Good time everyone! Everything is like many, if not all, I’m driving on my way and suddenly there’s a light, barely perceptible ding and the check light is lit up in a telltale yellow color... Like a true car driver, I look at all the available instruments, straining all my fibers and senses to feel what has changed in behavior of the car... and practically nothing has changed, well, with the exception of the yellow eye... Okay, I think I'll throw it off... I threw it off and everything was fine... After 24 km the story repeated itself, I threw it off again... this happened 5 times in a day... by the evening I was a little free, got into it to the point. but the gist is this: the error occurs when I give a little more revolutions, and there are no changes in the behavior of the car. Error P0106. P0106 The absolute air pressure sensor signal is outside the permissible range (see P0105) P0105 Incorrect signal in the air absolute pressure sensor circuit. External sign - the MIL lamp does not go out, insufficient engine response, increased fuel consumption, unstable idling. 1. Deterioration of DBP parameters or failure - wear or contamination of the sensor. Try replacing DBP. 2. The DBP type does not correspond to the standard one. Check markings and replace. 3. The mechanical throttle position sensor characteristic deviates from linearity. Try replacing the throttle sensor. 4. Wear, deformation or freezing of the throttle assembly. Eliminate possible intake faults. Try replacing the throttle assembly. 5. Replace the air filter element or replace the filter. 6. Eliminate the increased release of oil from the crankcase ventilation system to the inlet. 7. Eliminate possible leakage of unaccounted air at the inlet in elements mating with the throttle and receiver: hoses, fittings, injectors, adsorber, vacuum brake booster, etc. 8. The type of controller does not correspond to the standard one. Check the controller's passport data - type, designation, software version, VIN code (if available) and calibration sign. Install a standard controller. 9. Check and adjust engine valve timing. 10. Check and adjust valve clearances. Check the serviceability of the hydraulic valve compensators.

I immediately washed the DBP with carb cleaner, because... I really was a little oily. A running car reacts to the DBP being turned off, which means the sensor itself is normal. I washed the crankcase gas pipe, which cuts into the pipe in front of the throttle. I also replaced the stuck valve cover diaphragm gasket. By the way, I changed it a little over a year ago, there were no oil leaks. I installed the silicone blue one. Everything became normal... for half a day today... By the evening I couldn’t stand it, I decided to thoroughly investigate. Fortunately there is manual gas. I piled up the revs, look under the hood, smell it, feel it. Sprayed a quick start... no use. And then it dawns on me - the error occurs in a second... I asked my friend to periodically rev the gas. And here’s a wonderful miracle... the crankcase exhaust pipe, which goes into the intake manifold behind the throttle, threw out a little hot air... we disassemble, clean and put it on sealant (as it was before). And that's happiness. So far everything seems to be fine. I continue to observe, I hope not phases, because... the craving has not changed... Maybe someone knows what else? Maybe this has something to do with the establishment of good warm weather? By the way, the engine started heating up, not that it was actually boiling, but it became noticeably hot under the hood...

Read also: Fuel pump on gazelle injector does not work

Reviews. Auto News. Test drives

Main Menu

- Home

- Adviсe

- P0106 OBD-II Error: Air Pressure (MAP) Sensor Output Out of Range

What does P0106 mean?

Trouble code P0106 is a general trouble code that indicates that the voltage in the manifold absolute pressure sensor circuit is abnormal (compared to the manufacturer's specification). This means that the sensor is outside the range or performance specified by the vehicle manufacturer. The manifold absolute pressure sensor is an integral part of the fuel injection system. It sends signals to the Engine Control Module (ECM), which in turn uses the information received to ensure smooth engine operation as well as efficient fuel use.

UAZ errors via OBDI protocol. Self-diagnosis.

012 — operability of the diagnostic circuit.

013 - low signal level of the mass air flow sensor (MAF). 014 - high signal level of the mass air flow sensor (MAF).

017 - low signal level of the air temperature sensor. 018 - high signal level of the air temperature sensor. 021 - low signal level of the coolant temperature sensor. 022 - high signal level of the coolant temperature sensor.

023 - low signal level of the throttle position sensor (TPS). 024 - high signal level of the throttle position sensor (TPS).

025 - low voltage level of the vehicle's on-board network. 026 - high voltage level of the vehicle's on-board network.

