Why does a car need an intake manifold?

The intake manifold has many tasks, but the main one is supplying air (lots of air).

Speaking in technical language, he is responsible for:

- Supply of air flow involved in the preparation of the fuel mixture in compliance with the ratios specified by the engineers;

- Uniform distribution of air into the cylinders;

- Use of VUT vacuum to enhance forces in the braking system;

- Operation of the crankcase ventilation system (CVG);

- Controlling the speed of the power unit at idle due to the operation of the throttle.

For each power unit, its own intake manifold is developed, the geometry of which will be optimally matched to the engine architecture.

Manifold tuning

Engine tuning is a whole range of work to refine its individual components and parts. The intake manifold can also be modified to improve engine performance.

Tuning this part has two directions:

- to overcome the negative influence of its form;

- for finishing the internal surface.

What does form have to do with it?

The flow of air or working mixture in the manifold is uneven due to its shape. If the manifold is asymmetrical, then the largest amount of air or fuel-air mixture will enter the first cylinder, and less will enter each subsequent one. The symmetrical one also has a drawback: there, the largest amount of air enters the middle cylinders. In both cases, the cylinders operate unevenly on mixtures of different qualities. As a result, engine power decreases.

Device

Although from the outside the intake manifold appears to be just a pipeline of a specific shape, in fact a whole team of engineers works on its geometry, calculating the cross-section, length and volume.

Plus, it includes:

- Throttle valve;

- Supply chamber;

- Air filter;

- Inlet valve;

- Discharge chamber.

For engines with distributed fuel injection, injectors are additionally installed in the intake manifold, due to which the mixing of fuel and air masses occurs directly in the discharge chamber.

The pipeline itself can combine from 2 to 12 channels, depending on the number of cylinders in the engine block. At the same time, for a 4-cylinder engine, a manifold with three pipes is sometimes used.

It is also worth noting that most modern intake manifolds over the past 5 years have been made from special high-temperature plastic, while the exhaust manifold can still only be made from metal.

Intake and exhaust manifolds for cars

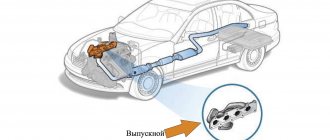

A manifold is a technical device that is part of the internal combustion engine in a car. The main function of the manifold is to supply hot mixtures to the engine, as well as to drain them. Typically there are two manifolds - intake and exhaust.

The intake manifold collects the flows of combustible mixtures and gas into one common one and distributes them among the cylinders of the car engine, due to which the car moves. The combustible mixture must be distributed evenly, in which case the engine will operate without failures and with high performance. The intake manifold can also act as a holder for the throttle body, injectors, carburetor, and other engine components.

During operation, a vacuum is created in the intake manifold, which is used to control various systems in the car, such as power brakes, windshield wipers, cruise control, etc. This manifold is also used to burn crankcase gases that are formed while the car is moving. The intake manifold was originally made of metal - aluminum or cast iron. However, plastic is used to produce modern collectors. Plastic, unlike metal, does not heat up, which improves the filling of the engine cylinders, and, as a result, increases engine power.

In turn, the exhaust manifold is part of the exhaust system of the vehicle; gas mixtures are exhausted through it, and internal combustion products are removed from the car. With the help of the exhaust manifold, the combustion chambers are also purged, which allows the engine cylinders to quickly fill with the next portion of the combustible mixture.

In the modern automotive industry, two types of exhaust manifolds are used - tubular and solid. The one-piece manifold is made of cast iron and has short channels combined into a common chamber. A one-piece manifold is not very efficient at removing exhaust gases, but it is affordable and easy to manufacture.

However, recently, cars have mostly been equipped with more efficient tubular manifolds. They are made of steel, and their design is created in such a way that the engine power is increased.

It is worth noting that on sports cars exhaust manifolds are often not installed, and each cylinder is attached to its own exhaust pipe, which allows the car to show higher speed qualities.

Principle of operation

The intake manifold is connected to the air supply system. The wide part, where the pipes are located, is attached directly to the cylinder head.

After which, through the intake system, the air masses enter the supply chamber, where the air supply temperature can reach up to 120 degrees.

Then the air passes through the filter and the intake pipe, from where it enters the discharge chamber through the throttle valves, and from there, through the intake pipes, the air masses are sent straight to the cylinders.

