Introduction

Owners of domestic vehicles, such as, for example, the VAZ-2103, quite often try to fix the car with their own hands. Despite the fact that modern service stations are located on almost every corner and by turning to qualified specialists one could avoid wasting one’s own time, many are in no hurry to solve their problems in this way. Some self-taught craftsmen independently carry out such complex operations, which include adjusting the VAZ-2103 carburetor. Of course, in order to do something like this with your own hands, you need not only free time and patience, but also important and useful knowledge regarding the design features of the device in question.

To adjust the VAZ-2103 carburetor, free time, patience and knowledge are required

In the material below, we will consider the principle of the design of the carburetor of the domestic VAZ-2103, its configuration and adjustment.

What problems in the operation of the VAZ-2105 may indicate the need to adjust its carburetor

The design solution of the carburetor on the VAZ-2105 is aimed at ensuring continuous operation of its engine. However, some circumstances can cause the device to malfunction:

- poor quality fuel;

- incorrect operation of the components of the mechanism;

- natural aging of parts, components and materials from which they are made.

The following malfunctions, which many VAZ-2105 owners may encounter, clearly signal that something is wrong with the carburetor. And it needs adjustment or even repair.

- The car, idling, suddenly stalls.

- The next time you press the gas pedal, acceleration does not occur immediately, but with a delay. Over time, isolated situations “enter” the system with a gradual increase in the interval between applying the gas and increasing the speed of the car.

- Intermittent engine operation, which becomes more noticeable in high gears.

- Increased consumption.

- It is difficult to start the engine after a long period of parking.

In all situations, experienced mechanics begin by removing the device to flush, clean, and purge jet clearances. Low-quality gasoline and failure of filters often cause clogging of the holes. Through them, the fuel mixture incorrectly enters the system, causing various problems.

The smell of fuel in the cabin or flooding of spark plugs may indicate that the carburetor of your VAZ-2105 is not working correctly and needs not just cleaning and purging, but adjustment. For beginners, it is better to turn to specialists who will competently perform all types of work. Experienced car owners do the adjustments themselves.

Kopek carburetor breakdowns

Now it’s worth considering what problems can occur in the carburetor. If suddenly the engine begins to operate unstably at idle, changes in crankshaft speed are observed, or the engine stalls if you do not press the accelerator pedal, there is no need to blame the carburetor for the troubles. In particular, this is relevant for those cases when such symptoms began to manifest themselves sharply, there were no prerequisites for this.

If a carburetor or some of its components suddenly fails, or its settings are lost, then the change in operation does not occur abruptly, but smoothly. Very often, the cause of floating idle speed is the solenoid valve, which is installed on the VAZ carburetor. If your car has a similar device in its design, then first of all you need to check it.

To do this, disconnect the wire that goes to it, and then apply plus to the valve contact from the battery. If the winding is working properly, a slight click will be heard. After this, the presence of voltage is checked on the wire that is connected to the solenoid valve. If there is no voltage, then there is damage to the wiring from the ignition switch to the solenoid valve.

Also, the symptoms described above may appear in cases where there is very large carbon deposits on the spark plug electrodes. As a result, the spark power is simply not enough to ignite the air-fuel mixture. If there is carbon deposits on the electrodes, then the carburetor itself should be blamed for this. The fact is that it supplies a lot of air-fuel mixture to the combustion chambers. The saddest reason for this is a burnt-out intake valve.

But don’t grab your head right away, first try to set the gasoline level in the VAZ 2101 carburetor. The float position must be adjusted correctly. Often the penny begins to stall and sneeze at high crankshaft speeds. The carburetor, as a rule, has nothing to do with it. The reason lies in the gasoline supply. The fuel pump diaphragm may already be worn out, but most often the fuel pump rod is worn out. You can read about it in a separate article.

Adjustment and design of the carburetor on the VAZ 2101

The carburetor on the VAZ 2101 requires periodic tuning and adjustment. Otherwise, the engine will not operate stably at idle or during acceleration. Starting difficulties may also occur. Setting up a carburetor requires some knowledge. However, knowing the technology of how the VAZ 2101 carburetor is adjusted, or as it is popularly called “Kopeyki”, you can perform the entire procedure with your own hands.

