The battery is charged - the starter does not turn at all

In practice, there are much more often cases when the starter struggles or shows no signs of life at all due to a discharged battery. Here the repair is as simple as a door - charged the battery and started. However, it is not so uncommon for a situation where the battery is new, fully charged, but the starter still stalls or completely refuses to do its job. This is where you should start.

How to check the battery charge level

In order for a working starter to work reliably, the battery must be charged at least 30%. This is if it is new or purchased relatively recently. If the battery is already “tired”, then being charged and at 50-60%, providing the starter with the necessary current within a few seconds may be an impossible task for it.

How can you quickly and without a specialist check whether the battery is charged and by what percentage? There are only three ways to do this:

- Voltage measurement . This method is suitable only for those cases when the battery has not received a charge for at least 8, or even 12 hours. If you recently drove a car, just started the engine, recharged the battery from a charger, this method is useless. If the battery was at rest for the specified time, then by the voltage at its terminals you can easily determine its charge level. If the device (multimeter in voltmeter mode) shows 12.7 V, the battery is 100% charged. Voltage 12.6 V is already 90% and so on. Accordingly, if the voltmeter shows 12 V, or even less, then the battery is charged 30% or less.

- Electrolyte density measurement . The advantage of this method is that to assess the charge level of the battery, you do not need to “wait” for 8-12 hours, which is necessary to equalize the voltage. The charge determined by the density of the electrolyte will be correct, even if you take the measurement directly while charging the battery from a stationary charger. This method also has one significant drawback - not all modern batteries have liquid electrolyte or access to it. A 100% charged battery will have an electrolyte density of around 1.26-1.27 units. Indicators at the level of 1.1-1.2 indicate that the battery is almost “dead”. You can also focus on a clear percentage scale, which is probably found on any car hydrometer (a device for measuring electrolyte density).

- Load fork test . Not every car enthusiast has such a device. But if there is one, the instructions for it describe in detail and clearly how to check the condition of the battery using a load plug.

- So, the battery is sufficiently charged...

But the starter still doesn't turn over

In such a situation, there can be, offhand, three reasons:

- Retractor mechanism jammed . This unit is part of the starter itself. With its help, the starter drive gear is brought into engagement with the engine flywheel. When the retractor jams, then when you try to start the engine, nothing happens at all - that is, no sounds are heard - clicking, rotation, and so on.

- Retractor mechanism failure . The node works, but does not work as it should. The retractor seems to be trying to bring the drive gear to the flywheel, over and over again. But the crankshaft does not rotate. This problem can be easily diagnosed, since if it occurs, characteristic clicking sounds or even a metallic ringing can be heard when trying to start the engine.

- Starter malfunction . When, when turning the ignition key, a clicking sound is heard once, after which nothing happens, the starter takes over or its main unit, which is a conventional electric motor, does not work. That is, the drive gear is brought into engagement with the flywheel (the same clattering sound), and this is where all the work ends. As a rule, at this moment there is a severe voltage drop in the on-board network, which can be seen by a flashing or dimming dashboard.

What to do if you experience one of the problems described is described below in the section on repairing and servicing the starter yourself.

The principle of operation of the starter and its design

If everything is in order electrically and the circuit is without damage, then it is worth dismantling the spare part for disassembly and detailed inspection in order to identify defects. But before doing this, you need to study the structure and principle of operation of a car starter.

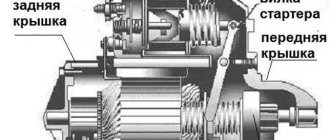

Car starter device: 1. front cover; 2. bendix; 3. gearbox; 4. anchor; 5. stator housing assembly; 6. fork; 7. solenoid relay; 8. brush assembly; 9. brushes; 10. rear cover of the car starter.

When you turn the key and start the engine, the following processes occur:

The contacts of the lock are closed and through the starter relay, power is supplied to the windings (traction and holding) of the solenoid relay.

The magnetic field in the windings forcefully pulls the armature inside the housing (compressing the return spring).

Starter operating principle

Then it begins to push the rod with the contact plate, which closes the contacts of the retractor relay, as a result of which the starter motor begins to rotate. And at the same time, the bendix moves forward from the armature, bringing its gear into engagement with the engine flywheel. Which consequently leads to the launch.

At the moment when the flywheel begins to rotate faster, is it not the Bendix gear, the overrunning clutch prevents the transmission of torque and the Bendix is pulled back by a lever and returns to its position thanks to the return spring.

The key in the ignition switch returns to its original position and the voltage at the control terminal disappears.

Based on the considered diagram, we can make assumptions about possible problems at the appropriate stages.

The battery is charged - the starter turns barely

In fact, it is quite rare that the starter does not turn at all with a normally charged battery. More often than not, it happens that he strains, makes the sounds of a dying toad, and dies without starting the engine. And the battery, with all this, feels acceptable. With such symptoms, the cause should be sought among the following five options:

- Wear of starter parts . Most often, brushes or bushings are to blame in such cases (we’ll return to them later).

