Diagnostics

The first step is to determine the source of the sound. You can do this yourself, but in this case you need to clearly know the characteristic sounds of each mechanism. The easiest way is to ask a friend to start the car, and listen and determine the source yourself.

In 99% of cases, the malfunction lies in such elements of the engine compartment as:

3) Power steering.,

Bearings creaking

Typically, various bearings run for 100 thousand kilometers or more. However, over time, the lubricant inside them runs out and the elements begin to rub, making a creaking noise. These bearings don't last long. In winter, this worsens due to the loss of lubricating properties of the filler.

Whistling belts

Whistling belts are the most common cause of all of the above. This occurs due to their wear and tear, as well as temperature changes. Some spare parts manufacturers make drive belts from low-quality rubber, which quickly hardens in the cold.

Power steering

If it whistles for 3-4 seconds and then stops, this is normal. In the cold, the technical fluid also loses its fluidity, so for some time the pump operates with overload. However, if the power steering does break down, you should not do it yourself, as it is a very complex mechanism.

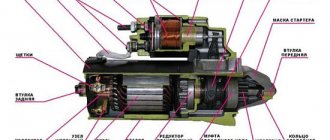

Starter

Most often, a grinding noise (precisely a grinding sound) occurs when the engine starts. In 99% of cases this is a bendix malfunction. The repair is very simple - you need to remove the starter and lubricate this same bendix. You should not delay this - over time it may fail.

Source

Noises when starting a cold car, which can provoke them

Below we discuss in detail the main most common types of abnormal noises when starting a machine when cold, as well as their possible causes:

- The sound of the engine being difficult to start. When starting off in a cold environment, a low intensity of headlight light is noted, and a sensation of sound is perceived, as if the car is starting without force. This is a symptom caused by problems with the battery (low charge or in poor condition) or the terminals (possibly making poor connections).

- “Skating” starter (“grrrrrrrrr…”). If the car starts to make friction noise between the gears when starting from a stop, there may be a problem with the starter.

- Engine noise (“chof, chof...”). If you hear a noise when starting a cold engine that sounds like “chop, chof...” and there is a strong smell of fuel inside the car, it is possible that the injectors are no longer sealed or are in poor condition. The noise that the injectors produce is very distinctive and this is due to the effect of fuel vapors escaping to the outside of the valve covers.

- Metal friction noise. It may happen that when starting the engine cold, a friction noise was heard between metal parts from the engine area. This situation may be a symptom caused by a faulty water pump. This metallic noise can occur when the water pump turbine comes into contact with the pump housing itself.

- Metallic noise (ringing) from the exhaust area. Sometimes, it may happen that some leak protector or clamp is loose or cracked. “Ringing” is produced by a metal part that has become loose or has cracks.

- Creak from inside the car. If there is a noise when starting the car when it is cold and it sounds like a squeak coming from the inside of the car, it is possible that the heating fan is in poor condition (the balance axis is probably broken or there is a lack of lubrication).

- The sound of metal sheets vibrating when starting up. The noise from vibration of metal sheets when starting is usually associated with the poor condition of the pipe protectors. These protectors can crack or break due to external factors such as temperature, mechanical stress, etc.

- Creak in the engine area. A creaking sound in the engine area when starting off may occur due to a timing belt pulley or tensioner in poor condition. This happens because the rollers or tensioners may become loose

- Intermittency or knocking noise in the engine compartment area. This noise when starting the car when cold occurs, as a rule, due to the timing chain being in poor condition (stretched or faulty). In this case, the chain cuts into the skates and produces these knocking noises, especially if the engine is not hot.

- Vibration of plastic in the engine area (“trrrrrrr…”). Vibration, changes in temperature or aging of the material can be caused by the fact that the cover that covers the engine is cracked or its supports are damaged, and, accordingly, vibrations of the plastic are heard.

- Metallic noise exactly during startup, accompanied by vibration in the body and steering wheel. This symptom can be considered if the engine pistons are in poor condition. These symptoms may lead to a more serious problem.

- A noise, as if metal was ringing at the start (“klo, klo,...”). When starting off, there may be a noise, a ringing of metal caused by a steering wheel failure. This can be caused by the steering wheel being unbalanced, causing vibrations that cause this noise. He's very characterful.

