If the turbine on your car makes a whistle: The most common malfunctions of automobile turbines.

The beginning of the 21st century can easily be called the era of turbochargers in the automotive industry. At the moment, most modern engines in cars have begun to be equipped with turbines, when just 10 - 15 years ago turbo engines were very rare.

See also: Automotive turbochargers: All the most important facts

Why have automakers made turbochargers popular in the auto industry? What advantages does a turbine give to modern power units? Are modern turbocharged engines reliable?

And the main question that interests many motorists today is related to their repair and restoration. And so, let's look at and answer all these questions that interest many of our motorists, and at the same time learn about the function of modern turbochargers and the most common causes of malfunction, and, of course, about their repair.

As the American saying goes, “Nothing can replace displacement.” We are talking directly about the internal combustion engine. From the very beginning of the automotive industry, it became clear that in order to increase the power of a car, it was necessary to increase the volume of the power unit itself. For a long time, engineers and designers could not figure out how to reduce the engine size without reducing its power. After all, the laws of physics, as you and I know, cannot be changed.

But with the advent of turbochargers, it became clear that these laws of physics are not an obstacle to a gradual increase in power while reducing the working volume of power units. As a result, it happened that starting from the 2000s, turbines began to gain popularity in the automotive industry, which made it possible to significantly increase the efficiency of vehicles and achieve an increase in engine power, and at the same time reduce their volume.

Today, modern technologies allow automakers to squeeze out up to 270 hp from a 1.6-liter four-cylinder engine. (eg Peugeot RCZ-R ).

As a result, turbochargers allowed many automakers to use six-cylinder power units in their cars instead of eight-cylinder engines, all without any loss of power. And in some cases, many of these six-cylinder engines have become even more powerful than their naturally aspirated eight-cylinder counterparts.

There is also currently a trend to reduce the number of cylinders in six-cylinder engines. On the market today you can see quite a few cars that, instead of six-cylinder engines, have 4-cylinder units with the same power, but much more economical. In particular, recently cars with three-cylinder engines began to appear on the car market, which replaced the same four-cylinder units.

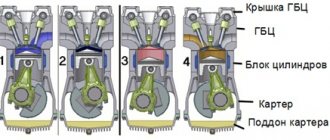

Turbocharger function

Turbochargers also have another name - like turbines. Most automobile turbines typically use energy from engine exhaust gases. That is, such a turbine spins up due to a certain pressure of the exhaust gases. Due to this, this turbine pumps an additional portion of oxygen into the engine and thereby increases the performance of the car. That's why motorists say so - “turbocharged engine”.

In fact, the design of the turbocharger itself consists of two separate turbines (volatiles in separate housings). One part of the turbine contains the turbine wheel (impeller). Inside the second part of the turbine (scroll coil) there is a compressor wheel (impeller). Both parts of the snails are connected to each other by a single turbocharger shaft. The turbine wheel itself is located in the engine exhaust system - i.e. on the exhaust manifold.

The pressure of hot exhaust gases from the exhaust system causes the turbine to move very quickly (the turbine wheel begins to rotate). For example, a turbine can spin up to 300 thousand revolutions per minute.

Since both parts of the turbocharger volutes are connected by a single shaft, when the turbine wheel rotates, the turbine compressor wheel, which is connected to the engine intake system, also begins to rotate at the same speed.

As this compressor wheel rotates, the turbine draws in additional fresh air, which is then compressed in the compressor housing and then pressurized into the engine cylinders.

When air is compressed, the turbine heats up.

To avoid overheating of the turbine, engineers came up with a turbocharger cooling system that allows for the removal of some of the heat generated during the air compression process.

As a result, by lowering the temperature of the air passing through the turbines, the system allows the directly charged air to be cooled, which enters the combustion chamber of the engine. This improves the efficiency and performance of the power unit.

Boost pressure control

To prevent the air boost pressure in the turbine from reaching a critical level when the vehicle speed increases (the faster the car moves, the more exhaust gases in the engine and, accordingly, the turbine spins faster), the turbocharger is constantly under the control of a vacuum system, which regulates its optimal operation .

Otherwise, the turbine and components in the engine will be overloaded.

Typically, the turbine operation itself is regulated using a bypass valve, which is installed on the side of it, i.e. in the place where exhaust gases enter the turbocharger.

As you already understood, the valve regulates the amount of exhaust gases entering the turbine.

Accordingly, it turns out that if the turbine spins too quickly, then this valve will reduce the flow of exhaust gases to the turbine wheel, and this is due to the release of excess pressure of the exhaust gases entering the turbine. Since the turbine wheel is connected to the turbine compressor wheel by a single shaft, the rotation speed of the turbocharger will decrease. As a result, the air pressure will also decrease.

