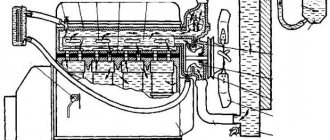

Cooling system ZIL-130

cooling system

(Fig. 28) is liquid, closed, with forced circulation of coolant.

The water pump (Fig. 29) is centrifugal, installed at the front end of the cylinder block.

To fill the cavities of the water pump bearings with lubricant, you need to unscrew plug 2 that closes the inspection hole. Refilling must be done until fresh lubricant appears from the inspection hole, after which the screw plug should be replaced.

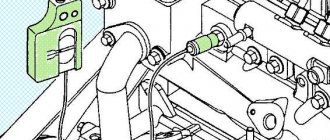

The water pump fan is driven from the crankshaft pulley by two belts. In this case, the front belt also covers the alternator pulley, and the second belt covers the power steering pump pulley.

The drive belts are tensioned (Fig. 30) by moving the generator and power steering pump. Under normal tension, the deflection of each belt between the fan pulley and the tension pulley under a force of 4 kgf (40 N) should be within 8-14 mm. The fan pulley drives the compressor.

The radiator is tubular-tape (snake), three-row. The radiator filler plug is sealed, with two valves: inlet (air) and outlet (steam).

The exhaust valve, loaded with a spring, maintains a pressure of 1 kgf/cm2 (100 kPa) in the cooling system. At this pressure, the boiling point of the coolant rises to approximately 119 ° C, which reduces its boil-off.

If the rubber washers of the radiator plug valves are missing or destroyed, then the operation of the cooling system as a closed system stops, and the liquid in this case boils at a temperature of 100 ° C.

An intake valve loaded with a weaker spring prevents the creation of a large vacuum in the system when the engine cools and protects radiator parts from damage.

When the coolant reaches a temperature of 115°C, the warning lamp 19 for emergency coolant overheating lights up on the instrument panel in the driver’s cabin. If the liquid in the cooling system overheats, open the radiator cap carefully to avoid hot water from being thrown out of the neck.

The radiator shutters are folding and controlled from the driver's cab. To close the blinds, you need to pull the handle towards you. The blinds should be closed when the engine warms up.

A thermostat (Fig. 31) with a solid filler is placed between the upper and lower nozzles of the water jacket. The thermostat serves to speed up the warm-up of a cold engine and protect it from overcooling.

It is necessary to fill the radiator with coolant to the lower end of its neck. After starting the engine and idling for about one minute, you need to check the fluid level in the radiator and, if necessary, add it. In severe frosts, it is necessary to cover the radiator using a warm hood and carefully monitor the coolant temperature gauge. Running a cold engine causes intense wear on the piston rings and cylinders.

To increase the reliability of the cooling system and protect it from freezing during severe frosts, it is recommended to use a special liquid that does not freeze at low temperatures (antifreeze).

Coolant is poisonous, so precautions must be taken when handling it. Ingress of even small quantities; This liquid into the human body can cause severe poisoning.

When pouring coolant, care must be taken to ensure that no air pockets form in the cooling system, preventing the system from filling. To avoid this, you need to open the radiator drain valve. The tap should be closed only after liquid appears from it.

The coolant from the cooling system must be drained through three taps: the radiator pipe tap and two cylinder block jacket taps; if there is a heater, also through three taps: the radiator pipe tap and two starting heater taps.

In winter, after draining the liquid from the cooling system, it is necessary to close the cockpit heater valve and open it again only after starting and warming up the engine.

The taps for draining the coolant are equipped with a remote control (Fig. 32), the control handles are routed through the first cross member of the frame under the buffer. To drain the liquid from the cooling system, you need to turn the valve drive handle a few turns. The taps must be screwed on very tightly. The boiler tap of the heater does not have a remote control.

Description of the cooling system

The cooling system of the ZIL 130 engine was never modernized during its production history, and therefore the same malfunctions arose. Therefore, car owners continued to struggle with the shortcomings that arose on their own, in some places quite successfully.

To understand how the engine cooling system on the 130 works, it’s worth considering the diagrams.

Rice. 1. Cooling system diagram

1 - radiator; 2 - water pump; 3 - compressor; 4 — bypass hose (bypass); 5 — thermostat; 6 — heater tap; 7 — supply tube; 8 — outlet tube; 3 — heater radiator; 10 — coolant temperature indicator sensor; 11 — dosing insert; 12 - drain valve; 13 — drain valve handle; 14 - drain valve of the radiator pipe

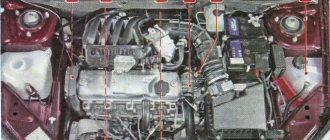

Rice. 2. Water pump

1 - bearing housing; 2 - plug; 3 — oiler; 4 - gasket; 5 - pump housing; S—pump impeller; 7 — oil seal; 8 - sealing washer; 9 — reflector; 10, 12 — ball bearings with seal; 11 — spacer sleeve; 13 — water pump shaft; 14 — fan pulley hub; 15 - fan; 16 - pulley; 17 — generator drive belt; 18 — power steering pump drive belt; 19 — compressor drive belt

