When should you clean your carburetor?

Before you clean the VAZ 2106 carburetor, you should study its design and become familiar with the main signs of failures that arise specifically because of this unit. After all, the car also has valves and a fuel pump; defects in them can also affect the stability of the internal combustion engine.

The main symptoms of a malfunction include:

- There is no idle, that is, the engine runs at high speeds of more than 800 rpm.

- The engine only runs when the gas pedal is pressed, and when released it stalls.

- The internal combustion engine operates unstably, jerkily, and vibrates strongly.

- The car will not start, although there is fuel in the pump and there is a spark.

- The smoke changed from white to black.

- Loud popping noises are heard during operation.

- Fuel consumption has increased (here is a summary table of fuel consumption for carburetor cars)

If any of the above is found on your car, then you should not put off repairing the VAZ 2106 carburetor until later. It is entirely possible to do it yourself; you just need to have the service manual in front of you when disassembling the unit.

All of the above symptoms may be the result of clogging and coating of its parts with soot, especially in front of the intake manifold. When contaminated with carbon deposits, the air damper may not close or open completely, which is why jerking occurs or the engine stalls.

In order to return the car to its previous performance characteristics, the carburetor must be thoroughly cleaned of carbon deposits and rinsed from small debris that got in with the fuel or through a clogged air filter; I reviewed the cleaning products here.

Good to know: There are several ways to repair a carburetor, but each of them involves a different level of maintenance, which can be performed in different situations. If the engine runs normally, but there are slight jerks, then cleaning is not necessary. Can be washed without disassembly. But if the internal combustion engine vibrates strongly and there is no idle speed at all, then repairs are required with disassembly and replacement of carburetor parts from a repair kit consisting of gaskets and jets.

Stages of work

- remove the VAZ 2107 carburetor. To do this, you must first remove the air filter along with the housing;

- External washing. Includes cleaning the housing from oil deposits, washing the housing channels with pure acetone or gasoline, and blowing them out of the compressor. Diffusers and emulsion wells are cleaned. All sealing elements that the carburetor contains are evaluated;

- Washing the float chamber filters;

- Washing the chamber itself;

- Cleaning jets;

- Checking the operation of the starter, float mechanism and idle mechanism.

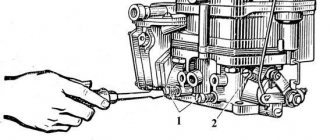

- Check the operation of the accelerator pump system. To do this, all parts are cleaned and purged with a compressor. Pay attention to how easily the ball moves in the valve - screw (9). Make sure that the pump elements move easily, namely the roller, diaphragm and lever. In this case, the diaphragm does not allow deformation.

It is worth saying that after cleaning and adjusting such an important unit as the carburetor, do not forget to pay attention to the air filter and replace it if necessary.

Types of carburetors

The technology for flushing and adjustment after repair depends on the design. Therefore, the first thing you need to do is determine which model of device is installed on your car.

Throughout the history of the existence and production of the VAZ 2106 and VAZ 2107, 3 types of carburetors were used:

| Carburetor photo | Name and description |

| DAAZ Weber - Dimitrovgrad plant produced a carburetor under license from Weber. They provided high speed, but consumed too much fuel. More than 10 per 100 km. | |

| DAAZ model “Ozone” is a second generation carburetor. It is more economical, environmentally friendly, but also complex in design, as it is equipped with a second combustion chamber. It uses a pneumatic valve, which can block the operation of the unit if it is dirty or incorrectly adjusted. Provided consumption of less than 10 liters per 100 km. | |

| DAAZ is the third modification of 21053. The device was produced under a Solex license. It is even more complex in design, since in addition to the second camera it also has feedback, which made it even more economical. But they were capricious about the quality of the fuel, because of which the jets quickly became clogged. |

Good to know: Regardless of the model, the carburetors used on the VAZ 2106 are two-chamber and consist of 3 main parts: the device cover (protects the fuel fittings from dirt), the housing (it contains chambers, diffusers, from which the mixture is transferred to the engine), lower part (the float chamber and throttle valves are located).

It is the small parts of the carburetor that play a very important role. Thanks to them, fuel enters the cylinders in certain proportions and is correctly mixed with air to form a high-quality fuel mixture.