This is interesting: What you need to know about car wheel alignment angles

A throttle, or simply a damper, regulates the cross-section of the pipeline, thereby controlling the speed and power of the engine.

Shape and volumetric efficiency

One of the most important parameters of the intake manifold that determines its efficiency is its shape. The basic rule that all engineers adhere to is that the intake manifold should not have any angular shapes , as this will provoke pressure drops and, as a result, worse filling of the cylinders with air or working mixture. Therefore, all collectors have smooth transitions between segments and rounded shapes.

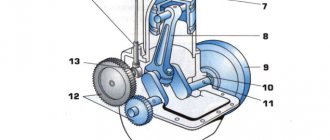

The vast majority of current collectors use runners. They are separate pipes diverging from the central entrance of the manifold to all available intake channels in the cylinder head. Their task is to use a phenomenon called Helmholtz resonance. The operating principle of the design is as follows.

At the moment when suction occurs, air flows at a very high speed through the open inlet valve. When the valve closes, the air that did not have time to enter the cylinder retains a large impulse, which means it presses on the valve, resulting in a high-pressure zone. Then pressure equalization occurs, with lower pressure in the manifold. Due to the influence of inertial forces, leveling occurs with fluctuations: first, air enters the runner at a pressure lower than in the manifold, then at a higher one. This process occurs at the speed of sound, and before the intake valve opens again, oscillations can occur many times.

The smaller the diameter of the runner, the greater the change in pressure due to resonant air vibrations. As the piston moves down, the pressure at the outlet of the runner decreases. This low pressure pulse then travels to the manifold inlet where it turns into a high pressure pulse that travels in the opposite direction through the runner and valve, after which the valve closes.

Changing the intake manifold geometry

As already mentioned, each engine has its own intake manifold geometry. This allows you to vary the speed and improve or worsen the combustion process.

In all cases, a change in geometry results in a change in airflow speed.

As you might guess, there are only three options for changing the geometry:

- Reduce or increase the length of pipes;

- Narrow or expand the cross-section of pipes;

- Combined approach.

Since it is often not possible to “play” with long pipes, they usually choose the second option - changing the cross-section. To do this, special dampers are used that regulate air flow differently than the factory mechanism.

Premium segment cars have a combined system for changing the geometry of the intake manifold.

These are precisely those cases when the manufacturer offers different options for driving modes, such as Comfort, Dinamic, etc. The change in engine characteristics is partly influenced by the operation of the intake manifold flaps.

Intake manifold - we remove and repair it ourselves

Why do we need to know how to remove the engine intake manifold? The answer lies in the numerous functions that this part performs, even indirectly, and if it breaks we risk experiencing very great discomfort. Let's look at everything in order.

What functions does the intake manifold perform?

The importance of this element cannot be underestimated, because it is here that the meeting of fuel and air occurs, resulting in a combustible mixture of the required consistency . He also controls the process in which it must be evenly distributed across all cylinders. And this is very important, since only then will the greatest performance of the car engine be achieved. So you cannot neglect such procedures as repairs, cleaning the intake manifold, etc.

In addition, some engine elements are attached to it, for example, fuel injection equipment, a carburetor, and throttle valves. And the vacuum that forms in it is the source of driving force for a number of systems (windshield wipers, cruise control, vacuum brake booster, etc.). And if one of these systems fails, you will most likely need to remove the intake manifold. Let's consider its design.

Intake manifold flaps and other structural elements

Most often, this part is made of aluminum alloys or composite plastic materials and is mounted on the cylinder head on the left side. A sensor on the intake manifold records temperature and pressure, and the control unit, in turn, calculates the mass of air in it. And based on this data, impulses are generated, through which the injectors are controlled. This is how the fuel-air mixture of a given composition is prepared.

Inside this part there is a switching shaft and a vacuum element, to which the vacuum generated by the tandem pump is supplied through the flaps to the intake manifold pipe. Each inlet channel is divided into a vortex and a filling section. The switching shaft, in turn, can only close the last one, and at this moment suction occurs through the first channel. So the flow speed in this channel increases significantly.

Why might you need to repair the intake manifold?

This part has a rather complex design, which means the likelihood of a breakdown increases significantly. Most often, dampers fail, this type of malfunction is especially relevant for Mercedes. In this case, the car significantly loses power, fuel consumption increases, traction and engine performance as a whole deteriorate. Manifold valves fail for the following reasons: elevated temperature, poor quality of the material from which they are made, and the appearance of oil condensation. The intake manifold flap control valve may also fail.