- Loud whistle in the engine compartment. Another possible noise when starting a car in cold weather is a whistle from the engine compartment, which may be caused by a defect in the exhaust manifold. A crack in this part, or a gasket in poor condition, both of which can create such a loud whistling noise.

- Engine chatter or discordant noises. There is a possibility that this kind of noise occurs in the engine when internal parts fail. As a rule, this malfunction is difficult to determine, since in order to accurately diagnose it, you need to disassemble the engine.

Recommendations

There are many possible abnormal noises during cold engine starting. When they are detected, it is important to have the vehicle checked as soon as possible, as these noises could be hiding a serious problem, or it could be a harbinger of a future serious problem.

To eliminate any type of noise when starting a car when cold, it is highly recommended to contact a workshop. Answer 2 important questions: “what noise?” and “where does it come from?” This information will help technicians diagnose the problem.

Some of these noises are caused by worn or broken parts, plastic or metal. In many cases, it is not possible to replace the part (due to their high cost, lack of goods, etc.) and, to eliminate the malfunction, in such cases, it is recommended to use two-component glue.

Source

Diagnostic and troubleshooting methods

Many car enthusiasts, leaving home in the morning and starting the vehicle engine, have encountered a grinding and crackling sound when starting up. In this case, the malfunctions are different and it is worth understanding what sound means what.

Starter, flywheel and solenoid relay

Perhaps it’s worth starting our consideration with the fact that a grinding noise appears during the start-up of the power unit. As it was found out earlier, the issue here is in the starter or flywheel. So, if the grinding noise continues until the engine starts, this is due to wear on the bendix or flywheel crown.

To be more precise, the teeth of one or the second element are worn out, and the part does not adhere well to the part. Also, the issue may be in the solenoid relay, which does not fully pull the bendix, which does not grab the flywheel.

To eliminate the malfunction, it is necessary to dismantle the starter and inspect the condition of the bendix, namely its teeth. If there is characteristic wear in the form of “licking” of the teeth, then it is recommended to replace the part. But that's not all. Also, since the starter has already been removed from the vehicle, it is worth checking the solenoid relay.

To do this, you just need to connect it to the on-board 12 volt network and listen to see if the solenoid relay clicks. If clicks are not heard, then you will have to disassemble the starter and replace the failed part.

Also, this malfunction and the grinding effect can be caused by the fact that the flywheel crown is worn out. It is worth noting that not all engines have a dismountable flywheel, so the entire assembly part is often replaced. Thus, the wear of the teeth leads to the fact that the Bendix cannot catch on them and turn the crankshaft. It is at this moment that a grinding noise occurs in the engine compartment.

Cracking - where to run and what to do

A cracking sound is a malfunction in the crank mechanism or cylinder head. So, first of all, it’s worth checking the cylinder head. Malfunctions must be looked for in the guide bushings, where wear may have occurred and the valve simply dangles, and hydraulic compensators can also knock and crack, which should be replaced because they have exhausted their service life.

The second place to pay attention is the cylinder block and its elements. So, a cracking noise can be caused by a lack of lubrication (engine oil), as a result of which the oil scraper rings scratch the cylinder walls. Also, special attention should be paid to the main and connecting rod bearings, which can rotate due to wear on the part of the block itself.

In this case, special attention should be paid to the condition of the crankshaft, which could have scratches and deep grooves.

The last element that can also cause cracking and damage the cylinder walls is the connecting rod bushings. They could become loose and go beyond the pressing limits. In this case, the danger is that the bushings can damage the cylinder walls so much that the only solution is to line the block or replace it.

Causes of malfunction

Before we begin to study the causes of the malfunction, we remind you that hereinafter we are talking about the crackling noise of the starter, which is most similar to the loud rattling of the contacts of an electromagnetic relay. If you hear an unpleasant metallic grinding noise from under the hood, then it appears due to poor engagement of the overrunning clutch (starter Bendix) with the flywheel teeth - that’s a completely different story.

Most often, the starter crackles when you turn the ignition key for three reasons:

Low battery

To understand the cause of the crackling noise due to a discharged battery, let's remember the starter device. When you turn the ignition key, the voltage from the on-board network is supplied to the coil of its solenoid relay. The electromagnetic forces that appear in this case cause the armature of the device to move. It closes the power contacts that connect the starter motor to the battery, and in addition, causes the Bendix gear to engage with the flywheel.