But during operation, due to contamination with small particles or dirt, especially with regard to the accelerator pump and jets, the operating modes of the carburetor are disrupted, which leads to malfunctions and failures when pressing the gas or “sneezing” of the carburetor. Flushing consists of removing dirt from all channels and jets, thereby ensuring their stable operation.

Cleaning, cleaning carburetors 2108, 21081, 21083 Solex and 2105, 2107 Ozone

Maintenance of carburetors 2108, 21081, 21083 Solex and 2105, 2107 Ozone mainly comes down to external cleaning and internal cleaning, as well as basic settings and adjustments.

The frequency of these procedures is once a year, and then only on condition that the contamination has reached such a degree that it interferes with the operation of systems and mechanisms (moving moving parts is difficult, channels, jets, float chambers, etc. are clogged) or in a situation where sudden blockage affects the efficiency of the carburetor.

External carburetor cleaning

Washing the external surfaces of Solex and Ozone carburetors can be carried out before making adjustments or, as previously written, before annual maintenance.

To carry out external cleaning of the carburetor, you must have a can of aerosol liquid for cleaning carburetors or 0.5 liters of acetone, a small brush and a lint-free rag. We remove the air filter housing, plug the carburetor from above with a rag so that dirt does not get inside, and successively apply aerosol from a can or acetone with a brush to each outer surface of the carburetor. We wait a couple of minutes. Using a brush, carefully and thoroughly, we remove the dissolved dirt from the recesses and flat surfaces. If desired, you can additionally wipe the outer surfaces with a rag moistened with gasoline or diesel fuel. After cleaning, blow the carburetor with compressed air from a pump or compressor.

Carburetor cleaning

We will clean the channels, jets, float chamber, and fuel filter. Very often, especially when the car has been in use for long periods of time, tar deposits accumulate in the channels and jets of the carburetor, reducing their cross-section, black and brown varnish deposits accumulate on the diffusers and walls of the mixing chambers, and sediments brought from the gas tank are deposited in the mesh filter and the float chamber.

You can clean all this equipment without removing the carburetor from the car engine, except in cases where it is completely coked. To do this, purchase a can of aerosol carburetor cleaner from the store, remove the air filter housing, and start the engine. We spray it into the carburetor from above, while periodically turning the throttle valve drive lever of the first chamber by hand so that the carburetor is properly “gassed.” We repeat this operation several times, trying to get the aerosol not only into the mixing chambers, but also into the channels of the air jets of the Main dosing systems of both chambers (they are clearly visible from above).

Places for cleaning Solex and Ozone carburetors

Next in line is the idle system. With the engine running, pull out the choke so that the rpm is at least 3 thousand. We completely unscrew the solenoid valve or the holder of the fuel jet of the idle system (depending on the carburetor model). And spray the aerosol directly into the hole formed. It’s worth giving the throttle a little with your hand again. After the procedure, blow out the fuel jet in the solenoid valve or holder and screw it back in.

Solenoid valves Solex and Ozone

Next is the float chamber. To clean it, you need to remove the top part of the carburetor (its cover). Use a rag to blot off all the gasoline in the float chamber. Pour acetone into it and let it sit for a while. Use a rag to carefully remove the bulk of the dirt, and use a brush to remove the rest. On a Solex carburetor, the structure of the float chamber is not very convenient for cleaning, so you can use a thin slotted screwdriver, the blade of which is wrapped in a rag, as an additional tool for cleaning recesses and inconvenient places. After cleaning, blow out the float chamber with compressed air.

Solex and Ozone float chambers

Since the carburetor cover has been removed, it is very convenient to unscrew the fuel and air jets and remove the emulsion tubes of the main carburetor metering systems. We also remove the accelerator pump nozzle. Soak everything removed in acetone for about fifteen minutes, then blow it with compressed air and install it back.

We clean Solex and Ozone gas pumps

And finally, a fuel filter at the inlet to the carburetor. We unscrew its plug and remove it from the hole. Soak briefly in acetone and then clean with a toothbrush. We blow it out and put it back, after making sure that there is no dirt in the hole where we screw it in.

How is a carburetor repaired and flushed?

Many problems can be eliminated by flushing the carburetor, but for it to be effective, the unit must be removed from the car. After which you will need to disassemble it to the required level so that you can gain access to absolutely all elements of the mechanism.

