Characteristic

Every car has an ignition system. However, it's not just spark plugs, a coil and armored wires. This system also includes a starter. The VAZ-2115 is also equipped with it. On Samara-2 cars it is of a gear type. The element is assembled with a traction relay and a drive mechanism.

The starter interacts with the ignition switch and the engine, being a kind of intermediate link. The main purpose of the element is to create the necessary torque for the engine, which will give the internal combustion engine the ability to work independently.

The starter does not work after turning the ignition key

During the operation of vehicles, regardless of the type of engine installed, a common malfunction is starter failure, as a result of which it is not possible to start the engine after turning on the ignition. In other words, the car starter does not respond to turning the key in the ignition switch. In such situations, after turning the key, instead of cranking the engine crankshaft, the starter is completely silent, buzzes or makes clicks, but does not turn the engine. Next, we will look at the main malfunctions when the starter does not respond in any way to turning the key in the ignition, as well as other reasons that may cause the starter to not work.

Device

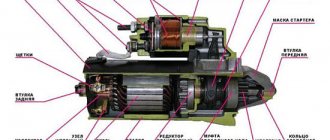

The VAZ-2115 starter itself consists of the following elements:

- Stator.

- Rotor (armature).

- Contact plate.

- Brushes with holder.

- Traction relay.

- Drive mechanism.

Power is supplied to the starter windings through a traction relay. So, when you turn the ignition key, a starting current (about 500 amperes) flows from the battery to the relay. Next, this mechanism moves the drive element.

The engagement includes the starter drive gear and the flywheel ring gear. A few revolutions are enough for the unit to start successfully (of course, if you have a working starter). VAZ-2115 has a simple design of this element. However, malfunctions with it should not be ruled out. So, let's look at why the starter on a VAZ-2115 car does not start and what to do about it.

Doesn't turn at all

If, when you turn on the ignition, the armature does not rotate and the traction relay does not operate, check the voltage in the battery. A minimum of 12 volts is required to start successfully. The starter takes a lot of energy from the battery. That's why it's so important to keep it in good condition. There are several ways to check the voltage on the battery. The best method is a multimeter. When the contacts are closed, the device will display the result. But if there is no such device, and there is no voltage indicator on the panel, you can use the old-fashioned method. To do this, take a 12-volt car light bulb and a pair of wires. With bare contacts it is closed to the terminals. If the voltage is 12 volts, it will light up properly. Anything less will burn very dimly.

The next reason why the traction relay does not turn on is loosely tightened wire tips (both on the battery side and on the starter side). Perhaps the contacts have oxidized there. Use a special cleaner or sandpaper. Experts do not rule out a break in the pull-in winding. If cleaning the contacts does not help and the starter does not turn, the VAZ-2115 requires replacing the traction relay. We'll look at how to do this at the end of the article.

Possible causes of problems with the starter

Conventionally, we can divide the causes of failure into two main groups, based on the signs of which it is possible to diagnose and identify a non-functioning link in the entire chain.

The first group of cases is characterized by the fact that the starter does not turn after turning the key, but the retractor relay is activated with a characteristic click, and the indicators on the instrument panel blink. First of all, this is typical for a dead battery if the car owner forgot to turn on electrical appliances in the car for a long time or left the car in severe frost.

Starter armature wear

The problem is solved by externally charging the battery or “lighting it” from another car, followed by charging the battery from the generator.

The problem may also be in the contacts themselves: severe oxidation or insufficient contact at the terminals and terminals of the relay can provoke increased resistance and, as a result, a lack of energy to crank the electric motor. All of these areas should be cleaned, lubricated and thoroughly tightened regularly.

In addition, there is some possibility that the contacts melt inside the solenoid relay, leading to significant voltage losses in the electric motor. More rare causes include excessive wear of the contact brushes of the electric motor or a short circuit of its winding - all this can be solved by replacing the corresponding components.

Worn starter brushes

The second group of factors due to which the starter on a VAZ 2114 does not work (when even the relay does not click, but the indicators on the panel are on) include reasons such as:

- The usual failure of the power supply fuse, which can easily be replaced with a new one.

- Burning of the contact group of the ignition switch, interfering with the closure of the circuit - in such a situation, you can identify the problem by connecting the output to the solenoid relay with any conductor: if the starter starts to turn.

- There is a problem with the lock.

- Short circuit of the winding to the relay, checked using the same method.

- An armature wedge, due to which it is not drawn in by the magnetic field and does not close the electrical circuit. To solve the problem, you will need to disassemble and clean the relay.

Bushing wear

Sometimes there are situations in which the cover of the relay itself is damaged - this leads to the armature spring losing support and, as a consequence, to the fact that the latter begins to move arbitrarily, from time to time closing the contacts and starting the starter.

An even more specific problem that the starter does not work on a VAZ 2114 is, in fact, a malfunction in its position: the bolts, when loosened, lead to the device being skewed and losing contact with the flywheel. Long-term use of the Lada can even lead to such severe wear of the gear that its teeth crumble and break off, which leads to a complete or partial loss of adhesion to the flywheel.

