were also no feeler gauges to measure the gap in the piston ring lock, but I estimated the caliper with a compass quite accurately, it turned out like this: At the top where the piston had not worn off (not the working surface) the gap was 0.4-0.6 mm And where the piston had bored everything out, there was 1.3 -1-4mm

What do you say? Apparently, most likely it won’t be possible to pinpoint it until the first repair? Won't he clean up this whole thing?

I have a previous 39 with an M51 engine, it has done 400 thousand and would still do the same. An excellent motor in this regard. But the fact that it doesn’t drive and rattles in winter is terrible and eats more. But with a mileage of 400 thousand without a glow plug, it always started with half a turn at -33 degrees! Well, who knows, maybe with a normal engine it will work in any frost. And another question, if suddenly I find a block and there will be a complete factory honour, present everywhere, on the entire surface. So you can even know without measurements that the cylinder clearances are normal?

In general, I probably didn’t listen to anyone. I took this cast-iron weight to the mechanics, they looked at it and said that due to overheating at such a mileage, everything had deteriorated like that. The crankshaft is perfect, just a little polish and that's it. The block is lined, the cylinder head is pressurized and, if anything, the valves with caps are ground in or replaced. They said they repair it all the time and know what's what. They sharpened the crankshaft from 2 refrigerators in front of me. He said that many people don’t trust and don’t like a sleeved motor, but in reality the engines last a long time; in extreme cases, with proper care, this body should be enough after a rebuild.

By the way, what parts does the tensioner consist of? Plastic, spring, piston, spring, piston? something like this? I brought the engine to the mechanics, and suddenly I was inspired to get a nail

As a result, 2 broken frames with photographs and a wall covered in oil. PPC shot for 4 thousand rubles like this.

By the way, what else should be changed besides the block and cylinder head consumables?!

1) All inserts 2) The chains are probably also worth it, after all, it’s already 260 thousand, although the engines run a lot more, they’ll be enough for the same amount or more, maybe then it’s not worth it? 3) All gaskets, seals 4) check the hydraulic compensators, squeeze them with pliers and see if they all open the same way?

I am begging you! The M51 is in any case softer in operation than the M47, if only because it has a 6-cylinder! And the M51 drives, too, I can’t say that it’s worse than the 39th M47! My brother had an E39 with an M47, so he was very lucky, he managed to push it into Raska when he was captured about 4 years ago! He was not happy with this engine!

Added after a minute:

Sorry, I didn’t notice that this is a 46 engine! But still, in terms of performance, the M51 is softer, in terms of agility, the M47 150 strong in the E46 will of course go more fun!

You need to ask the hucksters about money. Yes, and depending on what you have left alive! If you sell the crankshaft and attachments from the M47, then you can get a profit. I’m kidding, of course, but a couple of years ago in the Republic of Belarus they charged 800 euros for the crankshaft from a simple M47. and the M57tu swap has 2 undeniable advantages over the M47n repair: the engine is 218 hp with 6 boilers - it runs well, smoothly and no one took the engine apart for a long time! In terms of money it will definitely be cheaper than capital. but first you need to clarify the electrical connections.

Added after 3 minutes:

I forgot to say - if the car is tired, then it’s better to collect it, sell it as is and not suffer

The fact of the matter is that the car is fresh, mid-2004. Moreover, they don’t sell these 3-liter diesel ones, one is now hanging on Auto.ru for 600, I think.

billi11 I don’t have an m47, but an m47n, two different engines.

I'm aware, but this doesn't even add a fifth cylinder to it!

Methods for removing carbon deposits and coke

- Manual cleaning with disassembly.

- Cleaning with special solvents:

* through spark plug holes;

* through the oil filler neck.

To properly clean pistons from carbon deposits, you must use the manual mechanical cleaning method. If you choose this method, you will have to disassemble the engine and remove the pistons. This process is labor-intensive because you need a garage, knowledge and skill in disassembling the engine, and tools. After disassembly, clean the surface of the pistons with a scraper, then with sandpaper.

