For more than two centuries, the progress of mankind has been inextricably linked with various machines, especially vehicles. Which helped quickly move goods from suppliers to consumers. Those who invented the internal combustion engine (ICE) made a significant contribution to the development of human civilization. Because cars, ships and planes are still the main engine in human history. The first commercially successful internal combustion engine is considered to be the engine of the French inventor from Belgium Jean Etienne Lenoir.

First step

You may be interested in:Japanese samurai symbols: photo, meaning and description

At the end of the 18th century, the French mechanic Philippe Le Bon first obtained illuminating gas and patented a method for its production by pyrolysis of wood or coal. A mixture of methane, hydrogen and carbon monoxide has become widely used to illuminate the streets of European cities. Inventors in many countries around the world began to design an engine using this relatively inexpensive and efficient fuel.

Many engineers then realized that engine efficiency would increase if the fuel was not burned in a furnace, as in a steam engine. And directly in the cylinder.

However, the one who invented the first internal combustion engine was the same Philippe Le Bon. In 1801, two years after the discovery of illuminating gas, Le Bon received a patent for an engine running on a mixture of compressed gas and air. They were pumped into the working cylinder and ignited there. However, the invention remained only on paper; Le Bon was killed in 1804. He remained one of many engineers in the history of the creation of the internal combustion engine who invented, but did not put into practice his invention.

Influence of internal combustion engines on the environment, environmental requirements for internal combustion engines design

In ICE variants such as gas turbine and jet engines, combustion is organized continuously, and the maximum temperature is lower. Therefore, they typically have lower emissions of unburnt hydrocarbons (due to a smaller flame extinguishing zone and sufficient combustion duration) and emissions of nitrogen oxides (due to a lower maximum temperature). The temperature in such engines is limited by the heat resistance of the blades, nozzles, guides, and for transport engines it is 800..1200 oC[21]. Improvements in the environmental performance of, for example, rockets are usually achieved by selecting fuels (for example, instead of UDMH and nitrogen peroxide, liquid oxygen and hydrogen are used).

However, hundreds of millions of regularly used transport piston engines, consuming huge amounts of petroleum products every day[22], add up to large harmful emissions. They are divided into hydrocarbons (CH), carbon monoxide (CO), and oxides of nitrogen (NOx). Leaded gasoline was also previously used, the combustion products of which contained lead that was practically not excreted from the human body. This has the greatest effect in large cities located in lowlands and surrounded by hills: when there is no wind, smog forms in them. Currently, not only harmful emissions are regulated, but also the emission of carbon dioxide and water by vehicles (due to the impact on the climate).

In the first decades of the development of motor transport, this was not given enough attention because there were fewer cars. Subsequently, manufacturers were obliged to comply with certain emission standards, and over the years they became more stringent. In principle, three ways are possible to reduce emissions[23]:

- The choice of environmentally friendly fuel (hydrogen, natural gas) or improvement of traditional liquid fuel (petrol and diesel fuel “Euro-5”).

- Changing engine cycle parameters or developing new ones (reducing the compression ratio, charge stratification, intra-cylinder injection, computer control systems using oxygen sensors, Common rail system on diesel engines, etc.).

- Reduction of harmful emissions using thermal (formerly) and catalytic (currently) converters.

Existing toxicity standards in developed countries usually require the use of several methods at once[23]. In this case, the fuel efficiency of both cars and the entire transport (including oil refineries) complex usually deteriorates, since the optimum cycles for efficiency and environmental friendliness of engines usually do not coincide, and the production of highly environmentally friendly fuel requires more energy.

Recently, serious concerns have been expressed regarding the continued use of fossil fuel engines (most internal combustion engines), due to the problem of global warming[24][25]. Due to the introduction of new environmental regulations in Europe from 2025, European passenger car manufacturers plan to switch to the production of electric vehicles[26].

This is due not only to the increase in the number of cars, but also to the impact of emissions on the entire ecosystem: for example, it has been established that harmful emissions (largely caused by cars) reduce agricultural yields by 25%[27].

First commercial success

In the subsequent period, mechanics in many European countries tried to create a normally working example of an internal combustion engine using lighting gas. However, all these efforts for a long time did not lead to the appearance of an engine that could compete in efficiency with a steam engine.

