The process of changing antifreeze in GAZelle Next

When releasing a car, the manufacturer indicates that after two years of operation or a mileage of 60,000 km, the antifreeze for the GAZelle Next must be replaced. If the fluid is not changed in a timely manner, serious problems can occur in the vehicle's operation - engine overheating.

The coolant should be changed when the engine is cold. To change antifreeze you will need the following tools and materials:

- container for draining old fluid;

- funnel;

- for the drain tap pipe, you need to prepare a hose of the required size;

- screwdrivers.

All work is performed with rubber gloves and rubber shoes. The place where the fluid is replaced should be away from people due to the toxicity of the material.

Thermostat

Note: The thermostat housing is part of the intake manifold, if the thermostat housing is damaged, the intake manifold must be replaced.

Check before removal

After closing the thermostat for 1 minute with the engine running, do the following:

— to monitor the coolant temperature, connect a diagnostic tool.

Disconnect the radiator hose from the cooling system outlet pipe.

Install the hose onto the coolant outlet, tighten the clamp, and place the free end of the hose in a measuring container.

Start the engine and warm it up at rated speed for one minute, while monitoring the opening of the thermostat.

If the thermostat opens during this test, repeat it. Permissible coolant temperature 38˚ C

Stop the engine and measure the coolant volume in a measuring container.

If the volume of liquid collected is greater than permissible, the thermostat must be replaced.

Permissible volume 100 cm3

Replacing Gazelle Next antifreeze

Replacing Gazelle Next antifreeze in Moscow

Replacing antifreeze, or coolant, is one of the procedures that is carried out regularly. This is due to the fact that over time, foreign particles get into the antifreeze, which negatively affect its characteristics. Antifreeze stops working, the level of anti-corrosion elements decreases, and then the Gazelle Next internal combustion engine is not protected from corrosion.

The replacement of Gazelle Next antifreeze will be professionally carried out by auto technicians in Moscow. We will select the appropriate liquid and introduce it into the system. The coolant filling procedure has a number of features. The technicians will do everything in accordance with the regulations of the machine manufacturer. Before filling the composition, we will also flush the system.

Payment Methods

Choose the option that is convenient for you

Fuel system

The system providing continuous injection and fuel supply Gazelle Next consists of four components:

- injection pump

- Control block

- Common RAIL injector

- Fuel line

If you have a Gazelle Next with a diesel engine, then you must remember one simple truth: you must refuel only at proven gas stations, because the fuel system of this engine really “loves” high-quality fuel and, in turn, is very negative about the content of water and dirt particles or dust in the fuel. If it happened that you had to refuel at a low-quality gas station, or after refueling the engine began to run unevenly, then you need to quickly change the coarse fuel filter so as not to end up with expensive repairs of the fuel system.

Operation of Gazelle Next with a Cummins engine

One of the common diseases of the Cummins engine is the failure or improper operation of the Common Rail injectors. Injectors fail due to low-quality fuel and moisture.

If while operating your car you notice unstable operation at idle or when warming up, as well as black smoke when you lightly press the gas pedal and a significant decrease in power, then in 95% of cases this is due to faulty injectors. The manufacturer recommends that you immediately contact a diesel service to eliminate this malfunction, because a faulty injector pours more than the required amount of fuel into the cylinders and because of this, fuel consumption increases, and this can also lead to burnout of pistons or exhaust valves.

After replacing the injectors, you need to completely flush the fuel system with special products, and continue to enjoy life!)

Characteristics of the cooling system

The Gazelle was equipped with engines from the Zavolzhsky Motor Plant marked ZMZ 402, ZMZ 405 and ZMZ 406. The design, circuit and operating principle of all three cooling systems are similar. Of course, there are some differences, but they are not that big.

Like any other cooling system, the ZMZ 405 engine has both positive and negative sides. So, if the thermostat breaks down, the power unit begins to overheat very much, especially in the summer season, when the temperature outside is 30 degrees Celsius or higher.

The most dangerous thing in this case is the failure of the cooling fan.