- The advantage of manual mechanical cleaning is high-quality removal of soot, coke, and varnish.

- The downside is time and labor.

Methods for flushing the engine from soot and coke

Let's start with the fact that the engine can be cleaned in two ways, which can be divided into the following:

Let us immediately note that we will not focus on flushing oils and various fuel additives (even to the point of connecting the engine to a separate tank with a special cleaning agent to bypass the fuel tank). The fact is that these solutions help keep the fuel system, lubrication system, combustion chamber and other “insides” of the engine relatively clean only in the case of new or initially clean engines (for example, units after a complete overhaul). If the engine has already been coked, then such methods will not bring the desired effect and can only worsen the situation.

To clean the internal combustion engine from carbon deposits, it is necessary to carry out a more “strict” procedure for decoking the piston rings and the engine, clean the combustion chamber as efficiently as possible, etc. Let us add that this method of cleaning the engine from coke and deposits is very popular among car enthusiasts due to the fact that it avoids disassembling the engine.

You can read more about the engine decarbonization procedure in our separate article, which describes in detail the process of cleaning the engine from carbon deposits using the example of a diesel engine. We also note that various products for decoking piston rings and cleaning the combustion chamber are available for sale. Among domestic consumers, a composition called “Lavr” has gained wide popularity.

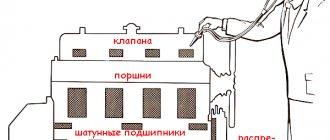

Now let's talk about mechanical cleaning. This method allows you to achieve maximum engine cleanliness, and also does not have the disadvantages that are present when cleaning with “chemicals”. In other words, the motor is disassembled, after which coke and carbon deposits are removed from the surfaces manually, using tools, grinding, and also using active detergents. This approach allows you to clean not only rings and individual sections of the combustion chamber, but also valves, as well as other hard-to-reach elements. At the same time, the oil channels of the engine lubrication system are washed, the cavities in the crankcase, the oil receiver, the oil receiver mesh filter, etc. are cleaned.

Soot information

The formation of carbon deposits in the combustion chamber of a gasoline engine is a natural process, but it must be controlled. There are many reasons for this process: low-quality engine oil, constant city driving, the formation of condensation in winter and its mixing with oil, violation of oil change instructions, and many others.

In carburetor engines, carbon deposits are deposited on the pistons and piston rings. The intake valves are washed with an air-gasoline mixture and self-cleaning. In engines with direct injection of a combustible mixture, carbon deposits coke on the valves, since they are not washed by the combustible mixture. Symptoms of contamination of the intake channels and valves may occur after 50 thousand kilometers of the car:

- Power drop up to 40%.

- Unstable engine operation.

- Reduced engine response when accelerating.

- Greater fuel consumption.

- Engine detonation problem.

There are many reasons for contamination of the pistons and throttle body, but the most obvious are frequent short trips, driving in traffic jams, and negative driving habits, such as idling the engine for long periods of time. The deposited carbon on the valves leads to their deformation, burnout and loose fit to the seat, thereby reducing the compression ratio in the combustion chamber.

Cleaning pistons from carbon deposits without disassembling

Many people choose the second method of cleaning pistons from carbon deposits - without disassembling. When decoking and sticking of piston rings, a method is used without dismantling engine parts.

The principle of such cleaning is the use of special products that can dissolve the resulting coke and plaque.

Such coke solvents are poured directly through the holes for the spark plugs (through the holes for the glow plugs - for diesel units) or through the lubrication system (neck for filling engine oil). The liquid poured in should dissolve the black carbon deposits that have formed.

Advantages of decarbonization and removal of carbon deposits with a special liquid:

- easy and fast;

- The oil scraper rings will decarbonize.

Minuses:

- Carbon deposits are not removed from the surfaces of the working combustion chamber, pistons and valves;

- It will not cope with a heavily coked engine.

There are two types of cleaning and decoking:

- Soft. If you pour solvent through the spark plug holes, this method is called “hard” cleaning.

- Solid. If through the oil filling hole, this is a “soft” cleaning.

