Purpose and design features

This part performs the most important function - the transmission of motor force in the “steering column-steered wheels” chain between parts with a variable contact angle. Therefore the tie rod end

It is made in the form of a hinged element, having moving parts in the design. Depending on the type and features of the automotive control system, there are from four to six tips in one car.

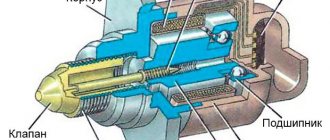

The steering tips in the vast majority of cars are extremely simple, which ensures a high level of their reliability. In general, this part consists of eight main parts, these are:

- a housing in which the axle shaft is built;

- a ball pin on which a thread is cut;

- an insert, most often made of Teflon, designed to fix and limit the movement of the ball pin;

- a cover that covers the body of the device, which prevents debris from getting inside that could damage the tip;

- a neoprene cover that protects the mechanism from foreign objects from the finger side;

- a ring with which the case is fixed on the finger;

- a spring that attaches the case to the body;

- finger nut.

Steering end device

Almost all steering ends have the same design, differing mainly in size and the materials from which their parts are made.

Basic faults

As a rule, the tie rod end does not fail quickly. The car enthusiast will begin to notice a change in the nature of the steering mechanisms even before the need to replace the tip becomes obvious. The first sign that it is time to change the tip is the appearance of play . Completely new and even seriously worn, but while the spare part is working there is no play - the ball pin is fixed as tightly as possible by the liner. To determine whether you need to replace your tie rod end, pay attention to the following:

- The nature of the gas pedal operation has changed;

- During disassembly, it became clear that there was play in the steering rod;

- The steering wheel turns too easily;

- When driving on bad roads, accelerating or braking, the steering mechanism knocks or creaks;

- When turning the steering wheel, a dull tapping sound is heard;

- During the wheel alignment procedure, failures occur.

According to experts, the service life of different tips is different. On average, a part needs to be changed every 40-50 thousand kilometers . Over time, the hinge joint wears out due to the ingress of dirt particles. If the boot was not damaged, then the tip can travel over 50 thousand kilometers .

Often the elements of the steering mechanism fail due to the car hitting an obstacle at high speeds. If the driver inadvertently drove onto a high curb or even got into an emergency situation, then in the near future it is worth checking the condition of the steering mechanism.

Faulty tie rod

Malfunctions of steering tips

happen extremely rarely if new parts are installed in the car. The tip, which has not yet been worn out, is completely free of play, since the liner made of Teflon fixes the ball pin in the body extremely tightly. But during operation, the liner gradually wears out, which is why the finger begins to move more and more freely, which leads to the appearance of play, which has an extremely negative effect on the quality of driving.

Detection of the slightest signs of wear on the tips should immediately serve as a reason to replace them, since otherwise you can expect steering failure and an accident on the road as a result.

What causes tie rod end failures?

Although the ball mechanism of the steering tip is movable, there are frequent cases when it fails. Here are some reasons for this:

- Driver negligence – late diagnosis. It is very easy to do when changing tires seasonally. The wheels still come off. This is a good opportunity to conduct a visual inspection of the part;

- Faults in the steering mechanism can increase the load on these elements;

- Due to poor road quality, the mechanical load on the joint bushing increases;

- Natural wear of the plastic cap or Teflon liner;

- The spring under the finger broke.