Features of the ZMZ-406 engine power system

In the fuel injection engine power system, the pressure is 30 MPa (3 kgf/cm2).

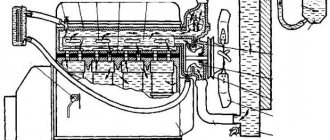

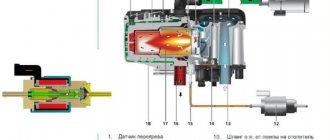

Therefore, it is forbidden to loosen the connections of the fuel lines while the engine is running or immediately after stopping it. To carry out repair work on the power system on a freshly stopped engine, it is necessary to first reduce the pressure in the power system. 2-3 hours after stopping the engine, the pressure in the system drops to almost zero. A fundamental feature of the ZMZ-4062 engine power supply system is the absence of a carburetor, which combines the functions of mixture formation and dosing of the air-fuel mixture into the engine cylinders. In the distributed injection system installed on this engine, these functions are separated - the injectors carry out dosed injection of fuel into the intake pipe, and the air required at each moment of engine operation is supplied by a system consisting of a throttle and an idle speed regulator. Control of the fuel injection system and ignition system is carried out by an electronic engine control unit, which continuously monitors, using appropriate sensors, the amount of engine load, vehicle speed, the thermal state of the engine and the environment, and the optimality of the combustion process in the engine cylinders. This control method makes it possible to ensure the optimal composition of the combustible mixture at each specific moment of engine operation, which allows you to obtain maximum power with the lowest possible fuel consumption and low exhaust gas toxicity. The diagram of the fuel injection system is shown in the figure.

Diagram of the ZMZ-4062 engine power supply system: 3—throttle; 4—engine fuel line; 6—nozzle 7—vacuum hose; 8—reducing valve; 9—fuel drain hose; 10—fuel tank; 11— fuel tank receiver; 12—low pressure fuel line; 13— fuel pump; 1— inlet pipe; 14, 16—high pressure fuel line; 2— air throttle valve; 15— fine fuel filter

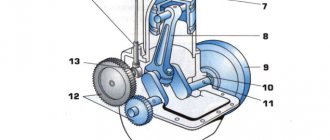

piston of the 1st cylinder at top dead center during the compression stroke and send an injection signal to the injector of this particular cylinder. Further supply of pulses is carried out by the control unit in accordance with the order of operation of the cylinders laid down in its program. If the phase sensor fails, the control unit switches to backup mode with fuel supplied to all cylinders simultaneously. This preserves engine performance, but significantly increases fuel consumption. A sensor malfunction is indicated by a warning lamp in the instrument cluster. The air filter with a dry replaceable filter element made of corrugated filter paper is located in the right front part of the engine compartment. The filter element is secured to the filter cover with a wing nut, and the cover is secured to the housing with three spring clips. The rotary-type electric fuel pump, driven by a DC electric motor, is located directly in the pump housing and operates in the fuel. In this regard, there are no seals of moving parts in the pump, and the rubbing surfaces are lubricated by flowing fuel. A check valve installed in the pump prevents fuel from flowing from the high pressure fuel line into the tank after the ignition is turned off. The electric fuel pump is of a non-separable design and must be replaced if it fails. The fuel filter is installed in the engine compartment above the vacuum brake booster. Replacing the standard filter with any other one, for example a standardized one in a plastic casing, is strictly prohibited due to high fuel pressure in the system. The crankcase ventilation system of a closed-type engine is forced, operating due to the vacuum in the intake manifold. When the engine is idling and at low loads, when the throttle valve is closed, crankcase gases are sucked through the hose of the small branch of the system directly into the engine intake manifold and then into the cylinders. In other modes, crankcase gases are suctioned through the hose of the main branch of the system into the throttle and from there into the intake manifold. During operation, it is necessary to monitor the tightness of the connection and the cleanliness of the pipelines, since when the crankcase ventilation system is not working, rapid oxidation and aging of the engine oil occurs. Clogging of the system pipelines leads to oil leakage through the oil seals and engine seals due to an excessive increase in crankcase gas pressure.

Supply system

- Spare parts catalog

- →

- GAZ spare parts

- →

- Engine parts

- →

- Supply system

The power system of a GAZelle car differs depending on which power unit is installed in a particular model. You can purchase components for the entire line of GAZ models using our store. The presented parts are of high quality and reasonable price, since we are official representatives of the GAZ Group. We offer delivery and various forms of payment. Carburetors | Fuel pump | Fuel tank | Fuel Air Filter | Fuel line |

| Name | Remainder | Availability | Order code | Manufacturer | Price, rub.) | Price, rub | Buy |

| Adsorber door ZMZ-405, door UMZ-4216 Euro-3 31105-1164010-1031105-1164010-10 Door adsorber. ZMZ-405, door UMZ-4216 Euro-3 | aa-40 pa-0 ar-0 nb-11 K15-1 | Magazine 1 pc. Warehouse 51 pcs. | 119839 | GAS | 570 | 570 rub. | |

| Adsorber with valve dv. ZMZ-405, 406 31105-1164010-0131105-1164010-01 Adsorber with engine valve. ZMZ-405, 406 | aa-0 pa-0 ar-0 nb-21 K15-1 | Magazine 1 pc. Warehouse 21 pcs. | 118534 | GAS | 700 | 700 rub. | |

| Fuel tank GAZ-2705 68l 2705-11010102705-1101010 Fuel tank GAZ-2705 68l | aa-10 pa-0 ar-5 nb-15 K15-1 | Magazine 1 pc. Warehouse 30 pcs. | 96010 | GAS | 6370 | 6370 rub. | |

| Fuel tank GAZ-31105 70 l (for a submersible pump) 3110-1101010-203110-1101010-20 Fuel tank GAZ-31105 70 l (for a submersible pump) | aa-0 pa-0 ar-0 nb-0 K15-1 | Magazine 1 pc. | 106977 | GAS | 8870 | 8870 rub. | |

| Fuel tank GAZ-3302 68l doors. ZMZ-4026, 4063, 40522 33023-110101033023-1101010 Fuel tank GAZ-3302 68 l door. ZMZ-4026, 4063, 40522 | aa-12 pa-0 ar-23 nb-12 K15-0 | Warehouse 47 pcs. | 122906 | GAS | 9615 | 9615 rub. | |

| Fuel tank GAZ-3302, 3307, 3308, 3309, PAZ, Valdai 105 l 33081-1101010 Suitable for vehicles GAZ-3307, 33081, 4301, 3302 | aa-20 pa-0 ar-0 nb-1 K15-0 | Warehouse 21 pcs. | 106566 | GAS | 10125 | 10125 rub. | |