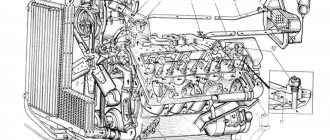

Cummins Engine Cooling System Repair

Cummins Engine Repair Tool

| Heads | Keys | Other |

| 10 mm | ||

| 12 mm | 8 mm | Hex key 8 mm |

| 13 mm | 10 mm | Swivel wrench (3/8" square drive) |

| 15 mm | 13 mm | Flat head screwdriver |

| 17 mm | 15 mm | Ratchet Wrench (3/8" Square Drive) |

| 18 mm | 17 mm | Ratchet Wrench (1/2" Square Drive) |

| 19 mm | 19 mm | Keys for unscrewing filters (75-80 mm and 90-95 mm) |

| 22 mm | 22 mm | Electric drill (1/4 inch) |

| 27 mm | 24 mm | Drill (3mm) |

| Hammer | ||

| Flat chisel | ||

| Puller (75 mm) | ||

| Sheet Metal Screw (#10) | ||

| Torque wrench | ||

| Pliers | ||

| Gear 3824591 for turning | ||

| crankshaft |

Cummins engine cooling system repair map

| Replaceable part or assembly unit | Tool | Preparatory operations |

| Accessory drive belt | 3/8" Square Drive Hinge Wrench | |

| Stretching device | 3/8" square drive ratchet wrench; 13mm socket; Torque wrench | Remove the accessory drive belt |

| Fan hub | Socket head/key 10 mm | Remove the accessory drive belt and fan pulley |

| Water pump | Socket head/key 10 mm | Drain the coolant and remove the drive belt |

| Thermostat | Sockets/wrenches, 10 mm, 18 mm 19 mm | Drain the coolant, remove the drive belt, loosen the alternator bar, remove the alternator mounting screw, remove the thermostat housing |

Cummins Engine Cooling System Repair

- Drive belt for Cummins Kamaz engine units - Replacement

3/8" Square Drive Hinge Wrench

Belt Tensioner on Cummins Engine - Replacement

Preparatory operation:

• Remove the accessory drive belt.

Fan pulley on Cummins engine - Replacement

Preparatory operation:

• Remove the accessory drive belt.

NOTE: Loosen the pulley mounting bolts before removing the belt, and tighten them to the required torque after installing the belt.

Remove the four bolts, fan and gasket. Replace the fan pulley.

Tightening torque:

Bolts 8 mm – 24 N•m [18 ft-lb]

Bolts 10 mm – 43 N•m [32 ft-lb]

Water pump on Cummins engine - Replacement

Preparatory operations:

• Drain the coolant.

• Remove the accessory drive belt.

Remove the water pump.

Install the water pump.

Tightening torque: 24 N•m [18 ft-lb]

Attention ! When filling the cooling system with liquid, ensure that air is released to avoid the formation of air locks. To do this, open the vent valve located on the charge air cooler, if equipped.

The rated coolant fill rate of the system is 19 liters per minute [5 US gallons per minute], which should not be exceeded. After filling the system, wait 2-3 minutes for air to escape from the system, then add fluid to the upper level.

| Cooling capacity | in nnTpaxfU.S. Quarts] (engine only) | ||

| 4В3.9 | 6V5.9 | ||

| 4VT3.9 | 4VTA3.9* | 6VT5.9 | 6VTA5.9* |

| 7,0 [7.4] | 7,9 [8.4] | 9 [9.5] | 9,9 [10.5] |

* 4VTA and 6VTA engines use water charge air coolers. If air coolers are used, the cooling capacity is the same as for non-turbocharged engines.

Install the filler cap. Run the engine and bring the coolant temperature to 80°C [180°F], then check for leaks.

Thermostat on the Cummins Kamaz engine - Replacement

Preparatory operations:

• Disconnect the cable from the negative terminal of the battery.

• Drain 2 liters [2.1 US Quarts] of coolant.

• Remove the radiator hose from the outlet pipe.

• Remove the accessory drive belt.

Loosen the lower bolt securing the tension bar to the generator.

Instructions for changing coolant

Replacing antifreeze in a GAZelle is carried out with a cold engine, following all the steps listed below.

At the first stage of work, it is necessary to carry out the following actions:

- Remove the radiator cap.

- Prepare a container and open the radiator drain cap.

- Drain the antifreeze from the GAZelle Next tank.

- Check the cooling system hoses for damage or cracks.

The second stage involves further operations:

- Flush the cooling system using a special product.

- Pour this product into the cooling system, add demineralized water to the radiator and tank. Water should fill the container to the brim.

