The cooling system of a vehicle's internal combustion engine (CO) is a design solution that removes excess heat from the vehicle engine and transfers it to the environment, and also allows the engine to quickly warm up. It is the ability to quickly warm up, reaching the optimal level of operating temperature, and maintaining this temperature at a given level - one of the most important factors in the efficient operation of the internal combustion engine. The purpose of the engine cooling system is to prevent damage to car engine parts as a result of overheating and wear, cooling exhaust gases, and oil in the lubrication system.

Air or dropsy

The cooling system of an internal combustion engine is designed to remove excess heat from engine parts and components. In fact, this system is bad for your pocket. Approximately a third of the heat obtained from the combustion of precious fuels has to be dissipated into the environment. But this is the structure of a modern internal combustion engine. The ideal would be an engine that can operate without dissipating heat to the environment, and convert all of it into useful work. But the materials used in modern engine construction will not withstand such temperatures. Therefore, at least two main, basic engine parts - the cylinder block and the cylinder head - have to be additionally cooled. At the dawn of the automotive industry, two cooling systems appeared and competed for a long time: liquid and air. But the air cooling system gradually lost its ground and is now used mainly on very small motor vehicle engines and low-power generator sets. Therefore, let’s take a closer look at the liquid cooling system.

Purpose

During operation of the internal combustion engine, temperatures in the combustion chamber can reach 2000 degrees. Without a reliable cooling system, oil and fuel consumption will increase. Overheating will lead to rapid wear and engine failure.

If the engine does not warm up enough, this will also have a negative effect on it. If hypothermia is observed, this threatens a decrease in power, intense wear, and increased fuel consumption.

Moreover, in most modern cars, in addition to the main tasks, this system also performs secondary functions. The first step is to ensure the heater is working. The system is also designed to cool not only the engine itself, but also the oil and fluid in the automatic transmission. Sometimes it also affects the throttle assembly along with the intake manifold.

In a modern system (whether liquid or air-cooled engine), up to 35 percent of the heat produced by the combustion of the fuel-air mixture is dissipated.

Cooling system design

The cooling system of a modern automobile engine includes an engine cooling jacket, a coolant pump, a thermostat, connecting hoses and a radiator with a fan. The heater heat exchanger is connected to the cooling system. Some engines also use coolant to heat the throttle assembly. Also, in engines with a supercharging system, coolant is supplied to liquid-air intercoolers or to the turbocharger itself to reduce its temperature.

The cooling system works quite simply. After starting a cold engine, the coolant begins to circulate in a small circle using a pump. It passes through the cooling jacket of the engine block and cylinder head and returns to the pump through the bypass (bypass) pipes. In parallel (on the vast majority of modern cars), the liquid constantly circulates through the heater heat exchanger. As soon as the temperature reaches the set value, usually around 80–90 ˚С, the thermostat begins to open. Its main valve directs the flow to the radiator, where the liquid is cooled by a counter flow of air. If the air flow is not enough, then the cooling system fan, in most cases electrically driven, comes into operation. The movement of fluid in all other components of the cooling system continues. Often the exception is the bypass channel, but it does not close on all vehicles.

In recent years, cooling system designs have become very similar to one another. But two fundamental differences remain. The first is the location of the thermostat before and after the radiator (along the direction of fluid movement). The second difference is the use of a circulating expansion tank under pressure, or a tank without pressure, which is a simple reserve volume.

Using the example of three cooling system schemes, we will show the difference between these options.

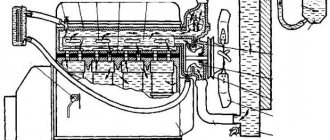

Cooling system of the Great Wall Hover SUV (now known in our market under the name Derways DW Hower H3). The thermostat is located in front of the radiator at the outlet of the cylinder head. The expansion tank is connected after the radiator plug and is not exposed to high temperatures and pressures. 1 - expansion tank; 2 — atmospheric hose of the expansion tank; 3 — heater radiator supply hose; 4 — heater radiator outlet hose; 5 — heater radiator; 6 — supply pipe of the coolant pump; 7 — outlet hose from the heating jacket of the throttle assembly; 8 — supply hose to the heating jacket of the throttle assembly; 9 — thermostat cover; 10 — supply hose to the radiator of the cooling system; 11 — filler plug of the radiator of the cooling system; 12 — radiator of the cooling system; 13 — fan casing; 14 — coolant pump; 15 — radiator outlet hose of the cooling system; 16 - hose connecting the radiator of the cooling system and the expansion tank. |

