How to quickly determine what mixture the engine is running on: lean or rich.

The mixture in the cylinder should burn completely when the piston is 15-20 degrees along the crankshaft rotation angle after top dead center.

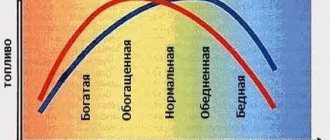

Whatever it is, the composition of the mixture should not go beyond a certain range. The burning rate of the mixture depends on its composition.

The mixture burns completely at a ratio of 14.7 grams of air to 1 gram of gasoline. This is the optimal combination of air and fuel, the combustion of which releases a minimum amount of harmful substances into the atmosphere. But it is impossible to maintain it in all modes, since the engine will not be torquey enough and will not develop the necessary power.

This mixture composition is maintained at idle and partial loads.

Anything greater than 14.7 to 1 (such as 17 to 1) is considered a lean and lean mixture. The burning rate of this composition decreases, and the mixture burns completely not at 20 degrees, but at a greater angle of rotation of the crankshaft after top dead center. Combustion occurs over a larger volume of the cylinder, which means it heats up more. If the mixture is very lean, it may continue to burn even when the piston is already at bottom dead center, and the engine will overheat. When the intake valve opens and a fresh fuel-air mixture begins to enter the cylinder, it will ignite from the old mixture that has not yet burned. The flame will spread through the intake system and there will be popping noise from the air filter.

Therefore, one of the signs of the engine running on a lean mixture is popping in the intake system.

If the composition of the mixture is less than 14.7 to 1 (for example, 12.5 to 1), then this means that the mixture is enriched. The maximum burning rate is achieved with this composition. The faster the mixture burns, the greater the pressure on the piston, which means the engine will be able to deliver its maximum power. Therefore, this air-fuel ratio is used in transition mode and maximum power mode.

But if the mixture is very enriched, then its burning rate drops. Just as in the case of a lean mixture, it continues to burn at the moment when the piston is already at bottom dead center.

But overheating does not occur due to a highly enriched mixture, because its combustion temperature is lower than that of a lean mixture.

When the exhaust valve opens, exhaust gases, along with unburnt fuel, enter the exhaust system. Here the fuel meets air, and the composition of the mixture is normalized, resulting in its burning out when leaving the muffler.

Therefore, when the engine is running on a very rich mixture, popping noises are heard from the muffler.

How to quickly determine.

In order to understand what mixture the engine is running on, you need to create a knowingly lean or knowingly rich mixture. That is, if the engine is idling unstably, then in order to determine whether this is due to a malfunction in the fuel supply system or not, you need to create an artificial air leak (to determine an over-enriched mixture) or supply gas to the inlet from a gas canister (to determine a lean mixture). mixtures). If the engine starts working normally at this moment, then you need to look for the cause in the power system.

Let's say the engine is running on a lean mixture and it shakes. The moment we supply gas to the intake, it mixes with air and the air-fuel ratio is normalized. The engine starts running normally until the gas burns out and the mixture becomes lean again.

Also with a rich mixture, when we create a choke, additional air is mixed with the fuel, the composition is normalized, and engine operation is stabilized.

Source

What are the signs of a rich mixture in the engine?

You don't need to be an experienced auto mechanic to recognize the signs of a rich mixture - they are impossible to miss and hard to ignore. If your car's engine runs on a rich mixture, you may notice a number of special signs:

- Popping noises and shots can be heard from the muffler, even at idle;

- Black or gray smoke coming from the exhaust pipe;

- The orange “Check Engine” icon on the dashboard came on;

- Computer diagnostics revealed error P0172;

- The dynamics fail - the car is “held back by something”, at the same time it “stumbles”;

- Fuel consumption has increased significantly;

- In the worst case, the car simply refuses to start when cold;

Operating a car with such problems is very difficult, sometimes even impossible. Inexperienced car owners may be frightened by this: images of satisfied mechanics at a service station and sums with zeros are drawn in their heads. The principle of treating a disease at an early stage suits this case perfectly. There is no point in starting this problem. How not to ignore the above symptoms.

Signs of a lean fuel mixture

Signs of a lean fuel mixture

Running a car engine on a lean fuel mixture is a malfunction. A fuel mixture containing more air than normal is considered lean. If the optimal composition is 15 parts air to one part gasoline, then a lean mixture will contain up to 19 parts air to one part gasoline. If 19/1 is exceeded, the fuel mixture will not ignite and the engine simply will not start.