- Close the lids and turn on the engine and heater. When the engine warms up to operating condition, turn it off.

- Wait for the engine to cool down. Remove the cap from the radiator and drain the filled liquid.

- Fill the system with plain water and close the lids. Turn on the engine for 15 minutes.

- Cool the engine and drain the water.

After all processes have been completed, the cooling system is ready to be filled with new antifreeze. Coolant should be added following the manufacturer's recommendations. The antifreeze concentration should be no more than 70%. The optimal concentration of liquid is 50% and the same percentage of water.

In the third stage, you should perform the following steps:

- Fill in antifreeze for GAZelle. Turn on the engine and heater to maximum. This will help distribute the fluid well and remove air from the system.

- After several days, check the antifreeze level. If necessary, add to specified level.

Malfunctions and repairs

You can repair an engine from this manufacturer yourself. Main faults:

- The engine starts, but the starting process itself is accompanied by smoke. This may be the result of air in the fuel system. It is necessary to bleed the fuel mechanism and check the tightness of the suction valve.

- Reduced pressure level in the power unit system. This malfunction may be caused by damage to the oil filter. It is recommended to check the operation of the pressure gauge.

- The coolant temperature is higher than normal. The cause of the breakdown may be a deformed radiator hose. The hose should be inspected for damage and replaced if necessary.

Error codes

Error codes for engines manufactured according to Euro 4 and 5 standards:

- 111 (red) - the problem is related to the control unit, the error type is critical.

- 112 (red) - the injection timing sensor has stopped responding.

- 113 (yellow) - short circuit in the fuel injection system.

- 114 (yellow) - open circuit.

- 115 (red) - there are no signals from the speed sensor and the crankshaft position.

- 116 (red) - short circuit in the fuel injection circuit.

- 117 (red) - open circuit of the pressure sensor.

A complete list of codes is provided in the engine repair manual.

If it doesn't start

If the Kamensk engine does not start, the reason may be:

- Increased resistance to crankshaft rotation. In this case, it is recommended to turn the crankshaft manually.

- Loose starting circuit contacts. All fasteners must be checked and tightened.

- Discharged battery. You need to check the battery voltage.

- Broken contact in the engine starting system circuit. In this case, you need to check the voltage level at the starter pull-out relay terminal.

- The motor is in mesh with the drives. All units should be turned off.

Replacing the motor

In order to replace the Kamens motor, you need:

- Remove the cabin trim.

- Remove the radiator and intercooler.

- Remove the front eye bolt.

- Remove the adjusting screws.

- Remove the bolts and washers from the rear bearing housing.

- Remove the gear.

- Remove the bolts from the cylinder block mounting.

- Remove the O-ring.

- Remove the push rods.

- Pull out the hydraulic coupling drive shaft.

- Remove the locking plates.

- Rotate the crankshaft so that the cylinder neck is at bottom dead center.

- Remove the engine.

- Install a new power unit, repeating all steps in reverse order.

Cost calculation

Personal calculation of repair costs

Prices for repairs and service depend on the car model, individual characteristics of the situation and your personal wishes for repairs. To receive an individual estimate of the cost of repairs, please consult with a specialist.

Find out the cost

Get a preliminary estimate of the cost of repairing your car!

Just call us at +7 (495) 662-99-55, request a call back or fill out a quick online form right now ↓ An AutoMD specialist will contact you shortly and advise you on the cost of services. By clicking the “Submit” button, you agree to the terms of the Privacy Policy.

Turbine

The next problem that the owner of a Gazelle Next may encounter during daily operation of a 2.8-liter Cummins diesel engine is a turbine malfunction.

During its breakdown, the turbine begins to leak engine oil and a leak occurs. You can check the operation of the turbine while standing still. All you need to do is raise the engine speed to 2500-3000 rpm. If blue smoke comes out of the exhaust pipe and smells of burnt engine oil, you should immediately contact a service center to repair or replace the turbocharger. If you have not yet encountered the problem of a turbine failure, we advise you to monitor the condition of your turbine so as not to end up with expensive repairs. You should monitor the amount of oil entering the turbine; if it is missing or insufficient, you should contact a service center to diagnose the problem. You should also be careful not to operate the turbine in critical modes, and also not to overheat it, and after a long trip at high speeds, you should let the engine breathe a little by idling for 5-7 minutes.

