When is it necessary to flush the engine when replacing antifreeze?

The engine cooling system must be flushed before replacing antifreeze:

- when changing the class of coolant, for example, they decided to replace G12 antifreeze with G13, or it is not known at all what kind of liquid is in the cooling system;

- if contamination of the coolant in the expansion tank of the cooling system is visually determined;

- if the drained coolant contains rust particles and other contaminants;

- if additional compounds were poured into the cooling system to eliminate leaks.

Flushing the engine cooling system yourself

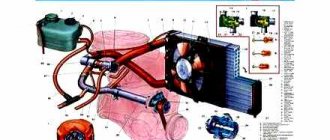

| It's no secret that the engine cooling system (ECS) can become clogged after a certain time. When the circulation of fluid in this system is disrupted, the stove begins to work poorly and the engine overheats. Do you know how to properly flush the cooling system yourself? |

Coolant replacement

Warnings

|

Preparing for work:

- ?place the car on a horizontal, level platform, or so that its front part is higher than the rear.

- ?disconnect the negative terminal of the battery.

- On VAZ-2110, -2112 engines the plug on the cylinder block is easily accessible, but to access it on the VAZ-2111 engine you will need to remove the ignition module.

To drain the coolant you will need:

- Remove the expansion tank plug.

- Place a container under the engine and unscrew the drain plug on the cylinder block.

- Place a container under the radiator and unscrew the drain plug on the radiator.

After all the coolant has drained out of the system, screw the plugs into the cylinder block and radiator. To prevent air locks from forming as the system is filled with coolant (the coolant will not completely fill the system), you should:

- If you have an injection engine, then loosen the clamp and disconnect the coolant supply hose from the throttle pipe heating fitting.

- If the engine is carburetor, then disconnect the hose from the carburetor heating fitting.

Fill the engine cooling system by pouring coolant into the expansion tank until the level is at the top edge of the expansion tank mounting belt. Close the expansion tank cap.

- ?Connect the hose back to the throttle pipe or carburetor heating fitting (depending on the engine model). Reinstall the ignition module and negative battery cable.

- ?Start the engine and let it warm up to operating temperature (before turning on the fan). After this, turn off the engine, check the coolant level, and if necessary, add it to the same level.

Warning

When the engine is running, monitor the coolant temperature according to the gauge. If the arrow moves to the red zone and the fan does not turn on, turn on the heater and check what kind of air flows through it:

|

How to flush the engine cooling system when replacing antifreeze

Washing is carried out with clean water, preferably distilled. It is advisable to fill not with water, but to prepare a solution containing 80% water and 20% antifreeze (which will be poured after washing).

This solution is relatively cheap, allows you to thoroughly flush the cooling system; the chemical elements of the new antifreeze will react with the elements of the cooling system and form a protective film.

If you use distilled water and antifreeze concentrate for pouring not ready-made antifreeze, the addition of the concentrate to the washing solution is reduced by 5 times the norm. If distilled water is not available, then it is permissible to use boiled water for rinsing (boil for 25–30 minutes).

Recently, a new product for flushing the cooling system has appeared on the market. It does not have a strong acid or alkaline reaction, its pH is neutral. This drug does not destroy the elements of the cooling system and is a “soft flush” option.

It is added to the expansion tank of the cooling system 1–2 thousand km before the planned replacement of the coolant. When using such preparations, it is advisable to then flush the cooling system with a solution of antifreeze and distilled water.

The use of various special compositions based on acids and alkalis is not recommended. After flushing with such compounds, leaks may form in the cooling system. In addition, it will not be possible to completely drain the coolant or flushing fluid; the remaining volume may have a bad effect on the composition of the new antifreeze.

Getting ready for the heat: the correct replacement of antifreeze

Please note: modern diesel engines (for example, Toyota 1GD) may not have the usual radiator cap - the radiator is directly connected to the expansion tank. And for others (Nissan YD25, V9X), on the contrary, there can be two caps with a valve at once: both for the radiator and for the expansion tank. Moreover, they are similar in appearance - car owners often confuse them during installation, which leads to overheating of the engine. On modern diesel engines, the cooling system is very complex, because it regulates the temperature not only of the engine, but also of many adjacent components: turbocharger, intercooler, EGR valve. It is better to entrust the replacement of antifreeze in such engines to car service specialists.

Flushing the cooling system

To remove the remnants of old antifreeze from the heater, flushing the cooling system is required. In a car service center, a device similar to a unit for changing automatic transmission fluid is connected to it. It works on the same principle: it supplies new antifreeze to the system, displacing the old one.