The one who invented the internal combustion engine, which achieved commercial success, was the Belgian mechanic of French origin, Jean Etienne Lenoir. He was the first to decide to ignite a gas-air mixture using an electric spark. Perhaps this idea came to him because the engineer worked at an electroplating plant. However, success did not come to him immediately. The first model worked for only a short time and stopped because the high temperature caused the piston to expand and become jammed in the cylinder. Lenoir supplemented its internal combustion engine with a water cooling system. And after the second unsuccessful launch, he designed a lubrication system. By 1864, he had sold more than 1,400 of his engines and became rich.

Inlet

So, in the combustion chamber of a power unit, energy conversion cycles begin with the combustion reaction of the fuel mixture. In this case, the piston is at its highest point (TDC position), and then moves down. As a result, a vacuum occurs in the combustion chamber of the engine. Under its influence, the flammable liquid sucks in fuel. The inlet valve is in the open position, and the outlet valve is closed.

When the piston begins to move downward, the volume above it increases. This causes vacuum. It is approximately 0.071-0.093 MPa. Thus, gasoline enters the combustion chamber. In injection engines, fuel is injected by an injector. After the mixture enters the cylinder, its temperature can be 75 to 125 degrees.

How much the cylinder will be filled with the fuel mixture is determined by the filling coefficients. For engines with a carburetor power system, this figure will be from 0.64 to 0.74. The higher the coefficient value, the more powerful the motor.

First engine in mass production

Among those who invented the internal combustion engine is the German engineer Nicholas Otto. He improved a machine running on illuminating gas, and in 1864 received a patent for his internal combustion engine model. Which was sold in quantities of more than 5,000 pieces.

In 1877, Otto received a patent for a four-stroke cycle engine. This principle still underlies the operation of most gas and gasoline engines. Over the next twenty years, more than 42,000 of these internal combustion engines were produced. However, the use of illuminating gas greatly limited the possibilities of their use.

Application of lean fuel mixture

An option to increase the efficiency of gasoline engines was the transition of some developers to the use of a lean fuel mixture. The engineers changed the usual fuel mixture ratio. In the second half of the 70s, engineers from Honda, Mitsubishi, Nissan, and some other manufacturers began to build their engines using this technology. But since engines developed for the use of lean mixture required the installation of complex and expensive catalytic converters, such units did not catch on and by the beginning of the 90s they almost completely ceased to be produced.

Invention of Diesel

At the beginning of the 19th century, a description of the Carnot process was formulated. It argued that in a heat engine, a rapid change in the volume of gas (rapid compression) would allow the working fluid to be heated to the combustion temperature.

In 1890, Rudolf Diesel invented a method for the practical use of the Carnot cycle. He was the first to invent a diesel internal combustion engine. Over the course of several years, the German engineer patented several design options. The first practically working model was assembled in 1897 and was called a diesel engine. Since 1889, mass production of diesel engines began.

Bibliography:

- Aviation engines. Design and calculation of engines. Edited by A.E. Zaikina. Moscow - 1941

- Aviation engines of foreign military air forces. Moscow - 1939

- XV Paris Aviation Exhibition. Moscow - 1938

- Engine design. Scan without details.

- Development of aviation science and technology in the USSR. Moscow - 1980

- Aviation power plants. NOT. Zhovinsky. Moscow - 1948

- Theory of piston aircraft engines. Edited by A.A. Dobrynina. Moscow - 1955

- Aircraft manufacturing in the USSR. Book 1 and Book 2. TsAGI. Moscow - 1992

- Aviation encyclopedia. Moscow - 1994

In search of new fuel

Simultaneously with the improvement of internal combustion engines, there was an active search for the most efficient fuel. Engines have already been tested using coal dust, hydrogen, a mixture of turpentine and alcohol, and oil as fuel. Some of them worked, but were not widely used due to the high price. However, the most promising direction for engineers was the use of evaporated liquid fuel vapor instead of gas.

In 1872, the American Brighton tried to work with kerosene. However, it did not evaporate very intensively, and he switched to lighter gasoline. To operate on the new fuel, it was necessary to develop an additional device that would convert the new fuel into a gaseous state. After which the gasoline vapor had to be mixed with air. Brayton also invented the first evaporative carburetor, which, however, was not very successful. But it was he who set the trend in the use of fuels and lubricants as fuel.

Piston internal combustion engine with compression ignition

Diesel engine operation

In a diesel engine, fuel ignition occurs without a spark plug. A portion of fuel is injected into the air heated by adiabatic compression in the cylinder through a nozzle and atomized. When spraying, combustion centers appear around individual evaporating drops of fuel, and as injection proceeds, a portion of the fuel burns in the form of a torch. Since diesel engines are not subject to detonation (due to the start of fuel supply and combustion after TDC of the compression stroke), the compression ratio is not limited by detonation. Increasing it above 15 practically does not increase efficiency [9], since in this case the maximum pressure is limited by longer combustion and a decrease in the injection advance angle. However, small-sized swirl-chamber diesel engines can have a compression ratio of up to 26, for reliable ignition under conditions of large heat removal and. Large-sized supercharged marine diesel engines have a compression ratio of about 11..14 and an efficiency of more than 50%[10].