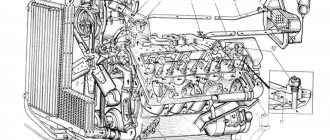

First generation Hyundai Solaris engine cooling system. The thermostat is located at the outlet of the radiator, and the expansion tank is located directly on the radiator and is designed according to the “no pressure” scheme. 1 — radiator outlet hose; 2 — coolant pump pulley; 3 — thermostat cover; 4 - hose connecting the expansion tank; 5 — filler plug; 6 — radiator supply hose; 7 - radiator; 8 - expansion tank. |

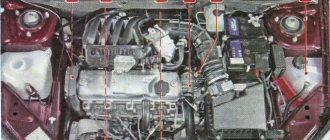

Cooling system of the eight-valve Lada Granta engine. The thermostat is located in front of the radiator. The circulation type expansion tank is under pressure and has a sealed plug. Coolant constantly flows through it. 1 - expansion tank; 2 — steam removal hose of the radiator of the cooling system; 3 — radiator outlet hose of the cooling system; 4 — coolant temperature sensor; 5 — thermostat housing; 6 - fan; 7 — cylinder head; 8 — radiator of the cooling system; 9 — supply hose to the radiator of the cooling system; 10 — coolant pump; 11 — cylinder block; 12 — pump supply pipe; 13 — heater radiator outlet hose; 14 — heater radiator; 15 — heater radiator supply hose; 16 - inlet hose. |

Types of engine cooling methods

The engine temperature is regulated by coolant and air. Based on this, three types of processes are divided:

- liquid (performed forcibly or due to the difference in density of cold and hot solutions; the combined option is ineffective when the engine is on/+40 degrees Celsius outside the window);

- air (blowing displaces warm air from under the hood, occurs naturally or with the help of a fan, is not used as an independent “cooler” - low efficiency);

- combined (includes “air” and “liquid” circuits simultaneously).

Solution-based engine cooling systems are either open or closed.

The former involve a larger amount of refrigerant (high boiling point). In the second case, the steam outlet tube ensures interaction with the atmosphere.

Components

Cylinder head and block jacket

They are channels cast in an aluminum or cast iron product. The channels are sealed, and the joint between the block and the cylinder head is sealed with a gasket.

Coolant pump

bladed, centrifugal type. It is driven by either a timing belt or an auxiliary drive belt.

Chevrolet Lacetti engine coolant pump

Chevrolet Lacetti engine coolant pump

Thermostat

is an automatic valve that is activated when a certain temperature is reached. It opens and some of the hot liquid is dumped into the radiator, where it cools. Recently, electronic control of this simple device has begun to be used. The coolant began to be heated with a special heating element to open the thermostat earlier if necessary.

Chevrolet Cruze engine thermostat: 1 — fluid supply pipe to the radiator of the cooling system; 2 — electrical connector of the thermostat heating element; 3 - body; 4 — sealing ring in the connection of the module with the liquid distributor; 5 - main thermostat valve; 6 — thermostat spring; 7—cylinder with heat-sensitive filler; 8 — additional thermostat valve; 9 — thermostat rod.

Chevrolet Cruze engine thermostat: 1 — fluid supply pipe to the radiator of the cooling system; 2 — electrical connector of the thermostat heating element; 3 - body; 4 — sealing ring in the connection of the module with the liquid distributor; 5 - main thermostat valve; 6 — thermostat spring; 7—cylinder with heat-sensitive filler; 8 — additional thermostat valve; 9 — thermostat rod.

Radiator

is a heat exchanger containing two tanks (input and outlet), connected by many aluminum tubes through which coolant passes. To increase heat transfer, thin plates are attached to the tubes, increasing the heat transfer surface many times over. To improve heat dissipation, air is forced through the radiator using an electric fan.

Radiator and fan of the Lada Largus engine cooling system: 1 - additional resistor; 2 - casing; 3 - electric motor; 4 - impeller; 5 - radiator.

Radiator and fan of the Lada Largus engine cooling system: 1 - additional resistor; 2 - casing; 3 - electric motor; 4 - impeller; 5 - radiator.

Heater radiator

performs the function of heating the air entering the car interior. Heater valves are not installed now, and therefore this radiator is always heated when the engine is warm, and only air dampers prevent hot air from entering the car interior in the summer.

Heater radiator for Renault Duster crossover.

Heater radiator for Renault Duster crossover.

Expansion tank

it is a liquid reserve storage facility. But depending on the type of cooling system (see above), it can be circulation or dead-end. Accordingly, to be under pressure or without it.

Cork

, ensuring the tightness of the system, can be installed either directly on the radiator or on the expansion tank. Regardless of the installation location, the plug provides increased pressure in the cooling system. This pressure (reaching 1.1–1.3 bar) increases the boiling point of the liquid, improves heat transfer, and prevents pump cavitation.

Radiator cap Lada 4x4. |

Chevrolet Cruze expansion tank cap. |

And the main component of the system is the working fluid

. Water would be ideal from a heating engineering point of view, but it causes corrosion and freezes in winter. Therefore, antifreezes with a low freezing point (-40°C or -65°C) and additives that reduce corrosion, foaming, etc. are used.