Soft decarbonization

The essence of this method is that before replacing the engine oil, a flushing liquid is poured into the engine with the effect of decoking the piston rings (for example, Liquid Moli, XADO / Xado).

When using this method, it is necessary to study the operating features of the engine after adding this liquid to the engine oil. As a rule, you should not put heavy loads on the engine (using a trailer, large luggage, slipping, exceeding average speed). This is due to the fact that the oil has become diluted and the physical and chemical characteristics of the oil have changed.

This cleaning method, that is, without disassembling the engine, but using a special liquid for decoking and removing carbon deposits from the CPG parts through the oil filler hole, should be used for prevention. Then there will be an effect.

Hard carbon removal

If deposits on the parts of the cylinder-piston group and valves are large, then you can use a non-separable method with pouring into the cylinders through the spark plug holes. Pouring a special soot solvent directly into the combustion chamber softens and peels off soot and coke from the part. Further, during engine operation, the softened plaque particles burn out.

To fill through the spark plug holes, aggressive solvent liquids are used to obtain maximum effect. This is, for example, the company Lavr / Lavr.

Rules for using a special cleaning agent through the spark plug holes:

- Measure the compression of all cylinders. This is not necessary, but it is useful to find out later whether there is a difference in pressure values before and after cleaning.

- Heat the engine to operating temperature.

- Unscrew the spark plugs or glow plugs.

- Set all pistons to the middle position. To do this, turn the generator pulley in neutral or with a raised jack at speed 4 or 5 and turn the drive wheel. Use a tape measure or a screwdriver to check the location of the pistons.

- Pour liquid through the spark plug holes into all cylinders to decarbonize and remove carbon deposits.

- Wait 30 minutes.

- Turn back and forth by the generator pulley in the neutral position of the gearbox or at 4 or 5 speed by the wheel so that the liquid gets into the sockets for the rings to loosen them if they are stuck. Move the pistons every few minutes.

- Turn the ignition key and start with the spark plugs removed so that the pistons expel any remaining fluid through the holes. Do this for about 20 seconds. If a lot of liquid remains, the engine may experience water hammer.

- Screw in the candles.

- Start the car engine. After cleaning pistons, rings, cylinder walls, and valves from carbon deposits and coke using liquid cleaning, the car engine may not start immediately.

- After starting the engine, let it idle for about 15 minutes. Immediately after starting the engine, black exhaust gas and a pungent odor will come out of the muffler.

- Drive a couple of kilometers until the color of the exhaust gases becomes normal.

- Check the oil, if not clean, replace the oil and oil filter.

Piston rings sometimes do not become movable immediately after decoking, however, after a short run the rings become functional.

Cleaning pistons from carbon deposits without disassembling the internal combustion engine

Let's start with the fact that carbon deposits from the piston and other elements can be removed efficiently and most efficiently only through manual mechanical cleaning. This only means that the power unit needs to be disassembled. It is quite obvious that this method, with all its advantages, is labor-intensive, costly and quite complicated, since not many drivers will immediately agree to disassemble the engine. This is especially true if the engine is operating relatively normally, that is, its repair is not expected in the near future. Also, some owners seek to remove carbon deposits not as a result of problems, but for preventive purposes.

For this reason, car enthusiasts are interested in how to clean pistons from carbon deposits without disassembling the power unit. Note that such a method exists and is well known. We are talking about decoking the engine and piston rings. The main feature of decoking is the ability to dissolve carbon deposits on the pistons. Products for removing carbon deposits from pistons are, in fact, active solvents that are poured into the engine through the lubrication system or directly through the spark plug holes.

As a result, the pistons are cleaned without the need to disassemble the unit, since it is enough to pour a special agent through the oil filler neck or unscrew the spark plugs on a gasoline engine (glow plugs on a diesel engine). In order to wash the pistons from carbon deposits, you can use two available decarbonization options. You can clean the engine from coke either quickly and gently (it is enough to purchase a ready-made decoking cleaner for piston rings), or you can carry out a deep decoking of the engine, which will allow you to remove carbon deposits not only from the rings, but also from the pistons. Similar solutions are commercially available and are products of well-known companies and small auto chemical manufacturers. Each of the cleaning methods with one or another composition has its pros and cons, which we will talk about in more detail. Below we will also answer the question of how to clean carbon deposits on pistons and valves, and in what cases to use various decoking compounds.

