A variator (CVT) is a type of gearbox that involves a continuously variable change in gear ratio, which ensures smooth acceleration and speed reduction without jerking, as happens in a classic automatic transmission. This “box” is distinguished by greater efficiency, reduced fuel consumption, lack of noise and constant traction. Below we will look at how the CVT transmission appeared, what elements it consists of, and how it works. We will separately highlight the types, pros and cons, as well as tips for using such a transmission.

The history of the variator

Leonardo da Vinci is considered the pioneer in the invention of the “constantly changing transmission”. It was he who invented the device at the end of the 15th century. At the same time, the official patent was received only several centuries later, which significantly slowed down the development of the direction.

In the middle of the 20th century, CVT (Continuously Variable Transmission) began to be used in motorcycles, and half a century later they became in demand in aviation. The first car with a CVT was produced by the manufacturer Daf in 1958. The mechanisms used at that time had a low level of reliability. Thus, rubber belts quickly failed, and the transmission often needed repairs.

Important

After some time, an engineer from the Netherlands, Hub Van Doorn, came up with a steel belt, which made the system more reliable and made it possible to use a CVT transmission on powerful cars, and in the 1980s, full-fledged production of cars with such gearboxes began.

Over the course of a long time, the variator was significantly improved. In particular, better materials began to be used, the diameter changed, the hydraulic component improved, the issue of the electronic part was optimized, etc.

Continuously variable transmission or how to decipher CVT

The name CVT itself is an abbreviation for “Continuously Variable Transmission”. Translated into Russian, it literally means “constantly changing transmission,” which many simply call variator from the word variable. This transmission is installed on different cars, often with low- and medium-power engines.

The CVT variator box under consideration has a number of design features, indicators and characteristics. Among the main ones are:

The most common type of CVT gearbox is a CVT box with a V-belt drive. A CVT transmission uses a steel belt or chain instead of classic gears (gears). The chain or belt moves between two mounted pairs on the output and input shafts by bevel wheels. In fact, these wheels are the pulleys between which the belt is tensioned.

As each conical pair approaches or diverges, the radius of the pulley changes smoothly. As a result, a smooth change in the gear ratio occurs, and torque is continuously transmitted from the internal combustion engine to the wheels.

Varieties of CVTs

When using CVTs, you need to understand that they come in several types. Let's briefly look at the features of each option:

- V-belt. Structurally, it consists of a pair of pulleys connected by a V-belt drive. The pulley consists of a pair of cone disks that are moved closer or further apart using hydraulics and a special spring mechanism. The cones are at a 20-degree angle for smooth movement with minimal resistance. Modern CVT boxes have belts made of steel strips, which are characterized by greater strength, minimal noise and a high degree of reliability.

- Wedge-shaped chain. From the name it is clear that these types of CVT use a chain that is formed from a variety of plastics. The transmission of torque is carried out by means of fixation with special cone disks. There is a high load at the contact points, which leads to heating, which is compensated by the cooling system. Such devices are characterized by higher efficiency, but they do not have reverse, which requires the use of an additional device.

- Toroidal. In this type of CVT transmission there is no chain or belt drive. Structurally, the device consists of 2 shafts with roller mechanisms fixed between them. The speed changes by changing the position of the rollers, and the moment itself is transmitted due to the contact of the working areas. This type of CVT is used the least often, but it is this type that is considered the most promising.

Operating principle and design of the variator

The simplest way to look at the operating principle of a variator is to use the example of the most common type of device: a V-belt.

On the shaft, which is connected to the motor shaft, there is a drive pulley made of two halves. The halves can move along the shaft (their axis of rotation). A similar (consisting of two halves) pulley is located on another shaft connected to the car’s wheel drives. This pulley is called the driven pulley. The driving and driven disks are connected to each other by a belt, V-shaped in cross-section.

At low engine speeds, the halves of the drive pulley are moved apart and the belt is “failed” towards the axis of rotation, but on the driven pulley it’s the opposite: the belt is “squeezed out” as far as possible from the axis of rotation.

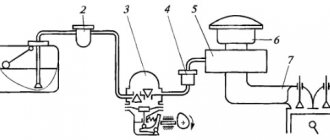

Thus, due to friction at the point of contact of the belt with the surfaces of the pulley halves, a belt drive is formed, schematically shown in the following figure.