When the battery is discharged, its energy may be enough to attract the metal core - cranking the crankshaft is out of the question. As soon as the starter contacts close and power is supplied to its electric motor, the voltage drops to such an extent that the electromagnet is unable to hold the metal core. Under the action of the return spring, it tends to take its original position and opens the power contacts. The restored voltage contributes to the repeated retraction of the anchor, and the situation is recreated many times.

To make sure that the culprit of the problem is a deep discharge of the battery, just turn on several consumers (lighting, electric heater motor, etc.) and press the sound signal. The latter will either not turn on at all, or will be heard with wheezing, reduced amplitude or attenuation.

Poor engine ground contact

The picture of what is happening is practically indistinguishable from the case discussed above, with the only difference that the test for battery discharge ends with a negative result - all consumers, including the sound signal, are working at full strength.

At the same time, it is very simple to determine that the cause of the malfunction is poor contact between the battery and the engine - just pay attention to the oil pressure warning lamp, which is located on the instrument panel. If the voltage in the car’s on-board network is below normal, then turning the ignition switch to the “Start” position will lead to a gradual attenuation of the brightness of the warning lamp (like all others).

In the case where the cause of the crackling sound of the starter solenoid relay is a bad ground, an attempt to start the engine will lead to its complete extinction in time with the clicks of the solenoid relay. At the same time, other indicators practically do not change the intensity of the glow.

Everything is explained very simply - the “mass” of the oil pressure sensor, as well as the starter, is the housing. Therefore, as soon as the electrical contact between the engine and the battery is lost, both of these devices stop working synchronously.

Open or shorted starter relay winding

Another reason why the solenoid relay cracks is an interturn short circuit or a break in its holding winding. In other words, the efforts of the electromagnet become insufficient to keep the power contacts of the starter relay in the closed state and engage the overrunning clutch gear with the flywheel ring gear. Under the action of the return spring, the bendix tends to take its original position, and the contact pad located on the armature opens the electrical connection. After this, the retractor winding turns on again and the situation repeats itself many times, which causes the crackling noise.

to determine that in this case the starter solenoid relay has failed by the behavior of the warning lamps located on the instrument panel. At the moment when the loud clicks of the starter are heard, their brightness does not change - the switching of the starter motor occurs for such a short time that the battery voltage practically does not drop.

Conclusion

Grinding and crackling noises in the power unit indicate that some engine parts have failed. So, the grinding noise is accompanied by a malfunction in the starter or flywheel. As for the crackling sound, the situation is much more complicated - most likely the problem is hidden in the crank mechanism or in the cylinder head.

If such malfunctions occur, it is recommended to contact a car service as soon as possible, so as not to cause more trouble than already exists.

Source

When starting the engine, you hear a whistle or any other extraneous sounds: we are looking for the cause

Even an inexperienced car enthusiast will say that the main unit in any vehicle is the internal combustion engine. If a malfunction occurs in the operation of this unit, the driver will know about it immediately by the behavior of the car. One of the common problems in engine operation is the appearance of extraneous sounds. Why a whistle is heard when starting the engine and what to do in this case - this material will help you understand the problem in detail.

Why is there a crackling and grinding sound when starting the engine? Most likely it's the starter

Drivers are often interested in why crackling and grinding noises are heard when starting the engine. There may be several reasons for this phenomenon. In any case, the source of this sound should be eliminated as quickly as possible. Otherwise, you risk a breakdown at the most inopportune moment. In general, if any strange sounds appear, you should check their origin. After all, this is most likely a sign of a breakdown.

The sooner you eliminate it, the better. After all, most faults can cause a chain reaction. And provoke breakdowns of other engine components. Therefore, always listen carefully to the operation of the power unit.

The driver's first actions when noise appears from under the hood

The first thing any car owner should do is to get rid of the cause as quickly as possible. If you have repair skills, you can change belts, bearings or disassemble the starter yourself. If you are going on a long trip and find such a problem before setting off, we would advise you to first stop at a service station and have it resolved. Otherwise, a malfunction may overtake you on the road.