Diesel engines usually, therefore, with equal power to gasoline engines, are characterized by greater torque on the shaft. Large diesel engines are designed to run on heavy fuels, such as fuel oil. Large diesel engines are usually started using compressed air, or, in the case of diesel generator sets, from an attached electric generator, which acts as a starter when starting.

Modern engines, called diesel engines, operate not according to the Diesel cycle, but according to the Trinkler-Sabate cycle with a mixed heat supply. Their disadvantages are due to the peculiarities of the operating cycle - higher mechanical stress, requiring increased structural strength and, as a consequence, an increase in its dimensions, weight and increased cost due to a more complex design and the use of more expensive materials. Also, diesel engines, due to heterogeneous combustion, are characterized by inevitable soot emissions and an increased content of nitrogen oxides in the exhaust gases.

Gas diesel engine

The main portion of the depleted gas-air charge is prepared as in any gas engine, but is ignited not by an electric spark plug, but by a pilot portion of diesel fuel injected into the cylinder similarly to a diesel engine. It is usually possible to operate on a pure diesel cycle. Application: heavy trucks, buses, diesel locomotives, often shunting locomotives. Gas-diesel engines, like gas engines, produce less harmful emissions, and natural gas is cheaper. Such an engine is often obtained by retrofitting a serial one, and the savings in diesel fuel (the degree of substitution with gas) is about 60%[11]. Foreign companies are also actively developing such designs[12].

Gas engine

When the most efficient type of fuel for internal combustion engines was determined, many engineers began working on a car that would run on gasoline. Among those who invented the gasoline internal combustion engine, Gottlieb Daimler made the greatest contribution. Together with his partner Wilhelm Maybach, he set up workshops in Stuttgart. They began producing glow gasoline engines there.

The Hungarian engineer Donat Banki is also one of those who invented the internal combustion engine. In 1893, he was granted a patent for a jet carburetor, the operating principle of which is still used in modern cars. The first internal combustion engines were with one cylinder, at the end of the 19th century two-cylinder ones appeared, and at the beginning of the 20th century - four-cylinder ones.

Source

The legendary Germans take the helm

In 1876, German developers began to take up the baton, whose names are resounding loudly these days. The first to be noted is Nicholas Otto and his legendary “Otto cycle”. He was the first to develop and construct a prototype 4-cylinder engine. After this, already in 1877, he patented a new engine, which underlies most modern engines and aircraft of the early 20th century.

Another name in the history of the automotive industry that many people still know today is Gottlieb Daimler. He and his engineering friend and brother Wilhelm Maybach developed a gas-based engine.

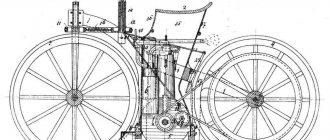

1886 was a turning point, since it was Daimler and Maybach who created the first car with an internal combustion engine. The power unit was called "Reitwagen". This engine was previously installed on two-wheelers. Maybach developed the first carburetor with jets, which was also used for quite a long time.

To create a functional internal combustion engine, great engineers had to combine their strengths and minds. So, a group of scientists, which included Daimler, Maybach and Otto, began assembling engines at a rate of two per day, which at that time was a high speed. But, as always happens, the positions of scientists in improving power units diverged and Daimler left the team to found his own company. As a result of these events, Maybach follows his friend.

1889 Daimler founded the first automobile manufacturer. In 1901, Maybach assembled the first Mercedes, which marked the beginning of the legendary German brand.

Another equally legendary German inventor is Karl Benz. The world saw his first prototype of the engine in 1886. But before he created his first motor, he managed to found. The rest of the story is simply amazing. Impressed by the developments of Daimler and Maybach, Benz decided to merge all the companies into one.

So, first, “Benz & Company” merges with “Daimler Motoren Gesellschaft”, and becomes “Daimler-Benz”. Subsequently, the connection affected Maybach and the company began to be called “Mersedes-Benz”.

Another significant event in the automotive industry happened in 1889, when Daimler proposed the development of a V-shaped power unit. His idea was picked up by Maybach and Benz, and already in 1902, V-twin engines began to be produced for airplanes, and later for cars.