Replacing starter brushes for VAZ 2114

Noise when rotating armature

In this case, check the condition of the drive shaft and armature bearing liners. Replace worn elements. The starter may have become loose or its cover at one end may be broken. Because of this, the mechanism works incorrectly. Inspect the flywheel itself. There should be no wear on its teeth. If present, the flywheel needs to be replaced. It happens that the gear does not disengage with it. In this case, the cause of the malfunction is in the clutch. It jams on the shaft splines. The VAZ-2115 starter relay can work normally. Clean the splines and treat them with oil. This helps eliminate jamming.

What should be done in this case?

If the starter stops working during a trip, you can start the engine without it, but such operation of the car is only relevant to complete the trip, after which the problem should be troubleshooted. When the VAZ 2115 injector starter does not turn, it is necessary to check the condition of the battery, as well as the fuses . Perhaps a short circuit occurred due to moisture, which subsequently led to the fuse blowing and the starter not working. Then you will need to replace the burnt fuse; if it is missing, put foil in place of the burnt thread. This will allow you to continue moving and if the wiring closes again, it will work as expected.

How to change a relay with your own hands?

To do this, we need to de-energize the on-board network - remove the terminals from the battery. Next, clean the surface of the starter from dust and dirt. Unscrew the nut from the relay and remove its contact. Unscrew the bolts securing the relay to the starter body. After this, remove the nuts from the end.

Next, you need to dismantle the old core and put a new one in its place. All elements are assembled in reverse order. It is important to check the operation of the new device immediately after repair. We install the starter in place, pump up the terminals and start the engine. The engine should start with half a turn (provided the battery is normally charged).

Lada 2115 Moskvichka › Logbook › Emergency, the starter does not turn (Solved)

2 months ago) was on a cold one.

Who thinks what? Electrical? Thoughts on the b-pump: I have an internal debate. On the one hand, it is impossible to drive with a non-working pump (there is no gasoline in the combustion chamber), but on the other hand, fuel may well come from the main line under the influence of a pressure difference! That is, it started from the pusher and then, by inertia, the engine itself pulls out of the line. Tell me I'm wrong =((

===========*=*============ Day 4. I went out to try, as a result, the first start with half a turn, I turned it off and that’s it, attempts to start it failed. I am leaning towards the retractor relay (because this is the only part that can work according to the principle that explains the situation as simply as possible, namely, the return spring has screwed up...

===========*=*============ Day 5. The situation has already begun to get out of control, namely: I leave work at 21:15 (the car was parked from 9:50, that is, idle time for almost 12 hours, everything that could reject it should have done it) and at least henna. Not only that, in the morning I was afraid to even go to a gas station - I poured

4 liters from a canister and was driving with the BC showing a decrease from 5 liters to 0 several times (yes, I have a problem with the fuel sensor, I haven’t gotten around to it yet) and thinking that stalling in the middle of the highway or in the left lane in the city would be very cool, don’t leave yet. Thanks to the man in the cruiser for being the only one standing in the parking lot at the gribanal. I even wanted to help push him manually out of a parking space. In general, I got home with 10 liters of gasoline, according to bk xD

Day 6. Finally I went to the electrician and found him 5 minutes before lunch. He was not happy with the fact that this was my fourth day with the starter. Service station "Quartet" in Gatchina - I recommend it! And here’s why: the man removed the starter from the car, together with me in his car he went to a friend’s modest workshop at the car wash for “starter repair”, etc., they quickly found brushes for me (so that I wouldn’t have to go shopping for another two days with a chance to buy a new starter ), because the old ones were almost completely erased (actually the basis of the problems!), they lubricated the rotor (the engine was dry as a rag in the trunk) and after checking, they loaded the electrics into the car. The guy went on business, dropping me off almost home. In the evening I calmly arrived at the designated time and everything was installed in 10 minutes. During the installation process, I found out exactly where the external temperature sensor is located (I want it to work, but my search in Murzilka was unsuccessful) and the belt whistle was eliminated! *The fact is that I did not have an adjusting “corner”. At Piter-lad they asked for 1000+ rubles for its installation and work (at that time I didn’t know what it was) and to leave the car until the morning, because they didn’t have the parts. Having politely refused, I decided to ride with an unpleasant, but free sound effect. * The electrician casually found a used “corner” lying around, got two bolts and nuts for it from a colleague and screwed it into its rightful place (I thought he would just hand it to me).

Result: with the starter 600 RUR starter repair 600 RUR starter brushes 200 RUR Belt adjustment as a gift!

Source

What else do you need to know about relays?

Since the starter consumes quite a powerful current, the integrity of its elements should be checked every 100 thousand kilometers or every 3 years. During this time, slight fluctuations in voltage may occur in the mechanism, which can cause the relay to fail.

You can check its functionality by a characteristic click. It happens that when starting, the starter continues to work. In this case, you will hear a sharp squeal. This indicates that the retractor has failed. The mechanism cannot return to its reverse position.