That is, the drive shaft is similar to a gear of small diameter, and the driven shaft is similar to a large one. Accordingly, at low speeds the angular speed of the driving pulley is significantly higher than that of the driven pulley, to which the maximum traction force (and minimum angular speed) is transmitted.

The halves of the drive pulley are moved by an end force generated, depending on the design of the variator, by inertial forces (from rollers inside one half of the pulley moving due to centrifugal forces - the simplest case) or by hydraulics receiving commands from an electronic control unit (modern systems).

In addition to centrifugal ones, electronically controlled torque transmission systems can be electromagnetic or multi-disc, but torque converters are the most widely used due to their advanced design.

At high speeds, the picture is the opposite: the “gear” of the drive pulley becomes large in diameter (the belt is squeezed out to the periphery of the pulley), while the halves of the driven pulley move apart and the belt “falls in” to a small diameter). The friction necessary to change the distance between the halves of the driven pulley and the belt tension is provided by a spring.

According to the principle of operation, in addition to V-belts, there are also torus variators.

In them, the role of composite pulleys is played by cone-shaped disks, and the role of a belt is played by mushroom-shaped rollers, which have the ability not only to rotate around their axis, but also to move relative to the axis of rotation of the disks. At different positions of the rollers, they come into contact with the disks in circles of different diameters, and due to this, the gear ratio between the disks changes. In practice, torus variators are found much less frequently than V-belt ones.

It would seem that if everything is so simple and the principle of operation of the device is well known, why did CVTs begin to be used on cars relatively recently?

The fact is that the belt material used in variators of scooters and snowmobiles is not designed for the level of loads that occur in cars. And only modern technologies have made it possible to develop a variator drive that can withstand high loads.

The belt of a modern automobile variator is metal, consisting of two metal belts and a set of elastic metal links inserted into them.

From the drive pulley, the link most clamped in it transmits the pushing force to the next link and further along the chain. It turns out that such a set-up belt does not pull, but pushes the driven pulley, and this allows greater forces to be transferred to it than in a conventional V-belt drive. It is this type of drive that has become most widespread in modern CVTs.

In some brands of cars (primarily Audi) there is a drive in the form of a multi-link chain instead of a belt.

This type of transmission is also called wedge-chain transmission. In contrast to a metal built-up belt, the contact patch between the end sections of such a chain and the conical surface of the pulleys is significantly smaller, and this circumstance places increased demands on the material and joints of the chain. The chain drive has the highest efficiency in transmitting force from the drive pulley to the driven pulley, has good durability, and is fairly easy to replace if necessary. But at the same time, the chain is a rather expensive drive.

The design features of the variator also include the need to integrate a reverse mechanism into the device - direct reversal of the variator pulleys is impossible. In practice, this is solved in the same way as in automatic transmissions: the design includes a planetary gearbox.

The difference between a CVT and a classic automatic transmission

New car owners often cannot choose which is better - a CVT or an automatic transmission (regular automatic transmission). In both cases we are talking about automatic gear shifting, but the operating principle is different. Unlike CVT, which provides smooth gear changes, in a standard automatic transmission the process occurs in steps.

Structurally, the automatic transmission consists of a control mechanism (hydraulics, electronics), a torque converter for the clutch and a planetary “box”. The device works as follows:

- The motor transmits torque through special shafts to a hydraulic transformer.

- The force is transferred to the planetary device.

- The latter receives signals from the control unit and turns on the desired speed.

In other words, in a classic automatic transmission, the function of the coupling device is taken over by a hydraulic transformer. Unlike the box discussed above, the variator belt provides a smooth change in torque without the slightest jerking at the moment of switching.

Operation of the CVT box

The V-belt variator consists of two main parts:

The closer the coaxial cones are to each other, the diameter of the circle that the belt describes decreases or increases. The parts listed are CVT actuators. And everything is controlled electronically based on information coming from numerous sensors.