Parts of the carburetor body 2107-1107010 in the diagram: 1 - rod of the pneumatic drive of the second throttle valve; 2 — pneumatic drive housing; 3 - diaphragm; 4 — pneumatic drive cover; 5 — fuel jet of the transition system of the second chamber; 6 — fuel nozzle body; 7 — small diffuser of the second chamber; 8 — accelerator pump nozzle; 9 — screw valve of the accelerator pump; 10 — main air jet of the second chamber; 11 — emulsion tube of the second chamber; 12 — main air jet of the first chamber; 13 — emulsion tube of the first chamber; 14 — main fuel jet of the second chamber; 15 — main fuel jet of the first chamber; 16 — accelerator pump adjusting screw; 17 — fuel jet of the idle system; 18 — fuel nozzle body; 19 — return spring of the accelerator pump; 20 — accelerator pump diaphragm; 21 — accelerator pump cover; 22 — small diffuser of the first chamber; 23 — lever return spring; 24 — three-arm air damper control lever; 25 — connection rod with the throttle valve; 26 — throttle valve return spring bracket

Repair consists of the following steps:

- Dismantling the device.

- Flushing, which includes cleaning and purging of carbon deposits and adhering dirt.

- Replacement of faulty parts.

Important: You need to remove the carburetor if you are 100% sure that the problem is in the carburetor, because the problem in other components of the car’s fuel system is also possible.

Where does carburetor repair on a VAZ 2106 car begin?

Do-it-yourself repair of a VAZ 2106 carburetor begins with its removal. To do this, you will need to remove the air filter, which will still have to be replaced with a new one, and dismantle its housing.

It is recommended to first seal the openings in the chambers with rags to prevent small objects from getting into them. After this, the hose going to the brake vacuum is removed from the pneumatic valve, the choke installation cable is unscrewed and the rod is removed from the gas pedal lever that controls the throttle valve.

If you have the latest Solex carburetor, then the wires from the throttle valve, air damper and economizer are disconnected, providing forced idle.

Next, remove the fuel supply and return hoses and the ventilation pipe. After disconnecting all suitable and supply elements, you can begin to remove the block itself. To do this, you need to unscrew the 4 fastening nuts and carefully remove the device from the studs. It is highly recommended to plug the hole in the collector with a soft rag.

Step-by-step instructions for removing the carburetor

For your convenience, I have compiled detailed step-by-step instructions for removing the carburetor from the photo:

Important to remember: Be sure to replace the gasket under the carburetor with a new one. To avoid air leaks.

What is included in the repair kit for carburetor VAZ 2106, 21061, 2121

Spare parts included in the carburetor repair kit for the VAZ 2106:

- Trigger diaphragm

- Jet body

- Idle jet - 2 pcs.

- Main air jet - 2 pcs.

- Main fuel jet - 2 pcs.

- Needle valve assembly

- Accelerator pump diaphragm

- Filter element

- Carburetor cover gasket

- Starter gasket

- Return spring

- Accelerator pump diaphragm spring

- Idle speed screw (adjustment needle)

- Ring sealing

- For R/K 2105-10, 2105-20, 2106, 2107-10, 2107-20:

- Acceleration pump nozzle

- Spray Valve

- Sprayer gasket - 2 pcs.

- Screw M5x0.8x20

- Screw M4x0.7x15

How to wash the strainer

Washing the strainer is a recommendation.

- Before you start washing the strainer, pump fuel into the carburetor using a fuel pump; naturally, this is done manually. This is done so that the required amount of fuel enters the float chamber and the closing valve closes.

- Next, unscrew the plug that holds the mesh filter, remove it, wash it (you can wash it with a solvent) and be sure to clean it with compressed air, to be sure.

- Also note that it is not recommended to clean the float chamber with a rag, since fibers from the rag can remain inside unnoticed by you and clog the fuel jets, including the idle jet.

- For cleaning, use a rubber bulb, which sucks out all the contaminants that are located at the bottom of the float chamber. Try to act carefully so as not to lift dirt from the bottom.

- After you have washed all the carburetor parts and jets, blow out all the holes and the float chamber itself with pressurized air.

- Next, check the tightness of the locking needle. To do this, connect an ordinary bulb to the inlet fitting and, pressing it, check the tightness of the shut-off valve. In this case, a pressure of 0.2 to 0.4 kgf will be created, which corresponds to the pressure created by the fuel pump.