You can flush the system yourself using distilled water and a cooling system cleaner. To do this, you need to close all the plugs (radiator drain valve, engine plug), slowly pour water into the radiator and add cleaner. Important: you cannot use ordinary tap water; you need distilled water without impurities. Next, you need to set the heater to the hottest air flow and start the engine for 10 minutes. You can give it a little gas so that the pump pumps the cleaning compound well through the system.

Self-flushing takes time: you will have to wait again until the engine cools down. But after draining the water from the radiator and engine, you will be surprised at its color - there is quite a lot of old antifreeze in the stove. In advanced cases, washing with water should be repeated (this time without the cleaner).

Filling with new antifreeze

Antifreeze concentrate must be prepared before pouring into the engine - diluted with distilled water in the required proportion. The ratio is indicated on the label: usually it is 50/50, 60/40 or 70/30 - the lower the proportion of water, the higher the frost resistance of the mixture.

But in most cases you won’t have to mix anything: concentrated antifreeze has almost disappeared from store shelves. Today, most coolants are sold ready-made - already diluted for a given frost resistance. Usually this is -40 or -50 °C, which is quite enough for the Russian climate.

Cooling system flushing process

The flushing procedure is not much different from replacing the coolant. It is carried out on a lift or using a pit, although if desired, on many car models, this work can be performed simply on a flat platform. All necessary tools and containers for drained liquid are prepared.

The procedure for flushing and replacing the coolant should be carried out on a cold engine, since when the engine is running, the coolant temperature reaches 78–115 °C. Hot fluid may be under increased pressure in the cooling system and pose a danger to humans.

How to flush the engine cooling system when replacing antifreeze:

- Visually inspect the cooling system hoses. If there are cracks, purchase new hoses and steel clamps to secure them.

- Remove the cap from the cooling system expansion tank.

- Place a container to collect the liquid under the drain hole in the radiator housing.

- Open the drain hole in the radiator housing (usually located at the bottom of the radiator).

- Open the filler hole in the radiator housing (usually located on top of the radiator).

- Allow the liquid to drain completely.

- Close the drain hole at the bottom of the radiator.

- Pour the flushing solution into the radiator up to the neck and then tightly close the filler hole with the cap.

- Pour the flushing solution into the expansion tank of the cooling system to the maximum level mark. Do not tighten the cap, just place it on top of the neck of the tank to avoid splashes.

- Start the engine, turn on the heater. Warm up the engine until the electric forced cooling fan (located next to the radiator of the cooling system) turns on. At the same time, monitor the fluid level in the expansion tank. Top up periodically. If necessary, squeeze the cooling system hoses with your hand to remove air bubbles more completely, using protective gloves, since the surface temperature of the hoses can be high.

- After the engine has completely warmed up, the air from the cabin heater is hot, let the engine run for 5-10 minutes and turn it off.

- Close the expansion tank tightly with the lid and let the car sit for several hours, or better yet a day, then drain the flushing fluid and add antifreeze.

Attention! An aqueous solution of antifreeze does not have sufficient frost resistance.

Flushing the cooling system

Coolant replacement must be carried out with mandatory flushing of the entire system. This must be done to remove deposits in the radiator and engine channels. You can flush the system with the following liquids:

- Distilled water;

- By special means.

Flushing the cooling system with distilled water is the least effective, but if the liquid is acidified, scale will be separated from metal parts much better.

To acidify water, you can use citric acid or vinegar essence.

You should not lower the pH level too much. In order not to damage the rubber parts of the cooling system, it is enough to use one packet of citric acid or half a small bottle of vinegar essence for the entire volume of liquid poured into the engine.

Flushing the cooling system with acidified distilled water is a budget option for cleaning the engine from internal deposits, but the time required to perform such an operation will be significant.

After the acid is thoroughly dissolved, water is poured into the engine cooling system. In this case, it is necessary to control the fluid level, which will constantly decrease as air is displaced from the engine and radiator channels.

When the coolant level is fixed and does not decrease, you need to start the engine for 15 - 20 minutes. During this time, the water temperature will increase to the operating value. After warming up, the engine should be turned off and the acidified water should be kept in the system for 5 - 6 hours. After this time, the water from the cooling system is drained and the cleaning cycle is completely repeated using clean distilled water.

When flushing with clean water, the required amount of liquid is also poured, then the engine is started for 15 - 20 minutes, after which the engine is allowed to cool for half an hour, and then the water is drained from the system.

A full cleaning cycle using acidified distilled water can take more than 7 hours. If there is no free time to flush the cooling system in this way, it is recommended to use a more expensive option.