There are several signs of this malfunction (lean fuel mixture), if detected, you should check the fuel supply system to the vehicle engine (power system) and (or) the electronic engine control system (ECM).

Signs of a car engine running on a lean fuel mixture

— Difficulty starting a warm engine

The engine starts with difficulty on a lean fuel mixture, or starts and stalls. Starting is only possible when you press the gas pedal.

— Reduced power and throttle response of the car engine

Reasons for the formation of a rich or lean mixture

Most often, a rich mixture is formed not because more fuel is supplied than necessary, but because less air is supplied than necessary. The most common and common reason is a clogged air filter. Unfortunately, many motorists forget that some components need to be changed regularly, even if they look like new. The air filter is one of these components; it needs to be changed at least every 30 thousand kilometers, and on powerful cars - even more often.

Also, the air supply can be “cut off” by a malfunctioning air pressure sensor - it needs to be adjusted. Paired with it is a fuel pressure sensor, which can also supply underestimated data to the engine's electronic control unit. Based on them, the block begins to pump more fuel into the cylinders, enriching the mixture. As we learned above, it worsens power and dynamics, the control unit doesn’t like it, and it supplies even more gasoline. Hence the greatly increasing fuel consumption.

The reason for the rich fuel mixture may also be hidden in the electronic engine control unit itself. These could be errors in his program, but also incorrect changes made to it. Self-taught craftsmen and simply unskilled craftsmen “tune” the control unit, deliberately increasing the proportion of fuel in the mixture. This way you can achieve a small increase in power, but it is much easier to upset the balance and achieve the opposite result.

Lean fuel-air mixture: injector, carburetor, LPG

A too lean air-fuel mixture is a fairly common problem that leads to serious engine malfunctions. Errors and disturbances in the mixture formation process can occur on carburetor or injection engines, as well as on power units with additionally installed gas equipment.

A lean and rich fuel mixture is a deviation from the norm, as a result of which the engine may begin to overuse fuel, has difficulty starting, loses power in different modes, smokes, and overheats.

For example, if a lean mixture is constantly supplied to the cylinders, the consequences can be quite serious. In a number of cases, the appearance of a white coating on the spark plugs and misfires have been noted; a lean mixture causes local overheating, burnout of valves and melting of the pistons.

In this article we will look at what a lean carburetor is and how to fix a lean mixture. We will also answer the question of what a lean mixture on an injector is, the reasons for a lean mixture when the engine is running on gas, as well as how to detect the problem yourself and carry out repairs.

Lean Burn Codes

Do not think that if a “lean mixture” error appears, only one code indicates the reasons for this. For example, P0171 is standard, but for Ford vehicles this code indicates problems in the first cylinder. Some Honda models may display error P0172, which indicates a lean mixture.

On the popular Chevrolet Captiva, the problem with the mixture is indicated differently - P2177. But to eliminate it you need to use universal methods. On a Japanese Mazda-6, code 2178 appears, which also indicates a lean mixture. All this is determined by computer diagnostics.

Leaning of the fuel-air mixture: causes and symptoms of a lean mixture

At the very beginning, you need to clearly understand what a lean mixture means. It should be recalled that in the combustion chamber the fuel charge not only consists of fuel, but also contains part of the air. These components are mixed in certain proportions in relation to different operating modes of the internal combustion engine.

Without going into too much detail, the optimal ratio is considered to be 1 kg of gasoline per 15 kg of incoming air. This mixture is called stoichiometric, that is, it has a ratio of 1:14.7. This ratio allows the engine to develop sufficient power while also maintaining acceptable fuel consumption.

If the amount of air is reduced, for example, to 13 kg, then the proportion of gasoline in the mixture will naturally increase. The engine will begin to produce even more power, while efficiency will deteriorate, that is, consumption will increase. Reducing the amount of air even more will cause the mixture to become too rich.

Ultimately, such enrichment will mean that the charge loses its ability to ignite, the spark plugs flood, and the cylinders do not work. With a ratio of 1:5, the over-rich mixture in the cylinders is no longer ignited by a spark.