027, 028, 029 — malfunction of the electrical circuit of the crankshaft position sensor (CPS).

031 - low signal level of the carbon monoxide (CO) sensor (potentiometer). 032 - high signal level of the carbon monoxide (CO) sensor (potentiometer). 035 - low signal level of the oxygen concentration sensor. 036 - high signal level of the oxygen concentration sensor.

041 — a malfunction in the electrical circuit of the knock sensor.

051 - malfunction 1 (failure) of the controller (ECU). 052 - malfunction 2 (limitation) of the controller (ECU).

053 — a malfunction in the electrical circuit of the crankshaft position sensor (CPS).

054 — malfunction in the electrical circuit of the phase sensor.

055 — a malfunction in the electrical circuit of the speed sensor.

061 — reset the controller (ECU) in working condition.

062 - malfunction of the controller's random access memory (ECU), its shutdown. 063 - malfunction of the programmable memory device of the controller (ECU).

064 — malfunction when reading the non-volatile memory of the controller (ECU).

065 - malfunction when writing to the non-volatile memory of the controller (ECU). 066 - malfunction when reading error codes.

073 - signal of an enriched mixture from the oxygen concentration sensor at maximum depletion. 074 - lean mixture signal from the oxygen concentration sensor at maximum enrichment.

081 — Maximum displacement of the ignition timing angle (IAF) by detonation in cylinder 1. 082 — Maximum displacement of the ignition timing angle (IAF) by detonation in cylinder 2. 083 — Maximum displacement of the ignition timing angle (IAF) by detonation in cylinder 3. 084 — Maximum displacement of the ignition timing angle (IAF) by detonation in cylinder 4. 085 - Maximum displacement of the ignition timing angle (IAF) by detonation in cylinder 5. 086 - Maximum displacement of the ignition timing angle (IAF) by detonation in cylinder 6. 087 - Maximum displacement ignition timing (IAF) for detonation in cylinder 7. 088 - Maximum displacement of the ignition timing (IAF) for detonation in cylinder 8.

Read also: Regulations then hover n3

091 - electrical short circuit in circuit 1 of the ignition system, short circuit of the coil of cylinders 1 and 4. 092 - short circuit in the electrical circuit 2 of the ignition system, short circuit of the coil of cylinders 2 and 3. 093 - short circuit in the electrical circuit 3 of the ignition system, short circuit of the coil of 2 and 3 cylinders. 094 - short circuit in the electrical circuit 4 of the ignition system, short circuit of the coil of cylinders 1 and 4.

131 - injector 1 malfunction, short circuit. 132 - injector 1 malfunction, open. 133 - injector 1 malfunction, short circuit to ground. 134 - injector 2 malfunction, short circuit. 135 - malfunction of injector 2, break. 136 - injector 2 malfunction, short circuit to ground. 137 - malfunction of injector 3, short circuit. 138 - malfunction of injector 3, break. 139 - malfunction of injector 3, short circuit to ground. 141 - malfunction of injector 4, short circuit. 142 - malfunction of injector 4, break. 143 - malfunction of injector 4, short circuit to ground.

161 - short circuit of winding 1 of the idle speed regulator. 162 - open circuit in electrical circuit 1 for controlling the idle speed regulator. 163 - short circuit to ground in circuit 1 of the idle air regulator control. 164 - short circuit of winding 2 of the idle speed regulator. 165 - open circuit in electrical circuit 2 of the idle air control control. 166 - short circuit to ground in circuit 2 of the idle air regulator control.

167 - short circuit in the electric fuel pump relay circuit. 168 - open circuit in the fuel pump electrical circuit. 169 - short circuit to ground in the electrical circuit of the fuel pump relay.

174 - short circuit of the load in the electrical circuit of the adsorber valve. 175 - open circuit in the electrical circuit of the adsorber valve. 176 - short circuit to ground in the electrical circuit of the adsorber valve.

177 - short circuit in the electrical circuit of the main relay. 178 - open circuit in the main relay electrical circuit. 179 - short circuit to ground in the electrical circuit of the main relay.

181 - short circuit in the electrical circuit of the “Check Engine” warning lamp. 182 - malfunction in the electrical circuit of the “Check Engine” warning lamp. 183 - short circuit to ground in the electrical circuit of the “Check Engine” warning lamp.

