In the last few years, equipping cars with an anti-lock braking system or simply ABS has become fashionable among famous manufacturers. According to various sources, about two thirds of all cars produced today are equipped with ABS, and there is a tendency for this technology to break through even into inexpensive basic versions of cars.

ABS system

Why did manufacturers decide to install the recently outlandish ABS system on most of their cars, and what benefits does such a technological spice provide to your car?

When was the anti-lock braking system introduced?

ABS was first tested in 1920 on aircraft landing gear. In aviation, to this day, every aircraft is equipped with a number of braking systems, including anti-lock braking systems.

The first workable version of the anti-lock braking system in automobile transport was tested by the German concern Daimler-Benz. Close on his heels was the engineering giant Bosch. Anti-lock braking systems, which were first installed commercially on the Mercedes S-Class and BMW 7 Series in 1978, were developed jointly by these corporations.

Since 2004, all European cars have had ABS as standard.

Why is ABS needed and how to drive with it?

A car's anti-lock braking system is a unique addition to your car's brakes. During hard braking, ABS helps maintain stability and brake faster, because the system prevents the pads from fully pressing the brake disc. This prevents the wheel from blocking when braking, reducing the chances of the car going into an uncontrolled skid.

ABS allows you to control braking on slippery roads - this is its main purpose. The system will also assist the driver during sudden braking. The presence of this system on board the car does not require any special driving skills from the driver. ABS makes life easier for the driver in difficult situations. In normal road conditions, control over the brakes is completely left to the driver.

For an inexperienced driver, the presence of an anti-lock braking system in a car is an excellent aid in mastering all the subtleties of driving skills. A person with extensive driving experience can independently control the moment when the wheels begin to lock, while weakening the braking force. With ABS present, you can simply press the brake pedal with maximum force - this will ensure effective braking.

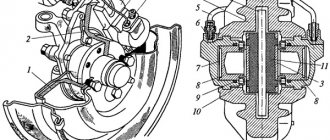

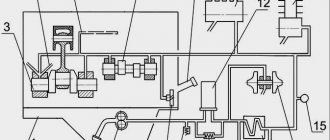

Anti-lock braking system - diagram

- compensation tank

- vacuum brake booster

- brake pedal position sensor

- brake pressure sensor

- Control block

- return pump

- pressure accumulator

- damping chamber

- front left brake inlet valve

- front left brake actuator release valve

- rear right brake actuator inlet valve

- rear right brake actuator exhaust valve

- front right brake actuator inlet valve

- front right brake actuator release valve

- rear left brake actuator inlet valve

- rear left brake actuator release valve

- front left brake cylinder

- front left wheel speed sensor

- front right brake cylinder

- front right wheel speed sensor

- rear left brake cylinder

- rear left wheel speed sensor

- rear right brake cylinder

- rear right wheel speed sensor

How does this ABS work?

The design of the system is relatively simple. The work is based on two speed indicators: the speed of rotation of the wheel and the speed of the vehicle.

Special sensors always compare these two indicators as soon as the driver presses the brake pedal. If one or more wheels begin to lock, that is, their rotation speed becomes less than the speed of the vehicle, the ABS is activated and artificially reduces the brake pressure on the wheel that caused the problem. As soon as the wheel speed is restored, the sensors give the command to again transfer the braking force to the hands (or rather, to the legs) of the driver.

The ABS system switches on/off automatically up to 30 times per second. Therefore, while the anti-lock braking system is operating, the driver feels a slight beating on the brake pedal. This factor suggests that the operation of the braking system is corrected by the anti-lock braking system.

In addition to the anti-lock braking system, high-spec cars include a number of other technical innovations: traction control, emergency braking assistance, and directional stability control. All these technological gadgets come from ABS and are essentially just assistants to the main anti-lock braking system.

Video: ABS operating principle.

Scope of application of the anti-lock braking system

Today, ABS is used wherever there are wheeled vehicles. Unless they have yet decided to install them on warehouse forklifts. The first area of use of the anti-lock braking system, as mentioned above, was aviation. When landing, the plane begins to move along the asphalt at tremendous speed. The absence of ABS would require a significantly longer braking distance than at current airports, and safety would be less.

In addition to cars, ABS is also installed on motorcycles, ATVs and even trailers. Trucks would not be able to transport trailers with cargo on difficult winter roads if it were not for the help of an anti-lock braking system.

