A starter is a device that starts the engine when the key is turned in the ignition or the start button is pressed. During operation, the device wears out a lot and ultimately fails.

It is generally accepted that unsuccessful attempts to start the engine are the consequences of a discharged battery. In some cases this is true, and the battery is often discharged due to a malfunction of the generator. However, most often the problem lies with the starter.

When it fails, there are several warning signs.

First news of the problem

It is quite possible that the cause may be damaged wiring or a faulty ignition switch.

If when you turn the key in the ignition switch you hear a click and nothing else happens, then the reason for this may be a discharged battery or the starter itself.

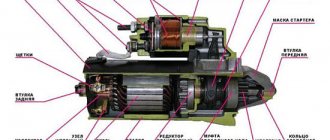

I will not describe the device and principle of operation of the starter; full information on this topic can be studied in the picture below.

Problems with the starting system can be caused by poor maintenance or simply wear and tear. With many modern vehicles equipped with a start/stop button, the load on the starter and battery has increased significantly.

What starter malfunctions do car owners most often encounter?

Possible starter malfunctions and methods for eliminating them depend on the condition of the device as a whole. Restoring a faulty unit is possible only after accurately determining the cause.

The starter does not turn on

One of the most common problems is that the starter unit does not work at all. The retractor relay clicks are not heard and the anchor element does not rotate.

Causes of the malfunction and ways to eliminate it

The device must be repaired taking into account the malfunction:

- Battery discharge or breakdown. Battery malfunction may be due to oxidation of the contacts on the clamps, destruction of the plates, or mechanical damage to the case. If the case is damaged or the plates inside the device have fallen off, the battery will need to be replaced. The problem of battery drain can be solved by recharging it.

- Oxidation of wires on the battery. To eliminate the problem, clean the tips, use a toothbrush or fine-grained sandpaper. You must act carefully so as not to remove the outer layer.

- Poor quality of tension of the tips. To eliminate the problem, the tips must be tightened to ensure quality contact.

- Disconnection or damage to the electrical circuit for connecting the solenoid relay. The malfunction must be looked for from the starter device or the ignition switch. The solution to the problem is to restore the wire by replacing it or soldering it. Troubleshooting depends on the nature of the damage.

- Interturn closure. The problem must be looked for in the winding of the solenoid relay mechanism or in a break or short to ground. The problem of interturn short circuit can only be solved by rewinding the wire on the winding or completely replacing it. The second option is more preferable, since poor-quality rewinding will not solve the problem. Opening and closing of contacts should be looked for using a multimeter by testing.

- Sticking of the retractor relay anchor device. The problem can be solved by replacing the relay.

- Malfunctions in the operation of the contact component of the ignition switch. It is not advisable to repair contacts, since such repairs often do not produce results. You will need to remove and disassemble the ignition switch, gain access to the contact part and replace it with a new one.

The ARBIX channel talked about the causes and solution to the problem if the car’s starter unit does not turn on.

The traction relay turns on, but the starter armature does not rotate or rotates too slowly

Clicks when the ignition is turned on indicate activation of the retractor relay. But the starter unit may not rotate intensively or may not rotate at all, which will not allow the engine to start.

Causes of the malfunction and ways to eliminate it

Causes of the problem:

- Battery discharge. The device requires charging.

- Oxidation of battery contacts or cable lugs installed on the clamps. The contact elements are being cleaned.

- The tightening of the fixation has loosened on the contact screws of the solenoid relay of the starter device. You need to tighten the bolts.

- Burning of the collector device. The element or the entire assembly is being replaced.

- Hanging of the brush mechanism or its critical wear. The brushes can be replaced after removing and disassembling the starter device.

- Break in the electrical circuit of the stator element or anchor device. A detailed testing of the power line is required to find the problem. The break is corrected by restoring the electrical circuit.

- Short circuit of the insulated brush assembly holder. The positive contact may short to ground.

- The appearance of a short circuit between the plate elements of the collector device. The short circuit problem can be solved by replacing the part.

- Interturn short circuit on the winding elements of the armature device or stator. The winding will need to be rewinded. A short circuit may occur between the winding contacts and ground.

Checking the operation of the traction relay:

- To diagnose the operation of the solenoid relay of the starter device, a voltmeter is connected to the power supply circuit of the part.

- A gasket is inserted between the restrictive ring and the gear of the drive device; its thickness will range from 12.8 to 15 mm. The thickness of the seal should be selected taking into account the type of starter device.