The principle of operation of the variator

Continuously variable CVT transmission device

So, if the diameter of the driving pulley is maximum (its cones will be located as close to each other as possible), and the driven pulley is minimal (its cones will diverge as much as possible), then this means that the highest gear is engaged (corresponding to the 4th or 5th transmission in a traditional transmission). And vice versa, if the diameter of the driven pulley is minimal (its cones will diverge), and the diameter of the driven pulley is maximum (its cones will close), then this corresponds to the “lowest gear” (first in a traditional transmission).

Due to the design features of the design, the variator can only be used on relatively small machines (with an engine power of up to 220 hp). This is due to the large forces that the belt experiences during operation. The process of operating a car with a CVT transmission imposes some restrictions on the driver. Thus, you cannot suddenly start from a standstill, drive for a long time at maximum or minimum speed, tow a trailer, or drive off-road.

Advantages and disadvantages

When considering the features of a CVT transmission, it is necessary to understand its weak and strong points. The advantages of CVT include:

- Smooth speed change. Unlike an automatic torque converter box, a variator provides an increase and decrease in speed without the slightest jolts / jerks.

- Increased motor service life. With proper operation, timely change of oil in the variator and performance of other routine maintenance, the device ensures smooth transmission of torque to the engine and thereby extends its service life.

- More economical fuel consumption due to the high efficiency of the mechanism. On average, the efficiency is 7-10% higher when compared with a classic automatic transmission.

- Ecological cleanliness of the mechanism. During operation, the CVT system emits fewer hazardous components into the atmosphere (when compared with other “boxes”).

- Fast acceleration. The absence of jerks helps to save time when accelerating, which provides better dynamics for the car.

- Ease of control. Just select the desired mode on the handle to start moving.

Despite the advantages, CVT also has a number of disadvantages:

- Maintenance difficulties. Repairing and replacing a variator is a very expensive operation, which only a few craftsmen undertake. Sometimes you have to call more than one service station to find a suitable option.

- High cost of oil. For filling into CVT, special lubricating compounds are used, which have a higher price.

- Once every 100-150 thousand kilometers the belt needs to be replaced, which is an expensive pleasure.

- Electronics addiction. During operation, a CVT transmission receives signals from many sensors. If any of them fails, the system will not work correctly, which will lead to the need to repair the variator and additional costs.

- Relatively small resource. The CVT does not like heavy loads, so it fails faster than a manual transmission. In particular, towing in snow or mud may be critical for it.

- Increased risk of breakdown due to improper use.

Manufacturers are constantly working to improve the variator and eliminate shortcomings. Many weaknesses associated with low reliability are a thing of the past. But the service life of the device largely depends on the car owner himself and following a number of rules.

CVT gearbox - what is it?

On new cars, in addition to manual and automatic, a CVT gearbox is often used. Popularly it is called a variator.

The abbreviation CVT means continuously variable transmission, that is, in other words, it is a continuously variable transmission.

There are no fixed gear positions here, since the optimal gear ratio is constantly selected.

The gearbox is used so that at constant engine speeds, it is possible to change the speed of movement.

The relationship between the speed of rotation of the crankshaft and the wheels of the car is characterized by the gear ratio.

The main advantage of this solution is that it allows the engine power to be used as efficiently as possible, while torque losses are minimized.

If on a car with a manual transmission, in order to change the speed, you need to shift manually, then in the case of a CVT, this happens constantly and without your participation.

Since there are no gears, there is no jerking when changing speed.

To answer the question, CVT transmission, what is it and what is its advantage over an automatic transmission, it must be said that the CVT provides smooth acceleration, it happens much faster than when using an automatic transmission.

In this case, the engine speed is almost the same and there are no differences from maximum to minimum values.

The CVT very precisely selects the gear ratio, which depends on whether you are accelerating or decelerating, so your driving style will be smoother, the load on the engine will be reduced and fuel consumption will be reduced.

Previously, CVTs were only used on scooters, but now they are installed on both passenger cars and bulky crossovers.

There are three types:

- V-belt;

- toroidal;

- wedge-chain.

The first two types are more common; today, CVT gearboxes are installed on their cars by such manufacturers as Mercedes-Benz, Nissan, Ford, Subaru, Audi, Honda and others.

Principle of operation

If we talk about what the simplest variator looks like, it will be two sliding pulleys that are connected and interact with each other using a wedge-shaped belt.