There is a lot of controversy and discussion surrounding the use of ABS today. Experienced drivers sometimes claim that this is a useless technical innovation that overloads the braking system. But hundreds of thousands of drivers who have managed to avoid unwanted consequences in difficult driving situations thanks to ABS will tell you the opposite.

ABS: our insurance against troubles

Imagine the situation: you are driving a car along a country road, enjoying the surrounding nature. Moving ahead at a short distance is a truck, the body of which is filled with some boxes and rubbish. Suddenly, jumping on a bump, he loses one of the boxes, and it falls right in front of your car.

We recommend: The best synthetic, semi-synthetic and mineral gear oils in 2021

What to do?

Of course, the driver’s first reaction in this situation is to try to brake and at the same time go around the obstacle.

And now, the culmination of the story - if your car is equipped with ABS, then it is quite easy to perform such a maneuver, but if this system is not there, then it is likely that a sharp blow on the brake pedal will lock the wheels, and the car will turn into an uncontrollable projectile, and this promises an unpleasant encounter with a dropped box.

As you already understand, ABS is not just a useful option, but simply a necessary system on which the safety of the driver and everyone in the car depends.

In addition to the fact that the anti-lock braking system helps maintain control of the vehicle in situations similar to the one described above, it also significantly reduces braking distance, improves maneuverability in difficult weather conditions and even helps save tires.

How the system works

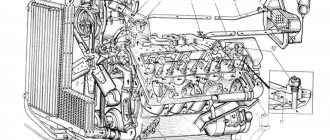

ABS system diagram

The anti-lock braking system performs its work cyclically, with each cycle consisting of three phases:

- Pressure increase (driver) . Braking occurs in normal mode, the pressure in the system increases as the driver presses the brake pedal. The inlet valves of the valve body are open, the exhaust valves are closed. If the wheel speed slows down too much and exceeds a certain value, the ABS control unit moves the intake valve to the “closed” position, and the exhaust valve is also closed. The system moves to the next phase.

- Holding pressure . At this stage, the ABS system, as it were, “cuts off” the main brake cylinder from the braking process, and a constant pressure is maintained in the “hydraulic unit - wheel brake working cylinder” circuit. Even if the driver presses the brake pedal further, the pressure will not increase. In this mode, braking occurs at maximum braking force, that is, most effectively. The control unit continues to monitor the speed of rotation of the wheels, and if it decreases below the permissible threshold, that is, there is a threat of wheel locking, a command will be sent to open the exhaust valve and relieve pressure.

- Pressure release . During this phase, the exhaust valve opens and the pressure drops sharply. First, the liquid enters the hydraulic accumulator, then it is pumped back to the GTZ by a pump. The inlet valve remains in the closed position. After the wheel deceleration speed returns to acceptable values, the exhaust valve closes. The intake valve opens and the cycle begins all over again.

There is a fairly common misconception that ABS independently increases the pressure in the brake system. In fact, this is not the case when it comes to the ABS system in its pure form (without ESP). The pressure in it increases solely due to the actions of the driver.

This cycle of operation of the vehicle's anti-lock braking system is repeated until braking is completed, and can be repeated approximately 6 times per second. Note that ABS is activated during emergency (sharp) braking. It is impossible to disable the ABS system without interfering with the car's design, since stopping its operation can lead to tragic consequences (therefore it is not provided for by automakers).

Note that ABS is integrated into the standard braking system of the car without changing it structurally. If the vehicle's anti-lock braking system is faulty, the corresponding indicator (warning lamp) will light up on the instrument panel.

Useful tips

If in developed countries cars without ABS are practically never found, then in the CIS there are quite a few such cars traveling on the roads (domestic auto industry, old foreign cars, some new ultra-budget models, etc.). Also, on many cars this system simply does not work, and the owners are in no hurry to fix the problem.

In any case, understanding why ABS is needed, what it is and how it works, allows us to give some recommendations to drivers who do not have such a system. Of course, if ABS is a guarantee that the wheels will not lock, then the absence of such a system means that the driver needs to acquire certain emergency braking skills.

We also recommend reading the article about whether you need to bleed your brakes after replacing the pads. From this article you will learn when it is necessary to bleed the brakes after replacing the brake pads, and also whether this procedure is required.

In other words, the operation of ABS can be replaced by intermittent braking, pressing the pedal with frequent pumping and jolting. Of course, in an emergency it is difficult to use such a technique, since the driver instinctively presses the brake with all his might without removing his foot.