The main sign that oil has entered the intake manifold is its increased consumption, sometimes it even exceeds 1 liter per 1000 km.

In plastic parts, separation of the tube from the swirler can quite often occur, which provokes the appearance of a characteristic sound during movement (crackling, noise). This breakdown can be completely eliminated on your own. In addition, air leaks may occur in the intake manifold. This malfunction will also affect the power, but in addition to this, a noise will appear that resembles blowing, or, on the contrary, suction.

In order to measure the absolute pressure in the intake manifold, there is a special sensor. He is also responsible for optimizing the process of formation and combustion of the air-fuel mixture. If it fails, the ECU will most likely operate in emergency mode, and sometimes the engine may not start at all. Despite the fact that a modern pressure sensor in the intake manifold is a fairly reliable device, malfunctions are nevertheless possible in it.

We remove the manifold ourselves

Basically, to repair or replace a part, you need to know how to dismantle the intake manifold. In principle, this task is not difficult, and you can cope with it in literally 10 minutes. We find the fuel pump and remove the fuse from it, and then start the engine. This will cause the pressure in the system to drop and the engine will gradually stall. After this, you can disconnect the battery and remove the decorative casing from the engine. Now you should remove the pipes from the air filter and remove it. Then you should unscrew the throttle assembly, but without touching the damper fasteners. Now you have reached the collector.

Next, in case of detachment of the square tube, it is necessary to drill two holes in the manifold (the drill diameter is taken to be 4 mm) so that this tube can be reached through them. Then we screw screws into these holes, fixing it. The dampers and control valve cannot be replaced separately or repaired, so you have to buy and install a new part entirely. If the cause of the breakdown is found in the sensor, then the failed element needs to be replaced.

Tuning

Tuning and changing geometry are two different things. When people talk about modifying the intake manifold, they usually mean increasing the incoming air volume and reducing the resistance along its path.

For this purpose the following procedures are provided:

- Replacing the air filter with a zero resistance filter. Thanks to the macroscopic holes in the latter, air is retained less and, accordingly, the speed and volume of passage increases;

- Enlargement of the throttle pipe. It also aims to increase air permeability. Usually, for this purpose, a damper is installed from another engine, which is more powerful than the original;

- Installation of a sports receiver. Short tubes with a larger cross-section, when properly configured, can reduce the pulsation of air masses, which allows the engine to gain speed faster.

There is also a tuning option when the intake manifold is completely removed and short pipes tuned to high speeds are installed instead. This option is provided only for naturally aspirated engines and is called a multi-throttle intake (that is, each cylinder essentially has its own manifold).

By the way, any changes in the intake system usually entail upgrading the exhaust manifold, camshaft and firmware of the electronic control unit.

Collector device

The manifold is connected to the cylinder head, of course, between them there is an exhaust manifold gasket, thanks to which exhaust gases do not escape into the engine compartment. The gasket is made from special materials, which ensures its long service life. If necessary, you can replace the exhaust manifold gasket; fortunately, on most cars this procedure is quite simple and quick. The exhaust pipe, or catalytic converter, is connected to the other end of the manifold.

Malfunctions

Like any other mechanical part, the intake manifold is susceptible to failure. Given the simplicity of the design, there are not many options for malfunctions.

Basic:

- Violation of tightness. Vibrations, pressure and high temperatures destroy seals over time. Depressurization affects the quality of the fuel mixture, loss of traction and speed. The problem is solved by replacing the gaskets, after which engine operation should return to normal;

- Collector contamination. Plaque accumulates on the walls, gradually reducing the cross-section of passing air masses. Requires disassembly and cleaning of tubes, throttle and discharge chamber;

- Mechanical damage. If the collector is made of plastic, it is only a replacement. If it is made of aluminum and the damage is small, argon arc welding will help;

- Excessive temperature in the manifold. There are a lot of reasons and you need to look for them in the cooling system, clogged radiator, damaged sensor, ECU error. Also, high temperature occurs due to the banal heat outside;

- "Clap." When forming the fuel mixture, the system must be sealed. If there are disturbances in the ignition system, the gas distribution mechanism, problems in the fuel mixture formation chamber, or the tightness of the intake manifold itself is broken, you can hear those same pops. It is worth looking for reasons in all of the above places.