| Fuel tank Gazelle Cummins 2.8 3302-1101006-603302-1101006-60 Fuel tank Gazelle Cummins 2.8 | aa-11 pa-0 ar-0 nb-4 K15-1 | Magazine 1 pc. Warehouse 15 pcs. | 138827 | GAS | 9370 | 9370 rub. | |

| Fuel tank Gazelle NEXT (TsMF) doors. UMZ-A274 with fuel intake module A31R33.1101006A31R33.1101006 Fuel tank Gazelle NEXT (TsMF) dv. UMZ-A274 with fuel intake module | aa-3 pa-0 ar-0 nb-0 K15-0 | Warehouse 3 pcs. | 138828 | GAS | 16138 | 16138 rub. | |

| Fuel tank Gazelle dv. ZMZ-405 bus (for submersible pump) 32213-110101032213-1101010 Gazelle fuel tank, d. ZMZ-405 bus (for submersible pump) | aa-0 pa-0 ar-9 nb-0 K15-0 | Warehouse 9 pcs. | 107639 | GAS | 9119 | 9119 rub. | |

| Fuel tank Gazelle dv. ZMZ-405 doors. UMZ-4216 Euro-4 (for submersible pump) 3302-1101010-303302-1101010-30 Gazelle fuel tank, door. ZMZ-405 doors. UMZ-4216 Euro-4 (for submersible pump) | aa-0 pa-0 ar-0 nb-0 K15-0 | To order | 122909 | GAS | 8100 | 8100 rub. | |

| Fuel tank Gazelle dv. ZMZ-405 thick neck 70 litres (for a submersible pump) 330243-1101010330243-1101010 Gazelle fuel tank, door. ZMZ-405 thick neck 70 litres (for a submersible pump) | aa-3 pa-0 ar-2 nb-0 K15-0 | Warehouse 5 pcs. | 101162 | GAS | 8817 | 8817 rub. | |

| Fuel tank Gazelle, Gazelle NEXT dv.UMZ-42164, A274, A275, Cummins 2.8 A21R23.1101006A21R23.1101006 Fuel tank Gazelle, Gazelle NEXT dv.UMZ-42164, A274, A275, Cummins 2.8 | aa-3 pa-0 ar-0 nb-0 K15-0 | Warehouse 3 pcs. | 25570 | GAS | 16138 | 16138 rub. | |

| Sobol fuel tank (for a submersible pump) 2752-11010102752-1101010 Sobol fuel tank (for a submersible pump) | aa-1 pa-0 ar-0 nb-0 K15-0 | Warehouse 1 pc. | 108795 | GAS | 9561 | 9561 rub. | |

| Fuel tank Sobol 2217-11010102217-1101010 Fuel tank Sobol | aa-7 pa-0 ar-3 nb-6 K15-0 | Warehouse 16 pcs. | 122894 | GAS | 8646 | 8646 rub. | |

| Air heater bushing bolt Cummins 2.8 4940117 Applicable: Gazelle Business, Sable Business, Gazelle NEXT with Cummins ISF2.8 engine | aa-0 pa-0 ar-2 nb-12 K15-2 | Magazine 2 pcs. Warehouse 14 pcs. | 109509 | CUMMINS | 55 | 55 rub. | |

| Engine fuel pipe mounting bolt. YaMZ-5344 (M10x1x21) 310122-P29310122-P29 Engine fuel pipe mounting bolt. YaMZ-5344 (M10x1x21) | aa-405 pa-0 ar-0 nb-13 K15-1 | Magazine 1 pc. Warehouse 418 pcs. | 139644 | YaMZ | 80 | 80 rub. | |

| Cummins 2.8 Euro-5 turbocharger mounting bolt 39039903903990 Cummins 2.8 Euro-5 turbocharger mounting bolt | aa-0 pa-0 ar-12 nb-0 K15-0 | Warehouse 12 pcs. | 118228 | CUMMINS | 45 | 45 rub. | |

| Cummins 2.8 injector mounting bolt 3914407 Applicable: Gazelle Business, Sable Business, Gazelle NEXT with Cummins ISF2.8 engine | aa-0 pa-0 ar-0 nb-17 K15-4 | Magazine 4 pcs. Warehouse 17 pcs. | 107801 | CUMMINS | 170 | 170 rub. | |

| Engine injector mounting screw YaMZ-5344 8.93398.9339 Engine injector mounting screw. YaMZ-5344 | aa-0 pa-0 ar-0 nb-0 K15-8 | Magazine 8 pcs. | 123169 | YaMZ | 45 | 45 rub. | |

| Air intake Gazelle NEXT A21R22-1109196A21R22-1109196 Air intake Gazelle NEXT | aa-0 pa-0 ar-0 nb-0 K15-1 | Magazine 1 pc. | 95506 | GAS | 350 | 350 rub. | |

| Air intake Gazelle NEXT A21R22-1109196-10A21R22-1109196-10 Air intake Gazelle NEXT | aa-0 pa-0 ar-0 nb-0 K15-1 | Magazine 1 pc. | 100949 | GAS | 250 | 250 rub. | |

| Air intake Gazelle Business Cummins 2.8 33023-1109180-1033023-1109180-10 Air intake Gazelle Business Cummins 2.8 | aa-0 pa-0 ar-0 nb-0 K15-1 | Magazine 1 pc. | 111111 | GAS | 530 | 530 rub. | |

| Air filter insert Gazelle NEXT Cummins 2.8 A21R22-1109079A21R22-1109079 Air filter insert Gazelle NEXT Cummins 2.8 | aa-0 pa-0 ar-0 nb-0 K15-0 | To order | 130437 | GAS | 100 | 100 rub. | |

| Air filter insert Gazelle Business, NEXT Cummins 2.8 Euro-4 3302-37613523302-3761352 Air filter insert Gazelle Business, NEXT Cummins 2.8 Euro-4 | aa-0 pa-0 ar-0 nb-0 K15-1 | Magazine 1 pc. | 111612 | GAS | 225 | 225 rub. | |

| Air heater bushing Cummins 2.8/3.8 3302-37614733302-3761473 Air heater bushing Cummins 2.8/3.8 | aa-0 pa-0 ar-0 nb-35 K15-1 | Magazine 1 pc. Warehouse 35 pcs. | 113751 | GAS | 25 | 25 rub. | |

| Fuel tank neck GAZ-2705, 2217 2705-1101060-122705-1101060-12 Fuel tank neck GAZ-2705, 2217 | aa-6 pa-0 ar-2 nb-0 K15-0 | Warehouse 8 pcs. | 101176 | GAS | 533 | 533 rub. | |