If the situation is predictable, then this technique is similar to the operation of a single-channel ABS. Intermittent braking will allow you to brake with sufficient efficiency and at the same time maintain control during braking.

Purpose and device of ABS

Anti-lock braking systems (ABS) are designed to provide constant control over the traction force of the wheels and the road and accordingly adjust the braking force applied to each wheel at any given moment. ABS redistributes the pressure in the branches of the hydraulic drive of the wheel brakes so as to prevent wheel locking and at the same time achieve maximum braking force without losing vehicle controllability.

The main task of ABS is to maintain the relative slip of the wheels within narrow limits near λkp during braking. This ensures optimal braking performance. For this purpose, it is necessary to automatically regulate the braking torque supplied to the wheels during braking.

Many different ABS designs have appeared that solve the problem of automatically controlling the braking torque. Regardless of the design, any ABS must include the following elements:

- sensors whose function is to provide information, depending on the adopted control system, about the angular speed of the wheel, the pressure of the working fluid in the brake drive, vehicle deceleration, etc.

- a control unit, usually electronic, which receives information from sensors, which, after logical processing of the received information, gives a command to the actuators

- actuators (pressure modulators), which, depending on the command received from the control unit, reduce, increase or maintain a constant level of pressure in the wheel brake drive

Rice. ABS control circuit: 1 – actuator; 2 – main brake cylinder; 3 – wheel brake cylinder; 4 – control unit; 5 – wheel speed sensor

The process of regulating wheel braking using ABS is cyclical. This is due to the inertia of the wheel itself, the drive, as well as the ABS elements. The quality of regulation is assessed by how much the ABS ensures the sliding of the braking wheel within specified limits. With a large range of cyclic pressure fluctuations, comfort during braking (jerking) is disrupted, and vehicle elements experience additional stress. The quality of ABS operation depends on the adopted regulation principle, as well as on the speed of the system as a whole. The response speed determines the cyclic frequency of change of the braking torque. An important property of ABS should be the ability to adapt to changes in braking conditions (adaptability) and, first of all, to changes in the coefficient of adhesion during braking.

A large number of principles (functioning algorithms) have been developed according to which ABS operate. They vary in complexity, cost of implementation and the degree to which the requirements are met. Among them, the most widely used algorithm is the function of slowing down the braking wheel.

The braking dynamics of a car with ABS depends on the adopted installation scheme for the elements of this system. From the point of view of braking efficiency, the best scheme is with autonomous control of each wheel. To do this, it is necessary to install a sensor on each wheel, and a pressure modulator and a control unit in the brake drive. This scheme is the most complex and expensive.

We recommend: What is a carburetor: device and purpose

There are simpler ABS schemes. Figure b shows an ABS diagram with adjustable braking of the two rear wheels. For this purpose, two wheel angular velocity sensors and one control unit are used. In this scheme, the so-called low- or high-threshold regulation is used. Low-threshold regulation involves controlling the braking wheel, which is in the worst traction conditions (the “weak” wheel). In this case, the braking capabilities of the “strong” wheel are underutilized, but equality of braking forces is created, which helps maintain directional stability when braking with a slight decrease in braking efficiency. High-threshold control, i.e. control of the wheel in the best traction conditions, gives higher braking efficiency, although stability is slightly reduced. With this control method, the “weak” wheel is cyclically blocked.

Rice. Schemes for installing ABS on a car

An even simpler diagram is shown in Figure c. It uses one angular velocity sensor located on the propeller shaft, one pressure modulator and one control unit. Compared to the previous one, this scheme has less sensitivity.

Figure d shows a diagram in which angular velocity sensors are used on each wheel, two modulators, and two control units. In such a scheme, both low- and high-threshold regulation can be used. Often in such schemes mixed control is used (for example, low-threshold for the wheels of the front axle and high-threshold for the wheels of the rear axle). In terms of complexity and cost, this scheme occupies an intermediate position between those considered.

The ABS operation process can take place in a two- or three-phase cycle.

With a two-phase cycle:

- first phase – pressure increase

- second phase – pressure release

With a three-phase cycle:

- first phase – pressure increase

- second phase – pressure release

- third phase – maintaining pressure at a constant level

When installing ABS on a passenger car, closed and open hydraulic brake actuators are possible.