Flushing with the help of special products allows you not only to carry out high-quality cleaning of the cooling system, but also save a considerable amount of time. The greatest efficiency when replacing antifreeze can be achieved if the flushing actions are carried out using a two-component product. Professional flushing fluids allow you to completely clean the cooling system of antifreeze decay products, as well as scale and corrosion products of metal engine parts. The cleaning process using special products is not too different from rinsing with distilled water. Time is saved due to the fact that such fluids contain highly effective additives, which make it possible to separate various foreign formations from metal parts of the cooling system within a short time. That is, it is not necessary to keep such liquids in the system for a long time.

Recommendations

If the flushing procedure is carried out in winter in an unheated box, immediately after turning off the engine, drain the flushing fluid and add antifreeze.

Leaving flushing fluid at subzero outside temperatures can lead to defrosting of the cooling system, even leading to destruction of the radiator, water pump, and engine cooling jacket.

Defrosting the engine leads to a very expensive overhaul. The cooling system radiator is also not the cheapest spare part in a car.

How to flush the engine cooling system with your own hands?

Operating a car involves regularly replacing technical fluids, otherwise the car will not be able to perform its functions properly. The replacement of coolant is regulated by each manufacturer individually, but often factories require changing antifreeze or antifreeze once every 60 thousand kilometers. In practice, you need to change the fluid much more often - once every 15 or even 10 thousand mileage.

The final range of kilometers depends on the quality of the liquid poured into the cooling system and other operating factors. Many drivers are wondering how to flush the engine cooling system and not pay for this procedure at a service station. The washing process is not so complicated, so everyone can do it in their garage.

Engine cooling system flushing process

This task often becomes quite a difficult test for the car owner. It is necessary not to succumb to the persuasion of thousands of myths and harmful advice that almost every driver gives. There are a lot of myths about replacing coolant and flushing the engine that can ruin your powertrain.

Why is it necessary to change the coolant?

Antifreeze differs from distilled water in its boiling point and the rate at which heat is removed from the walls of the block. The liquid in the cooling system is periodically changed, since it is designed for a certain resource, after which the anti-corrosion and functional properties of the coolant are lost.

Check the coolant level in the expansion tank. The liquid gradually boils away and needs to be replenished periodically.

Replacement is also carried out when the cooling system is contaminated. The radiator and pipes gradually become clogged, which can lead to a blockage. The engine may overheat and seize due to a clogged cooling system:

- corrosive particles and dust;

- salt deposits on the internal channels of the radiator and block;

- blockage of pipes with oxidative sediment.

The expansion tank of the engine cooling system is used to control the coolant level. When adding fluid in a timely manner, pay attention to the visual condition of the antifreeze. Signs for replacement: change in color, consistency, appearance of cloudy sediment and solid particles.

Filling with new coolant

Now we can start filling in new coolant. Remember, pouring new antifreeze when replacing is only possible in a clean cooling system.

However, before doing this, it is important to understand what exactly you are going to fill. After all, there is no such confusing classification as that of coolants anywhere else. Therefore, we strongly recommend that you first study what types and types of antifreeze there are, and then you will understand what is best to pour into the engine cooling system.

If you use antifreeze concentrate when replacing, it must first be diluted with distilled water in a one-to-one ratio before filling. With this ratio, it can withstand frost down to -40 °C. All proportions and diagrams are usually indicated directly on the coolant package.

To avoid the formation of air jams in the system, the car must be in a strictly horizontal position. Then follow in this order:

- Disconnect the uppermost pipe that supplies antifreeze to the engine (usually located in the intake manifold area). See the video below for an example.

- New coolant should be poured through the neck of the expansion tank. For convenience, it is better to use a funnel.

- Fill in antifreeze until it begins to flow out of the pipe disconnected at the first point.

- Insert the pipe into place and clamp it at the connection with a clamp.

- Do not fill the tank full of antifreeze. The optimal level will be between the MIN and MAX marks.

After filling, close the reservoir cap tightly, start the car and warm it up until the fan comes on. Then wait until the engine cools down and check the coolant level in the expansion tank. If necessary, antifreeze should be added to the required level, but this can only be done with a cold engine!

This completes the independent coolant replacement.

Coolant replacement

After traveling a certain mileage or identifying problems in the cooling system, it is necessary to undergo vehicle maintenance. You can visit a service station or perform the process yourself. How to replace coolant?

Replacement is carried out on a cooled engine and using protective equipment.

To carry out the procedure you will need:

- set of tools - screwdrivers and wrenches,

- containers for draining waste,

- rubberized gloves,

- flushing additives,

- new coolant - distilled water, antifreeze or other antifreeze.

The car is placed on an inclined platform or overpass - in this position the liquid drains better from the system.

You may also be interested in the question of how to correctly and competently change the oil in an automatic transmission.