Device generations

Methane or a propane-butane mixture is used as fuel for automobile engines. Currently, vehicles use several types of LPG:

- second generation - for installation on old carburetor cars;

- third generation – transitional system;

- fourth generation and newer - for installation on modern cars equipped with injection engines with a microprocessor control system.

The second generation equipment has the required minimum of devices and manual switching of fuel types. The latest generation of gas-cylinder equipment automatically switches to another fuel when the operating mode of the car’s engine changes, depending on the software settings of the control unit.

Frequent breakdowns, how to fix them

Let's look at the most common breakdowns of gas equipment on a car and how to repair them yourself.

The most common causes of breakdowns of gas equipment in cars are damage to connections in gas pipelines, seals and gaskets in gas valves and distribution devices.

By the nature of the vehicle's behavior when running on gas, one can judge the location of equipment damage. If the filter is clogged or the gearbox is faulty, the engine will have unstable idling and failures during sudden acceleration (pressing the gas pedal).

If connections or gaskets on equipment are damaged, you may smell gas. You need to immediately turn off the car and begin troubleshooting and repairs.

You can determine the location of a gas leak using a soap solution, which is applied to the areas of the gas line being tested using a brush or sponge. The liquid will bubble at the leak site.

When filling with low-quality gas, the gas filter may become clogged. It is not necessary to change the filter on your car. It is enough to disassemble it and wash it in some solvent.

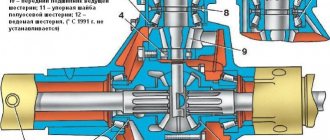

Gas reducer Lovato for injection system (4th generation LPG)

The advent of gas injection systems required the creation of a fundamentally different gearbox (see the section on the principle of operation of gas equipment). The main purpose remained heating and evaporation of the gas coming from the cylinder, as well as maintaining a stable differential pressure at the outlet of the reducer.

By differential pressure we mean the difference between the pressure at the output of the gearbox and the pressure in the intake manifold of the car engine. And when the driver presses the accelerator pedal, the gas pressure at the outlet of the gearbox will increase in proportion to the increase in pressure in the intake manifold, due to constant feedback from the manifold to the working diaphragm of the gearbox.

Injection gearboxes are usually single-stage. But, despite the apparent simplification of the design, choosing a good and suitable gas reducer for a given vehicle and gas electronics can be quite a difficult task.

The reducer must reliably heat the gas before supplying it to the gas injectors and provide stable pressure, as discussed above. The 4th generation Lovato gas reducer must efficiently handle some transitional moments during engine operation. For example, for many gearboxes, a very difficult mode is exiting the cut-off mode (engine braking); in this mode, many gearboxes strongly increase the differential pressure, which often leads to the engine trying to stall. The second critical point is a sharp increase in the load on the engine - many gearboxes, due to insufficient performance, first drop pressure, and only then begin to equalize it.

Thanks to a well-thought-out design, all Lovato gearboxes are practically free of the above-mentioned disadvantages. And minor pressure deviations are compensated electronically, because In the software of the electronic unit of the Lovato gas system, the company's engineers take into account all the behavioral features of their gearboxes.

At the time of writing, Lovato produces 3 models of 4th generation propane injection gearboxes:

- RGJ 3.2.L - for cars of low and medium power, allowing the Lovato gas system to operate confidently on engines up to 150 horsepower;

- RGJ UHP - for medium and high power vehicles, allows you to install Lovato LPG on engines up to 350 horsepower;

- RGJ 3.2.L-DD - for kits intended for cars with direct gasoline injection. With this reducer, the outlet pressure changes in a different ratio (increasingly) in relation to the pressure in the intake manifold, which allows it to provide more comfortable conditions for the Lovato gas control unit (ECU) when working with direct injection.

All Lovato propane reducers are designed and manufactured in strict accordance with European standards ECE 67R-01 and certified in Russia in accordance with the Technical Regulations of the Customs Union (TR CU 018/2011).