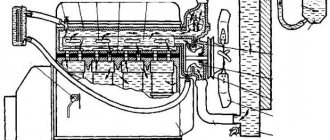

Rice. Diagram of the pressure modulator of the hydrostatic brake drive

A closed or closed (hydrostatic) drive operates on the principle of changing the volume of the brake system during braking. This drive differs from a conventional one by installing a pressure modulator with an additional chamber. The modulator operates in a two-phase cycle:

- The first phase is pressure increase; the winding of electromagnet 1 is disconnected from the current source. Anchor 3 with plunger 4 is under the action of spring 2 in the extreme right position. Valve 6 is pressed away from its seat by spring 5. When you press the brake pedal, the fluid pressure created in the master cylinder (pin II) is transmitted through pin I to the brake wheel cylinders. The braking torque increases.

- The second phase is pressure relief: the control unit connects the winding of electromagnet 1 to the power source. Armature 3 with plunger 4 moves to the left, thereby increasing the volume of chamber 7. At the same time, valve 6 also moves to the left, blocking output I to the working brake cylinders of the wheels. Due to the increase in the volume of chamber 7, the pressure in the working cylinders drops and the braking torque decreases. Next, the control unit gives a command to increase pressure, and the cycle repeats.

An open or open hydraulic brake actuator (high pressure actuator) has an external power source in the form of a high pressure hydraulic pump, usually in combination with a hydraulic accumulator.

Currently, preference is given to a high-pressure hydraulic drive, which is more complex than a hydrostatic one, but has the necessary speed.

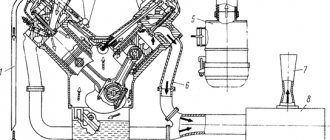

Rice. Double-circuit brake drive with ABS: 1 – wheel angular speed sensor; 2 – modulators; 3 – control units; 4 – hydraulic accumulators; 5 – check valves; 6 – control valve; 7 – high pressure hydraulic pump; 8 – drain tank

The brake drive has two circuits, so it is necessary to install two autonomous hydraulic accumulators. The pressure in the hydraulic accumulators is maintained at 14…15 MPa. A two-section control valve is used here, providing a follow-up action, i.e. proportionality between the force on the brake pedal and the pressure in the brake system. When you press the brake pedal, pressure from the hydraulic accumulators is transferred to modulators 2, which are automatically controlled by electronic units 3, receiving information from wheel sensors 1. The figure shows a diagram of a two-phase spool pressure modulator for a high-pressure hydraulic brake drive. Let's consider the phases of operation of this modulator:

- Pressure rise phase 1: The ABS control unit disconnects the solenoid coil from the power source. The spool and solenoid armature are moved to the upper position by spring force. When you press the brake pedal, the control valve communicates with the hydraulic accumulator (pin I) with the discharge channel of the pressure modulator. Brake fluid under pressure flows through port II to the working cylinders of the brake mechanisms. The braking torque increases.

- Pressure Relief Phase 2: The control unit communicates the solenoid coil with the power source. The solenoid armature moves the spool to the down position. The supply of brake fluid to the working cylinders is interrupted: outlet II of the working brake cylinders communicates with drain channel III. The braking torque is reduced. The control unit commands the pressure to increase, disconnecting the solenoid coil from the power source, and the cycle repeats.

Rice. Scheme of operation of a two-phase high-pressure modulator: a – phase 1; b – phase 2

Currently, ABS operating on a three-phase cycle are more common. An example of such a system is the fairly common ABS 2S system from Bosch.

This system is integrated as an additional system into the conventional braking system. Between the main brake cylinder and the wheel cylinders, injection (H) and unloading (P) solenoid valves are installed, which either maintain a constant level or reduce the pressure in the wheel drives or circuits. The solenoid valves are driven by a control unit that processes information from the four wheel sensors.

The control unit, which continuously receives data on the rotation speed of each wheel and its changes, determines the moment the blockage occurs, then, if necessary, releases the pressure and turns on the hydraulic pump, which returns part of the brake fluid back to the master cylinder feed tank.

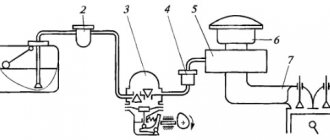

Rice. Functional diagram of ABS Bosch 2S: 1 – control unit; 2 – modulator; 3 – main brake cylinder; 4 – tank; 5 – electric hydraulic pump; 6 — wheel cylinder; 7 – wheel sensor rotor; 8 – wheel inductive sensor; 9 – signal lamp; 10 – brake force regulator; N/R – discharge and discharge solenoid valves; — .-. CU input signals; - - - - CU output signals; –––– brake pipe

The ABS modulator contains solenoid valves, a hydraulic pump with fluid pressure accumulators, a solenoid valve relay and a hydraulic pump relay.

