Causes of piston group wear

Constant operation of the machine inevitably leads to damage to the steam generator. Like any other element of the power unit, pistons wear out due to obsolescence or due to overheating caused by a disruption in the combustion process.

What causes piston crown wear?

Seizures on the piston bottom are formed due to clogging or deformation of the oil nozzle, installation of elements with different sizes, or a malfunction in the cooling system.

Pistons on used cars often show impact marks. They are caused by an overly large piston protrusion or improper adjustment of the end side of the cylinder head. This also happens due to engine oil deposits on the head of the element, an unusually narrow gap in the valve drive and incorrect installation of the gas valve phases.

Damage is also determined by metal deposits on the elements. This happens when the injector is faulty - in this case, the injection quantity is determined incorrectly by the system. This will also indicate insufficient compression, late or early ignition.

If cracks are observed on the piston crown and in the combustion chamber cavity, this is evidence of a faulty injector or insufficient compression. This is also possible if the engine is not properly chipped, when they try to increase the power of the unit through modernization.

checking the piston for wear

Causes of ring damage

As a rule, this happens due to erosion of the material in the ring area caused by improper installation, excess fuel in the combustion chamber, or violation of the thermal gap between the piston and its cylinder. The same thing happens with strong axial wear of the piston grooves and vibrations.

Another reason is radial wear associated with mixing. Any disturbance in the fuel combustion process, as well as insufficient compression pressure, lead to such a malfunction.

Axial wear is also possible as a result of simple contamination, when soot particles stick in the groove due to insufficient filtration. This could be sawdust, blast residue, or any other abrasion product.

Why is the piston skirt damaged?

Several reasons contribute to this - deformation of the connecting rod, crookedly installed cylinders, excessive play of the connecting rod bearing. In these cases, an asymmetrical, clearly visible spot forms on the skirt.

There may also be 45-degree burrs and other friction marks caused by an overly tight pin fit or an error in the installation of the hot-pressed connecting rod. The reason is also called a low compression percentage, misfires, and dilution of the oil with gasoline.

The main signs indicating resource depletion:

- blue exhaust color;

- active carbon deposits on spark plugs;

- drop in engine power;

- unstable operation of the unit at neutral speed - quickly determined by strong vibrations of the gearshift knob.

And, of course, the most important sign is increased engine oil consumption.

How to choose a new piston and rings?

Pistons are selected in accordance with the repair size of the cylinders. The marking is usually placed on the bottom of the part.

Each piston is selected individually to obtain the correct clearance size. Its value is determined using a special probe tape, which is pulled between the cylinder and the piston. A dynamometer is installed on the side opposite the skirt cut. The force on the device when moving the probe through the gap should not exceed the established limits.

It is easy to check whether the piston is selected correctly experimentally: the part should move smoothly in a vertically mounted cylinder under its own weight.

In addition to the clearance, it is necessary to take into account the weight of the pistons - the maximum difference in the weight of parts of one set should not exceed 5 grams.

Worn and lost elasticity piston rings are replaced with new ones. Their repair size must correspond to the dimensions of the cylinder and piston.

To select a ring for the cylinder, you need to place it in the sleeve, align it with the piston and use a feeler gauge to measure the gap at the joint. If it is missing or insufficient, then the joint is enlarged with a file. Too much clearance indicates that the ring is unsuitable for the cylinder.

To match the piston, the ring is “rolled” along the groove of the part. If the gap is too small, the ring will jam. In this case, its end part must be sanded using sandpaper.

The elasticity of new piston rings is checked with a special device. The magnitude of the load must be equal to the value of the gap at the joint of the ring installed in the cylinder.

How to choose new pistons when purchasing?

There is a wide range of these products on the domestic market. It is usually difficult to choose between pistons manufacturing technology - forged or cast. The first varieties are much more expensive. The second ones are more common. Before making a choice, you need to understand whether the car requires an increase in standard power. If yes, then definitely give preference to forged analogues.

Pistons are regularly subjected to high loads, so the performance of the internal combustion engine directly depends on their quality. An important parameter is also the weight of the product. Manufacturers try to make them light, but at the same time durable.

When choosing, it is recommended to pay attention to the German brands Kolbenschmidt, Mahle, Prima . The Russian Motordetal-Kostroma and STK have proven themselves to be quite good at producing such products.