We recommend: The brake pedal fails: causes and methods of troubleshooting

A whistling sound is heard when starting the engine

A whistling sound at start-up usually comes from the alternator belt or the cooling system water pump (pump). The malfunction manifests itself in the form of a high-frequency squeak or squeal after starting the internal combustion engine, and can also make itself felt already on a warm engine when you sharply press the gas pedal and increase the crankshaft speed.

- If there is a problem with the belt, you need to check its condition and tension. Sometimes it temporarily helps to apply special rubber care compounds, which allow the surface of the belt to remain soft and elastic, protect against cracking, etc. If the tension is clearly weakened, the generator belt must be tightened, while simultaneously checking the condition of the pulleys and tensioner. Let us add that it is not recommended to tighten a strongly stretched belt, since the whistle will appear again after a short period of time. In this case, and also when it is not possible to further tighten the alternator belt, only replacement is indicated. If the belt is tensioned normally, does not slip on the pulleys, but still whistles, then it may be of poor quality and requires replacement.

Let us also add that the cause of the whistle can be not only the belt, but also the generator itself. More precisely, problems may arise with the bearings of its drive. This is indicated by a characteristic rustling, whistling, and slight crackling sound when the engine is running at idle.

- The pump also makes a thin whistle at idle speed, and the problem may be accompanied by a rumbling or crackling sound. This symptom is a reason for mandatory inspection and replacement of this element.

To check the generator and/or pump, you can take a block of wood, you can also attach a tin can to the end of a wooden stick, etc. Then one end of the bar or stick is applied to the drive area of the generator or pump with the engine running, and the other end of the bar or a tin can attached to the stick is brought to the ear. This solution allows you to more accurately determine the source of noise and localize the fault. By the way, if possible, instead of a homemade device for listening to noise, you can use the so-called car stethoscope (sometimes a medical one is also used).

If the source of the noise is not fully identified, then it is necessary to remove the generator belt, after which the pump or generator pulley is sharply turned by hand. The appearance of noise, difficulty during rotation, beating, play and other deviations from the norm will indicate a problem. In the case of a generator, the device can be repaired by replacing the bearings. It is recommended to change the pump immediately, since on many cars a jammed water pump leads to a broken timing belt.

We also recommend reading the article on how to check the pump on a car without removing it. From this article you will learn about ways to check the functionality of the water pump, as well as methods for independently determining malfunctions of this element of the engine cooling system.

An additional reason to replace the pump is considered to be the appearance of antifreeze or antifreeze drips at the place of its installation. Coolant leaks pose a danger in the form of overheating of the internal combustion engine; a broken timing belt means that the piston hits the valves, causing the valves to bend. Ultimately, if these problems are ignored, the engine may require expensive or even major repairs.

How to fix a rattling starter

The method for troubleshooting depends on what is causing the problem. If the starter cannot work normally due to a discharged battery, it is enough to charge it to the required parameters. Typically, charging is carried out with a current of 0.1C, where C is the battery capacity in ampere-hours. At the same time, highly discharged current sources and calcium batteries should be charged with low currents (1-2 A) to at least 25% charge (this parameter is controlled by the density of the electrolyte). The gentle mode will take more time, but will protect the battery from many negative aspects.

Note! Often, when the battery is discharged, car owners try to start the engine “from a tow”. Note that this method is only suitable for the simplest power units, but not for injection engines. Launching the latter “from the pusher” often leads to a failure of the electronic control unit software.

In this case, the ECU begins to behave unpredictably - for example, request permission to start from a disabled immobilizer. The situation can only be corrected by reflashing the “brains”, and this, as you yourself understand, is an additional and completely unjustified expense.

In the case where the cracking of the solenoid relay occurs due to poor contact with the vehicle ground, it is enough to simply restore the electrical connection. To avoid problems in the future, it is recommended to remove the tire that connects the engine to the body and clean the contact pads with sandpaper. A thin layer of technical Vaseline or VD-40 universal lubricant will help prevent their oxidation.

If the source of the malfunction is the retaining winding of the starter solenoid relay, then try to repair it. If this is not possible, then a decision is made to replace the solenoid relay assembly. As you can see, even a novice driver can cope with finding the fault that is causing the starter to crack.