231 - open circuit in electrical circuit 1 of the ignition system. 232 - open circuit in electrical circuit 2 of the ignition system. 233 - open circuit in electrical circuit 3 of the ignition system. 234 - open circuit in electrical circuit 4 of the ignition system. 241 - short circuit to ground in electrical circuit 1 of the ignition system. 242 - short circuit to ground in electrical circuit 2 of the ignition system. 243 - short circuit to ground in electrical circuit 3 of the ignition system. 244 - short circuit to ground in electrical circuit 4 of the ignition system.

Causes of error P0106

The most common causes of the P0106 code are:

- Abnormal (compared to the value specified in the manufacturer's specifications) voltage in the manifold absolute pressure sensor circuit

- Loose or damaged vacuum hose on the manifold absolute pressure sensor

- Damage to the MAP sensor electrical wires or connector, or the electrical wires or sensor itself being too close to higher voltage components (such as the alternator, ignition wires, etc.), which could cause interference affecting the signal sent on the vehicle's ECM

- Worn or damaged internal components of the manifold absolute pressure sensor

- The manifold absolute pressure sensor is not functioning properly, causing the sensor to send incorrect signals to the vehicle's ECM, which in turn is unable to control engine operation properly

- Low fuel pressure or damage to internal engine components (such as a burnt valve)

- In rare cases, a faulty engine control module (ECM)

How does a mechanic diagnose a P0106 code?

First, the mechanic will connect the OBD-II scanner to the vehicle's diagnostic port and read all the stored data and error codes. He will then clear the error codes from the computer's memory and test drive the vehicle to see if the P0106 code appears again. If the error code appears again, a mechanic will visually inspect the vacuum and air intake hoses for looseness, wear, or damage. If the hoses are OK, the mechanic will start the engine and check the voltage output at the manifold absolute pressure sensor to see if the voltage reading varies with engine speed and load. The mechanic will also check the electrical wires from the engine control module (ECM) to the manifold absolute pressure sensor.

UAZ Patriot (2013). Cause of error P0106

P0106 - Absolute Pressure Sensor/Barometric Pressure Sensor Error

Depending on the make and model of the car, every modern vehicle is equipped with an absolute pressure sensor (MAP) or a barometric pressure sensor (BARO).

The absolute pressure (MAP) sensor measures the absolute pressure inside the engine intake manifold

The barometric pressure sensor (BARO) measures atmospheric pressure, which constantly changes depending on vehicle speed and engine load.

Causes of error (code) P0106:

- Blockage due to damage to the vacuum line that goes to the sensor - Electrical problems with the wiring. Problems with the Engine Control Module (ECM) mind or power supply - Malfunctioning MAP/BARO sensors - Dirty throttle body - EGR problems - Bad Mass Air Flow (MAF) sensor - Mechanical engine problems - Exhaust system problems (for example, the catalyst is clogged)

What you need to check if error code P0106 occurs:

-Check the MAPS sensor, it should produce nominal values -Check the battery for low voltage, charge it -Check the throttle valve, clean it from carbon deposits

One of the causes of the error is a clogged air filter. If the filter is clogged, it just doesn’t look very clean, or the air duct is clogged, we fix the problem. We clean the air duct, the filter housing, and replace the filter with a new one. We inspect the vacuum lines. The presence of cracks, leaks, and lack of clamps is unacceptable in the highways. We replace tired hoses, check the tightness of connecting the hoses to the fittings on one side and the other.

Depending on the car model, the reasons for the error may vary slightly. It all depends on the complexity of the intake tract and the number of additional vacuum hoses connected to the manifold. Be that as it may, methodical diagnostics should reveal the breakdown.

In some cases, the error code P0106 was caused by a low battery charge, since the sensor is sensitive to the supply voltage. Sometimes it is enough to charge the battery and the error can be painlessly reset via OBD using a scanner.

The level of pressure in the manifold cannot but be affected by the state of the throttle valve. That is why, before replacing the sensor, we check the condition of the damper and diffuser. In many cases, carbon deposits on the damper were the cause of error p0106. If the throttle is dirty and has a layer of carbon, after carefully removing it, the error disappears.