| Fuel tank neck GAZ-3302 3302-11010613302-1101061 Fuel tank neck GAZ-3302 | aa-18 pa-0 ar-3 nb-3 K15-0 | Warehouse 24 pcs. | 100970 | GAS | 1948 | 1948 rub. | |

| Damper of fine fuel filter housing YaMZ-534,536 536.1117153536.1117153 Damper of fine fuel filter housing YaMZ-534,536 | aa-0 pa-0 ar-0 nb-5 K15-6 | Magazine 6 pcs. Warehouse 5 pcs. | 131424 | YaMZ | 500 | 500 rub. | |

| Dosing unit (actuator) injection pump Cummins 2.8 0 928 400 672 The actuator, which is an important component of the Common Rail system, is a sensor responsible for regulating the pressure in the fuel rail. Based on its readings, the engine's electronic control unit issues a command to open the valve, which redirects excess fuel back to the tank. Manufactured at the enterprises of the German company BOSCH, this part is highly reliable and provides the necessary accuracy in measuring the controlled parameters. | aa-0 pa-0 ar-0 nb-0 K15-1 | Magazine 1 pc. | 112119 | BOSCH | 7350 | 7350 rub. | |

| Dosing unit (actuator) injection pump Cummins 3.8 Euro-4 294200-296294200-296 Dosing unit (actuator) injection pump Cummins 3.8 Euro-4 | aa-0 pa-0 ar-0 nb-0 K15-1 | Magazine 1 pc. | 118531 | 5800 | 5800 rub. | ||

| Dosing unit (actuator) injection pump, d. MMZ D-245.7 Euro-3 0 928 400 6400 928 400 640 Dosing unit (actuator) injection pump, d. MMZ D-245.7 Euro-3 | aa-0 pa-0 ar-0 nb-9 K15-0 | Warehouse 9 pcs. | 115531 | BOSCH | 7698 | 7698 rub. | |

| Dosing unit (actuator) injection pump, d. MMZ D-245.7 Euro-4 0 928 400 6890 928 400 689 Dosing unit (actuator) injection pump, d. MMZ D-245.7 Euro-4 | aa-0 pa-0 ar-0 nb-5 K15-0 | Warehouse 5 pcs. | 139065 | BOSCH | 4741 | 4741 rub. | |

| Throttle Cummins 2.8 49947074994707 Throttle Cummins 2.8 | aa-18 pa-0 ar-0 nb-0 K15-1 | Magazine 1 pc. Warehouse 18 pcs. | 127892 | CUMMINS | 9750 | 9750 rub. | |

| Throttle motor ZMZ-40524 Euro-3 40624.114809040624.1148090 Throttle motor. ZMZ-40524 Euro-3 | aa-36 pa-0 ar-0 nb-63 K15-1 | Magazine 1 pc. Warehouse 99 pcs. | 113110 | ELKAR | 7450 | 7450 rub. | |

| Throttle motor UMZ-42164, A-274 Euro-4 4216-1148010 (28316394)4216-1148010 (28316394) Throttle motor. UMZ-42164, A-274 Euro-4 | aa-0 pa-0 ar-0 nb-0 K15-0 | To order | 117322 | NPP ELKAR | 7350 | 7350 rub. | |

| Throttle with engine sensor ZMZ-405, 409, doors. UMZ-4216 4062.1148100-134062.1148100-13 Throttle with engine sensor. ZMZ-405, 409, doors. UMZ-4216 | aa-14 pa-0 ar-0 nb-41 K15-1 | Magazine 1 pc. Warehouse 55 pcs. | 108601 | Baker | 2860 | 2860 rub. | |

| Throttle with engine sensor ZMZ-4062, 40522 4062.1148100-024062.1148100-02 Throttle with engine sensor. ZMZ-4062, 40522 | aa-12 pa-0 ar-0 nb-14 K15-0 | Warehouse 26 pcs. | 106125 | Baker | 3214 | 3214 rub. | |

| Throttle with engine sensor UMZ-4216 Euro-3 4062.1148100-174062.1148100-17 Throttle with engine sensor. UMZ-4216 Euro-3 | aa-0 pa-0 ar-5 nb-0 K15-0 | Warehouse 5 pcs. | 20641 | Baker | 3214 | 3214 rub. | |

| Cummins 2.8 separator cap plug OS00192OS00192 Cummins 2.8 separator cap plug | aa-0 pa-0 ar-0 nb-0 K15-5 | Magazine 5 pcs. | 100324 | CUMMINS | 70 | 70 rub. | |

| Cummins 2.8 injector clamp 5405579 (5261097)5405579 (5261097) Cummins 2.8 injector clamp | aa-0 pa-0 ar-0 nb-0 K15-2 | Magazine 2 pcs. | 121509 | CUMMINS | 520 | 520 rub. | |

| Engine injector clamp Chrysler 53013504AB53013504AB Engine injector clamp. Chrysler | aa-0 pa-0 ar-0 nb-0 K15-0 | To order | 118607 | MOPAR | 400 | 400 rub. | |

| Air filter latch Gazelle Business AK2217-1109290AK2217-1109290 Air filter latch Gazelle Business | aa-55 pa-0 ar-2 nb-0 K15-27 | Magazine 27 pcs. Warehouse 57 pcs. | 99217 | AUTO COMPONENT | 40 | 40 rub. | |

| Air heater bushing insulator Cummins 2.8/3.8 3302-37614723302-3761472 Air heater bushing insulator Cummins 2.8/3.8 | aa-0 pa-0 ar-0 nb-20 K15-1 | Magazine 1 pc. Warehouse 20 pcs. | 107764 | GAS | 100 | 100 rub. | |

| Cummins 2.8 Air Heater Insulator 53052575305257 Cummins 2.8 Air Heater Insulator | aa-0 pa-0 ar-2 nb-0 K15-2 | Magazine 2 pcs. Warehouse 2 pcs. | 149967 | CUMMINS | 150 | 150 rub. | |

| Cummins 2.8 Air Heater Insulator 55367935536793 Cummins 2.8 Air Heater Insulator | aa-0 pa-0 ar-3 nb-0 K15-2 | Magazine 2 pcs. Warehouse 3 pcs. | 95504 | CUMMINS | 240 | 240 rub. | |