In a car, this unit has a more complex design, since it must provide reverse movement and lower gears.

The V-belt design includes the following elements:

- sliding pulleys, they are located on the same shaft and are driven by hydraulic cylinders. The pulleys move apart depending on the crankshaft rotation speed or they act on a signal coming from the control unit;

- V-belt, this part consists of two metal belts with steel plates. At the top the plates look like a cone, they are in close contact with each other, at the bottom they have grooves;

- the torque converter converts and transmits torque, which allows the car to start moving smoothly;

- using a differential, torque is evenly distributed to the drive wheels;

- to ensure reverse movement, there is a planetary mechanism, with its help the secondary shaft can rotate in the opposite direction;

- To ensure the pressure of the working fluid, there is a hydraulic pump, it is driven by a torque converter. The working fluid is supplied under pressure, due to which the hydraulic cylinders come into operation;

- To control the operation of this unit, there is a control unit, this is a microprocessor device. It takes into account such indicators as crankshaft position, fuel consumption, etc., in accordance with the obtained indicators, the operation of the mechanism is adjusted.

The difference between the toroid type is that it has two wedge-shaped disks, one of which is driven and the other is driven.

A special roller is installed between the disks; it can rotate about a horizontal axis and at the same time, the roller can move vertically up and down.

As the roller moves, it comes into contact with sections of the disks that have different diameters.

To obtain a low gear, the roller moves between the small diameter of the drive disk and the large diameter of the driven disk.

If the diameter of the driving pulley becomes large, and the diameter of the driven pulley is small, then the opposite relationship occurs.

To operate a toroidal type variator, a special lubricant is required, its cost is significant, so it is less popular compared to the V-belt type design

.

Operation of a V-belt variator box

When the speed increases, the torque converter starts working and transmits rotation to the input shaft and drive pulley.

Under the action of hydraulic cylinders, its cheeks begin to narrow, so the friction between them and the belt increases.

This results in rotation being transmitted to the driven pulley and output shaft. At this time, the driven pulley has a maximum diameter, so the lowest gear is obtained.

When you increase engine speed, the diameters of the pulleys change, causing the speed to change.

The driven shaft transmits rotation to the differential, which distributes torque evenly to both drive wheels.

When the planetary gear is engaged, the output shaft begins to move in the reverse direction, which provides reverse movement.

The change in pulley diameters is controlled using a control system.

This design of the variator ensures smooth movement; there are no jerks during driving, which saves fuel.

The control system selects the optimal operating mode of the motor and, in accordance with it, adjusts the diameters of the pulleys.

Some drivers who switched to a car with a CVT were not happy with the fact that there is no characteristic change in engine operation when the gear ratio changes. The developers solved this problem and created conditional step switching.

Now, at the beginning of the movement, you need to engage first gear, when a certain speed is reached, the lever is moved to the next one.

The control unit is programmed for certain gear ratios and it seems that you are driving a car with a manual transmission. If you go into automatic mode, the electronics do all the work.

To engage lower gears, the lever is placed in the appropriate position and then higher gears are not engaged, even when the engine is running at high speeds.

CVT gearbox - pros and cons of the design

pros

:

- Smooth ride.

Neither a manual nor an automatic transmission can provide such a smooth ride as a CVT design.

This is due to the fact that the CVT design simply does not have steps. Many cars have steering wheel paddle shifters, with which you can shift manually.

This is ensured by an electronic control system that regulates the fixed diameter ratios of both pulleys.

- Fuel economy.

With this design, the engine power is used optimally, therefore its maximum efficiency is achieved, which leads to lower fuel consumption.

But you shouldn’t expect significant savings; cars with CVTs do not consume much less fuel than those with automatic transmissions.

- Less acceleration time.

If we compare it with cars that have an automatic transmission, the acceleration of a CVT will be slightly faster, although it happens more and more smoothly.

- Less noise.

With a CVT transmission, the engine does not have to reach maximum speed, so it runs quieter.

Drivers who switched to such cars from other types of gearboxes will at first feel a little strange and uncomfortable.

- Longer engine life.

Since the engine does not operate at maximum speed, it wears out less and its service life increases accordingly.

- Less weight.