Idle speed adjustment

Adjusting the fuel system involves adjusting the idle speed at the final stage. You will need to warm up the engine for 15 minutes. Then the engine must be turned off. The quantity and quality screws are tightened until they stop. The first of them needs to be released 3 turns. The quality screw is unscrewed 5 turns.

The motor starts. The quantity screw sets the speed, which is about 800 per minute. Then the quality screw is slowly tightened. This way you can reduce the enrichment of the fuel mixture. This procedure is carried out until the speed begins to drop. After this, the quality screw must be unscrewed another half turn and fixed in this position.

Knowing how the carburetor adjustment procedure is carried out, you can do the job well yourself. The engine will operate stably, and the VAZ 2101 will operate in normal mode.

Purpose of an important node

Many motorists who have no idea how to adjust the carburetor on a VAZ-2103 simply do not understand the principle of operation and design of this device. The function of any carburetor is to mix gasoline and air together. Thanks to this simple device, a special mixture appears in the car at the moment the power unit is activated, transported into the engine cylinders. In fact, how efficiently the vehicle itself operates depends on how well the engine is supplied with gasoline.

Among other components of the device in question, it is worth noting such elements as air and throttle valves, mixing chambers and idle air valve. Of course, these are not all the components of the VAZ-2103 carburetor; in the material below we will consider in detail the operation and principle of setting each individual unit.

The function of the VAZ-2103 carburetor is to mix gasoline and air together

The functionality of any power unit that interacts with a carburetor depends on several important criteria:

- starting and warming up the engine;

- idle devices;

- design responsible for controlling the amount of fuel;

- accelerator pump (how quickly the car can accelerate depends on it);

- the performance of the elements located in the central dosing chamber;

- econostat (located in one of the internal combustion chambers of the engine).

Adjusting the performance of the accelerator pump

At the third stage, work should begin with checking the functionality of the pump. To do this, the fuel generated during ten full cycles of operation of the throttle valve control lever is collected in a special beaker. If everything is functioning normally, you will have approximately 5.25-8.75 cubic centimeters of fuel mass. Otherwise, the pump must be completely pumped (about 9-10 times), after which the check is repeated. In that situation, if bleeding does not help, the fuel pump accelerator should be replaced with a new one.

Adjusting the dampers:

The VAZ 2106 carburetor must first be removed. How to do this is described in the article:

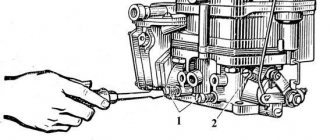

The following step-by-step photo instructions will help you understand the adjustment process:

General information about the VAZ-2105 carburetor

Listed below are basic information about the carburetors used on the 2105 VAZ model.

- Purpose. To obtain gasoline from the fuel system, mix it with air and transfer it to the engine cylinders.

- Operating modes. There are four of them: preheating, idle load, medium speed, increased power.

- Carburetor type: 2105-1107010 for engines with a power of 1.3 liters. The marking is applied to a special plate that manufacturers attach to various places on the outside of the device. The most popular modifications presented on the Russian market are DAAZ, Ozon, Solex. They are selected according to the volume of the car engine.

- A carburetor is a complex system of interconnected structural parts for various purposes. His main responsibility is to ensure correct fuel consumption and efficient engine operation.

The quality of operation of the 2105 device depends on the modification of the product, the reliability of its components, the brand and quality of gasoline, compliance of the settings with the technical requirements of the operation of the vehicle, sanitary condition, etc. Features of the functioning of carburetors affect the operation of the engine and can change the speed of acceleration and movement car, average gasoline consumption, ignition features.

Pneumatic drive of the throttle valve of the secondary chamber

Designed to smoothly turn on the main metering system of the secondary chamber (Fig. 35) and eliminate the need for strong enrichment of the combustible mixture compared to carburetors with sequential opening of the throttle valves. The pneumatic drive automatically adjusts the position of the damper depending on the speed of the engine.