Methane reducer Lovato

Methane reducers differ from their propane counterparts by the presence of an additional stage to reduce the pressure from 200 Bar to 10 Bar. For methane gearboxes, heating is less important, since methane enters the gearbox in a gaseous state. Lovato methane reducers have high performance and reliability, which is confirmed by the frequent choice of these components by automakers when installing a gas system on a conveyor (OEM projects).

Read more: Change the exhaust sound without replacing the muffler

Lovato methane injection gearboxes

At the time of writing, Lovato produces 2 models of methane injection gearboxes:

- RMJ 3.2.S - for cars of low and medium power up to 190 horsepower;

- RMJ 3.2.HP – for medium and high power vehicles, allows the system to confidently operate on engines up to 272 horsepower.

All Lovato methane injection gearboxes are manufactured in accordance with the rules of ECE R110, ARAI, INMETRO and comply with ISO 15500 - 9 standards, certified in Russia in accordance with the Technical Regulations of the Customs Union (TR CU 018/2011). Both gearbox models are equipped with an electric shut-off valve with an extended inlet filter. They are equipped with a pressure gauge with the ability to connect a level sensor with an indication of the gas reserve with output to the fuel type switch.

Lovato traditional methane reducers

Lovato produces 3 automotive gas reducers for traditional systems:

- RME 090 – for cars of low and medium power, designed for engines up to 122 horsepower;

- RME 140 – for cars up to 190 horsepower;

- RME 180 – high power gearbox for engines up to 245 horsepower.

All RME model gearboxes are a three-stage gearbox for carburetor (gas supply through a mixer) systems using compressed natural gas. Production is carried out in accordance with ECE R110, ARAI and INMETRO regulations, complies with ISO 15500 standards. Gearboxes are certified in Russia in accordance with the Technical Regulations of the Customs Union (TR CU 018/2011). The gearboxes are equipped with a solenoid valve located between the second and third stages, and a mixture quality adjusting screw.

Safety of Lovato gas reducers

Traditionally, Lovato pays the closest attention to safety issues, and the gearboxes, of course, meet all the necessary safety standards for gas equipment. For example, Lovato injection gearboxes - in addition to the mandatory solenoid valve that shuts off the gas flow if the car does not use gas fuel or the engine is not running - are equipped with a separate additional safety valve. The safety valve is activated (reduces the pressure inside the reducer) if the pressure inside the reducer exceeds the norm (approximately 4.5-5 Bar). The presence of a safety valve guarantees the integrity of the reducer and also prevents rupture of the gas hose at the output of the reducer. This is just one example of why we think Lovato is ahead of the curve when it comes to HBO safety.

Authentication of Lovato gearboxes

Today, Lovato gearboxes have deservedly gained immense popularity among both gas equipment installers and ordinary users. The natural reaction of the market was the appearance of counterfeits. While their level is quite low - they are not difficult to distinguish visually, but Lovato is already taking active measures to protect its products. Each gearbox is marked with a special code, and for each product it is possible to determine not only when the part was produced, but also for which country and which supplier sold it.

The authenticity of Lovato gearboxes of any generation can be checked here.

Hello. In the previous article, I talked about how to disassemble the Tomasetto AT-07 gas reducer at home. This time we will talk about the gas reducer again, and today you will learn how to disassemble the Lovato gas reducer and install a repair kit. The need to disassemble and clean the gearbox occurs when certain symptoms indicate a malfunction. How to understand that it’s time to clean the gearbox is written in this article.

To work you will need:

- Set of hexagons and screwdrivers;

- Lovato gearbox repair kit

- White Spirit, detergent;

- Rags.

Safety first! Before disassembling the gearbox : find a well-ventilated area, turn off the gas supply, remove the negative terminal from the battery. And most importantly, remove any sources of fire!

Gearbox adjustment

After the car gearbox has been repaired, it needs to be adjusted, which may vary slightly for different models. For do-it-yourself adjustment, there are two screws on the gearbox - for regulating the idle speed and a sensitivity screw (gas amount).