| Carburetor Volga, Gazelle engine. ZMZ-402 K151-1107010 BASIC SYSTEMS AND DEVICES: Two main dosing systems - primary and secondary chambers, Autonomous idling system in the primary chamber with quantitative adjustment of the mixture of constant composition, Transition systems of the primary and secondary chambers, Forced idling economizer to turn off the supply of the mixture to forced idling, Diaphragm-type accelerator pump with mechanical drive, Econostat with output to the secondary chamber, Semi-automatic system for starting and warming up the engine with manual control and a pneumatic corrector that controls the air damper. ADDITIONAL SYSTEMS AND DEVICES Fitting and channels of the engine crankcase ventilation system, Fitting and channel for control of the engine exhaust gas recirculation valve. A fuel bypass fitting that prevents the formation of vapor locks. FUNCTIONAL CHARACTERISTICS Carburetors provide: Engine power in accordance with engine specifications, Stable engine operation in all operating modes, Compliance with the requirements of GOST 17.2.2.03-87 on exhaust toxicity gases, requirements OST 37.001.054-86 and UNECE Rules N83, TECHNICAL CHARACTERISTICS: Diameter of the mixing chamber (mm): - primary - 32 - secondary - 36 Diameter of diffusers (mm): - large primary chamber - 23 - large secondary chamber - 36 - small for both cameras - 10.5 Dimensions (mm) - 176 * 185 * 133 Weight (kg) - 3.5 APPLICABILITY: Volga GAZ-3102, -31029, -3110, GAZelle GAZ-3302 Engine - ZMZ-402.10, ZMZ-4021.10 , ZMZ-4025.10, ZMZ-4026.10 | aa-13 pa-5 ar-0 nb-0 K15-0 | Warehouse 18 pcs. | 16912 | Baker | 10909 | 10909 rub. | |

| Carburetor Volga, Gazelle engine. ZMZ-402 K151S-1107010 MAIN SYSTEMS AND DEVICES: Two main dosing systems - primary and secondary chambers, Autonomous idling system in the primary chamber with quantitative regulation of the mixture of constant composition, Transition systems of the primary and secondary chambers, Forced idling economizer to shut off the supply of the mixture to forced idling, Diaphragm-type accelerator pump with mechanical drive, Econostat with output to the secondary chamber, Semi-automatic engine starting and warming up system with manual control and a pneumatic corrector that controls the air damper. ADDITIONAL SYSTEMS AND DEVICES Fitting and channel for controlling the engine exhaust gas recirculation valve. Fitting fuel bypass, preventing the formation of vapor locks. A small diffuser of a new design, providing a higher vacuum and having greater stability of performance in mass production, Acceleration pump with nozzles in both chambers and a modified cam profile, Stepless drive of the starting device, allowing more flexible engine control in the start-up and warm-up modes and eliminates the need to press the gas pedal before starting a cold engine, Modified adjustment of the metering elements, ensuring the best driving performance of cars while unconditionally meeting exhaust gas toxicity standards. FUNCTIONAL CHARACTERISTICSCarburetors provide: Engine power indicators in accordance with technical specifications engine, Stable engine operation in all operating modes, Compliance with the requirements of GOST 17.2.2.03-87 on exhaust gas toxicity, requirements of OST 37.001.054-86 and UNECE Rules N83, TECHNICAL CHARACTERISTICS: Mixing chamber diameter (mm): - primary - 32 - secondary - 36 Diffuser diameter (mm): - large primary chamber - 23 - large secondary chamber - 36 - small for both chambers - 7.5 Dimensions (mm) - 176 * 185 * 133 Weight (kg) - 3.5 APPLICATION: Car - Volga GAZ-3102, GAZ-31029, GAZ-3110, GAZelle, SobolEngine - ZMZ-402.10, ZMZ-4021.10, ZMZ-4025.10, ZMZ-4026.10 | aa-15 pa-0 ar-0 nb-0 K15-0 | Warehouse 15 pcs. | 95618 | Baker | 10610 | 10610 rub. | |

| Carburetor GAZ-2410 K126GM-1107010 MAIN SYSTEMS AND DEVICES: Two main metering systems - primary and secondary chambers, Idle system in the primary chamber, Transition system in the secondary chamber, Semi-automatic starting device for starting and warming up the engine, Piston-type accelerator pump with rubber cuff , Econostat system. TECHNICAL CHARACTERISTICS: Diameter of the mixing chamber (mm): - primary - 32 - secondary - 32 Diameter of diffusers (mm): - large primary chamber - 24 - large secondary chamber - 26 - small - two, 11 each Dimensions (mm) - 176 * 159 * 135 Weight (kg) - 2.6 APPLICABILITY: Volga GAZ-24 car Engine - ZMZ-402.10, ZMZ-24-01, ZMZ-24D | aa-10 pa-4 ar-0 nb-0 K15-0 | Warehouse 14 pcs. | 96064 | Baker | 7656 | 7656 rub. | |

| Carburetor GAZ-53, 3307, PAZ door. ZMZ-511, 513 K-135MU-1107010K-135MU-1107010 Carburetor GAZ-53, 3307, PAZ door. ZMZ-511, 513 | aa-18 pa-0 ar-2 nb-0 K15-0 | Warehouse 20 pcs. | 126333 | Baker | 13780 | 13780 rub. | |

| Carburetor GAZ-53, 3307, PAZ door. ZMZ-5231, 52342 Euro 3 K-135G-1107010K-135G-1107010 Carburetor GAZ-53, 3307, PAZ door. ZMZ-5231, 52342 Euro 3 | aa-13 pa-0 ar-0 nb-0 K15-0 | Warehouse 13 pcs. | 126332 | Baker | 18535 | 18535 rub. | |

| Carburetor GAZ-53, 3307, PAZ K135-1107010K135-1107010 Carburetor GAZ-53, 3307, PAZ | aa-23 pa-0 ar-0 nb-0 K15-0 | Warehouse 23 pcs. | 113959 | Baker | 12781 | 12781 rub. | |