It is important to take into account that in some engines the inner surface of the throttle is coated with a non-stick microlayer. If you clean it using barbaric methods, you can damage the non-stick layer. Therefore, we carry out cleaning with special aerosols, but so that carbon deposits do not get into the intake manifold. Naturally, if you are not too lazy, it is advisable to remove the throttle before doing this. This will protect the power system from debris and other errors. Regardless of the engine model, having carried out a set of these diagnostic and preventive measures, we will get rid of error P0106 forever, and at the same time we will put the air supply system into the intake manifold in order.

content .. 144 145 146 147 ..

Common mistakes when diagnosing code P0106

The most common mistake when diagnosing the P0106 code is to rush to replace the MAP sensor or engine control module (ECM) without performing a thorough check. It is also a mistake to neglect to check the output voltage of the sensor. The voltage at idle is usually 1-1.5 volts, and at wide open throttle it is around 4.5 volts.

Before replacing the manifold absolute pressure sensor or engine control module (ECM), you must ensure that the problem is indeed with these components.

Work on errors: P0106, causes, diagnostics and engine hygiene

Depending on the car model, the reasons for the error may vary slightly. It all depends on the complexity of the intake tract and the number of additional vacuum hoses connected to the manifold. Be that as it may, methodical diagnostics should reveal the breakdown.

In any service station, you will have to pay for searching for a breakdown and wasting the technician’s time, but if we ourselves are not savvy, we will try to find the causes of the error ourselves. In order of priority, we check the following:

Air filter, check or replace

The first reason is a clogged filter.

We remember when we had to change the air filter. If we can’t remember, we proceed to replace it without talking, regardless of the condition of the installed filter. If the filter is clogged, it just doesn’t look very clean, or the air duct is clogged, we fix the problem. We clean the air duct, the filter housing, and replace the filter with a new one.

We inspect the vacuum lines. The presence of cracks, leaks, and lack of clamps is unacceptable in the highways. We replace tired hoses, check the tightness of connecting the hoses to the fittings on one side and the other.

Checking the MAPS sensor

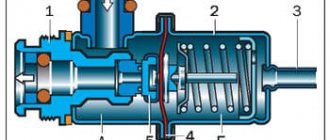

MAP sensor location

This is not difficult to do. First, let's figure out where the absolute pressure sensor is located in the manifold. It is easy to find it according to the factory diagram, or logically, it is always located behind the throttle valve. For example, on KIA Rio cars it can be found in the housing of the vacuum chamber of the intake manifold; in Hyundai Sonata, Solaris, Kia Sportage, Hyundai ix35 cars with G4KD, G4KE engines we look for it there.

Interesting on the topic: Chery Arrizo 6, first photos before the premiere

Sensor connection diagram

A voltmeter will be needed to check the sensor. Depending on the engine model, the voltage on the sensor will change as the number of revolutions changes (accordingly, the pressure also changes) from 0.79 V at a pressure of 20 kPa at low speeds, to 4 V at a fully open throttle valve, which corresponds to a pressure of about 100 kPa .

Sensor location on the manifold

If the values do not fit within the nominal limits or there is no signal at all, first of all we check the contacts on the sensor terminal block. Perhaps they have oxidized or the wire has broken. If the wiring and contacts are fine, the sensor is at fault. The MAPS sensor costs between $20-30 depending on the engine model, but do not buy the sensor until you have checked all the circuits. The sensor rarely fails.

Battery

In some cases, the error code P0106 was caused by a low battery charge, since the sensor is sensitive to the supply voltage. Sometimes it is enough to charge the battery, and the error can be painlessly reset via OBD using a scanner.

Throttle valve, cleaning and checking

Dirty throttle - the cause of error P0106

The level of pressure in the manifold cannot but be influenced by the state of the throttle valve . That is why, before replacing the sensor, we check the condition of the damper and diffuser. In many cases, carbon deposits on the damper were the cause of error p0106. If the throttle is dirty and has a layer of carbon, after carefully removing it, the error disappears.

It is important to take into account that in some engines the inner surface of the throttle is coated with a non-stick microlayer. If you clean it using barbaric methods, you can damage the non-stick layer. Therefore, we carry out cleaning with special aerosols, but so that carbon deposits do not get into the intake manifold. Naturally, if you are not too lazy, it is advisable to remove the throttle before doing this. This will protect the power system from debris and other errors.