Rice. Electrohydraulic modulator: 1 – solenoid valves; 2 – hydraulic pump relay; 3 – solenoid valve relay; 4 – electrical connector; 5 – electric motor of the hydraulic pump; 6 – radial piston element of the pump; 7 – pressure accumulator; 8 – muffler

The system operates according to a program divided into three phases: 1 – normal or normal braking; 2 – maintaining pressure at a constant level; 3 – pressure release.

We recommend: Passenger car body types: pickup, station wagon, coupe, sedan

The ABS system consists of:

- hydraulic block;

- control unit;

- wheel brakes;

- sensor speed sensors.

ABS system

as you understand, it is a control unit; it receives signals that come from touch sensors in the form of the number of wheel revolutions. After this, the received data is processed and, based on it, the block makes a conclusion about whether the wheel is slipping or not, slowing down or accelerating. Decision making occurs at lightning speed, after which a signal is received in the form of a command to the magnetic valves of the hydraulic unit, which actually execute these commands.

Video about safe braking

Finally, the second mode is a balance between the previous one, ideal for classic road driving.

Full instrument panel. It includes speedometer, speedometer, odometer, two trip meters, transmission speed, coolant temperature, ambient temperature, autonomy, average consumption, instantaneous consumption, traction control and clock. It is designed to help the driver maintain some control and prevent skidding when braking. This promotes directional stability and allows steering control, maximizing braking. For now, this is still an item that will cost you a little more when it comes to purchasing your car.

The hydraulic unit is located between the brake caliper cylinders and the brake master cylinder (MBC). The pressure that comes from the GTZ is converted into pressure force in the brake caliper cylinders, due to which the brake pads are pressed against the brake discs. Regardless of how hard the driver presses the brake pedal and in what situation, the pressure in the brake system will always be optimal.

This creates less time for the vehicle to brake and prevents you from losing control of the vehicle, especially when it comes to emergency braking. If a wheel begins to lock, a series of hydraulic valves limit or reduce wheel braking. This prevents slippage and allows steering control.

Why do I need or want this?

The car's braking and handling are limited. If you are looking for direction while braking, 100% of the traction the tire can generate will be split between the two tasks. For example, if you need 50% for steering, that leaves 50% of traction for braking. If you need 10% for steering, you have up to 90% for braking. Keep in mind that 100% dry grip is much more traction than 100% ice grip! Therefore, the vehicle may not be able to navigate and stop on a slippery surface as it might on a dry road.

The beauty of the ABS system is that it is able to analyze the condition of each wheel and individually select the optimal pressure to prevent wheel locking. Braking to a complete stop is controlled by ABS using the pressure in the brake drive system, so it is directed directly towards braking.

The device that controls the magnetic valves is capable of operating in three different positions

What do you think we forgot to explain?

Leave your questions and suggestions in the comments below! Then register your email and get the latest news. With an anti-lock braking system, the primary function is to provide safety as well as control when braking, regardless of the road conditions. Brake pressure control is monitored while the vehicle is in motion and whenever the driver releases the service brake - this can be done by pressing the pedal or using the trailer brake valve. Everything about ABS: operating principle, what it consists of, fault diagnosis

Pressure adjustment occurs according to the following principle: touch speed sensors count the revolutions of not only the front wheels, but also the rear axle differential (in rear- and all-wheel drive models), and the rear wheels. The control unit needs the data to calculate the peripheral speed of the wheels. Once the count is complete and it is determined that a wheel or wheels are locked or on the verge of locking, a command is sent to the magnetic valves and the return pump of the corresponding wheel(s). Each of the calipers receives such pressure that allows the wheel to provide maximum effective braking and a complete absence of blocking effect. Rear-wheel drive and all-wheel drive cars, equipped with only one sensor speed sensor on the differential of the rear axle, the possibility of wheel locking is determined by the one wheel most located to this wheel, after which the braking force is determined for the entire row. As a result of this, the wheel with the best coefficient of adhesion receives slightly less braking, which cannot help but increase the braking distance, but at the same time much better vehicle controllability is maintained compared to a vehicle without ABS.