Rice. 35. Pneumatic drive of the throttle valve of the secondary chamber of carburetors 2105-1107010-20 and 2105-1107010-10:

1 – pneumatic drive nozzle located in the diffuser of the primary chamber; 2 – throttle valve drive lever; 3 – lever rigidly connected to the axis of the throttle valve of the primary chamber; 4 – lever that limits the opening of the throttle valve of the secondary chamber; 5 – pneumatic drive jet located in the diffuser of the secondary mixing chamber; 6 – lever connected to lever 9 through a spring; 7 – axis of the throttle valve of the secondary chamber; 8 – pneumatic drive rod; 9 – throttle control lever of the secondary chamber; 10 – channel for supplying vacuum to the pneumatic drive; 11 – rod bushing; 12 – working cavity of the pneumatic drive.

When the throttle valve of the first chamber is open, as the load on the vehicle increases, the crankshaft rotation speed and, consequently, the vacuum in the mixing chambers decrease, and the secondary chamber valve closes. The main air flow will pass through the primary mixing chamber, improving fuel atomization. When the throttle valve control pedal of the primary chamber is sharply lowered, the primary chamber flap closes and lever 4 forcibly closes the secondary chamber throttle valve, preventing an increase in the crankshaft speed. The possibility of self-oscillation of the pneumatic drive mechanism is eliminated by connecting cavity 12 with diffusers of both the secondary and primary mixing chambers through jets 1 and 5.

The principle of setting up the VAZ-2103 carburetor

Before you begin repairing the VAZ-2103 carburetor, you should make sure that it is correctly adjusted.

If the owner of a domestic vehicle is sure that the VAZ-2103 carburetor urgently needs repair, do not rush to premature conclusions. Quite often, a simple but competent adjustment is enough for the machine to start functioning as before. Setting up such a unit, by the way, requires the knowledge of the master regarding all calibration data (set values). For carburetor tuning to be successful, it is important to adjust all components of the system. Typically, such actions should begin with external control components. You should make sure that the throttle valves are working properly: if the gas pedal is not under pressure, they should be closed. As soon as the gas pedal is pressed, the dampers should open as smoothly as possible (not jerkily).

The next step, which involves correctly setting up the VAZ-2103 carburetor, should be checking the air damper. If the drive is recessed, the structural element being tested must be vertical so that the passage leading to the throttle valve does not block.

Carburetor tuning begins with checking external control components

The accelerator pump deserves no less attention. Its functionality helps to detect sudden pedal input. The condition of the pneumatic drive diaphragm should also be determined. Only after the motorist is confident in the normal operation of the elements (after an external check), it will be necessary to spend some time cleaning the jets and sprayers. First of all, you should get rid of the cover of the device being adjusted, then, using a pump, free the float chamber from various sediments. If there is heavily hardened sediment, you can resort to a metal or wood spatula.

Proper adjustment and cleaning of the carburetor should include the absence of any rags that could clog the jet. As a result, the jets and channels will have to be flushed with clean fuel and purged with air. In order to make sure that all components are completely clean, you need to dismantle them before flushing all the channels. It is important to monitor the order in which the jets will be removed, since subsequent incorrect installation will lead to failure of the power unit. All openings can be freed from harmful accumulations with wire.

It is necessary to completely clean all components: dismantle them and wash all channels

Strainer performance

Adjusting the VAZ-2103 carburetor requires checking the strainer. This element is responsible for the cleanliness of the fuel that enters directly into the float chamber. To clean it, you will have to remove the plug and filter, then free the mesh from any unpleasant stuck particles and blow out the filter itself so that air flows in the direction opposite to the movement of fuel. In this case, any mechanical impact should be avoided.

Before you return the element to be cleaned to its place, you will have to make sure that the fuel nozzle is functioning well. If necessary, it can be blown out. Typically, the float chamber should be drained of gasoline and its needle valve should be open. Before the strainer returns to its rightful location, you need to check the sealing gasket, which can prevent fuel from leaking.

Adjusting the VAZ-2103 carburetor is not complete without cleaning the strainer

Checking the functionality of the float chamber

If you need to adjust the VAZ-2103 carburetor, you will have to pay some attention to the float chamber. If the owner of a vehicle notices increased gas consumption, most likely the reason will be hidden in the too high level of fuel that is in the system being tested. If a completely opposite malfunction is noticed (lack of gasoline), you should check the level of gasoline in the float chamber and the functioning of its needle valve.

