The engine plays the most important role in the design of a vehicle. Romantic drivers call it “the heart of the car.” But the power unit has one weak point - the lubrication system for rubbing parts. The only control element of this system is the oil pressure sensor (OPS), which can present the driver with many surprises.

- 2 Types of DDM and the principle of their operation in modern cars

2.1 Mechanical sensor - 2.2 Electronic sensor

- 3.1 Table: where are the oil pressure sensors located on popular car models

- 6.1 Video: replacing DDM with your own hands

Why do you need an oil pressure sensor?

DDM is an essential component of the lubrication system of an engine unit. The device is responsible for monitoring the oil pressure that is supplied to the engine and, in case of any failures, transmits a signal to the driver’s cabin - the corresponding light comes on.

The light comes on immediately after the DDM is triggered

To understand the importance of the sensor in the design of a car, you will need to know how exactly the oil is supplied to the rubbing parts in the engine. Depending on the type of machine and its year of manufacture, lubricant can be supplied in various ways, including simple spraying. However, even this method involves creating the necessary pressure so that the optimal amount of oil is supplied to the unit. If the amount of lubricant is stable, the rubbing parts of the engine will ensure good, uninterrupted operation without rapid wear.

To promptly prevent various negative factors in the lubrication system, a DDM is installed, which is sensitive to all changes in oil supply.

The driver is given a signal by sound and visual methods: a sharp squeak is heard in the cabin and a red indicator in the form of an oil can appears on the instrument panel. In some types of cars, oil pressure characteristics are displayed in a separate dial gauge, which shows the current state of the lubrication system.

Did you know that the level of seat pressure can be influenced by the height of the vehicle's location relative to sea level?

Oil pressure may vary depending on how high the car is above sea level

Types of DDM and the principle of their operation in modern cars

The modern automotive industry uses two types of such sensors. Each type works with certain types of engines and talking about which sensor is better/worse is not acceptable.

Mechanical sensor

The device most accurately determines the oil pressure in the system and transmits the readings to a scale in the dashboard.

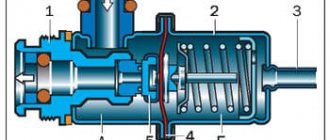

The mechanical device has a complicated design: a housing cup, a membrane, a pusher, a slider and a nichrome wire winding. Due to the use of many components, mechanical sensors are expensive.

The operation of such a device is as follows: the slider, which is located on a platform with a nichrome winding, receives the force of oil pressure, rises or lowers. His every movement is transmitted to a dial indicator in the car’s interior, so the driver will always be accurately informed about the pressure of the lubricant in the engine. The slider receives data from the effect of oil on the sensor membrane.

It has large dimensions and a complex internal design

Electronic sensor

This type of sensor is simpler, but it cannot transmit all changes in the lubrication system to the driver. As a rule, the electronic type of device shows only two main values: normal pressure and critical.

Thus, its only purpose is to convey to the driver the information that the pressure in the system is zero. To do this, its design uses only a housing cup, a membrane, a pusher and a contact system with an oil pressure light in the car's interior.

Accordingly, if the pressure disappears, the membrane straightens, since nothing presses on it. The pusher immediately slides into the housing, the contacts close - an alarm signal is sent to the cabin.

On some vehicle models, two types of sensors are installed at once. This expands the driver’s ability to constantly monitor the engine lubrication system. If one device fails, you can rely on the readings of the second.

Structurally simpler device

Types of DDM

Oil pressure sensors are divided into two types:

- Mechanical. They are used on cars that have become legends in the automotive industry, in particular, VAZ 2101, UAZ, Moskvich 401/407/412/, 2141 and others.

- Electronic. Installed on all modern cars, for example, domestic VAZ 2114, Kalina and other Lada models, as well as foreign cars.

Mechanical sensors

Mechanical sensors by design are divided into:

- Devices with two rods and a capillary tube.

- Devices with a rheostat.

The first ones consist of a body, a membrane, two rods, and a sealed tube.

As the pressure in the lubrication system increases, the membrane bends, putting pressure on the first rod, thereby increasing the pressure in the tube. The second rod takes this pressure and transmits it to the differential pressure gauge (located on the instrument panel).

The pressure increases - the arrow of the device deviates in a larger direction, falls - the arrow goes down to the left. The principle of operation is the same as that of a pressure gauge.

The mechanical oil pressure sensor with rheostat consists of:

- Cases.

- Membranes.

- Slider.

- Nichrome winding (resistor).