- We create pressure and listen to whether the shut-off valve allows air to pass through. If air passes through, the valve body and needle should be replaced.

Also, do not forget to check the sizes of the jets using special gauges. For such a check, you can use drills of the required sizes.

The specifics of servicing the VAZ 2107 carburetor are very similar to the specifics of servicing carburetors of other brands of VAZ cars. We also recommend reading the article about adjusting valves on the VAZ 2106.

Nail Poroshin presents.

How to clean a VAZ 2106 carburetor without removing it

The first cleaning method is to do it without disassembling the mechanism. The fact is that not every car enthusiast is able to disassemble and reassemble the unit. A special technique was developed for its washing. For this purpose, a special aerosol product in cans is used. Common cleaners include “ABRO”, “Mannol”, here I made an overview table of carburetor cleaners, perhaps it will be useful to you when choosing.

To clean, you will need to perform the following steps sequentially:

- Warm up the engine and turn it off.

- Remove the filter and its housing.

- To effectively flush, remove the solenoid valve by unscrewing it from the housing.

- Special nozzles are sold with the cans, which effectively distribute a powerful stream of product. All visible parts are treated with the substance.

- Afterwards, process the external parts of the device.

- Next, you need to wait from 5 to 8 minutes, which depends on the manufacturer. During this time, the product dissolves carbon deposits, after which it is easily washed out with gasoline and the dirt burns in the cylinders along with the fuel.

Cleaning a VAZ 2106 carburetor is usually accompanied by replacing the gasket, which is located between the carburetor body and the manifold. The manufacturer produced several types of gaskets made of paronite, metal and heat-resistant special cardboard. If you are not sure about modifying your carburetor, then take it to the market with a real material example.

To replace the gasket, the seating area should be thoroughly cleaned of dirt and wiped with a rag. Lay the new one in the same way as the old one was laid, install the mechanism on it and tighten the fastening nuts.

How to clean the carburetor on a VAZ 2106 using a solvent

One of the most accessible ways to flush the carburetor on a VAZ 2106 is to flush the carburetor with a solvent. The washing process is clearly shown in this video:

How to quickly blow out a carburetor with your own hands

If you do not have a compressor or any other specialized equipment for purging, you will need a regular car compressor, which can be bought in a store for pennies. How to blow through a carburetor on a VAZ 2106 with a car compressor in this video:

Adjustment and routine cleaning of the carburetor on a VAZ-2107 car

All old VAZ car models were equipped with carburetors from three manufacturers: Ozon, Weber, Solex. Oddly enough, over time, the popularity of cars with carburetor engines has not decreased, but, on the contrary, has increased significantly. Carburetors, like other elements of cars, fail over time and need to be repaired, cleaned, and adjusted. To perform all these actions, certain knowledge is required, as well as free time for the motorist. Of course, you can turn to specialists, but this costs money, and since in some cases the carburetor has to be adjusted quite often, it is better to perform this operation yourself once, which will not only have a positive effect on the state of your wallet, but will also add you will have very useful knowledge in the field of the device of your car.

Carburetor settings

After flushing and disassembling the VAZ 2106 carburetor, you will need to adjust the engine performance characteristics.

There are several points for this:

- Float mechanism tongue - when the float stroke is less than 8 mm, consumption and toxicity increase, power decreases.

- Quality screw – allows you to adjust the amount of incoming air to prepare the mixture.

- Quantity screw – adjusts the amount of the finished mixture.

These two screws adjust the idle speed according to the manual. But initially they are both screwed all the way and unscrewed 3 turns.

To adjust the thrust, you will need to set the thrust; there should be a distance of 80 mm between the guides. With these settings, the throttle should open fully when the gas pedal is pressed to the floor. If this does not happen, then the throttle assembly must be cleaned.