| Carburetor Gazelle dv. ZMZ-4063 K151D-1107010 BASIC SYSTEMS AND DEVICES: Two main dosing systems - primary and secondary chambers, Autonomous idling system in the primary chamber with quantitative regulation of the mixture of constant composition, Transition systems of the primary and secondary chambers, Forced idling economizer to turn off the supply of the mixture to forced idling, Diaphragm-type accelerator pump with mechanical drive, Econostat with output to the secondary chamber, Semi-automatic engine starting and warming up system with manual control and a pneumatic corrector that controls the air damper. ADDITIONAL SYSTEMS AND DEVICES Fitting and channel for controlling the engine exhaust gas recirculation valve. Fitting fuel bypass, preventing the formation of vapor locks. FUNCTIONAL CHARACTERISTICSCarburetors provide: Engine power in accordance with engine specifications, Stable engine operation in all operating modes, Compliance with the requirements of GOST 17.2.2.03-87 on exhaust gas toxicity, requirements of OST 37.001.054- 86 and UNECE Regulation N83, TECHNICAL CHARACTERISTICS: Diameter of the mixing chamber (mm): - primary - 32 - secondary - 36 Diameter of diffusers (mm): - large primary chamber - 23 - large secondary chamber - 36 - small for both chambers - 10, 5Dimensions (mm) - 176*185*133Weight (kg) - 3.5APPLICATION:Car - GAZelle GAZ-3302Engine - ZMZ-4061.10, ZMZ-4063.10 | aa-0 pa-0 ar-0 nb-0 K15-1 | Magazine 1 pc. | 21543 | Baker | 10250 | 10250 rub. | |

| Valve (bolt-fitting) of the fuel drain pipe Cummins 3.8 39572903957290 Valve (bolt-fitting) of the fuel drain pipe Cummins 3.8 | aa-0 pa-0 ar-0 nb-0 K15-1 | Magazine 1 pc. | 121033 | CUMMINS | 600 | 600 rub. | |

| Canister valve, d. Chrysler 4669940AB4669940AB Engine canister valve Chrysler | aa-0 pa-0 ar-0 nb-0 K15-0 | To order | 108167 | MOPAR | 2500 | 2500 rub. | |

| Fuel tank valve 66-01-110128166-01-1101281 Fuel tank valve | aa-0 pa-0 ar-0 nb-8 K15-0 | Warehouse 8 pcs. | 108613 | GAS | 575 | 575 rub. | |

| Fuel tank gravity valve 31105.116403431105.1164034 Fuel tank gravity valve | aa-0 pa-0 ar-0 nb-14 K15-0 | Warehouse 14 pcs. | 17719 | Automotive industrial unit | 95 | 95 rub. | |

| Pressure and vacuum valve 31105-116406031105-1164060 Pressure and vacuum valve | aa-0 pa-0 ar-0 nb-91 K15-5 | Magazine 5 pcs. Warehouse 91 pcs. | 111827 | GAS | 50 | 50 rub. | |

| Pressure and vacuum valve Gazelle Business 31105.1164060-2031105.1164060-20 Pressure and vacuum valve Gazelle Business | aa-0 pa-0 ar-0 nb-0 K15-4 | Magazine 4 pcs. | 119845 | GAS | 70 | 70 rub. | |

| Fuel rail pressure limiting valve Cummins 2.8 / 3.8 1 110 010 028 replacement 3974093, 1 110 010 015 | aa-0 pa-0 ar-0 nb-0 K15-1 | Magazine 1 pc. | 109780 | BOSCH | 3700 | 3700 rub. | |

| Bypass valve for injection pump Cummins 2.8 / 3.8 F00N200798F00N200798 Bypass valve for injection pump Cummins 2.8 / 3.8 | aa-0 pa-0 ar-0 nb-0 K15-2 | Magazine 2 pcs. | 109835 | BOSCH | 1150 | 1150 rub. | |

| Canister purge valve 1103.1164200-031103.1164200-03 Canister purge valve | aa-0 pa-0 ar-0 nb-30 K15-2 | Magazine 2 pcs. Warehouse 30 pcs. | 116093 | 370 | 370 rub. | ||

| Canister purge valve 21103-1164200 Designed to ensure purge of the canister as gasoline vapor condenses in it in AvtoVAZ cars with an electronic engine control system for EURO-3 toxicity standards. Technical characteristicsValve type normally closed Supply voltage, V 12 Actuation voltage, no more than 8 V Winding resistance, 28 .5 Ohm Switching frequency, 32 Hz Working fluid of gasoline vapor and air Consumption of the working fluid when discharged 50 kPa, l/min at KIZ: 100% 45 ± 530% 8.5 ± 1.515% 4 ± 1.5 Operating ambient temperature, from -40 to +145Weight, kg 0.11 | aa-0 pa-50 ar-0 nb-36 K15-0 | Warehouse 86 pcs. | 121373 | 422 | 422 rub. | ||

| Canister purge valve, engine ZMZ-406, 40522 Euro-2 2112-1164200 Designed to ensure purge of the canister as gasoline vapor condenses in it in AvtoVAZ cars with an electronic engine control system for EURO-2 toxicity standards. Technical characteristicsValve type normally closed Supply voltage, 12 Operation voltage, no more than 8 V Winding resistance, 29 Ohm Switching frequency, 16 Hz Working fluid pair of gasoline and air Consumption of the working fluid when discharging 50 kPa, l/min 54 ± 4 Operating ambient temperature, from minus 40 to plus 130 Weight, kg 0.15 | aa-0 pa-50 ar-0 nb-66 K15-0 | Warehouse 116 pcs. | 109346 | 422 | 422 rub. | ||

| Engine fuel line pressure reducing valve ZMZ-405, 406 406.1160000-03 Application for completing the fuel line 406.1104.058-21, 406.1104.058-40 Weight, kg: 0.160 | aa-7 pa-18 ar-0 nb-0 K15-0 | Warehouse 25 pcs. | 111700 | SOATE | 1242 | 1242 rub. | |

| Engine fuel line pressure reducing valve ZMZ-4062, 40522 406.1160000-01 Application for completing the fuel line 406.1104.058-11 Weight, kg: 0.140 | aa-0 pa-18 ar-11 nb-0 K15-0 | Warehouse 29 pcs. | 20643 | SOATE | 1242 | 1242 rub. | |

| Engine fuel line pressure reducing valve ZMZ-4062, 40522 406.1600000-01406.1600000-01 Engine fuel line pressure reducing valve. ZMZ-4062, 40522 | aa-0 pa-0 ar-0 nb-0 K15-0 | To order | 101831 | Baker | 720 | 720 rub. | |

| Engine fuel line pressure reducing valve UMZ-4216 420.1160 000420.1160 000 Engine fuel line pressure reducing valve. UMZ-4216 | aa-17 pa-0 ar-5 nb-0 K15-1 | Magazine 1 pc. Warehouse 22 pcs. | 126364 | SOATE | 840 | 840 rub. | |

| Exhaust gas recirculation valve 402.1213010402.1213010 Exhaust gas recirculation valve | aa-2 pa-0 ar-0 nb-9 K15-0 | Warehouse 11 pcs. | 23628 | GAS | 2138 | 2138 rub. | |