The weight of such a box is less than that of an automatic transmission, due to the fact that it contains fewer parts;

- Safety. When driving on ice, higher safety is achieved compared to manual or automatic transmissions.

Despite the large number of advantages, the CVT transmission also has some disadvantages that you need to be aware of.

Minuses

:

- Device complexity. This is its main drawback. Due to the complexity of the design, the mechanism does not work for long. For a CVT gearbox you need about 5-6 liters of expensive gear oil; if any part fails, be prepared for serious financial costs.

- You cannot suddenly switch from high gear to low gear, so this design cannot be used in a car with a sporty character.

- Due to the design features, difficulties arise when towing a car; if a breakdown occurs, you will have to call a tow truck.

If you decide to buy a used car with a mileage of one hundred thousand kilometers or more, then it is best to purchase those that have a manual or automatic transmission, since in this case you will have to spend a lot of money on repair and maintenance of the variator.

CVT gearbox - the pros and cons of this solution indicate that if you want to drive smoothly, comfortably and are not afraid of significant costs for maintenance and repairs, it is the most modern among the available proposals.

Recommendations for the driver for operating the CVT

To extend the service life of the variator, it is important to know the features of its operation and follow some recommendations. The most important points include:

- Monitor the presence and level of lubrication and change the CVT oil promptly. When choosing a product, take into account the manufacturer's recommendations, which should be indicated in the service book. If this information is not available, contact your dealer.

- In winter, warm up the variator before driving. This takes longer than heating the motor. If this is not done and you start to accelerate sharply, the mechanism may be damaged.

- Do not tow vehicles with CVT as this will cause wear or damage to the transmission. Also, you cannot use a car with a CVT as a “tractor”. It is only allowed to transport a trailer if its weight does not exceed the norm. If towing is required, the only option is to hang the front wheels.

- Do not overuse off-road driving. Such cars are classified as SUVs, because a hit on a protrusion or bump can result in serious damage, including the need to replace the entire unit. Slipping in mud/drifts is also prohibited. If you frequently change the mode from “D” to “R”, this can lead to wear on the splines and damage to the gears.

- Periodically perform computer diagnostics of the engine to identify errors in the electronics.

- Change the oil, belt and filter of the variator in a timely manner to extend the life of the mechanism and prevent premature failure of an expensive unit.

What's the result?

As you can see, a CVT transmission, due to its design and operational features, is a rather isolated unit compared to other types of automatic transmissions. In fact, a high level of comfort and good dynamic performance at an affordable price at first seem like a clear advantage.

If we add to this the “chip” design of the engine, it becomes clear that the CVT gearbox, which is not designed for high loads, quickly fails. It is important to understand that such a gearbox is suitable for calm and measured driving at low and medium speeds on good roads, that is, without loads.

If you “rip” from a place, skid and load the car, in this case the life of the variator is noticeably reduced. To preserve the resource and increase the service life, the CVT gearbox must be properly operated and timely serviced.

CVT variator: operating principle and types of variator, pros and cons of CVT gearboxes. Renault-Nissan CVT X Tronic gearbox, features of a CVT of this type.

Operation of a CVT gearbox: features of driving a car with a CVT, maintenance of a CVT gearbox. Useful tips and tricks.

How does a variator work, how does this type of box differ from a manual transmission, automatic transmission or robotic transmission. Advantages and disadvantages of a variator.

CVT gearbox: what is it, how does this type of transmission work. Pros and cons of CVT gearbox, features. What should the owner of such a gearbox take into account?

What is a variator: design of a CVT variator box, types of variators, operating principle. Pros and cons of a CVT transmission.

CVT transmission: what is a CVT transmission, how a CVT works, its service life, advantages and disadvantages of a CVT.

Source

What is a CVT gearbox , and how does it differ from a traditional transmission? This question may be of interest to both existing car owners with this type of torque transmission and future ones. This type of gearbox implies the absence of fixed gear ratios. This gives a smooth ride and also allows you to use the engine in optimal modes. Another name for such a box is a variator. Next, we will consider the pros and cons of the CVT gearbox, the nuances of its use, as well as reviews from motorists who already own cars with a continuously variable transmission.

Types of variators and their operating principles

Below, in the video lesson, the principle of operation of a typical variator is shown and described in detail, after watching which you will better begin to understand the operation of CVT.