These are the most common problems with the Cummins diesel engine that Gazelle Next owners encounter. If we take it this way, then this engine is generally unpretentious and does not differ from other diesel engines if it is operated correctly and regular scheduled maintenance is carried out and the necessary parts are replaced in a timely manner.

https://avtomagazin78.ru/catalog/gaz/kammins/ Cummins spare parts

Specifications

Technical characteristics of KamAZ engines from Cummins:

| Number of cylinders | From 4 to 18 |

| Arrangement of cylindrical elements | 1 row or V-shaped |

| Working volume, l | From 2.2 to 7.8 |

| Camshaft location | Top or bottom |

| Engine power | From 109 horsepower |

| Type of fuel used | Diesel |

| Electronic fuel injection system | Eat |

| Cylinder diameter, cm | 12 |

| Piston stroke, cm | 13 |

| International environmental standard | Euro 3, 4, 5 |

| Maximum torque, Nm | 2200 |

| Weight, kg | From 11300 |

Technical parameters of the Cummins 4ISBe-185 engine:

| Number of cylinders | 4 |

| Electronic control system | Eat |

| Fuel system | Bosch |

| Power | 185 horsepower |

| Working volume, l | 4,5 |

| Piston stroke, cm | 12 |

| Diameter of cylindrical elements, cm | 12 |

| Intermediate air flow cooling system | Eat |

| Maximum torque, Nm | 686 |

| Engine speed | 1400 rpm |

| Environmental class | Euro-3 |

| Diameter of the piston part, cm | 10,2 |

| Cylinder arrangement | Row, top |

| Weight, kg | 600 |

| Dimensions, cm | 100*96*90 |

How the stove works in Gazelle Business

For correct diagnosis and repair, it is important to know the structure and operating principle of the heater, so that at the first sign of a breakdown, you can identify the problem or make repairs, preventing failure of the entire unit as a whole. Most breakdowns can be predicted by subtle signs and their progression can be prevented. To do this, you need to know and understand what any of the components is responsible for and what the meaning of its work is.

Car cooling system

In Gazelle Business, the stove is considered an important part of the engine cooling system. During engine operation, a lot of heat is generated that needs to be removed. Heat is released due to fuel combustion and from rubbing surfaces. If the heat is not removed, the motor will quickly heat up and break down. The cooling system has 2 circuits (small and large circle), they are divided by a thermostat. When the liquid is cool, it moves in a small circle, and when it warms up, it moves in a large circle. This makes it possible to quickly reach operating temperature and not get too hot. In the warm season, heat is released into the atmosphere, and when cool weather sets in, part of the heat is spent on heating the cabin.

Once we understand how the cooling system does not stop working, we can move on to heating the cabin. The heater circuit on a Gazelle car is similar to the heaters of other cars that have a liquid-cooled engine. Liquid can circulate through the heat exchanger of the heater no matter whether the thermostat is open or not. For better heat supply, the fluid for the stove comes from the hottest part of the engine (from the cylinder head). Thanks to this, on an engine that has not yet reached operating temperature, pleasant air still comes out of the deflectors. The heater has a valve in its design that either allows liquid to flow into the heating device or discharges it back. And the temperature of the environment leaving the deflectors depends on how much it is open. The valve position is adjusted from the heater control panel. The faucet is equipped with an electric drive that changes the position of the valve. It is also possible to change the blowing intensity and direction from the control panel. The intensity is controlled by a motor with an impeller, the rotation speed of which changes the intensity of the airflow.

Changing the position of the dampers changes the direction of the airflow (to the face, to the legs, to the chest, to the glass). The heated coolant from the engine penetrates through the line into the heater of the stove, causing it to heat up. At this time, air blown by a fan passes through it. Then it passes through air channels, the dampers of which are open. Then the hot air enters the car interior and warms it up. For repair work or diagnostics of breakdowns of this equipment, there is an electrical diagram on which all components of electrical devices are indicated. And in case of breakdowns or incorrect operation of devices, you need to read it in detail in order to understand where it is powered from and how the failed device changes.