| Exhaust gas recirculation valve 410.1213010410.1213010 Exhaust gas recirculation valve | aa-0 pa-0 ar-0 nb-0 K15-0 | To order | 109783 | Baker | 285 | 285 rub. | |

| Injector valve with rod Cummins 2.8 F00VC01383F00VC01383 Injector valve with rod Cummins 2.8 | aa-0 pa-0 ar-0 nb-0 K15-1 | Magazine 1 pc. | 106987 | BOSCH | 3200 | 3200 rub. | |

| Solenoid valve 1902.3741 Application: auto economizer system. VAZ, UAZ, GAZWeight, kg: 0.104 Active medium air with gasoline vapor AI-93 (15%) Throughput at a vacuum of 0.06 MPa 2.78 x 10-4 m3/s Rated DC supply voltage of the winding 12 V Winding resistance 32 - 42 Ohm Current, consumed by the coil 0.375 A (no more) Operating temperature range from -40°C to +80°C Dimensions Maximum diameter 40 mm Maximum length 70 mm | aa-87 pa-50 ar-0 nb-0 K15-0 | Warehouse 137 pcs. | 17766 | SOATE | 499 | 499 rub. | |

| Intake manifold Cummins 2.8 Euro-4 52676175267617 Intake manifold Cummins 2.8 Euro-4 | aa-0 pa-0 ar-0 nb-0 K15-1 | Magazine 1 pc. | 139420 | Foton | 3750 | 3750 rub. | |

| Intake manifold UMZ-4216 4216.10080154216.1008015 Intake manifold UMZ-4216 | aa-12 pa-0 ar-0 nb-0 K15-0 | Warehouse 12 pcs. | 150193 | UMP | 4926 | 4926 rub. | |

| O-ring of the fuel pump module Gazelle Business, NEXT 426-064 Volga GAZ-31105, ZMZ engine, Chrysler quick-release fittings EURO-3 | aa-0 pa-0 ar-0 nb-0 K15-8 | Magazine 8 pcs. | 115020 | GAS | 80 | 80 rub. | |

| O-ring of the submersible pump module Gazelle dv. ZMZ-405, door UMZ-4216 3111-11010223111-1101022 O-ring for Gazelle submersible pump module, d. ZMZ-405, door UMZ-4216 | aa-0 pa-0 ar-0 nb-695 K15-13 | Magazine 13 pcs. Warehouse 695 pcs. | 106362 | YARTI | 15 | 15 rub. | |

| O-ring for the outlet pipe of the TKR door. YaMZ-5344 5340.11152855340.1115285 O-ring for TKR outlet pipe, door. YaMZ-5344 | aa-0 pa-0 ar-2 nb-1 K15-3 | Magazine 3 pcs. Warehouse 3 pcs. | 107417 | YaMZ | 30 | 30 rub. | |

| O-ring for the outlet pipe of the TKR door. YaMZ-5344 53404.1115285-1053404.1115285-10 O-ring for TKR outlet pipe, door. YaMZ-5344 | aa-0 pa-0 ar-0 nb-0 K15-1 | Magazine 1 pc. | 103089 | YaMZ | 35 | 35 rub. | |

| O-ring for air pipe Cummins 2.8 / 3.8 30901263090126 O-ring for air pipe Cummins 2.8 / 3.8 | aa-0 pa-0 ar-7 nb-0 K15-4 | Magazine 4 pcs. Warehouse 7 pcs. | 109992 | CUMMINS | 115 | 115 rub. | |

| O-ring for intake air pipe Cummins 2.8 49911494991149 O-ring for intake air pipe Cummins 2.8 | aa-0 pa-0 ar-4 nb-0 K15-1 | Magazine 1 pc. Warehouse 4 pcs. | 127935 | CUMMINS | 200 | 200 rub. | |

| O-ring for the air flow sensor pipe Cummins 2.8 52542155254215 O-ring for the air flow sensor pipe Cummins 2.8 | aa-0 pa-0 ar-10 nb-0 K15-1 | Magazine 1 pc. Warehouse 10 pcs. | 127936 | CUMMINS | 150 | 150 rub. |

Power supply system GAZ 1 - 80 of 525

1

We diagnose the Gazelle engine and control system

Abstract Engine cooling system VAZ 2108 Similar works

This time we came across a Gazelle. Probably the most common vehicle for small transport. Due to high demand, the number of such cars is constantly growing. This means it will be very useful to consider some of the dark sides. These include a microprocessor ignition system installed on 406 engines. The gazelle, or rather its owner, came with complaints. The loss of power and jerky pats did not allow our horse to work calmly.

In our case, we will have to check “everything” - the power system, ignition, engine. We checked the carburetor using a four-component gas analyzer. Idling, operation of the first and second chambers, enrichment in power mode, cutoff, everything turned out to be normal. Let's move on to the engine. We measured the compression. In the 4063 engine it must be at least 9.6 / cm2, and in the 4061 at least 8.2 kg/cm2. The compression turned out to be normal, but upon repeated measurements it floated a little by 10%. We decided to check the valve timing. That’s right, it turned out that the upper chain jumped two teeth - so you get jerks and pats.

Gazelle

How does the VAZ 2114 engine cooling system work?

Model 40524.10 is a gazelle carburetor known to everyone. Car brand - Gazelle is one of the most popular and affordable trucks in Russia, which were originally intended for transporting small loads. Due to the huge number of such machines, let’s look at the nuances of different gazelle systems. microprocessor, For example, the ignition system that is installed on the 406 model.

If the driver claims that his car makes some popping noises, jerking noises and loses power. In this case, the power supply system, engine and ignition system should be checked. We checked the carburetor with a gas analyzer not during the operation of the 1st and 2nd chambers, cut-off time and idle enrichment and did not find any violations. Next they check the engine. When checking the compression, there were no problems as follows, but when detected, deviations from Was were detected. standards, it was concluded that the jerks and pops that the driver did not like were due to the jumping of the teeth of the upper chain.

What to do if you lose a gazelle? power

From the very beginning, you need to do how to check the functioning of the diagnostic circuit and the on-board diagnostic system, because when the drive mode image is activated, a violation operating code should be obtained - 12. To read the code, the 10th and 12th contacts of the diagnostic block must be closed. Using the diagnostic toaster, measurements are taken from engine parameter sensors and then they are compared with the values of typical average engines. The most common reason for a decrease in car power is contamination of the tubes connecting the intake manifold and the sensor system.

gazelle ignition pressure

The microprocessor system ignites the working fluid in the cylinders and sets the required ignition timing of the vehicle for all engine modes. The ignition system regulates the operation of the forced stroke economizer. Thanks. By idling the ignition system, the operation of the engine becomes more economical, compliance with all toxicity standards of exhaust gases is monitored, and an increase in and detonation of the vehicle’s power is eliminated. If we compare the classic system with this one, then this ignition system is much more reliable and durable. The only thing that can wear out here is the spark plugs.