Piston 6D16 ME072549 (set of 6 pcs.) for 6D16 engine on Mitsubishi

What tools are needed to replace pistons

The following set of tools is required to replace a piston engine:

- spanners;

- heavy hammer;

- a piston ring remover, which is a pliers - if there is no such device, you can use a regular thin flat-blade screwdriver;

- vice;

- burner;

- micrometric bore gauge;

- torque wrench;

- a guide sleeve and a mandrel with a handle and a threaded hole at the end of a special or homemade design - can be turned on a lathe;

- a drift to the size of the piston pin - must go inside the hole;

- file;

- wooden blocks;

- ratchet with heads of different sizes.

Of course, you need to prepare a new set of pistons. It is recommended to pay attention to the quality of the rings and the appearance of the packaging - manufacturer’s name, material. The rings should be marked to indicate the top side. In order to maximize the service life of the pistons, an anti-friction coating is applied to the skirts of the products. For example, a suitable option is Modengy solid lubricant.

Piston pin repair

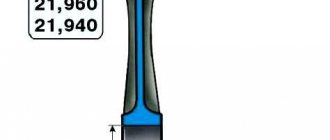

Piston pins with wear in diameter of more than 0.5 mm must be replaced, and those with wear of less than 0.5 mm are restored by regrinding to a smaller size (if the pin was oversized), chrome plating or expansion.

The pin is ground on a cylindrical grinder or lathe using a special support-grinding device. This device consists of an electric motor with a grinding stone, it is fixed in the support of the lathe.

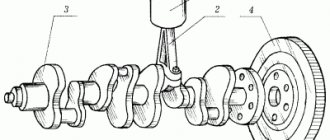

Rice. Piston pin extension: 1 - mandrel; 2 - matrix; 3 — piston pin; 4 - base.

The original size of the finger is restored by chrome plating or spreading. Dispensing is carried out in a special device consisting of a base, a matrix and a mandrel (punch). The finger is heated to a temperature of 800-900° and installed in the matrix, then a mandrel is driven inside the finger under pressure from a press or with hammer blows. The matrix limits the expansion of the finger and gives it the correct shape. After distribution, the finger is subjected to quenching in oil, followed by tempering and ground to the nominal size.

A repaired or new piston pin is selected according to the connecting rod bushing and the holes of the piston bosses.

Rice. Checking the fit of the piston pin in the connecting rod head bushing.

The piston pin enters the connecting rod bushing under the pressure of the thumb. It also enters the holes of the aluminum piston bosses under hand pressure, but for this the piston must be heated in oil to a temperature of 70-80°.

Replacing pistons yourself

It all starts with preparatory work. First you need to disconnect the battery, drain the antifreeze and engine oil from the oil pan. Then carry out the stage of qualified diagnostics. This is done in two ways: without removal and with removal of the motor unit.

To get by with little cost, only the cylinder head and pan are dismantled. Carbon deposits are removed from the top of the cylinders with a file. Following actions:

- measure the diameter between the cylinder walls with a bore gauge and compare it with the passport data;

- Make sure by turning the crankshaft that there are bores on the liners - if the condition of the liners is beyond doubt, the engine does not need to be removed;

- inspect the bottom of the pan - metal shavings in an oil film should alert you, indicating wear of the rings and liners;

- check the condition of the pistons by carefully removing them along with the connecting rods and rings - normally there should be no deep scuffs on the skirt, burnout of the bottom, or wear of the upper groove beyond the permissible value.

checking engine pistons

How to replace piston rings on an engine is described in detail below.

How to install a new piston instead of the old one?

If the damage is significant, the piston must be replaced. To do this, it should be separated from the connecting rod by removing the retaining rings from the holes in the bosses. The finger is removed using a drift.

More information on how to separate (knock out) the piston from the connecting rod:

- place the piston on two wooden blocks;

- insert a drift into the hole under the cylindrical rod on the piston;

- hit the top of the drift with a hammer several times until the finger pops out.

To install a new piston, you first need to insert your finger into it. It is also recommended to replace this element. The finger should enter the hole with little effort. If it falls out, it definitely does not fit in size. In this case, a different rod is selected for the articulated movable joint.

The pin is pressed in “hot” using a special mandrel or a homemade device with a guide bushing. It should be a few microns thicker in diameter than the hinge element. The “fixture” is assembled before inserting the pin onto the connecting rod and piston like this: first, the pin is put on the mandrel, then a drift is placed on top. The whole thing is tightened at the end of the rod with a holding screw.