Rice. 3. Scheme for checking drive belt tension

1 — crankshaft pulley; 2 — generator pulley; 3 — compressor pulley; 4 — water pump pulley; 5 — power steering pump pulley

Rice. 4. Scheme of remote control of drain taps

1 - drain taps; 2 — handle for driving drain valves; 3 — drain valve of the radiator pipe; 4 — handle for driving the drain valve of the radiator pipe

Rice. 5. Thermostat operation diagram

a - thermostat in closed position; b — thermostat in open position; 1 — thermostat bottle; 2-active mass (ceresin); .3 - membrane; 4 — guide sleeve; 5-rod; 6 — return spring; 7 — thermostat damper; 8,13- pipes; 9 — damper rocker arm; 10 — thermostat housing; 11-buffer; 12 — clip; I - to the radiator; II - to the water pump

Disassembling the water pump

To repair this unit it is necessary to disassemble it. The operation is carried out sequentially according to the following scheme:

- The device is installed and fixed in a vice.

- The nuts are unscrewed, the gaskets and spring washers (3, 2, 1) are removed, the housing (9) is removed.

- The bolt (6) securing the impeller is unscrewed, after which the latter is dismantled.

- The bushing, bearing retaining ring and key are removed.

- The unit roller is pressed out on the press along with the bearings (5).

- The bearings, diagonal bushing and water release valve (4) are removed.

- The race and seal are removed from the impeller (7).

- All parts are washed.

- Unusable and deformed elements are replaced.

- Assembly is carried out in reverse order.

Cooling system composition

As it became clear from the diagram, the main elements of the cooling system are a thermostat, radiator, water pump, various pipes, drain valves, fan, compressor, temperature sensor and heater. All these elements make up the cooling system.

Many car enthusiasts are interested in the question: how many liters of coolant does the system hold? The answer to the question is simple, according to the manufacturer’s recommendation, the coolant volume is 28 liters.

Radiator

The cooling system radiator is a part that provides cooling of the coolant using a counter flow of air. On the ZIL 130, the cooling system was installed of an old model, and therefore the radiators were mounted from copper and had a 3-row system.

Considering the service life of the motor, operation on water and the age of the parts, these elements often fail. This is primarily due to wear and corrosion, since you rarely see ZILs that are operated on antifreeze. Usually, to save money, these vehicles are usually cooled with water, often not even distilled. Replacing a radiator takes quite a long time, since the location of the part is quite inconvenient.

Fan

The fan is installed forced and mounted on a pulley of the water pump, which is driven by a belt from the crankshaft. The main problem that may arise is the breakage of the fan blades or attachments to the pulley.

Thermostat

Thermostat - provides regulation of the flow of coolant from a small circle to a large circle and vice versa. This is done to ensure maximum cooling or heating effect of the power unit. This part is most susceptible to malfunction, since a stuck thermostat often leads to boiling of the motor. This will all lead to negative consequences.

In order to replace the thermostat, it is necessary to drain the coolant level from the system, and then unscrew the upper pipe from the thermostat cover. Then, you need to unscrew the top cover of the thermostat mount and remove the product directly. The next step will be installing a new spare part and filling in antifreeze. As practice shows, about 0.5-1 liter of liquid is lost during the change process, so it is recommended to purchase the required amount.

Water pump

The water pump or water pump circulates coolant throughout the system. It has a centrifugal design. In case of minor damage, this part can be easily repaired using a repair kit.

The pump is located on the front cover of the cylinder block. The part consists of a housing, a shaft with bearings and an impeller. Usually, when carrying out repair operations, it is the repair kit that is used.

If the cover is corroded or the shaft mounting seats are worn out, then it is necessary to replace the part.

temperature sensor

The temperature sensor installed on the ZIL 130 was the most primitive, and apart from demonstrative functions, it did not perform any others. By exponential function we mean that the sensor determined the engine temperature and transmitted the indicator to the dashboard, where the driver himself controlled the process. As practice shows, on the remaining operational ZILs the temperature indicator on the dashboard does not work.

Drain taps

Drain valves required to drain coolant from the system. They are located on the cylinder blocks and radiator. As practice shows, if you do not drain the antifreeze for a long enough time, or if the vehicle is operated on water, these parts stick and are quite difficult to unscrew.

Compressor malfunctions and repairs

In the design of the ZIL-130 cooling system, extraneous noise during compressor operation or the appearance of oil in the air tank indicate a malfunction of the unit. During operation, cracks and chips appear on the crankcase, which requires replacement of the part. If the deformations are insignificant and located on the fixing flange, they can be eliminated by welding.

To check the tightness of the cylinder, the element is placed in a water bath, after which compressed air is pumped in. The appearance of bubbles indicates that the seal is not all right. Repair is carried out by boring the tank with honing to the repair size. The permissible error is no more than 0.04 mm. The corresponding parameter of the pistons is determined by the markings stamped on the bottom (+04, +08). If the ball bearings become worn, they should be compressed and replaced with new parts. Replacement of the entire crankshaft is required if the wear of the connecting rod journals exceeds 0.05 mm. To eliminate wear on the upper head of the connecting rod, press the repair sleeve through a prepared hole with a diameter of 14.01 mm.

Source