The device operates on the principle of a voltmeter. The rheostat and slider play a key role here.

The rheostat changes its resistance depending on where the slider is moved. The latter, in turn, shifts in one direction or another as the membrane bends or straightens.

When there is no pressure, the membrane is not deformed and the slider does not move, the current passes freely without encountering any resistance along its path.

As the pressure increases and the membrane deforms, the slider moves along the rheostat, thereby increasing the resistance in the circuit; accordingly, the current readings change, which is displayed on the device in the driver’s cabin.

All this is recorded by the ECU, to which the sensor is connected. It is programmed in such a way that only one period of current values is equal to the standard oil pressure. Exceeding this interval is equivalent to an incorrect value.

This is clearly visible on dial analog pressure gauges, which, in fact, are ordinary voltmeters.

Electronic sensors

Electronic DDM is much simpler than its mechanical counterpart, so it is considered more reliable.

Essentially, this is an emergency sensor that does not show the pressure in the system, but only notifies the driver when it is within normal limits and when it is not.

It consists of:

- Cases.

- Membranes.

- Contacts

- Stock.

Principle of operation. When pressure is not applied to the sensor membrane, it is not deformed. The rod is in a position in which the circuit contacts are closed and current flows through them. At this moment, a lamp is lit in the cabin, which is monitored by the driver.

When the engine starts, the oil pressure in the system increases, the membrane bends, the rod moves, opening the circuit. The light goes out.

If after starting the engine the lamp does not go out within 1-2 seconds, you must immediately turn off the engine and do not start it until the cause of the malfunction is determined.

Read more here - what to do if the oil pressure light is on.

Based on the above, we can conclude that the basis for checking the oil pressure sensor on modern cars is measuring the resistor resistance with a multimeter and checking the DDM for opening and closing the circuit.

To do this, the multimeter is switched to resistance or continuity measurement mode. It depends on what type of sensor is being tested with or without a resistor.

But there are other verification methods, which we will discuss below.

Location of the device in different types of cars

Depending on the make and model of the car, the location of the sensor may vary. Each automaker has its own approach to combining engine compartment mechanisms.

Most often, the DDM is located in close proximity to the cylinder head and oil filter. In some cases, to get to the device, you just need to open the hood and get to the sensor without dismantling other elements. In other situations, the sensor can only be removed from below, through the wheelbase.

The usual location is near the engine

Table: where are the oil pressure sensors located on popular car models

| Automobile | Where is the oil pressure sensor located? | The most convenient access to the sensor |

| VAZ 2108/09/099 VAZ 2110/11 (8-valve engine) | Behind to the right of the engine in the socket of the main cylinder block, near the belt guard. One wire comes from the sensor. | Above |

| VAZ 2110/11 (16-valve engine) | To the left behind the engine on the camshaft block. A wire extends from the sensor, and next to it there are 2 bundles of wires in a black insulator. | Above |

| Lada Kalina | Behind to the right of the engine in the socket of the main cylinder block, near the belt guard. One wire comes from the sensor. | Above. You must first remove the plastic cylinder block cover. |

| Audi - most models | In close proximity to the oil filter. There may be a second sensor - on the main cylinder block. A characteristic feature is that one wire comes from it. | Above |

| Chevrolet Lanos | On the oil pump at the bottom of the engine. A characteristic feature is that a bundle of wires in an insulator extends from it. | From below (when the car is on an overpass or above a pit). |

| Ford Transit | Under the front bumper near the oil cooler in the middle of the car on the engine. | From below (when the car is on an overpass or above a pit). |

| Mercedes-Benz - most models | On the crankcase slightly to the right of the center of the car. | From below (when the car is on an overpass or above a pit). |

| Mitsubishi Lancer | Behind and slightly to the right of the engine (screwed into the engine) next to the oil filter. A characteristic feature is that one wire comes from it. | From below (when the car is on an overpass or above a pit). |

| Nissan X-Trail | Below on the block next to the power steering pump. | By removing the right wheel and plastic belt guard. |

| Opel Astra | At crankcase level on the right side of the generator. A characteristic feature is that one wire comes from it. | Removing the right wheel. |

| Volkswagen Golf, Jetta | The emergency oil pressure sensor is located on the left end of the cylinder head. Another sensor - insufficient pressure - is located on the oil filter to the right of the car. | Top and bottom respectively. |

| Volkswagen Passat | Two sensors: the first is located on the bracket upstream of the oil filter, the second is at the outlet of the oil filter. | |

| Gazelle (ZMZ-405 engine) | Top right on the main cylinder block. A wire comes from the sensor. | Above. |

Causes and symptoms of malfunction

The driver of any vehicle should know that most often, malfunctions in the lubrication system do not present any particular difficulties in eliminating them. However, breakdowns may also occur that require the intervention of a service station specialist and specialized equipment.