When and how a valve that is controlled by a vacuum device opens. This device consists of a membrane and a spring.

| The higher the boost pressure, the more power |

| Many turbocharged car tuners often strive to increase maximum boost to achieve increased powertrain performance. So, to achieve this, a bypass valve is installed there, which opens only at very high pressure. Until the 1990s, tuners used steam valves to increase preload. This type of valve is classified as a mechanical component. In modern cars, the exhaust gas flow rate is controlled by solenoid valves. As a result, to adjust the operation of the bypass valve, it is enough to do electronic chip tuning. Also, engine power has now become popular in tuning, in addition to chip tuning, which uses modified solenoid valves that operate at full turbine power for a given short time. That is, to protect the turbine from overheating and engine wear, the maximum power of the turbine occurs strictly at a given time, and this without damage to the components of the turbocharger itself and the combustion chamber. |

Variable geometry turbines (TIG)

Also today there are turbochargers with variable geometry. Most often, such turbines can be found on cars with diesel engines. The variable geometry turbine, instead of a wastegate, is equipped with special guide vanes that control the flow of exhaust gases entering the turbocharger.

Typically, such turbines are designated by the abbreviation “VIG” (in Russian, TIG - Variable Geometry Turbine).

The turbine guide vanes are controlled in the same way as conventional wastegate valves in these turbines, i.e. using a vacuum system.

When the turbine blades of a diesel engine are closed, the exhaust gas flow passes by the turbocharger. Accordingly, the turbine does not work at this time.

For example, at low or mid-range engine operation, the turbine blades are open to a minimum level, since there is usually no power required at low engine speeds. But as soon as the driver presses the pedal to the floor, the blades immediately allow free access to the exhaust gases into the turbine and oxygen begins to flow into the engine under pressure, which instantly affects the increase in power.

Unfortunately, the VIG system is very sensitive to high temperatures. Therefore, turbines with variable geometry, as a rule, are used primarily on diesel engines, where the exhaust gas temperature is much lower.

And only uses these “VIG” turbines on gasoline engines (on models 911 Turbo and 718 Boxster /Cayman S).

To achieve this, engineers install turbochargers whose components are made from expensive, high-strength materials that are resistant to extreme temperatures. But in cases of large serial production of such machines, installing such turbines is simply not economically feasible. That's why such turbines are installed either in diesel power units or in limited edition gasoline cars, which cost a lot of money by today's standards.

The most common causes of turbine failure

The most common cause of turbine failure is damage to the internal components of the turbocharger due to insufficient lubrication or its complete absence.

As we said above, most automobile turbines are equipped with a working shaft, which, when rotating, experiences considerable uneven loads due to constant changes in exhaust gas pressure. The bearing surface of this shaft, which connects the turbine wheel to the compressor wheel, is lubricated with oil to reduce friction on the rotating components of the turbine. Thanks to oil lubrication, turbine components have a long service life.

If the oil supply to the turbocharger deteriorates, then grooves begin to form on the bearing surface of the turbine shaft (i.e., wear appears). As a result, the turbocharger shaft may break.

For what reasons may the turbine not be lubricated enough?

Most often, a lack of lubrication in a turbocharger is associated with: poor fuel quality, clogging of the car’s oil system, due to the presence of fuel in the oil, as well as due to a clogged oil filter or clogged oil passages in the engine.

Also, such a rapid failure of the turbine may be associated with “hot parking” of the car.

For example, if the owner of a car, after a long drive at full throttle, begins to park and immediately turns off the engine, then there is a certain risk of rapid wear of the turbocharger components.

The point is this: when the engine operates for a long time at high speeds, the turbine can become very hot (heats up to 1000 C° Celsius). And if, after parking the car, you immediately turn off the engine, the supply of coolant and oil to the engine is abruptly interrupted. As a result, cooling of the engine and, accordingly, the turbocharger itself stops.

In this case, the heat accumulated in the turbine can burn the remaining oil, which in turn will clog the oil passages, and this will lead to insufficient oil supply to lubricate the turbine in the future. Ultimately, as we have already said, the turbine will begin to experience a lack of oil and, as a result, the production (wear) of its internal components in the turbocharger will accelerate in the shortest possible time.

Another important factor in turbine wear is the formation of carbon in the engine oil during operation of the machine. Carbon can typically collect in the turbine as deposits, which over time can lead to thermal problems and turbine imbalances, etc. problems.

It is for this reason that any automobile turbine needs regular maintenance. For example, in the same cleaning. To do this, you need to use a special spray cleaner, which is sold today in any car dealership.

Most turbos can be cleaned without removing them from the vehicle. In addition, this turbine cleaner also helps remove not only carbon deposits, but also a number of other unnecessary substances that can form on the internal components of the turbocharger.

Causes of turbine failure.

Lack of lubrication

The most common cause of turbine failure is damage to the internal components of the turbocharger due to insufficient lubrication with oil or its complete absence.