Interesting on the topic: Ford Focus 2 cabin filter: replacement without removing the gas pedal

Regardless of the engine model, having carried out a set of these diagnostic and preventive measures, we will get rid of error P0106 forever, and at the same time we will put the air supply system into the intake manifold in order. Good luck with all the repairs and smooth roads!

How serious is the P0106 code?

Error P0106 is quite serious, as when it appears, problems with the engine may occur. Under certain circumstances, damage or failure of the manifold absolute pressure sensor can lead to increased fuel consumption, unstable engine operation, and engine starting problems. In some cases, damage to internal engine components may occur. If this code is detected, it is recommended that you contact a qualified technician as soon as possible to diagnose and resolve the error.

Often, if the Check Engine Light comes on immediately after starting the engine, the OBD-II system can be reset and the vehicle will continue to operate normally.

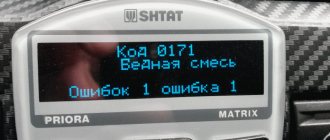

When error signal P0172 is triggered

In order for the ECU to show this error, if present, the engine must be started and an oxygen sensor must be installed - a lambda probe. Also, the error of the engine coolant temperature sensor, intake air temperature sensor (IATV), absolute pressure sensor (MAP-sensor), throttle position sensor (TPS), mass air flow sensor DFID, camshaft position sensor (error P0021) should not be displayed. and crankshaft position sensor (CPS).

Causes of error P0172

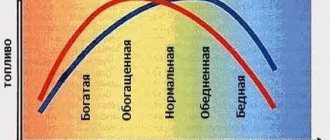

This is an error in supplying a rich mixture, which means you need to find out why little air is added.

Reasons for enriching the mixture:

- the fuel does not burn completely due to inconsistent spark supply to the spark plugs (or the problem is in the spark plugs, or the ignition coil, or in the high-voltage wires);

- Excessive amount of oxygen is supplied due to improper operation of the oxygen sensor or injectors;

- the required amount of oxygen is not supplied.

More often, problems with the fuel mixture are caused by a lack of air, and an excess of air is less common. When supplying air to form a combustible mixture, a lambda probe and a MAP sensor are involved.

The reason for the enrichment may be associated not only with improper operation of the sensors, but also due to a violation of tightness, low cylinder compression, and malfunction of the gas distribution mechanism.

Signs of engine operation on a rich mixture:

- Bad dynamics. Pressing the gas pedal does not accelerate the engine speed.

- Increased fuel consumption.

- Exhaust gases are black.

- Popping sounds from the muffler due to the fact that the fuel does not have time to burn in the working combustion chamber of the cylinder and burns out in the exhaust system. They are clearly audible when releasing the gas.

- The spark plugs have a black velvety residue.

To determine the cause of error P0172, you must do the following:

- Start the engine and bring it to the mode when error 0172 appears.

- Analyze the error from a scanner, for example OBD2.

- Inspect the components of the power unit, check the connections; if air is sucking in, it will be noticeable.

What repairs can fix the P0106 code?

To resolve error P0106 you may need to:

- Check for the error code using a scan tool, clear the code from your computer's memory, and test drive the vehicle to see if the P0106 code appears again.

If the error code appears again:

- Replacing worn or damaged vacuum and air intake hoses, and reconnecting, repairing, or replacing electrical wires or manifold absolute pressure sensor connector

- Replacing the Manifold Absolute Pressure Sensor or Engine Control Module (ECM)

Decoding error code P0106

All new models of Ulyanovsk-made Patriot cars are equipped with an electronic control unit (ECU). This allows the machine systems to diagnose components using standard tools, find breakdowns and display error codes on the display.

Code P0106 means "the MAP sensor signal is out of range." The MAPS sensor (converter) itself (Manifold Absolute Pressure sensor (MAP-sensor)) breaks down extremely rarely.

The design of the converter is based on a sensor. On one side there is a vacuum, on the other there is the influence of gas or liquid pressure. Receiving the output signal from the sensor, the electronic unit estimates the absolute pressure (i.e. pressure relative to vacuum) and calculates the amount of air that is supplied to the cylinder during the intake stroke. In accordance with this value, the required amount of gasoline is calculated to obtain the air-fuel mixture of the required composition.

If the supplied air volume differs from the nominal value, error P0106 appears.