A method for “soft” cleaning of engine rings

So, the first method of so-called “soft” cleaning includes flushing the engine lubrication system with the effect of decarbonizing the piston rings. The products are represented by the brands Liqui Moly, Xado and others. This composition is poured directly into the engine oil a couple of hundred kilometers before it is changed. While using the product, the unit cannot be loaded, that is, some restrictions arise. It is forbidden to rev the engine above medium speed, drive under tension, tow a trailer, transport cargo, etc. These recommendations are due to the fact that the addition of a cleaner affects the properties of the oil, and also manufacturers of the formulations insure that softened deposits from the channels of the lubrication system do not clog the system under high pressure under loads on the internal combustion engine.

As for the composition itself, piston ring decarbonizers, as a rule, only wash oil scraper piston rings. These rings are located at the very bottom and occur most often. The advantages include the availability of the solution, the absence of any additional manipulations, a gentle effect on the internal components of the engine, etc. The disadvantage of this method is that it does not allow removing carbon deposits from the combustion chamber, from the surface of the piston and valves.

For this reason, the solution can be considered exclusively preventive, since this will no longer help a heavily coked engine. In such cases, you can use another method, which is called “hard” decoking of the engine and piston rings.

Removing carbon deposits from the piston and combustion chamber

As you probably already guessed, this method involves pouring a solvent cleaner directly into the combustion chamber. This method allows you to loosen the carbon deposits, after which the deposits burn out while the engine is running. The chemicals used for such decarbonization are more aggressive, and the procedure itself will require some time and a number of specific actions. The most popular product today is Lavr cleaner. There is also a group of analogues on the market.

- At the very beginning, you will need to warm up the engine to operating temperature, and with the engine warm, unscrew the spark plugs or glow plugs (depending on the type of engine).

- Next, the pistons must be positioned in the engine so that they take the middle position. To do this, the car should be raised on a jack (on a car with rear-wheel drive, the rear wheel is raised, on a front-wheel drive car, the front wheel is raised).

- Next, 4th or 5th gear is engaged, after which the engine is cranked by turning the jacked wheel. The position of the pistons can be determined in different ways. The simplest way is to check the location of the pistons using a screwdriver, which is inserted into the combustion chamber through the spark plug hole.

- Then, through the spark plug holes, a special decarbonizing compound is poured into each of the cylinders, after which the car can be left for an average of 30 minutes. During this period, the carbon deposits begin to soften.

- After the specified period of time has passed, you should return to the jacked wheel and rock it slightly back and forth (a few degrees). This is necessary so that the cleaner can flow to the rings to decarbonize them. The wheel can also move the pistons while the carbon deposits are just softening. This should be done every 5-10 minutes.

- Now you can move on to the final stage. The task comes down to cranking the engine with the starter with the spark plugs removed. This must be done for about 15 seconds with the gear engaged. This operation allows you to remove residual fluid from the cylinders through the spark plug wells. If this is not done, then when cranking the engine with the spark plugs screwed in, a water hammer may occur.

We also recommend reading the article about what engine water hammer is. From this article you will learn about the reasons for water ingress and the consequences after incompressible fluid enters the engine cylinders.

At the end of the procedure, you can screw the spark plugs into place and try to start the power unit. You should be prepared for the fact that the engine will not start immediately, as the cleaner will wash away the oil film from the cylinder walls. After starting, thick black smoke with a pungent odor may come out of the exhaust system, then the engine should be allowed to idle for about 15 minutes. Then you should drive the car for several kilometers until the intensity of smoke from the exhaust system decreases.

Then you should either immediately replace the engine oil with fresh one, or drive another 150 km in a gentle mode, after which the lubricant and oil filter are replaced. It is also advisable to measure the compression before decarbonization in order to compare the current results later. Note that in some cases, after decoking, the rings do not become mobile immediately, but after 100-200 km.