It is highly advisable to carry out the fitting step before pressing. The finger is threaded into the piston hole, without a connecting rod. Then it checks how he entered. If it is uneven, then a washer is added to the device.

Further:

- clamp the connecting rod in a vice;

- Heat the inside of the connecting rod journal with a hand burner for 1.5-2 minutes;

- place the piston on top, with the arrow pointing towards the connecting rod locks - indicated by the manufacturer on the head of the element;

- insert the mandrel with the pin into the piston and connecting rod until it stops;

- Unscrew the lock, remove all excess, leaving the finger inside the piston.

pressing the piston into the connecting rod

After cooling, the piston movement is checked. Its minimal mobility will indicate that the work is being carried out correctly.

How to replace piston rings?

The oil pan must be removed. Additionally, the oil pump is also removed - it is recommended to check its condition. Next, the connecting rod caps are unscrewed, the latter are pushed upward with the pistons.

Attention! The connecting rod caps cannot be swapped. At the final stage, each is screwed to the “native” connecting rod.

Replacement of piston rings is carried out with special removable pliers. After removing the worn rings, all carbon deposits are removed from the grooves. This can be done with a piece of rigid wire or a piece of an old ring. Deposits should also be removed from the piston crowns. For convenience, the surface can be moistened with kerosene.

Ring pliers

Installation of new oil scraper rings is carried out according to the instructions. The oil scraper ring is installed first, then both compression rings. During installation, extreme care is taken, since the elements are extremely fragile and break easily. The exception is the first compression ring - it is durable.

Particular attention is paid to the location of the piston ring locks. It is better to place them at an angle of 120°. If the locking pattern is incorrect, gases may escape from the combustion chamber into the crankcase.

Watch the piston replacement video for a complete picture https://www.youtube.com/watch?v=iOhU9w1e8Ow

Piston installation

Insert a retaining ring into any boss of the piston pin. It is most convenient to insert the ring with small round nose pliers. After installation, check how well and tightly the retaining ring fits.

- If the retaining ring does not cover the entire surface, but only a small part of it, replace it with a new one.

- If the retaining ring does not lie tightly in the groove and dangles, straighten it a little

Lubricate the bearings of the lower and upper connecting rod heads and the piston pin bosses with clean engine oil. We put the piston on the connecting rod, orienting it with the “IN” mark to the inlet port; if there is an “arrow” on the piston instead of the “IN” mark, orient the arrow to the exhaust port. We insert the piston pin into the boss - orient the piston on the connecting rod so that the pin hits the connecting rod - install the pin all the way into the locking ring and secure it from falling out with the second locking ring.

We install the cylinder guide bushings on the studs and put on the gasket. It is advisable to place the gasket on the sealant, but without fanaticism.

Replacement cost

Here are approximate prices for replacing piston rings in services:

- domestically produced passenger cars - from 7-8 thousand rubles;

- Japanese foreign cars in sedan, hatchback, station wagon bodies - from 10 thousand rubles;

- jeeps, crossovers, minibuses - from 15 thousand rubles.

And the price for replacing a piston is usually high. This is explained by the fact that the procedure is included in the list of engine overhauls. Therefore, the cost is appropriate - from 20 to 40 thousand rubles.

Running in the engine after replacing the piston

Replacing a piston group is always accompanied by running in or checking the performance of the engine. This is done simply - the engine starts at idle. If within 5-10 minutes of operation there is no drop in speed or other signs of instability, a run-in is carried out for 2-3 thousand kilometers (diesel units are run in for at least 8-10 thousand km). It is advisable to carry it out at third speed. Before running in, it is recommended to check the condition of the battery - it should be 90-100% charged. And most importantly, it is recommended to cover the first 300 km in one race along a country road!

Advice on how to avoid problems during your first race. After replacing the piston, the car engine needs to be warmed up well, and for this it is better to do this. First let it idle to 80 degrees. Then stop the engine and let it cool to 40 degrees. Start it again at idle, allowing it to warm up to 80°. Repeat the procedure 8-10 times.

During the run-in it is prohibited:

- heavily load the car - for example, seating passengers or towing;

- accelerate sharply;

- go uphill;

- increase speed above 3000/min;

- engine braking;

- drive at lower speeds;

- drive on an engine that is not warm enough.

What does running in give you? It allows new engine parts to run in without unnecessary overload after replacing the piston. At a service station, running-in is often carried out using a stand. After replacing the piston, an electric motor is connected to the machine’s engine, which “grinds” it. At home, this is done directly on the machine, using the method described above.