This process can also occur in the reverse order, that is, the proportion of air in the mixture increases. In this case we are talking about charge depletion. With a lean mixture, fuel consumption is lower, and engine power is also noticeably reduced.

This allows you to best balance engine power and fuel consumption. For example, with minimal engine loads, there is no point in supplying a stoichiometric or rich “power” mixture to the cylinders all the time.

If the loads increase, then there is no talk of saving fuel by depletion, since in loaded modes the unit requires normal or even maximum performance.

So let's get back to our problem. As already mentioned, a too lean mixture on gas or gasoline can appear on both carburetor and injection engines. It is quite obvious that the main reasons for this impoverishment are:

- insufficient fuel supply;

- intake of excess air;

What is a rich mixture?

If you take the name “Internal Combustion Engine” and examine it, you will see that the name contains its basic operating principle: ignition and combustion of fuel occurs in its cylinders. The combustion process is impossible without oxygen. Therefore, for the reaction to proceed normally, the engine requires a constant flow of oxygen (air). The most interesting thing is that there is not enough oxygen in the air for proper combustion (only 20%). For the normal course of the fuel combustion reaction in the cylinders, the engine needs 15 times more air than fuel (gasoline, diesel).

The phrase Rich Mixture is nothing more than a violation of this proportion - more fuel is supplied to the engine than necessary. Adjustments are made to the normal operation of the internal combustion engine: a larger amount of gasoline simply does not have time to burn and is supplied with exhaust gases to the exhaust system. The car does not receive enough power, the engine choke. In some cases, there may be so much fuel that gasoline simply floods the cylinders.

Lean mixture at idle and under load: carburetor, injector

To determine the possible causes of a lean mixture, let's start with a simpler carburetor internal combustion engine. On such motors, the problem is most often localized in the power system. The list of common faults includes:

- the carburetor prepares a mixture whose composition does not correspond to the operating mode of the engine;

- there is an insufficient supply of fuel from the fuel tank; there is a low fuel level in the carburetor float chamber;

- fuel does not reach the carburetor in full, that is, a leak has occurred;

It turns out that incorrect settings of the dosing system (carburetor) can lead to a lean combustible mixture. For example, if the fuel level in the float chamber is set to low. Also, one should not exclude the possibility of clogging of fuel jets, individual violations during their adjustment, etc.

As for the air supply, third-party suction is most often noted in those places where the carburetor is connected to the intake manifold, as well as in the area where the intake manifold is connected to the internal combustion engine, etc. Excess air can be sucked in as a result of loose fasteners, destruction of sealing gaskets, cracking of structural elements and other defects.

Lean mixture on the injector: “check”, lean mixture

The fuel injection system is more complex than a carburetor, as it includes a large number of electronic sensors. Failure of individual devices or depletion of the mixture for other reasons leads to the fact that in some cases a “check” lights up on the instrument panel.

For example, air may be sucked in at the place where the idle speed sensor is installed. One of the simplest reasons may be a cracked or damaged rubber gasket ring, which seals and seals the connection.

In the list of the most common problems, experts highlight:

- contamination of injection nozzles;

- intake air leak;

- oxygen sensor (lambda probe);

- mass air flow sensor (MAF);

Constant malfunctions of the internal combustion engine due to mixture formation are usually caused by a dirty air flow sensor. This sensor simply loses the ability to correctly calculate the amount of air consumed. Also note a possible vacuum leak.

Another cause could be the EGR valve. The specified valve of the exhaust gas recirculation system becomes very dirty during operation and ceases to close tightly, as a result of which excess air is sucked into the intake through the slightly open valve. Increased air flow through the EGR valve can also be caused by a failure of the pressure difference sensor in the recirculation system.

As for the power system, the mixture becomes leaner:

- decreased fuel pump performance;

- contamination of fuel filters and fuel supply lines;

- decreased performance and contamination of injection nozzles;

- leaks through the fuel pressure regulator in the fuel rail;

In the exhaust system, special attention should also be paid to the lambda probe and catalyst. Quite often, it is the lambda that shows a lean mixture, when scanning, the error “lean catalyst mixture” is recorded, the diagnostics determines an incorrectly functioning oxygen sensor, a lean mixture is formed due to malfunctions of the oxygen sensor and a failed/burnt-out catalytic converter.