Idle speed adjustment

After installing the carburetor on the VAZ-2107 engine, adjust the idle speed. This is done with the “quality” and “quantity” screws. The adjustment technology is as follows:

- We set the screws to the initial position, screwing them in until they stop, and then unscrewing them a certain number of turns (for a “quality” screw - 2-3 turns, and for a “quantity” screw - 3-4);

- We start the engine and warm it up to operating temperature (85 degrees);

- With the engine running, rotate the “quality” screw to set the maximum crankshaft speed at idle (without pressing the gas pedal);

- By rotating the “quantitative” screw, we further increase the speed as much as possible (it will not increase much);

- By rotating the “quality” screw in different directions, we check whether the highest speed is set (they should not increase);

- By tightening the “quality” screw, we lower the speed to the level of 800-900 rpm;

After the adjustment, we check that it was carried out correctly. To do this, sharply increase the speed with the gas pedal and release the accelerator. If the adjustment is done correctly, there will be no dips when the throttle valves are opened sharply, and the speed increase should be fast. After releasing the pedal, the speed will drop to the idle level (800-900 rpm), the power plant should not stall.

Plaque on carburetor parts

If you disassemble the carburetor to service it, you may notice a dark brown tarry coating on its internal parts, do not be alarmed. This plaque is a natural formation. It is formed as a result of the operation of forced crankcase ventilation.

And the older the engine, it has more wear, and as a result, the amount of these gases that rise in the cavity of the air filter increases, while more contamination of carburetor parts occurs. This is the relationship.

Plaque on carburetor parts and the walls that are located near them must be cleaned. But it is not necessary to clean the deposits on the walls of the neck, the walls of the dampers, and diffusers, since this deposit does not significantly affect the overall operation of the carburetor.

So don't waste your time. Although if you are a pedantic person and you have time, you can clean the carburetor to perfect cleanliness, in any case it won’t make it worse and in the future it will have a better effect on the adjustment of the VAZ 2107 carburetor.

Due to the fact that the secondary chamber of the carburetor is in operation for a short time, its secondary jet and the main air jet do not become very dirty. However, it is still necessary to check the degree of contamination.

It is recommended to do this every time you remove the carburetor cover.

It is recommended to clean the jets with either gasoline or solvent. You can use a thin wire for this.

To ensure that you do not encounter any troubles related to the operation of the carburetor along the way, every 50 - 80 thousand kilometers, check the condition of the mesh filter, which is located in the float chamber of the carburetor at the inlet.

The fact is that thanks to the effective operation of the fuel purification system of the VAZ 2107, this filter rarely becomes clogged. However, if you do not change the fine fuel filter in a timely manner, then there may be problems along the way, since this mesh filter will quickly become clogged.

All parts and cavities of the carburetor must be washed carefully. Let's say the float chamber, where there are resin deposits, it is advisable to wash it with a solvent or other effective means.

But, for example, you should only wash the diaphragms themselves and gaskets with pure gasoline, since all solvents can seriously damage them, and for this they must be washed separately.

Washing with partial disassembly

Let's consider the process of flushing a carburetor with its partial disassembly using the example of a Solex carburetor and Jet 100 Ultra. You don't need to buy a lot of it. One 200 ml can will be enough. The cost of this product is 450–500 rubles. In addition to the special liquid, you will also need:

- set of wrenches;

- Phillips and slotted screwdrivers;

- pliers;

- a container with a wide “neck” with a volume of 2–3 liters (for soaking the carburetor lid);

- a container with a wide “neck” with a volume of 0.2–0.5 l (for soaking small parts);

- kerosene (refined gasoline, acetone);

- tire pump or compressor with a tapering tip;

- toothpicks;

- old toothbrush;

- a clean, dry, lint-free cloth (preferably rough);

- a small wooden spatula (like an ice cream stick).

- Open the hood. Remove the air filter cover by unscrewing the nut with a 10mm wrench and opening the 4 spring latches.

To remove the cover you need to unscrew the nut and press the latches

Removing the air filter housing

The power wire is connected to the solenoid valve

To remove the cover, you need to unscrew five screws

The cover must be carefully removed so as not to damage the gasket.

The valve is unscrewed with a 13 key

The fuel filter is located under the plug

The jets are unscrewed with a slotted screwdriver. Below them are emulsion tubes

To remove the sprayer, you need to pry off its upper “proboscis”

Fuel jets are unscrewed with a thin slotted screwdriver

Diffusers are removed using pliers

Before cleaning, it is recommended to soak the parts in kerosene or acetone.

Apply liquid to the internal surfaces of the carburetor

The lid must be removed first from the inside, then from the outside.

After washing, the jets must be blown out with a stream of air.