Signs of a malfunction in the oil pressure sensor may include:

- loss of power by the car during acceleration;

- instability of the ignition switch;

- sharp jolts when driving at low speeds;

- inability to start the car.

The reasons why the DDM fails include:

- exhausted life of the device;

- membrane deformation;

- short circuit in the wiring;

- sensor relay failure.

Therefore, it is necessary to pay the utmost attention to such a device as the DDM, since the condition of the engine depends on its performance. If the sensor begins to “lie” and “get confused in the readings,” the rubbing parts of the power unit will wear out very quickly, which will ultimately lead to engine seizure.

How to connect an oil pressure sensor or everything about repairing a unit

Let's say the need to repair the oil pressure sensor is confirmed. What to do next? First of all, it is worth checking the unit for serviceability, of course, with the exception of the case when it simply leaked. Often the sensor is checked as follows:

- The device is removed from the engine crankcase;

- A suitable pipe is placed on its outlet;

- Using a pipe and an atmosphere meter, a vacuum is created that corresponds to the standards for pressure in the crankcase of your car’s engine. After which it abruptly goes astray. The procedure is repeated several times. If the light comes on/off consistently, then everything is normal with the sensor. Otherwise, the unit requires replacement.

Speaking about how to install an oil pressure sensor, it is worth highlighting the following procedure:

- We disconnect the pipe used to check it from the sensor;

- We remove the sensor from the car structure;

- Installing a new device. The renovation is complete.

In general, there are no particular difficulties in repairing and checking the oil pressure sensor. To correctly implement these procedures, it is enough to adhere to the provisions noted above, nothing more. This concludes, perhaps, the most important information on oil pressure sensors. We hope today’s article was useful to you and provided answers to your questions. Good luck on the roads and in car repairs!

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them

How to connect an external

In some cases, vigilant and experienced car enthusiasts connect a remote oil pressure sensor to their car. This is a measure that will ensure reliable control over the engine lubrication system. On the one hand, the functions of the sensor will be provided as usual, and on the other hand, it will be possible to look at the pressure force in the system at any time.

The procedure for connecting the remote device:

- Open the hood.

- Install the tee (adapter) in place of the oil pressure sensor.

- The sensor itself and the signaling device are connected to the adapter connectors.

- The wire from the device is pulled into the cabin.

- The color of the wires determines the connection to the instrument panel.

Thus, without much difficulty you can install and connect an additional device for monitoring oil pressure.

Thanks to a clear graduation scale, the driver will always know the exact pressure in the system

Engine oil pressure sensors: types, features and testing methods

As you know, the engine lubrication system performs the most important functions, eliminating dry friction and providing cooling at the points of contact of mating parts. Motor oil also washes away mechanical wear products and all kinds of deposits from surfaces. As a rule, the main indicator of a healthy lubrication system is tightness and the ability to maintain the required oil pressure in the engine.

It is for this reason that most cars have an oil pressure indicator on the instrument panel. In the event of a malfunction, the emergency oil pressure sensor sends a signal to the indicator in the cabin. Next, we will look at where the oil pressure sensor is located, what types of sensors there are, and also how to check the oil pressure sensor in the engine.

How to replace

Replacing the DDM if it breaks is a necessary operation. Without this device, further operation of the vehicle is impossible or unsafe . In addition, almost any driver can change the sensor themselves.

It is recommended to wear gloves to avoid getting your hands dirty or injured.

The replacement procedure will largely depend on the location of the device. However, in general, the main stages of the procedure take place according to established rules:

- Open the hood and wait until the engine cools down.

- Find the DDM and provide a convenient approach to it.

- Remove the contact wiring from the device.

- Use a wrench to unscrew the sensor from the mounting socket.

- Along with the sensor, you will also need to remove the aluminum ring, which served as a seal. When replacing the sensor, you will also need to change the ring.

- The new sensor is screwed with a new seal into the vacated socket.

- In some cases (replacing DDM on domestic cars), a sealant is applied to the threads of the device.

- Connect a wire to the device contacts.

- Test the new oil pressure sensor: start the engine, make sure that the oil can icon is not lit.

You will need to securely tighten the new sensor, and then check the connection for leaks