First of all, you should get rid of the carburetor cover and, after it is in a horizontal position, adjust the gap that will be formed between the floats and the place where the device being removed will be attached to its base (the distance should not exceed 6.5 mm ). This is exactly the gap that should exist at the maximum possible level of gasoline in the float chamber. To adjust the system, you need to use the float tongue. After this, it is important to check the functionality of the needle valve by removing the float axes and dismantling the valve itself. Both elements must not have mechanical damage.

Float chamber of the VAZ-2103 carburetor

After the adjusting element of the system is installed in place, you should use a bulb to ensure that gasoline flows through the filter. The driver's task is to move freely through the needle valve. The floats should be in place, then it is important to re-pump the gasoline to make sure that there are no leaks anywhere. The result of the work should be installing the cover and checking the gasket (located in the middle between the structure and its cover). The latter must be positioned in such a way that it cannot interfere with blocking the channel and at the same time is located in the mounting holes. The lid should be tightened so that there is no overtightening (there should be no deformation). Otherwise, a deformed part of the system will cause air leaks or gasoline leakage.

It is worth noting that adjusting the VAZ-2103 carburetor is advisable only after warming up the engine and pressing the choke button.

Setting up the starter

The starting system can be configured both with the unit removed and while it is in the car.

Adjustment of the VAZ-2103 carburetor will not be complete if the motorist forgets to adjust the starting system. It is worth noting that a similar procedure can be performed both on a previously removed unit, and directly while it is in the car. If the car owner decides to adjust the starting device without removing the carburetor, he will first have to take care of dismantling the air filter, activating the power unit and slightly raising the choke. As a rule, engine speed should not fall below 3200 per minute.

As soon as the above recommendations are completed, it will be necessary to forcibly raise the air damper (at least by a third). Thanks to this manipulation, the number of revolutions should decrease by 300 units.

The clearance of the VAZ-2103 carburetor should be about 5.5 mm

There are times when such actions are not enough. The driver will have to adjust the speed using the thrust from the pneumatic drive by adjusting the length of the thrust. Adjusting the same structural element on a removed carburetor requires adjusting the distance between the opposite sides of the air damper.

If you are thinking about how to adjust the carburetor on a VAZ-2103, you should not forget about the need to take into account the gap (it should be about 5.5 mm). In view of this circumstance, you need to remove the starting unit tube and use a thin screwdriver to turn the adjusting element of the structure. If you start tightening this screw, the gap will gradually become smaller, otherwise it will become larger. If a motorist independently adjusts the carburetor of the domestic VAZ-2103, he must control the gap that remains between the throttle valve and the diffuser. This gap should not exceed 0.8 mm.

Idling of the device

If the idle speed is set correctly, the number of revolutions will not fluctuate up and down.

Often people who are interested in adjusting the VAZ-2103 carburetor mean by performing the process only adjusting the idle speed. Before you begin this procedure, you need to activate and slightly warm up the power unit (it should reach a temperature of 90 °C). As a rule, adjusting the idle speed of the device in question is impossible without the participation of two screws (quantity, as well as composition of the combustible mixture). One of the screws must be closed with a plug, after which the motor must be activated. Using the screw responsible for the amount of mixture, you should increase the engine speed to 1000 units. And use the mixture composition screw to reduce the adjustable value by 200 units. If configured correctly, the motor will function stably, vibrations should not appear, and the number of revolutions should not vary up and down.

Choosing a carburetor for the “classic”

If you are a fan of drive and want more than what the standard system gives you, then the DAAZ 21053 carburetor, manufactured under license from the French company Solex, may be suitable for you. This carburetor is the most economical and provides the best dynamics for classic engines, but it is quite difficult to find it on sale; not all sellers know about its existence. It uses a design that is fundamentally different from the designs of previous DAAZ models. A fuel reverse supply system is used here; there is an outlet through which excess gasoline is returned to the tank, this allows you to save about 500-700 grams of fuel per 100 kilometers.

Depending on the model, there may be many auxiliary electronic systems, such as: an idle system controlled by an electro-valve, an automatic choke system and others. But most of them are installed on export models; we mainly have only an idle system with an electric valve. By the way, it can give you a lot of problems, in this carburetor there are very small channels for fuel and air, and they very often become clogged, if they are not cleaned in time, then the first thing that starts to work poorly is the idle system. This carburetor uses about 6-9 liters of fuel during normal driving, while providing the best dynamics of all the units presented above, except for Webers. If you want to get the most out of the engine, but at the same time not bore yourself with unnecessary details of carburetor settings, then feel free to choose it.