Checking and eliminating causes

General diagnostics begins with the ECM sensors. Typically, the P0171 code occurs due to a malfunction of the MAF sensor (mass air flow sensor). The fact is that the specified sensor ceases to respond in a timely manner to changes that relate to air flow. The cause is usually an accumulation of contaminants.

In this case, the control unit automatically reduces the fuel supply so that the amount of air increases. The result is a lean mixture at different operating modes of the power plant. After this, error P0171 occurs; in parallel, error P0100 or P0102 can be detected. Such codes usually indicate problems and malfunctions in the mass air flow sensor.

To eliminate the causes, the sensor must be removed, after which it is cleaned. You can use carburetor cleaner as a cleaner. The device must be cleaned carefully so as not to damage the sensitive element. If cleaning does not help, then the sensor needs to be replaced.

If the mass air flow sensor is in working condition, then further checking is to determine possible depressurization and air leaks. Defects may occur in the inlet pipe area, in the throttle body area.

- It is necessary to separately check all vacuum hose connections, intake manifold mounting location, throttle body gasket, intake manifold gaskets, etc.

- Also, cracking or other damage to the crankcase ventilation system pipes, fuel vapor recovery system hoses, and plugs on the intake manifold is not allowed.

- The exhaust system must be completely sealed (without corrugations, etc.), since defects near the installation site of the oxygen sensor will also lead to mixture formation failures.

Causes of error P0171

If a lean mixture enters the combustion chamber of a car engine, there can be two reasons for this: too much air is supplied or too little fuel is supplied. Each of these reasons can arise due to a number of problems.

Why does a lot of air enter the combustion chamber:

- Malfunction of the air flow sensor. This may be due to contamination, which prevents precise control of air flow;

- Additional air enters the intake manifold through the exhaust gas recirculation (EGR) valve. This reason is most often due to the fact that the valve does not close well, thereby allowing exhaust gases to be directed into the intake manifold;

- Increased air flow through the EGR valve due to improper operation of the EGR differential pressure sensor;

- Presence of a vacuum leak.

Why is there little fuel entering the combustion chamber:

- The fuel pump is not doing its job;

- Fuel injectors are damaged or dirty, causing them to not deliver enough fuel in the allotted time;

- The supply of the required amount of fuel is hindered by resistance from the fuel filter;

- Fuel partially leaks out of the pressure regulator without entering the combustion chamber in full.

As you can see, there are many reasons for error P0171. To find the engine element that is causing a lean fuel mixture in the combustion chamber, you will need to check sensors, injectors, filters and a number of other components.

Gas equipment malfunctions: “lean mixture” error on gas

You need to understand that HBO is a separate power system. For this reason, to check the lean mixture when driving on gas, only some of the operations will be the same as in the case of determining the cause of lean mixture on a conventional carburetor or injection engine.

If no air leaks are detected anywhere, and the electronic sensors are also in perfect order, then special attention should be paid to the following points:

- correct installation and configuration of gas equipment;

- cleanliness of gas filters and gas supply channels;

- condition and settings of the gas reducer;

- gas injectors, their performance and quality;

Taking into account the fact that there are many generations of HBO, various malfunctions occur on such systems. So in some cases it is necessary to diagnose certain installed elements.

For example, the first generations of gas installations (GBO-I, GBO-II) were characterized by such a problem when the performance (power) of the installed gearbox could simply be insufficient, as a result of which when operating in loaded modes there is not enough gas, the mixture becomes lean, the engine does not pull , errors appear, etc.

Also, the gas injectors themselves can be a common cause of a lean mixture, regardless of the generation of gas equipment. It is enough to imagine a situation where the electronic unit opens all the injectors for the same time, but one of them closes earlier. As a result, the mixture will become lean in only one of the cylinders.

The consequences of driving a rich or lean mixture

Nothing good will come from driving a rich mixture. If the problem is not resolved in time, it can lead to the following consequences:

So at the first sign of enrichment of the fuel mixture, it is better to immediately visit a car service center. Moreover, the problem is very quickly and easily determined by the on-board computer memory scanner - it displays error P0172. Also, in many cases, repairs are inexpensive and fairly quick.

According to statistics, problems associated with a rich mixture often occur in cars: Opel Astra, Vectra, Volkswagen Passat B3 (single injection), Audi 80, A4 (injector), Nissan, Peugeot 308, Citroen, Volvo, Mazda, Ford Focus, BMW , Renault