- The relay is being activated. When power is applied, the current should be no more than 23 amperes, and the voltage parameter should be 9 volts. If the obtained values are higher, this indicates a malfunction of the relay winding or the drive mechanism of the mechanism. If the value deviates from the nominal value, the winding is diagnosed for the presence of a short circuit.

The procedure for diagnosing winding short circuits is performed using a multimeter or test light:

- To perform the task, the winding output is disconnected from the solenoid relay.

- The insulated brush assembly rises.

- The electrical circuit of the non-insulated brush holder is disconnected from the shunt winding coil. To do this, you need to unscrew the bolts securing the brush component in advance.

- By means of a control light indicator, 12-volt voltage is connected to the winding terminal, as well as to the housing of the starter device. If after connection the indicator starts to light, this indicates a short to ground.

Diagnosis of the presence of a short to ground of the brushes is carried out in a similar way, only the voltage must be connected to the housing of the starter device and the insulated brush holder. To make sure that there is no short circuit in the commutator device, the brushes must be lifted and the voltage wires must be connected to the mechanism body and the commutator. When the indicator light comes on, the winding is short-circuited. Failed parts must be replaced.

User Alexander Movchan spoke about the diagnosis and repair of the traction relay of the starter unit.

The traction relay turns on and off immediately (frequently repeating knocking)

When starting the engine, it is possible that the solenoid relay will be activated, which will be indicated by clicking sounds. But after turning it on, it immediately turns off and the problem is accompanied by a repeated knocking sound.

Causes of the malfunction and ways to eliminate it

Causes of the problem and methods to resolve the problem:

- Battery discharge. Depending on the wear of the battery, it is recharged or replaced.

- The resistance parameter of the electrical circuit of the starter mechanism has increased. An increase in resistance may be due to oxidation of the clamps on the battery contacts or the tips of electrical circuits. To eliminate the malfunction, you will need to clean the contact elements. After cleaning, the clamps must be tightened tightly and treated with petroleum jelly.

- Broken ignition switch. To fix the problem, you will need to dismantle the lock, completely disassemble it and repair it. Depending on the nature of the problem, the switch may need to be replaced.

- Damage to the solenoid relay. The problem may be a break or poor contact of the fixing winding that secures the relay to the body. The solenoid relay is being replaced.

The Resta channel showed the procedure for diagnosing the traction relay of the starter mechanism.

The starter turns on, but the crankshaft does not rotate

The starter may be activated normally when trying to start the internal combustion engine. But the crankshaft does not respond to the driver’s actions and does not rotate the power unit.

Causes of the malfunction and ways to eliminate it

Briefly about the causes of the problem and options for resolving the problem:

- The clutch responsible for free movement slips. Troubleshooting involves replacing the starter mechanism drive unit.

- Failure of the clutch deactivation lever. The problem may be that it jumps out of the axis. To eliminate this, the shaft thread is washed and then treated with lubricating fluid (motor oil).

- Failure due to wear of the coupling drive ring. The buffer spring may also be damaged.

- Sticking or weak movement of the drive device on the axis of the anchor element shaft.

All the problems of starting an internal combustion engine described in this section can be solved by dismantling the starter mechanism, disassembling it and further repairing it.

The starter turns on, but the gear does not engage

When the starter is activated, the gear may not engage the flywheel. The malfunction is often accompanied by a grinding noise that is uncharacteristic of the operation of the mechanism.

Causes of the malfunction and ways to eliminate it

Details about the causes of problems:

- The starter unit is not functioning. The buffer spring may have weakened. Car owners rarely encounter such a malfunction; to eliminate it, it will be necessary to dismantle and disassemble the mechanism. If the spring is weakened, it must be replaced. Alternatively, you can completely replace the starter assembly.

- The appearance of nicks on the gear teeth of the drive device. Also, nicks may appear on the teeth of the flywheel crown. To fix the problem, you will need to use a file or other abrasive tool. If the wear of the drive device is serious, it must be replaced. The same goes for the flywheel ring gear.

- Incorrect adjustment of the gear travel of the drive device, as well as the closing moment of the contact elements on the lock. Troubleshooting involves adjusting the stroke and closing torque. It is important that the contact elements close correctly on the solenoid relay.

The MegaDetection channel spoke about the signs and causes of damage to the overrunning clutch or Bendix gear.