Dimensions

Above, among the shortcomings, we highlighted the item about dimensions. If we compare the sizes of motors with different types of cooling and other identical characteristics, then the advantage will still go to the “air vent”.

Even though the fan and deflector are quite bulky devices, the parameters of the “air vent” are smaller than in the liquid-cooled version.

Additionally, housing a traditional water system requires more space under the hood to accommodate additional equipment. A rather large radiator with a fan is installed on the body. Hoses and pipes take up a lot of space.

Cooling system malfunctions

Everything that can flow will flow sooner or later. This is not only one of the interpretations of Murphy's law, but also a clear description of the main malfunction of the cooling system. The system, which sometimes includes more than 10 rubber hoses, gradually ages and begins to lose its tightness. The hoses themselves leak, passing liquid through the thread reinforcement, and the clamp connections leak. Over time, under the influence of deicing agents and stones flying from the road, the radiator loses its seal. It especially suffers on cars without air conditioning, where it is not covered by the heat exchanger of this system. Also, the radiator takes on all the “blows of fate” even in minor accidents. Leaking of the heater heat exchanger, although it is located in a place more “protected” from external influences, is also common. The same antifreeze, leaking through the pump seal, damages the bearing, and - “Hello, pump replacement.” And it’s good if you watch out for signs of pump failure in time, otherwise its breakdown will lead either to a broken timing belt and an engine failure, or to the inability to move further on cars where a chain drive of the gas distribution mechanism is installed.

The thermostat, that little precise device, can also start to mope. Its valve may be stuck either closed or open. In the first case, overheating of the engine is inevitable even in cold weather, and in the second, the engine will not warm up to operating temperature. Increased engine wear and fuel consumption, a non-heating stove - this is what guarantees us a constantly open thermostat. There is still an expansion tank left. Its leak occurs only in the cooling system circuit, where it is under operating pressure.

And the last component that may lose its seal is the radiator plug or expansion tank. And although the liquid will not flow through it immediately, it will happen after the first boil of the engine. And it will boil quickly. Remember the purpose of a cork? Correct: ensure an increase in the boiling point of the liquid. No modern engine can operate without a sealed plug, except in cases of very low ambient temperatures and light load on the engine.

An interesting test to determine the causes of overheating can be taken here

Popular myths

The first known air-cooled car was the Zaporozhets. He completely undermined the confidence of the domestic driver in such a system. Car owners often complained about severe overheating, insufficient power and frequent breakdowns. At the same time, the German “Beetle” with approximately the same system was very popular, the demand for it was very good.

Let's, based on the characteristics of the German automobile industry, take a closer look and destroy the popular myths that haunt engines of this design.

Fluid replacement and flushing

If you have not had to replace any component in the cooling system before, then the instructions recommend changing antifreeze at least every 5–10 years. If you have never had to add water to the system from a canister, or even worse, from a roadside ditch, then when replacing the fluid, the system does not need to be flushed.

To remove coolant, there is a drain hole with a plug at the bottom of the radiator.

To remove coolant, there is a drain hole with a plug at the bottom of the radiator.

But if the car has seen a lot in its lifetime, then when replacing the fluid it is useful to flush the cooling system. Having opened the system in several places, you can thoroughly rinse it with a stream of water from a hose. Or simply drain the old liquid and fill with clean, boiled water. Start the engine and warm up to operating temperature. After waiting until the system cools down, so as not to get burned, drain the water. Then purge the system with air and add fresh antifreeze.

Flushing the cooling system is usually started in two cases: when the engine overheats (this manifests itself primarily in the summer) and when the stove stops heating in winter. In the first case, the reason lies in the radiator tubes overgrown with dirt on the outside and clogged on the inside. In the second case, the problem is that the heater radiator tubes are clogged with deposits. Therefore, during a scheduled fluid change and when replacing cooling system components, do not miss the opportunity to thoroughly rinse all components.

Tell us what cooling system malfunctions you have encountered. And I wish you a hot heater in winter and good cooling in summer.

Engine cooling system: how does it work and is it necessary to flush it in winter?

DVO loses to the liquid system due to overheating

This is not the ultimate truth. In fact, temperature characteristics, on the contrary, should be considered an advantage. Naturally, due to reduced thermal conductivity, the air simply will not be able to remove heat as quickly as in systems with antifreeze.

But the difference between the temperature on the cylinders and the temperature of the external environment is much greater than between the liquid and the walls of the block and cylinder head. The weather is less able to influence the cooling temperature regime. Engines with liquid systems have an increased risk of overheating in the summer. This is especially true on a hot, sultry day. Owners may also encounter the problem of why the cooling fan turns on when the engine is cold. There is no such thing in “air balloons”.