In the latter case, of course, it is easier to rely on the errors reported by the ECU or sign up for a comprehensive diagnostic service.

Replacing the VAZ 2114 manifold

- 1 0 1k

- 4 0 21k

The collector (resonator, “pants”) is an engine attachment; it is a closed reservoir of complex shape with a common chamber (receiver) and outlet pipes. Depending on the nature of the functions performed in a car, there are two types of manifolds - exhaust and intake.

The main task of the intake manifold is to supply air from the distribution system, mix it with fuel and transform it into an air-fuel mixture of the desired consistency, followed by a uniform supply to the combustion chamber of the cylinders. Therefore, the main task of the exhaust manifold is to collect exhaust gases from the engine cylinders into a single pipe.

The main signs and causes of failure of the VAZ 2114 intake manifold

- The main symptom of a failed intake manifold is a sudden loss of car engine power.

- at the same time, there is an increase in fuel consumption , with a deterioration in traction and a drop in engine performance.

- Often a problem is indicated by a missing stud in one of the manifold flanges. It simply comes off when the collector goes “screw”, that is, due to temperature changes, for example in winter, or over time (average service life is 7 years), the collector begins to bend along the plane, and the pin simply “spits out”, pulls out .

- Due to the fact that the manifold has “leaded”, a crack may form and, as a result, exhaust gases from the engine escape, and the manifold must be replaced.

Tips for replacing the intake manifold

Also, do not neglect the procedures for repairing and cleaning the intake manifold. The stability of the VK is very important for the normal functioning of the car. A certain vacuum is formed in the intake manifold, which is the source of drive force for many systems: cruise control, windshield wipers, vacuum brake booster. In the event of a collector malfunction, this threatens the failure of one or more of the above systems.

To avoid the appearance of cracks and distortions, you must use a torque wrench to tighten the nuts on the manifold and follow the tightening order of 20.9-25.8 (2.13-2.63) N_m (kgf_m). As a rule, it is recommended to start tightening the nuts from the center and gradually move towards the periphery, alternately tightening the nut on one side or the other.

Types and design features of collectors

Structurally, all exhaust manifolds are divided into two large groups:

- Solid;

- Tubular.

One-piece manifolds are designed simply - they are a cast structure in which short pipes from each cylinder are combined into a common chamber or exhaust pipe. Due to the short length of the channels and the peculiarities of their location, such collectors have low efficiency and cannot be used to properly adjust the outlet. However, they are very simple to manufacture, so they are widely used on cheap engines and low-speed tractor diesel engines.

Often the one-piece manifold is combined into one unit with the intake manifold - this part is called a gas pipeline. This solution is widely used on domestic engines.

Tubular manifolds (they are often called “spiders” in our country) are a more complex design, but at the same time a more effective system with which you can fine-tune the exhaust. Such collectors are usually made of steel pipes, which at a certain length merge into a common receiving pipe.

Tubular collectors are divided into two large groups:

- “Short” manifolds of type 4-1 - in such a manifold, the pipes from each cylinder are the same length and in one place converge into one exhaust pipe;

- “Long” manifolds of the 4-2-1 type - in such a manifold the pipes are combined in pairs (usually the 1st and 4th, and the 2nd and 3rd cylinders are connected, they form a Y-shaped structure), and then two pairs are connected into one common receiving pipe.

These collectors are called "long" and "short" because of the path that the exhaust gases take. In 4-1 manifolds, gases travel a shorter distance, so they are better suited for high-speed engines (and they provide the best operating modes for engines with an operating shaft speed of 6000 rpm and above). In 4-2-1 manifolds, gases travel a longer path, so they are better suited for lower-speed engines and are widely used today.

Tubular collectors have characteristic shapes, for which they received the name “spider”. Such shapes are given to the collector pipes for a reason - the pipes coming out of each cylinder must have a strictly defined length, and so that all the pipes converge at one (for 4-1 collectors) or three (for 4-2-1 collectors) points, they have to be bent and twisted. The tightness of the engine compartment also plays a role here.

It is important to note that each engine must be equipped with a manifold designed for it, otherwise there will be a loss of power and deterioration in the performance of the power unit

Therefore, when boosting and tuning an engine, much attention is paid to the correct calculation and manufacture of manifolds for it. And with the right approach, using a collector alone, you can increase engine power by 3-5%