Well, I have listed for you all the standard carburetors that are installed on classics without modifications, you just need to remember that if you buy a carburetor, then you need to select it according to the engine size of your car. Even if you get a good carburetor, but it is designed for a different cubic capacity, then with the help of a specialist you can change the jets in it and adjust it to your needs.

But don't think that choosing to install a carburetor ends with this list.

If you want to get even more from your car and have a good carburetor technician or can customize them yourself, then you can turn your attention to two more types of carburetors, Solex 21073 and Solex 21083:

- the first is designed for a volume of 1.7 cubic centimeters (for the Niva engine), it differs from 21053 in that it has larger channels and larger jets. After installing it, you will get even more dynamics, but fuel consumption will be 9-12 liters per 100 km. So if you want a lot of dynamics and at the same time have the money to pay for the extra expense, you can choose it.

- the second (21083) is intended for VAZ 2108-09 cars, and is installed on classic engines only with modifications, because the gas distribution systems of engines 01-07 and 08-09 are different. And if you install the carburetor as is, then at a speed of about 4000 thousand, the speed of the intake air can approach above the sound speed, which is unacceptable, the engine simply will not accelerate any further. If you want to install it, you will have to drill out the diffusers of chambers 1 and 2 to a larger size, and install slightly larger jets. All these alterations are worth doing only if you are a sincere connoisseur of the classics, as they are quite labor-intensive. The price of the alterations is consumption of less than 21,053, increase in dynamics by even more than 21,073.

We can say even more, there are single-chamber and double-chamber carburetors from imported companies, but they are, firstly, expensive, and secondly, they do not always provide better dynamics and economy than those listed above. So it’s up to you to decide what to choose and how to drive.

Sources

- https://vaz-russia.ru/remont/zamena-karbyuratora-na-vaz-2101-vaz-2107.html

- https://zarulemvaz.ru/vybor-karbyuratora-na-vaz-2101-2107/

Float system adjustment:

Before you begin this work, you need to make sure that the needle valve is working reliably.

- We take a measurement between the float and the gasket. This distance should be 6.5 millimeters. A slight deviation of 0.25 millimeters is allowed. You can also simply use a suitable drill bit to measure.

- The clearance is adjusted by changing the angle of the float tongue.

- Turn the float all the way. We measure the distance to the gasket in this position. It should be equal to 8 millimeters. Using the tongue we achieve the desired value.

Repair instructions

As a rule, carburetor adjustment is required after 7500–8000 km. If the car is not used much, then this work should be carried out at least once a year. Before tuning, thoroughly clean the spark plugs, distributor and check the wiring.

Tip: During repairs, new cuffs and jets may be needed; these parts should be purchased in advance.

List of tools and preparatory work

Adjustment does not require much physical strength, the main thing is to do everything accurately and accurately. Preparing the tool:

- set of wrenches;

- flat and Phillips screwdrivers;

- rags;

- latex gloves;

- toothpicks;

- solvent;

- pump or can of compressed air.

The first step is to remove the top cover, float and vacuum valve from the carburetor.

After unscrewing the 4 nuts, remove the top cover of the carburetor and clean the chambers

The internal chambers must be thoroughly cleaned of dust and soot residues. replacing the timing belt on a VAZ 2109. Detailed instructions for bleeding the brakes on a VAZ 2101 yourself + video. In this article you will learn how to properly bleed the brake system of a VAZ. How to properly tighten the timing belt on a VAZ 2108. We clean small holes with air using a spray can or a regular pump. Warm up the engine and set it to the handbrake.

Typical faults

The DAAZ carburetor is distinguished by some typical “diseases”. To successfully configure it, you need to see and remember its problems. This device is responsible for the dynamics characteristics of the car. Therefore, malfunctions manifest themselves in the form of any problems of this nature.

If there is a problem with this device, the engine may have difficulty starting and may sneeze.

If at least one of these problems is observed, then adjustment operations need to be performed.