Video: Why the starter cracks. Useful advice from an auto electrician.

The appearance of extraneous sounds in the engine compartment during or immediately after starting the engine is a reason to diagnose and check the internal combustion engine. Various deviations from the norm can occur as a result of wear of individual elements of attachments, drives, bearings, pulleys or belts. Also, one should not exclude the possibility of breakdown of the power unit itself and its components. Drivers often notice that when starting the engine when cold, a grinding noise is heard, something creaks in the engine, a whistle appears, etc.

It should be noted that usually many sounds are better heard during a cold start, although in some cases the noise does not go away even after the power unit warms up. It should also be added that in some cases the problem progresses noticeably, that is, the sound gets stronger each time or gradually. In other situations, extraneous noise may not change its tone and intensity over hundreds or even thousands of kilometers.

In this article we will talk about what kind of breakdowns can lead to noise being heard during a cold engine start, as well as how and by what additional signs you can determine the malfunction yourself.

Read in this article

Causes

Why is there a crackling and grinding sound when starting the engine? This question is often asked by beginners and not-so-motorists. Many people are frightened by the strange sound heard when starting the engine. Although in many cases this is not a difficult problem. But it still needs to be eliminated, and for this it’s good to know where to look for the problem. There are several places that produce crackling and grinding noises during startup:

- Starter;

- Flywheel;

- Roller mounting bolt (timing).

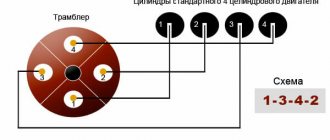

Knowing the main places of breakdowns, you will quickly find out where the main problem is. For a more accurate diagnosis, open the hood and ask someone to start the engine. If there are problems with the starter and flywheel, a cracking noise will be heard from the rear of the engine when the bolt is unscrewed at the front.

Main symptoms of malfunctions

So, what to do in such a situation, and where to look for the problem, if you got behind the wheel of a car and turned the key in the ignition, but this did not give the desired result. The reasons may lie in the battery itself, or malfunctions of the starter, or in various connections and switching. Most often, of course, the culprit is the battery itself. It may simply discharge, and the following signs will indicate this:

There is a knocking sound when starting the engine

The appearance of knocking in the engine should be divided into problems with the gas distribution mechanism and the elements of the internal combustion engine itself (crankshaft and CPG, pistons, connecting rods, crankshaft, etc.). Extraneous sounds in the timing area may indicate significant wear of the rollers, defects in the timing belt or chain.

The rollers may whistle, howl, crunch or tap. In some cases, the timing belt rubs against the protective casing. We also note that on motors with a chain, when the chain itself is stretched or the tension is insufficient, the sound resembles a rustling chirping, and popping noises can also be heard. If you increase the speed, such sounds disappear and appear again after releasing the gas. In this situation, the timing chain needs to be tightened or replaced.

A characteristic knock of the gas distribution mechanism is the knock of the intake and/or exhaust valves. This knock differs in frequency from other knocks and has regular intervals. The fact is that the camshaft rotates twice as slow as the crankshaft. Improper adjustment of the thermal clearance of the valves can cause knocking noises.

On engines with hydraulic compensators, a common cause is failure of the latter or clogging of the oil supply channel to the hydraulic compensator. In this case, the sound is clear, clear, and can be easily heard in the valve cover area. Note that on many cars, after a cold start, the hydraulic compensators knock for several seconds until the engine oil reaches them. This is considered the norm. If the knocking does not go away after the engine warms up, then you need to contact a service center or solve the problem yourself.

The starter relay clicks, but it doesn't turn over.

If, when you turn the ignition key, clicks are heard from the starter relay, but the unit itself does not spin, then the problem may be associated with a malfunction of the control cable that powers the relay, or with a problem in the performance of the relay itself.

In such a situation, the car can be started if you short-circuit the “plus” from the battery to the positive control terminal from the ignition switch (the smallest wire of the three is connected to it). If, with such a connection, the starter starts to spin, then the malfunction is definitely not related to the battery, and the problem should be looked for in the relay, ignition switch or wiring.