To adjust the LPG gas reducer, start the car engine using regular fuel - gasoline - and wait until it warms up to operating temperature. The dispenser on the cylinder should be fully open, the sensitivity screw should be fully tightened, and the idle adjustment screw should be unscrewed five turns.

Switch the car engine to run on LPG. While maintaining the speed with the gas pedal or choke handle so that the engine does not stall, turn the adjustment screw from idle until it operates at maximum speed. Now, when tightening the screw, you need to set the engine speed to the same speed as when running on gasoline.

Next, unscrew the sensitivity adjustment screw until the idle speed begins to change. From the found position, the screw must be returned back 3/4 - 1.5 turns.

The engine should respond almost instantly to pressing the gas pedal. To fine-tune the gearbox, you need to rotate the sensitivity screw a small angle in both directions, checking the engine response. After achieving the desired result, the equipment repair is completed.

Pros and cons of HBO Lovato

Why do car enthusiasts choose this Italian brand?

- Reasonable price plus the highest quality. Since the beginning of its journey (since 1922), the company has been focused on the mass consumer.

- A large network of importers around the world, Lovato products can be purchased in any city. Replacing the repair kit is not difficult.

- Car service technicians undertake the installation of equipment from the Italian brand, so installation instructions, operating manuals, and diagnostics are simple and available to auto repairmen.

- All Lovato equipment has a manufacturer’s warranty of up to three years (approximately 250 thousand kilometers, which is an excellent indicator for the 4th generation LPG).

- The issue of servicing a car with Lovato 4th generation LPG is not difficult; the instructions for setting up the ECU are not complicated.

- The company produces absolutely all gas equipment components, that is, it is a monobrand, which is very convenient for consumers.

- Lovato's equipment doesn't take up much space. The compact LOVATO JLP4 EP injector rail for 4 cylinders is not difficult to install in such a way that it does not interfere with wiring and gas lines.

- Lovato gearboxes are standards in power and pressure stability.

- Installation is carried out very quickly (in half a day).

- Gas tank 45 l. enough for a range of 400 to 500 kilometers.

- In liters, gas consumption is higher than gasoline consumption, but the difference in prices shows that switching to gas is much more profitable.

- The life of the piston group increases due to the fact that gas fuel is of higher quality. It cannot be “diluted” (can be seen from gas-burning oil, which is lighter than usual).

- If the Lovato 4 HBO connection is carried out normally, then it pays for itself in six months.

- Clear switching from one type of fuel to another.

- Car owners note that a gas-fueled engine runs the smoothest.

- Diagnosis of HBO Lovato 4th generation with your own hands is available, the instructions are clear to a beginner.

- An “advanced” microprocessor with the latest control options for gas and gasoline injectors allows you to effectively manage the system.

- Lovato's electronic brains are equipped with a diagnostic function for each component of the gas system, this makes it easier to find errors before they cause problems for the engine, and thereby facilitates vehicle maintenance.

Read more: Fighting ice on roads

Disadvantages that are identified when installing HBO:

- small indicators for reducing engine power when switching to gas, on average 5%;

- there is a loss in dynamics, an increase in acceleration time;

- on long trips, it may become a problem to find gas filling stations (mainly methane ones);

- the engine compartment space is reduced;

- a lot of space is given over in the luggage compartment for a gas tank;

- the likelihood of spontaneous popping noises in the injector (breakdown of spark plugs), the issue can be resolved by installing a computer.

These disadvantages are inherent in any gas equipment. As for the reduction in engine life. This statement is associated with the combustion temperature of the gas mixture. But in the latest developments of the 4th generation, fuel injection into the injectors occurs in the same way, both on gasoline and on gas.

The resource of the power plant depends most of all on the quality characteristics of the fuel and on how professionally the equipment is connected. It is strictly not recommended to do this yourself, but only in trusted centers.

On a note! Installing LPG is a responsible process. They install gas equipment to save on the budget. To achieve this, it is not advisable to save at the installation stage. You should carefully consider the recommendations of fellow car enthusiasts and get acquainted with reviews of the work of car services.