As we have already said, most automobile turbines are equipped with a working shaft, which, when rotating, experiences considerable uneven loads due to constant changes in exhaust gas pressure. The bearing surface of the shaft that connects the turbine wheel to the compressor wheel is lubricated with oil to reduce friction on the rotating components of the turbine. Thanks to oil lubrication, turbine components have a long service life.

If the oil supply to the turbocharger deteriorates, grooves (grooves) form on the bearing surface of the turbine shaft. As a result, the turbocharger shaft may break.

For what reasons may the turbine not be lubricated enough?

Most often, a lack of lubrication in a turbocharger is associated with poor fuel quality, clogging of the car’s oil system, due to the presence of fuel in the oil, due to a clogged oil filter, or due to clogged oil passages in the engine.

Also, rapid turbine failure can be associated with “hot parking” of the car.

For example, if the owner of a car, after a long drive at full throttle, immediately turns off the engine after parking, then there is a risk of rapid wear of the turbocharger components.

The fact is that when the engine operates for a long time at high speeds, the turbine can become very hot (up to 1000 C° Celsius). And if, after parking the car, you turn off the engine, the supply of coolant and oil to the engine is abruptly interrupted. As a result, cooling of the engine and, accordingly, the turbocharger stops.

In this case, the heat accumulated in the turbine can burn the remaining oil, which will clog the oil passages, resulting in insufficient oil supply to lubricate the turbine in the future. As a result, as we indicated above, the turbine will begin to experience a lack of oil. As a result, in a short time the production (wear) of its internal components in the turbocharger will accelerate.

Another important factor in turbine wear is the formation of carbon in the engine oil during operation of the machine. Carbon can typically collect in the turbine as deposits. Over time, this leads to thermal problems, imbalance in turbine operation, etc.

This is why any automobile turbine needs regular maintenance. For example, in cleaning. To do this, you need to use a special spray cleaner, which is sold in car dealerships.

Most turbos can be cleaned without removing them from the vehicle. Turbine cleaner also helps remove not only carbon deposits, but also a number of other substances that can form on the internal components of the turbocharger.

Damage to the turbine due to a dirty particulate filter

Since the turbine in a car operates using exhaust gases, a very common cause of its failure is, of course, problems in the exhaust system.

Diesel units that are equipped with a particulate filter are especially vulnerable. For example, if the particulate filter is clogged, this can increase the pressure of the exhaust gases entering the turbine. As a result, the turbocharger shaft becomes overloaded, which can ultimately lead to an unpleasant whistling sound from the turbocharger. This unusual sound usually indicates that the turbine shaft is damaged.

True, such a whistle in some turbines can also occur in the early stages of a lack of oil in the turbine.

But in any case, remember, if you start to hear a whistling turbine in your car, then you need to diagnose it as soon as possible in order to prevent more serious damage in time.

How quickly does the particulate filter clog?

Everything certainly depends on the driving style, the operating conditions of the car and the quality of the diesel fuel. For example, if you use a diesel car mainly in the city, the particulate filter can quickly fail due to insufficient exhaust gas temperature.

It is also not recommended to operate diesel vehicles in quiet mode. Therefore, we must remember and know that from time to time their owners must use the car at high speeds to burn through the exhaust system to remove the soot that has formed in it.

See also: Everything you need to know when using AdBlue in your car

Another factor dangerous to the turbine is any malfunction of the exhaust gas system, which reduces the flow of exhaust gases entering the turbocharger. For example, if the exhaust pipes are damaged or the gaskets of the exhaust system are worn out, the turbine will begin to work ineffectively, which can lead to its failure in a short time. Therefore, any malfunctions of the exhaust system in cars with turbocharged engines must be repaired as soon as possible.

Turbocharger malfunctions

The turbocharger operates under more severe conditions than other engine components and is subject to high temperatures and dynamic loads.

And yet, most often the cause of a turbocharger malfunction is not the turbocharger itself, but deviations in the operation of other engine systems or unprofessional operation.

For all questions regarding the operation of turbochargers, please contact the Tavria Turbo company or its branches located in all regions of Ukraine.

The main symptoms of a turbocharger malfunction are as follows:

- black smoke from the exhaust pipe;

- blue smoke from the exhaust pipe;

- increased oil consumption;

- drop in engine power;

- increased noise.

Black smoke from the exhaust pipe is a sign of insufficient air entering the engine cylinders, which may be caused by a clogged air cleaner or charge air cooler, if equipped, an air intake duct, or an air leak due to a loose connection. This can also happen due to a malfunction of the exhaust system.

Blue smoke and increased oil consumption are a consequence of oil combustion in the turbine due to oil ejection from the engine or failure of the gas-oil seal of the turbine part of the turbocharger.