- Starter clogged . In quite rare cases, water or even dirt gets inside the unit in question. All this can both complicate the operation of the electric motor and even block it altogether.

- Long downtime . If you don’t touch the car even for several days, the oil that has settled on the engine parts during operation drains and flows into the crankcase. As a result, the rubbing surfaces remain completely without lubrication; accordingly, even the most energetic tandem of battery and starter may find it difficult to turn the whole thing over. This symptom is quite normal and goes away immediately after the first successful start of the engine.

- "Tight" gearbox . Solidified or frozen transmission oil, severe wear, minor breakdowns, etc., seem to “hold” the engine crankshaft connected to the clutch. As a result, it is difficult for the starter to “carry” two units at once. The problem goes away, if not completely, then at least partially, if you depress the clutch when starting the engine.

- "Tight" engine . At first, after a major overhaul, when the new parts have not yet gotten used to each other properly, cranking the engine (especially a cold one) requires a truly titanic effort. Therefore, it is quite natural that even a vigorous starter, powered by a fully charged battery, finds it as difficult to rotate the crankshaft as it is for a cyclist going up a hill to pedal. Similar problems can arise with a technically faulty engine - something gets stuck somewhere, gets caught, and so on.

Elimination of the first two reasons is described below, and the solution to the rest is already obvious.

Why does the starter turn poorly?

Often, car owners who are faced with a problem when the starter turns sluggishly think that the battery is “to blame” (its significant wear, insufficient charge), especially if the situation occurs at negative ambient temperatures. In fact, besides the battery, there are many other reasons why the starter takes a long time to spin the engine to start it.

Many car enthusiasts do not carry out diagnostics in full and rush to buy a new battery or starter, and often this does not help them. Therefore, in order not to waste money in vain, it makes sense to figure out why the starter turns sluggishly when the battery is charged and take appropriate repair measures.

The engine is cold - the starter is “struggling”

Motorists usually encounter this kind of problem only in winter, with the onset of negative air temperatures. At the same time, the warmed-up engine is cranked by the starter cheerfully and vigorously. There are no problems in summer either.

In this situation, the reason should be sought in only two directions:

- Low battery . How to “calculate” it is described above. If this is the only problem, then it will go away immediately when the battery is recharged from a stationary charger or after the engine has been successfully started (from the generator).

- Thickened oil . When the temperature drops below the zero mark of the thermometer, any motor oil thickens - be it mineral water or synthetic. The viscosity class plays an important role, which is one of the main criteria for the selection and purchase of this consumable. If the engine oil is not selected correctly for specific climatic conditions, problems with the starter in cold conditions will continue until the end of winter.

If, however, the problem is not in the battery, then it is most likely in the oil. Apart from replacing it with an option suitable for the viscosity class, there is no other way to eliminate this reason (unless you always leave the car overnight in a heated garage, and never leave it in the cold for a long time).

The engine is hot - the starter turns sluggishly

If the starter turns the engine even when it has already warmed up to operating temperature, then you need to “dig” in the following directions:

- "Dead" battery . After several years of service or due to careless operation, the battery may not be restored even after starting the engine and generator. Or it is charging, but “gains” so few ampere-hours that there are simply not enough of them for the next job of the most powerful consumer in the car - the starter. The same applies to the strength of the starting current, which, unfortunately, decreases irrevocably in batteries over the years.

- "Tight" motor . This and the next two reasons are described above.

- Starter wear.

- Starter clogged.

- Starter malfunction.

- Poor electrical contact . Since the starter of an average production passenger car consumes 100-200 amperes of current during operation, wires of sufficient cross-section (almost as thick as a little finger) are needed to transmit it from the battery. If there is poor contact at the terminals, the power wires were incorrectly selected during repairs, broke, lost several wires, and so on, a noticeable voltage drop will occur in this area. Accordingly, the starter “will not receive” all the energy that the battery gives it, since a lot of it will be spent along the way (it will turn into useless and even dangerous thermal energy).

Whatever the cause of a stalled starter, it is fairly easy to diagnose. At the very least, most of the problems described can be identified and eliminated without any experience, simply by carefully (perhaps several times) reading this material.

The starter turns hard

The current travels from the battery to the starter a long way through the electrical network, which consists of a large number of connections and wires. During operation, oxidation processes occur, contacts and wires undergo corrosion. In addition, the wiring may burn out, which leads to disruptions in the integrity of the electrical network and interruptions or complete cessation of the supply of electric current to the starter.

Possible reasons

If the starter slips when starting, this is mainly due to damage to the contacts. First of all, you need to ring the wiring, check its integrity. Particular attention should be paid to the collector, where the wires often burn out. With prolonged use, the wiring may rot over time.