The operating principle described above refers to the classic design of a V-belt variator. There are two types of them:

- Actually V-belt, in which a steel belt is used to transmit rotation;

V-belt variator - Chain, designed on the same principle, but a steel chain is used as a transmission element.

Chain variator

So far, the V-belt is the most promising type of variator, which is gradually being improved.

There is a third type, in which the transmission of torque is implemented in a completely different way - a toroidal (toroidal) variator.

Toroidal variator

In a toroidal variator, rotation is transmitted from the engine to the input shaft using a different scheme:

Scheme of operation of a toroidal variator

- Two cones, pointed towards each other, are connected to the drive and driven shafts;

- The transmission of torque occurs through rollers connecting these two cones;

- The rollers can move along the axis of rotation of the cones, sliding along their surface, moving closer or further from their apexes;

- Upshifts and downshifts occur due to the contact of rollers with a smaller or larger diameter of rotation, and therefore the transmission of faster or slower rotation to the driven shaft.

Below is a visual video lesson on the operating principle of a toroidal variator, which is very accessible and understandable.

Currently, V-belt types of variators are being improved more actively than toroidal ones, and they can more often be found installed on a car. If new types of design do not appear, it is V-belt variators that will gradually develop towards greater reliability, durability and convenience.

Toyota RAV4 2.5 Hybrid Dynamic Force FWS e-CVT - pros and cons

Body and interior:

+ impressive body appearance, excellent finish, spacious interior, plenty of space for luggage, 19 cm ground clearance;

— It’s easy to scratch the plastic in the trunk.

Drive system:

+ modest fuel consumption (especially impressive on the highway), good performance, smooth gearbox operation;

— rather loud operation of the internal combustion engine, monotonous sound under strong acceleration.

Driving characteristics:

+ high driving comfort, good maneuverability and reliable handling, straight line stability;

— problems with traction after adding more gas with skidding on the wheels, bad brakes.

CVT resource

The nuances of operation (road conditions, driving style) and the frequency of maintenance of a CVT transmission affect the service life of the device.

If the manufacturer's instructions are not followed or regular maintenance regulations are violated, it is useless to expect a long service life.

The service life is 150 thousand km; the transmission, as a rule, does not last longer. There are isolated cases when the CVT was changed as part of warranty repairs on cars that had not traveled 30 thousand km. But this is an exception to the rule. The main component that affects service life is the belt (chain). The part requires driver's attention, since if there is severe wear, the CVT gearbox can completely break.

conclusions

When it comes to cars with continuously variable torque transmission, there is reason for negative assessments. The reason is that the node requires regular maintenance, and its resource is short. Everyone decides for themselves whether to buy a car with CVT. The transmission has advantages and disadvantages. In conclusion, we can give a warning comment - when buying a used car that has a CVT gearbox, you need to be extremely careful. The owner of a used car can hide the operating features, and the variator in this regard is a sensitive version of a mechanical transmission.

Pros and cons of a CVT gearbox

Like a manual or automatic transmission, a continuously variable transmission has its advantages and disadvantages. The advantages are:

- comfortable movement in a car (position “D” on the selector is set before starting to move, the engine accelerates and slows down the car without the shocks typical of manuals and automatics);

- uniform load on the engine, which is combined with precise operation of the transmission and helps save fuel;

- reduced emissions of harmful substances into the atmosphere;

- dynamic acceleration of the car;

- no wheel slip, which increases safety (especially when it comes to driving in icy conditions).

Of the disadvantages of a continuously variable transmission, noteworthy:

- design limitation on the combination of a CVT with a powerful internal combustion engine (so far we can only talk about a few examples of cars with such a tandem);

- limited resource even with regular maintenance;

- expensive repairs (purchase);

- high risks when buying a used car with CVT (from the “pig in a poke” series, since it is not known for certain how the previous owner operated the car being sold);

- a small number of service centers where technicians would undertake to repair the device (only a few know everything about CVTs);

- restrictions on towing and trailer use;

- dependence on monitoring sensors (the on-board computer, in the event of a malfunction, will provide incorrect data for operation);

- expensive gear oil and the requirement for constant monitoring of its level.