Typically, the distance required to stop the vehicle safely can also be reduced. The tip must hold the pedal depressed. If everything is in order, the driver should be aware of other items that may affect safety. Tires must be in good condition for the vehicle to maintain proper grip on the road and improve driving safety by avoiding accidents.

While driving, the driver's action to brake the vehicle should be: step on the pedal, maintaining pressure even if the pedal is pulsating and step on the steering wheel, if so, to distract from the obstacle. The truck driver can perform a pre-trip check, just check to see if the lights on the panel are working properly.

The simplest way to brake a car

Many drivers believe that in order to quickly stop the car, you need to press and hold the brake pedal (brake to the floor). Of course, this method will force the car to stop, but such braking will not be effective.

When braking to the floor, the wheels lock , i.e. The car's wheels stop rotating. At first glance, it seems that with locked wheels the car will stop faster. But this is only at first glance. Let us remember a small element of a school physics course: “The force of static friction is always greater than the force of sliding friction.” Those. If the car's wheels are rolling (unlocked), the car will brake faster than if the wheels are locked. This is due to the fact that in the first case, the contact patch of the car’s wheels is in a stationary state relative to the road surface, i.e. the static friction force acts. In the second case, when the wheels of the car are blocked, the sliding force of the thorn acts on it.

There is also a second drawback to the simplest method of braking - a car with locked wheels completely loses controllability . Those. If you lock the wheels in a turn, the car will continue to move straight ahead by inertia, and not towards the turned wheels.

It is obvious that the simplest method of braking is imperfect and sometimes dangerous. Therefore, to assist the driver when braking, special anti-lock braking systems (ABS) .

The device that controls the magnetic valves is capable of operating in three different positions:

- The first is creating pressure

. The GTZ is connected to the brake cylinder, which means that the exhaust valve is closed and the intake valve is open, therefore the pressure can easily increase. - The second is maintaining pressure

. Interruption of communication between the GTZ and the brake caliper cylinder is a condition when the pressure in the brake drive system is unchanged. That is, a signal is sent to the inlet valve, as a result of which the valve remains closed, thereby preventing an increase in pressure. - Third - reducing pressure

. The pressure in the brake actuator system is reduced because the release valve receives a signal to relieve pressure, after which it opens. At the same time, the pressure decreases due to the inclusion of the return pump, as a result of which the inlet valve closes.

Thanks to three different operating positions, the ABS system is able to increase or decrease the pressure in the brake drive system according to a “step” principle, by acting stepwise on the solenoid valves. In a working system, these positions can change from 4 to 10 times per second, this largely depends on the type of road surface.

It was designed to maintain control and prevent over-braking. It is currently in the process of becoming a standard braking system in Brazil. This is considered safer as it promotes steering stability during the process.

Heavy braking control

This occurs due to the adjustment of the wheel rims. The system prevents them from completely blocking or skidding on the track. When a wheel shows signs of abnormal locking, a series of hydraulic valves are activated to regulate its action.

If a malfunction is detected in the system, it is immediately deactivated, at the same time the braking system

continues to operate normally, but without ABS.

The braking itself is significantly different and has significantly less efficiency. About. that the ABS system

has failed by the emergency indicator located on the instrument panel. The method for finding and determining the malfunction may differ; the year of manufacture and type of ABS play a greater role here.

The vehicle becomes more stable and can be controlled during braking. Since the system prevents the wheel from suddenly locking, maneuverability can be maintained even while braking. This avoids accidents and gives the driver the ability to act in an emergency.

Therefore, it is important to maintain constant pressure on the pedal to ensure the best results. It is not recommended to make different pedal strokes. If you have never driven a vehicle with the system, there are some things to be aware of. Often, a pulse is usually observed on the brake pedal. It is important to know these characteristics so that they do not cause unexpected surprises or reactions.

Nothing is perfect

It may seem that the anti-lock braking system is perfect and flawless. In fact, this is not the case, and it has its own disadvantages that you need to be aware of.

So, for example, ABS can be a disservice when braking on snow, sand, dirt roads or on ice. The fact is that in these cases, in terms of the length of the braking distance, a locked wheel would be ideal, especially if it is shod with studded tires.

But ABS demonstrates itself in all its glory on wet, dry and even surfaces - it has no equal here.

With this, dear readers and subscribers, our short story about the anti-lock braking system can be completed.