When you know the working principle and device, it is much easier to navigate in case of breakdowns. After all, to successfully carry out a repair, it is necessary to understand the cause of the breakdown, otherwise the repair will not be completed successfully. For correct diagnosis, it is also necessary to understand the method of action of the entire mechanism in general. Nowadays, a driver does not have to know how to repair a car; there are service stations that deal with repairs of varying complexity. But it happens that a problem catches you on the road, and there is no opportunity to use the services of professionals. This is when knowledge of the automotive device and its mechanisms comes in handy. When you know how the Gazelle stove works, then if a breakdown occurs on another car, it will be easier to navigate when carrying out repairs or diagnostics, since in all cars they are almost equal, except for small invisible moments. And you can easily determine the breakdown.

Masters of their craft

Our best team of professionals

Highly qualified craftsmen who sincerely love their work are the main component of high-quality repairs and service. This is exactly the team of highly qualified specialists that works for you at the AutoMD car service center in Moscow. We are always happy to help you!

AutoMD car service is a friendly team of professionals, each of whom knows their business to perfection. Contact us, we guarantee excellent results!

Golovakha Pavel

master inspector

Work experience 14 years

Do you want to tidy up the electrical system in your car? Contact the professional car service “AutoMD”! I guarantee that all work will be completed at the highest level!

Golovakha Anton

Electrician

Work experience 16 years

I always complete every repair job to the best possible result. Contact me, I will be happy to get your car in order!

Bryksin Nikolay

Mechanic

Work experience 8 years

Since my youth I have loved repairing cars, which is why I chose a profession to my liking. I love my job and do it well. Come visit AutoMD, I’m glad to be of service to you!

Bogomolov Vladimir

Mechanic

Work experience 21 years

The highest reward for me is sincere and warm feedback from clients! I always do the work carefully and efficiently so that you are happy and satisfied with the result!

Pepe Franco

Mechanic from Italy

Work experience 16 years

I am used to doing any work quickly and efficiently. I love it when people are satisfied with the result. I will always be happy to help solve problems with your car!

Gribanov Andrey

Motor mechanic

Work experience 8 years

I have been working as an auto mechanic for a long time and I know almost everything about cars. Come to our car service! I guarantee fast and high-quality troubleshooting.

Belugin Andrey

Auto Mechanic

10 years of experience

The main thing for me is a quality result. I approach my work responsibly: I carefully carry out diagnostics and repairs, pay attention to detail. I'll be glad to help!

Khudyakov Alexey

Auto Mechanic

Work experience 4 years

My motto is impeccable results in everything! I carry out repairs on every car as if it were my own - carefully and scrupulously. Contact us, I’m always happy to help with repairing your car!

Mikhailov Ivan

Auto Mechanic

Work experience 3 years

AutoMD car service is a place where you solve all problems with your car: perform diagnostics, maintenance, repairs, buy spare parts. Contact our auto repair center and save time and money!

Surikov Grigory

Auto Mechanic

Work experience 6 years

I am always ready to provide quality assistance and solve the problem with the electrical wiring of your car in a short time! Contact me, I will be glad to help!

Zabelin Denis

Electrician-diagnostician

Work experience 5 years

AutoMD will always provide quick and high-quality assistance to your car. You can find all the necessary specialists, equipment and spare parts in one place, saving time on searching.

Valainis Donat

Warehouse employee

Work experience 7 years

AutoMD specialists work according to the motto: “Quality and in the shortest possible time!” We will always be happy to help you and will be glad to see you as our regular customer.

Marcin Georgy

Sales specialist 1st category

Work experience 6 years

Come to our auto repair center for quality car repairs. We will carry out a comprehensive diagnosis of the machine and repair it in the shortest possible time. We will be glad to see you as our client!

Kashaev Victor

Senior warehouse employee

Work experience 5 years

Come to our auto repair center and we will be happy to help solve your car problem at the highest professional level!

Owner reviews and prices

Purchase and rental price: the engine cannot be rented, it can only be purchased. The average cost is 500,000 rubles.

Alexander, 53 years old, Lipetsk: “I work on a KamAZ truck with an ISBe engine. During 3 years of operation, the starter and radiator had to be replaced.”

Ivan, 44 years old, Voronezh: “In six months of work, we already had to change the injectors 2 times. Otherwise the engine is running properly."

Mikhail, 35 years old, Izhevsk: “During 4 years of work there were few breakdowns. I only replaced the front crankshaft oil seal.”