How does the diagnostic work? mode

When the ignition system is turned on, the indicator lights up. At that very moment, the diagnostic system begins to work. If the system is working properly, the light stops lighting, but otherwise it continues to light. That is, when the indicator goes out, it means that the ignition system is absolutely working.

Why does the 406 engine sometimes freeze when starting?

The most common reasons why the 406 engine does not start:

- Poor quality oil;

- powerful Battery is insufficient, preventing it from starting Faulty;

- engine starter;

- Misregulated ignition system;

- gasoline Poor quality;

- Failure to supply gasoline.

How to adjust the carburetor?

- Disconnect the air damper cord;

- Remove the air filter and cover Check;

- carburetor float chamber level, it should be below 3 centimeters from the edges;

- Remove the plug from the float rod;

- Make sure the sealing valve is tight. Install;

- rings on the top of the carburetor;

- Install the choke air cable and air filter;

- Screw in the screw for adjusting the idle speed all the way, unscrewing it five turns. Do the same with the quality screw, but unscrew it three turns;

- Start the power unit;

- Let it heat up to 90?;

- By rotating the operating screw, select the crankshaft speed control, about 700 rpm;

- Press the pedal quickly and release the accelerator. If the engine stalls, increase the frequency;

- Stop by a car dealership and adjust the CO and CH of the engine.

Replacing wiring

Advice: replacing functional control devices on the panel due to new connectors is not justified.

Therefore, when integrating new wiring, the connection diagram in the connecting terminals only changes, and for alignment you should use the wiring diagram of the new power unit.

Changing everything to 406 is certainly not impractical.

The fact is that on newer versions of Gazelles, the connection diagram of certain devices also changed:

- Gazelle 406 wiring is integrated into the standard electrical system in the engine compartment;

- electronic components and control devices are connected using terminals;

- The voltage and correct connection are checked using testers.

After assembling the wiring into a single whole, its functionality is checked. Subsequently, the operation of the power unit is adjusted.

Conclusions: Replacing a power unit inevitably involves changing the standard electrical wiring of the car. That is why it is important to have a visual aid at hand when carrying out such an operation, and the factory one will allow you to avoid mistakes.

Today, Gazelle cars are used in many sectors of modern business. To ensure the operability of the vehicle, it is necessary to pay attention not only to the performance of the main components and assemblies, but also to the electrical circuit of the Gazelle car. From this material you will learn everything you need to know about the operation of wiring and its malfunctions.

Adjusting the K151D carburetor

Radiator cooling fan - operating principle and malfunctions

Like other types of CUs (Ozone, Solex, etc.), the K151D carburetor can be adjusted and configured, the main settings are:

- XX adjustment;

- setting the gasoline level in the float chamber;

- debugging the launcher.

“One Hundred and Fifty-First” resembles the K126 model, and seems to be an improved version, although it has a more complex design and is considered more “capricious” to configure. But adjusting, for example, idle speed, is not so difficult here; besides, the minimum speed on the Gazelle can be set using the tachometer.

The most basic of the available K151 settings is the XX adjustment; it is performed on a warm engine, while all other elements of the fuel system, ignition circuits and the engine itself must be in good working order. We adjust XX like this:

- we start the engine at idle speed, unscrew the large quantity screw (with the spring), and also unscrew the quality screw, thereby setting the speed to the maximum;

- alternately tighten both screws, slowing down, until the engine starts to work intermittently;

- “quantity” we add a little XX, then “quality” we level the internal combustion engine, but it is better to try to unscrew this screw as little as possible, it affects gasoline consumption;

- Using the quantity screw, we reduce the speed to normal, that is, to approximately 700-750 rpm (look at the tachometer).

After adjusting the idle speed, the car is usually checked in action, and if necessary, the adjustment is repeated.

Electrical diagram of GAZ-Z302 and GAZ-2705 with engines of the ZMZ-406 family

The outline for a more detailed study consists of two parts.

Failures of electrical equipment are explained by the simplest reasons, such as corrosion of connector contacts, failure of a fuse, burnt-out fuse-link or damaged relay. Visually check the condition of all fuses, wiring and connectors on the circuit before proceeding with a more detailed check of the serviceability of its components.

If diagnostic tools are used for troubleshooting, carefully plan (in accordance with the supplied electrical diagrams) at which points in the circuit and in what sequence the device should be connected to most effectively identify the fault.

In addition, you should always have in your car a set of wires for starting the engine from an external power source (the battery of another car), equipped with alligator clips. As already mentioned, before you start checking the circuit using diagnostic equipment, determine the location of its connections using the diagrams. Basic diagnostic equipment includes an electrical circuit tester or a voltmeter (you can also use a 12-volt test lamp with a set of connecting wires), open circuit indicator (probe), which includes a lamp with its own power source and a set of connecting wires.

Consumption rate what numbers are certified by the manufacturer

The Volga line of power units includes five different assemblies with a displacement from 2.3 to 2.5 liters. The most popular were versions of cars with the legendary 402 engine, which was equipped not only with cars of the Volga family, but also of the Gazelle family, and Latvia minibuses. The engine power is 100 horsepower, which allows the vehicle to reach a speed of 100 km/h in 15 seconds. For that time, this was a truly outstanding indicator. After some time, the GAZ-3110 began to be equipped with an injection ZMZ-406.

Official fuel consumption rates in the urban/extra-urban cycle:

- ZMZ-402 – 13/9 liters;

- ZMZ-4021 – 12/8 liters;

- ZMZ-406 – 11.5/7.5 liters.

ZMZ-4021 is characterized by lower power - 90 horsepower. Due to technical changes, the 2.4-liter engine began to consume less gasoline, but the official standard was still at a fairly high level, which did not suit many domestic drivers. Turbo diesel power units GAZ-560 and GAZ-5601, produced under the Stery license, were less popular. People's distrust of the quality of diesel fuel has left its mark on the number of sales of GAZ-3110 modifications with a diesel engine under the hood. Due to the low level of diesel fuel consumption - 8 liters in the city, there was still a small demand for them.

The correct choice of carburetor for a Gazelle with a ZMZ-406 engine

The K151D is a rather capricious device; not all drivers and owners of GAZelle cars are happy with it; the question often arises as to what is better to install instead. The most commonly considered options here are carburetors:

- "Solex", developed for the Volga GAZ-31029;

- DAAZ 4178-1107010, intended for UAZ vehicles;

- "Ozone" from VAZ-2107;

- Weber.