The starter does not turn off after starting the engine

The starter assembly can rotate and start the engine, but after the power unit starts, the mechanism does not turn off. If this happens, then long-term operation of the node cannot be allowed. You must immediately deactivate the ignition and disconnect the wire from the traction relay.

Causes of the malfunction and ways to eliminate it

Faults that may cause this problem:

- Jamming of the drive lever on the shaft of the anchor device or sticking of the contact elements of the retractor relay. A complete disassembly of the starter mechanism will be required to diagnose the problem. The malfunction can be eliminated only after the cause of the sticking has been eliminated.

- Closing of contact elements in the ignition switch. The contact component or the entire lock assembly is replaced. On many cars, the ignition switch key is used to open the trunk door, as well as the driver's door lock. If the lock or switch cylinder is changed, the new key cannot be used to open the door or trunk. The larvae on these lock products will also need to be replaced.

- Jamming of the lock itself. The solution to the problem is to change the switch device.

- A short circuit in the relay winding of the starter mechanism or jamming of the device. Restoring the operation of the unit is only possible by replacing the part with a new one.

- Distortion of the starter unit, which occurred as a result of loosening of the device’s fixation on the machine motor housing. Troubleshooting involves aligning the unit and securing it properly to the car engine.

- Damage or wear of the spring element installed in the lock. The switching device must be removed and disassembled to find the cause of the problem. If possible, replace the spring. If other components of the mechanism are faulty, the lock must be replaced.

- Physical damage or loss of performance of the return spring components of the starter assembly. We are talking about stretching parts. The reason may be the operation of the solenoid relay.

Sergey Kisiletskiy spoke in more detail about the reasons for the operation of the starter unit after the ignition is turned off using the example of classic VAZ models.

Increased noise level when rotating the starter armature

The starter mechanism can start the engine. But when the anchor device rotates, noises are observed that are uncharacteristic of the normal operation of the unit.

Causes of the malfunction and ways to eliminate it

Causes of malfunction:

- Loose starter mechanism clamp to the clutch bell. You can try to shake the knot with your hand. If play is felt, you need to tighten the nuts securing the starter to the engine with the required torque. After fastening, the engine is started for diagnostics.

- Wear of the bushings of bearing parts or journals located on the shaft of the anchor device. All components are replaced with new ones.

- Failure or partial damage to the teeth located on the gear of the drive device or the flywheel crown of the power unit. The malfunction can be diagnosed by dismantling the mechanism and visually inspecting the clutch bell hole. To fix the problem, you need to replace the flywheel, crown, or turn the latter over. To change the ring, you need to remove the used part, warm up the new one, and while it is hot, install it on the flywheel. If you turn the crown over, then before dismantling it is heated and removed, and then heated again and mounted in place.

- Damage to the cover on the drive side. The housing needs to be replaced. Finding a new one can be problematic, then a complete replacement of the unit is performed.

- The traction relay lock in the mechanism body is loose. Because of this, the gear will not move completely. The clamp will need to be tightened.

- The starter sliding clutch does not move correctly, causing the gear to not fit into place. The reason is often due to contamination of the shaft. The solution to the problem is to dismantle the starter mechanism and clean the shaft. After cleaning, it must be treated with high-quality grease. Before installing the device in place, you need to diagnose the movement of the gear.

- The problem may be the fork that moves the sliding clutch. This element may fail or become deformed during prolonged use. The plug needs to be replaced.

If a metallic ringing occurs when starting the internal combustion engine, most likely a piece has broken off from the body of the unit. There are quite a few reasons that can lead to this malfunction. It is advisable to weld a broken piece if you have welding equipment. It is difficult to find separately the so-called body beak, which usually breaks off. Therefore, it would be advisable to completely replace the housing or assembly.

If you hear a squeal and the power unit starts every other time, then the cause must be looked for in the Bendix. A bendix or overrunning clutch is used to connect the gear to the shaft of an electric motor when the internal combustion engine is started. To find the problem, you will need to dismantle and disassemble the starter mechanism.

The solution to the problem is as follows:

- The thrust bushing is pressed from the installation site. The element must be carefully removed from the axis where it is installed.

- Using a flat-blade screwdriver, pry and remove the retaining ring.

- The bendix is being dismantled. The overrunning clutch is removed from the seat along with the gear.