Why is black carbon deposits on the piston dangerous?

The presence of black carbon deposits on the piston can cause serious damage to the internal combustion engine:

- detonation (sharp explosion of the fuel-air mixture in the combustion chamber);

- glow ignition (the fuel-air mixture ignites on its own due to overheated parts, without supplying a spark);

- dieseling (spontaneous combustion of the fuel-air mixture without a spark, due to high compression).

The appearance of detonation, glow ignition and dieseling significantly reduces the overhaul life of the engine. A sign of glow ignition and dieseling is that the car engine does not stall after switching off.

Cleaning pistons from carbon deposits

In the combustion chamber of the engine, the energy of the rapidly expanding gases is transferred to the piston, after which the crankshaft is driven through the connecting rods. This element of the CPG is constantly exposed to mechanical, temperature and other loads. The piston experiences the force of gas pressure, heats up significantly from contact with fuel combustion products, and experiences heating as a result of friction against the cylinder walls.

Being one of the most loaded engine elements, and also taking into account operating conditions, the pistons gradually become covered with soot during the operation of the internal combustion engine. Accelerated carbon formation can also occur if there is any engine malfunction that leads to disturbances in the combustion process of the fuel-air mixture in the cylinders. Next we will talk about what could be the cause of carbon deposits on the pistons, as well as how to remove carbon deposits from the pistons and how to do it.

Advice from experienced drivers

As a result of trial and error, obtained by car enthusiasts when cleaning a car engine, cheap and effective technologies were revealed. Drivers try to flush the combustion chamber with liquid without removing the cylinder head. The composition of the liquid that dissolves dirt was obtained experimentally. Its composition consists of hydrocarbons capable of softening charred oil impurities:

Take the components in equal quantities, usually 0.5 liters each. Pour the mixture into the cylinders overnight. After washing, change the oil.

How to avoid carbon deposits

To avoid the formation of plaque, soot, and coking of moving and stationary parts of an internal combustion engine, the following preventive measures should be carried out:

- Fill with high-quality motor oil.

- The ignition, the valves, and everything that is needed for the correct operation of the internal combustion engine must be correctly adjusted. The more completely the supplied fuel burns, the less carbon deposits will be on the pistons, valves and combustion chambers. There should be no over-suction or overflow. Therefore, the condition of pistons, cylinders, connecting rods, injectors, spark plugs, valves, valve seals will increase the period of formation of soot and coke.

- Change oil and filters in a timely manner. If you fill in the cheapest oil, then at least you need to change it more often (for example, after 7 thousand kilometers). The cleaner the engine oil, the correspondingly cleaner the parts will be (no soot and coke). When using high-quality expensive motor oils, the replacement schedule is 15 thousand kilometers.

- Pass maintenance in a timely manner.

- Fuel with quality fuel. The fuel liquid contains resins, their content must comply with the standards. Therefore, it is better to refuel your cars at large gas stations.

Also, if desired, before updating the engine oil according to schedule, you can do a “soft” cleaning to prevent the formation of layers of soot and coke.

When high oil consumption begins, problems with the engine have already begun, for example, these are signs that:

- piston oil scraper rings are stuck or worn out;

- not working valve stem seals;

- burnout of valves or coking of valves.

The conclusion from everything described above is that the cost of effort and money for prevention is much less than repairing a coked engine.

This video describes how to decarbonize parts of the cylinder-piston group.

Author of the publication

15

Comments: 25Publications: 324Registration: 04-03-2016

How to clean carbon deposits from pistons

Types of plaque or deposits on the piston surface:

- varnish formations;

- coke;

- soot;

- sludge

Since the internal combustion engine is subjected to high temperature loads, the engine oil decomposes and oxidizes, forming deposits. Separated and burnt oil particles settle and stick to the parts of the cylinder-piston group. If you do not clean the pistons, rings and working chamber, the layers of deposits will increase, which will lead to engine failure.