Choosing the right carburetor for a Gazelle is not an easy task; each option has its own disadvantages. In any case, when replacing a standard unit with any other device, modifications have to be made, and the most common tuning of the control unit is:

- adjusting the air filter housing;

- installation of jets (fuel and air) of a different section;

- replacement of diffusers and emulsion tubes;

- adjusting the accelerator pump nozzle.

In each case, fitting requires an individual approach and some experience in this matter, and it would be a shame to buy a carburetor but not get the desired results (no gas savings, no improvement in dynamic performance, a car with a new carburetor will not start). However, the price of Solex or Ozone is relatively small, and besides, a part that is no longer needed can always be sold, even cheaper.

Replacing a carburetor with an injector on a ZMZ-4063 engine

In order to improve technical characteristics, quite often Gazelle owners replace the carburetor system with an injector, although this pleasure is not cheap. For such a modification it will be necessary to purchase additionally:

You may also need various small things, such as gasoline hoses, clamps, fuses, gaskets, fuel filter bracket, etc. The work here is labor-intensive, but the end justifies the means. The advantages of an injector over a carburetor are significant:

Some injector spare parts are expensive, but it is not necessary to purchase them at the store. Excellent quality used parts can be found at car dismantling yards or through advertisements from private traders, especially since you can almost always bargain. Definitely, it is better to buy a used collector (receiver), since it almost never wears out, and there is no point in overpaying here.

Video on repairing the Gazelle ZMZ 406 engine:

Source

General characteristics

The ZMZ 406 engine is a carburetor, four-cylinder, and also in-line with a microprocessor ignition system. ZMZ 406 equipped with a carburetor has a power of 110 hp. s., and with an injector - 145 liters. With. In addition, injection modifications have different environmental standards. For example, ZMZ 4062.10 is class 0, and ZMZ 40621.10 is Euro class 2. An oil cooler is considered an extra part in ZMZ 406, because the 6th engine does not heat up. In the ZMZ 405, the oil cooler does not perform its functions, and the engine overheats in hot weather and naturally does not start.

The cost of gasoline for a ZMZ 406 carburetor directly depends on the conditions and driving style, as well as the time of year. The ignition system of the ZMZ 406 carburetor is considered quite reliable. The engine will be able to reach speeds of up to 500 thousand kilometers using high-quality oil and gasoline, as well as careful handling of the pedal.

Various circuits depending on the engine

The ZMZ 402 carburetor engines were the very first to be installed on the Gazelle. For the operation of the internal combustion engine ignition system, it was necessary to supply power to the ignition coil, distributor and switch. The next one to enter the series was also in a carburetor version.

But it no longer had a coil, distributor and switch; instead, an electronic ignition control unit was installed.

Later, Gazelles began to be equipped with a ZMZ 405 injection engine, which instead of a carburetor had a distributed injection system.

This is what the ZMZ 405 engine looks like

The engine wiring on this engine is completely different - the control unit has become common to both the ignition system and distributed injection. have their own electrical circuit, and it differs depending on the type of internal combustion engine installed: Cummins or UMZ-A274. The Gazelle Next has been equipped with a new 2.7 liter engine since the end of 2014.

Fuel system and ignition diagrams for Gazelle with engine 406

GAZ commercial vehicles began to be produced in 1994, at first they were equipped only with ZMZ-402 engines. Later, carburetor 16-valve engines ZMZ-4061.10 (for A-76 gasoline) and ZMZ-4063.10 (for running on Ai-92 fuel) began to be installed on these machines.

ZMZ-4063 is an internal combustion engine (ICE), which is no longer produced by the Zavolzhsky Motor Plant, but is still in use today. The engine has an electronic ignition system, but at the same time a fuel system with carburetor injection (CI), the carburetor model installed from the factory is K151D. The ignition circuit is microprocessor-based and includes the following elements:

- electronic control unit;

- two double coils;

- high-voltage wires with lugs;

- crankshaft and camshaft position sensors;

- spark plug;

- coolant temperature sensor;

- wiring (“braid”).

The power supply system (circuit) for cars with HF is very simple, consists of a minimum of components, and these are:

- gas tank;

- fuel lines, including supply and return hoses;

- fine/coarse fuel filters;

- mechanical fuel pump;

- air filter housing;

- carburetor.

If desired, you can install gas cylinder equipment (LPG) on a Gazelle with an internal combustion engine ZMZ-4063, but only the first or second generation; you can buy it very inexpensively. There is only one significant drawback here - the equipment is already considered outdated and does not meet all modern safety requirements.

Signs of trouble

There are several types of electrical circuit conditions in Gazelle 405 euro 2, 402, 406, 4216, 2705, 3302 or business diesel cars:

- The engine does not start. A car cannot perform its primary function if the engine is not running. Either the wiring on the Gazelle business diesel, 402, 406, 405 euro 2, 4216, 3302, 2705 is damaged, or one of the units or mechanisms of the car has failed.

- The car engine starts, but the electrical equipment functions incorrectly or intermittently.

If, as a result of an attempt to start the engine, the unit does not start, but fuel enters the engine, then most likely the problem lies in the electrical equipment:

- If the vehicle is equipped with a carburetor, first you should pay attention to diagnosing high-voltage cables and spark plugs. By the way, quite often on older Gazelle cars with a carburetor, in practice, high-voltage wires cause inconvenience to the driver. If the high-voltage cables have exhausted their service life, the engine will not operate correctly. So check them first. On a Gazelle with a carburetor, it would not be a bad idea to check the performance of the distributor and coil. In addition to high-voltage wires, you can diagnose the electrical circuit in the engine compartment.

- In the case of an injector, the situation is slightly different. Of course, high-voltage wires can also cause breakdowns, but first of all you need to pay attention to electrical equipment. In particular, you are interested in the engine management system. If the injector control system is not able to properly process the pulses coming from the regulator, then as a result it will not be able to give commands to other components and mechanisms. Accordingly, interruptions in engine operation will begin.

Electrical wiring of the engine compartment

As practice shows, in most Gazelle business diesel cars, 402, 406, Euro 2,405, 3302, 2705 and others, the causes of breakdowns are acidified or burnt contacts. In this case we are talking about the contacts in the ignition switch. If the ignition switch or unit is inoperative, at least the lighting in the vehicle interior will not be able to work. Also, faulty electrical equipment can lead to inoperability of washers, fans, windshield wipers, etc.