In conclusion, I would like to say that no matter how perfect the car’s electronics are, the driver always remains a person. Therefore, it’s still not worth relaxing behind the wheel, relying on all-powerful modern technologies.

Vigilance and attention on the road is what will primarily protect you and your loved ones from unpleasant situations.

See you again, friends!

Subscribe to new material and share the knowledge you have gained, because this is our safety and the safety of our loved ones.

Design and main components of the system

ABS system components

The anti-lock braking system includes:

- Wheel speed sensors. The sensors operate based on the Hall effect and are installed on the hub of each wheel. They determine the speed of rotation of the wheels and transmit a signal to the ABS control unit.

- Control block. The main function of the electronic control unit (ECU) is to ensure that the braking system operates in the most effective and stable range, in which the braking force will be maximum and the vehicle's wheels will not lock. To do this, the control unit continuously calculates the change in wheel speed (deceleration). Based on these indicators, control signals are generated for actuators: the pump and solenoid valves of the hydraulic unit.

- Hydraulic block. This ABS component is the actuator. The hydraulic unit includes solenoid valves (inlet and outlet), hydraulic accumulators, a cam pump with an electric motor, and damping chambers.

Solenoid valves control the braking process, each in its own circuit. For each brake wheel cylinder, a pair of valves is assumed (one inlet and one outlet). Hydraulic accumulators are designed to speed up the release of pressure in the brake circuit. They are filled with brake fluid when the exhaust valves open. Next, the cam pump is activated, pumping the brake fluid back into the master cylinder. It is for this reason that when the ABS system is operating, the driver feels shocks on the brake pedal. Damping chambers dampen fluid vibrations during system operation. Since the car has two hydraulic circuits for the brake system, two pressure accumulators and two damping chambers are usually integrated into the hydraulic unit.

Pros and cons of the ABS system

The anti-lock braking system has both advantages and disadvantages. Its advantages include the following.

- Improving vehicle handling. By adjusting the wheel speed, the car remains controllable even during emergency braking. This significantly increases the safety of traveling by car.

- Reducing the braking distance. In most cases, using ABS reduces braking distance. This also makes driving the vehicle somewhat easier.

- Improved car behavior when turning. If the driver makes a mistake and the car skids, if the vehicle has ABS, the risk of rollover is much less.

- Driving a car requires fewer skills. ABS significantly “makes life easier” for inexperienced drivers who have only recently received their license to drive. After all, using the system allows you not to think through some steps, since this is done for the motorist by the electronic control unit. In addition, with ABS, many mistakes are forgiven (for example, the aforementioned sharp turn, which can cause a skid). Thus, the system makes operating the machine much easier.

But the system also has disadvantages. The main ones include the following.

- Ineffective at low speeds. It has already been mentioned that ABS does not take into account slight changes in the intensity of wheel rotation. This causes the system to be ineffective at low speeds. For example, when driving smoothly down a mountain at a speed of 4 - 6 km/h, a vehicle equipped with an anti-lock braking system will behave exactly the same as a car without it. This also applies to prolonged slow movement by inertia. This needs to be taken into account.

- Ineffective on some road surfaces. The system does not work well on all roads. For example, on primers or asphalt with a lot of unevenness (which is not uncommon in our country), ABS functions much worse. This is explained by the frequent movement of the wheels in the vertical plane, which affects the operation of the sensors. As a result, the braking distance increases significantly and the behavior of the vehicle when braking changes.

- Ineffective on icy roads. Also, ABS does not work very well on a road from which ice, snow, and other foreign coatings have not been removed. Due to the difference in the adhesion properties of asphalt and, for example, ice, the sensors also cannot normally obtain information about the speed of movement from the wheel.

Normal braking phase

During normal braking, there is no voltage on the solenoid valves; from the master cylinder, brake fluid under pressure freely passes through the open solenoid valves and actuates the wheel brakes. The hydraulic pump is not working.

Rice. Braking phases: a) normal braking phase; b) phase of maintaining pressure at a constant level; c) pressure release phase; 1 – wheel sensor rotor; 2 – wheel sensor; 3 – wheel (working) cylinder; 4 – electrohydraulic modulator; 5 – solenoid valve; 6 – pressure accumulator; 7 – injection pump; 8 – main brake cylinder; 9 – control unit

The task of every driver is to avoid an accident, and the anti-lock braking system provides invaluable assistance in this.