- Repairing Bendix in a garage is problematic and impractical. Therefore, it is replaced with a new device. Further assembly of the unit is performed in reverse order.

Useful recommendations for diagnosing the starter device are provided by the HF Autoelectrics channel.

The starter continues to operate after the engine starts

When the engine starts and you release the ignition key, the power supply to the traction relay stops and the bendix returns to its original position under the action of a spring.

If power continues to flow, this most likely indicates soldering of the main contacts in the solenoid.

The first thing to do is exclude the battery and generator from the list of possible causes.

Don't forget that the starter only works properly if the battery is fully (or sufficiently) charged.

Therefore, if the engine does not start, try starting it from an external power source using special connecting wires or use a jump starter.

After a successful start, it becomes clear that the problem lies in the electrical system.

Checking the starter retractor relay and troubleshooting

Welcome, friends, to the DIY car repair website. Almost every driver, at least once in his life, has encountered a problem related to starting a car engine.

Usually the problem is solved by simply recharging the battery or cleaning the contact connections. The situation is much worse when the cause of engine failure is hidden in a malfunction of the solenoid relay or the starter itself.

This is interesting: Setting up the carburetor on an Alpha moped

Starter solenoid relay

A new problem arises for the motorist - how to check the starter solenoid relay, identify the fault and, if possible, repair it at home, with your own hands.

Last attempt to start the starter

When trying to turn the key in the ignition switch, one faint click is heard. There is one trick that can help. It may sound strange, but if you press down on the back of the starter while turning the ignition key, the engine can start.

After asking a friend to turn the key in the ignition, press the starter with a hammer. Even if the engine starts, the starter should be repaired or replaced immediately.

Repair of starter retractor relay

If you have come to the conclusion that the starter traction relay has failed, you need to repair it. We would like to note right away that in most cases it is much easier to replace this element than to restore its functionality.

Many manufacturers produce non-separable relays in order to make this unit the most reliable. In such situations, you will simply have to replace the solenoid relay with a new one. If the starter in your car is equipped with a detachable relay, you can repair it yourself. Often the relay does not work for the following reasons:

- the mechanical drive has worn out and failed;

- a short circuit has occurred in the winding;

- “nickels” or contacts were burnt.

Each of the above faults can be determined after disassembly. True, to determine the integrity of the windings you will have to use an ohmmeter. When measuring the resistance between the ends of the wire and the body, this indicator should be at least 10 kOhm. Otherwise, the windings have shorted, so you will need to go to the store for a new relay.

Installation of a new or restored relay is carried out in the reverse order of dismantling. Many car enthusiasts at this stage have a problem, which is how to connect the starter relay. In order to avoid such troubles, we recommend that you first mark the disconnected terminals. Before installing the relay, be sure to thoroughly clean the contacts and degrease them.

This is interesting: The carburetor jerks when accelerating the VAZ 2107

How to check if the starter is taking current

It happens that when the starter is started, the light bulbs powered from the on-board network dim, the volts drop to 10-9.5 - there are signs that there is a current drawdown. This is a very real picture even in the warm season, and it indicates a malfunction of the starter. Many people do not understand how to check the starter if it takes on a lot of starting current, and what, in fact, is the reason for this phenomenon.

Most likely, the reason is the wear of the bushings, which is why the armature begins to touch when the stator rotates. This leads to overheating of the elements and destruction of parts. There is a risk of an interturn short circuit, which can only be detected with a special device - a megger. The bushings must be replaced, and the anchor can be replaced if necessary. Another cause of jamming is sometimes the internal gearbox, which requires lubrication.

If the starter is not working correctly, it is better to contact a trusted specialist who can determine the true cause of the breakdown.

Having summed up all the above tips, it is appropriate to highlight some recommendations from professionals. For example, when several starter parts or even the solenoid relay fail, it is best to purchase and install a completely new starter. Otherwise, the device can be disturbed more than once over all sorts of trifles, not to mention possible inconsistencies in the sizes of some spare parts.

Experts also strongly advise buying new parts rather than repairing old ones, and not giving preference to the cheapest options. Such savings can be completely offset by the negative consequences resulting from early breakdowns.

We will answer your questions for FREE regarding deprivation of rights, road accidents, insurance compensation, driving into the oncoming lane, etc. Daily from 9.00 to 21.00

Moscow and Moscow region

St. Petersburg and Leningrad region

Free call within Russia 8-800-350-23-69 ext.418