Solenoid relay diagnostics

If the starter does not turn when the engine starts, but clicks are heard, the first step is to diagnose the relay itself. It connects to the battery and ignition switch via 2 cables. One of them (thick section) comes from the positive terminal of the battery, and the second (thin section) goes from the positive control terminal of the ignition switch. The relay also has a third terminal (thick section), which connects it to the starter motor.

To diagnose a possible malfunction in the solenoid relay, you need to use a jumper to connect two terminals to which thick wires are suitable. To connect them to each other, you can use a regular screwdriver, wrench or other available tools. Grasp the insulated surface of such a tool and use it to connect the two large terminals (it is important that the “jumper” does not touch any other metal parts under the hood).

If the result of shorting the terminals is the rotation of the starter, then the problem is related to the contact pads in the relay, which could be burned due to the high current supply. In such a situation, it is necessary to replace the relay, since the procedure for cleaning the contacts will take a lot of time, but due to the lack of an alloy of non-ferrous metals on them, which is applied at the factory, they will not work for long.

Diagnostics of wiring and contacts

If the starter clicks but does not turn, poor contacts or wiring problems may be to blame. Most often, a malfunction occurs along the path of current transmission from the positive terminal of the battery to the solenoid relay. The starter requires about 200 Amps to start, but if there are problems in the wiring and contacts, much less current can reach it. This leads to the fact that it is possible to power the solenoid relay (which requires 10 Amps), but there is not enough current to spin up the starter itself.

With such a malfunction, clicks may be heard in series or stop from time to time. If there is such a problem, you need to check the wiring, make sure there is no oxidation on the pads and that they are tightened enough to fully transfer current.

Why else might there be noise in the engine compartment?

- Separately, among the problems of extraneous sounds in the engine compartment, one can highlight the situation of starting a diesel engine when cold.

- Strong vibration and a characteristic knock may also indicate a problem with the cushions that hold the internal combustion engine.

- The power steering pump, its drive or the steering rack may make a squeal, squeak, howl or whistle when starting a diesel engine.

- If starting the engine is combined with the air conditioner being turned on, the reason should also be looked for in the air conditioning compressor or in its drive.

- Due to the fact that in many cars the gearbox is located close to the engine in the engine compartment, it can be difficult to distinguish its noise from the engine noise. Most often, a dead release bearing is responsible for transmission noise.

- Another very dangerous sound that can hardly be confused with something is the detonation knock of the engine, when a mini-explosion occurs as a result of improper combustion of the fuel mixture in the cylinder. The shock wave is reflected from the piston, destroying it. Indirect signs of diesel engine detonation are, in addition to a sharp metallic knock, the engine tripping, a decrease in its power, and unstable operation.

What else can knock, make noise or whistle in the engine after starting?

As you can see, there are quite a lot of reasons for the appearance of knocks and noises. It should be added that when starting a cold engine, especially in winter, increased noise and chirping can be produced by the injection nozzles themselves on units with a pressure fuel injection system.

In some cases, this does not indicate any malfunction, since after a slight warm-up the noise intensity decreases or the extraneous sound completely disappears. A knock can also occur at the moment of starting in the cold due to heavily hardened ICE cushions (the engine is conditionally driven when the starter rotates slightly forward, and after starting it “bounces” back).

You should also not forget about the air conditioning compressor, especially if the engine is started in parallel with the air conditioning turned on or the climate control is activated immediately after starting. The compressor drive or the compressor itself is often the cause of extraneous noise.

The appearance of unnecessary sounds can also be associated with faulty gearboxes or clutch elements. For example, a hum after starting the engine may well come from a release bearing. It should also be taken into account that on many cars the gearbox is located directly in the engine compartment near the internal combustion engine. If it is the transmission that is humming, then this noise needs to be differentiated separately, since the engine and attachments in this case do not require additional diagnostics.

Drivers are often interested in why crackling and grinding noises are heard when starting the engine. There may be several reasons for this phenomenon. In any case, the source of this sound should be eliminated as quickly as possible. Otherwise, you risk a breakdown at the most inopportune moment. In general, if any strange sounds appear, you should check their origin. After all, this is most likely a sign of a breakdown.

The sooner you eliminate it, the better. After all, most faults can cause a chain reaction. And provoke breakdowns of other engine components. Therefore, always listen carefully to the operation of the power unit.