Increased noise may be a sign of a loose fit of the air supply connectors to the engine, as well as a lack of tightness in the exhaust gas system. Also, increased noise may result from the compressor and turbine wheels rubbing against the housing parts due to increased rotor play.

If these potential turbocharger failures are not addressed initially, turbine failure lead to costly repairs or replacement of the turbocharger.

To prolong trouble-free operation of the turbocharger, observe the following operating rules:

- use only high-quality oil and only the brand specified in the operating instructions;

- change the oil filter promptly;

- change the oil in a timely manner;

- warm up the engine before operation, especially in the cold season;

- Before stopping the engine, let it idle for 2-3 minutes.

Turbocharger malfunctions and diagnosing them on the engine with regular professional maintenance can extend the life of the charging unit.

The main causes of turbocharger malfunction :

- Foreign objects entering a turbine or compressor wheel, which leads to chipping of the turbine or compressor wheel blades, as shown in Figure 1

Picture 1.

- Malfunction of the lubrication system:

– low-quality oil, or does not comply with the operating instructions;

– dirty oil;

– clogged or kinked oil supply or drain pipes;

– oil pump malfunction;

– poor quality or clogged oil filter;

– lack of oil in the system.

All this leads to increased wear of the rotor shaft and bearings, and also disrupts the operation of the gas-oil seal. Possible consequences are presented in Figure 2.

Figure 2.

In addition to the reasons already mentioned, there are other reasons for turbocharger malfunction , namely:

- damage to the turbine rotor and housing due to thermal fatigue;

- wear of bearings due to frequent repetition of sudden starting and stopping of the engine under high load;

- reduction in effective performance due to contamination of the compressor and turbine flow parts;

- imbalance of the rotor due to chipping of the blades of the turbine and compressor impellers. which leads to disruption of lubrication, and accordingly to dry friction and jamming, which can lead to rotor failure, Figure 3.

Figure 3.Tavria Turbo turbocharger plant in Melitopol can solve all your problems related to the purchase and repair of domestic and imported turbochargers in the shortest possible time and at reasonable prices.

Damage to turbines caused by foreign bodies

Another known cause of damage to turbochargers is foreign bodies entering them through the vehicle's air intake. Due to the enormous speed of rotation of turbine elements, even the smallest particles can cause significant damage to its internal components.

For cars with high mileage, the inner wheels of the turbine compressor (impellers) wear out evenly. As a result, the vehicle's power decreases over time as these turbine wheels wear out. This occurs because much less oxygen begins to flow into the engine as the turbine components age. But such uniform aging of the turbocharger is an ideal combination of circumstances.

Most often, the turbine fails unexpectedly and not due to the end of the service life of the internal components. For example, due to the same broken turbine wheel blades. As a result of such a breakdown (at least one blade) on the turbine wheel, a loss of rotation balance occurs. As a result, the shaft and its bearings can suffer serious damage.

At the final stage of turbocharger wear, the old rotating wheels begin to grind the turbine housing. As a result, the turbocharger begins to destroy itself.

Typical causes of turbocharger failures

Extreme operating conditions

Twist/Overblow/Excessive temperature

A typical malfunction is high temperature on the plain bearings (bushings). In the photo, the oil burned and coked the tube shaft. Often the back side of the turbine shaft bends a little, usually accompanied by an “orange peel” effect and very clearly indicates over-twisting and over-blowing.

Torsion can cause the turbine shaft to lose some of its blades, causing the damage to appear as if a foreign body has entered the turbine part.

In extreme cases, the shaft may break due to torsion. Minute stress leads to the appearance of cracks, which increase with each twisting cycle and ultimately lead to rapid rupture of the turbine shaft.

Entry of a foreign body and damage from them

Solid foreign matter in the compressor causes damage to the compressor part. Traces of its influence are visible on the compressor scroll. Salt and sand can cause erosion and corrosion of compressor wheel blades.

A soft foreign body, such as rags or paper, can cause this failure. It is common for compressor wheel blades to become bent, and in extreme cases they can break off.

A solid foreign body that gets into the turbine part breaks off the blades of the turbine shaft. Even small objects, such as scale from the exhaust manifold, can cause significant damage to the turbine shaft blades due to the high speed of its rotation.

External causes of malfunctions independent of the turbine

Before blaming the turbocharger for malfunctions, you should consider the most common external factors that cause the unit to be repaired.

Common Cause: Oil Contamination

Dirty oil with a finely dispersed component is not visible to the eye, but these micro particles polish the turbocharger bushings and wear them along their outer diameter.

Large particle pollution is a more serious issue. Deep grooves on the bushings, the inner diameter wears out, damage to the shaft is caused by large foreign particles contained in dirty oil.

Change the oil in an internal combustion engine equipped with a turbocharger as often as possible - this will help avoid many breakdowns in the future.

Lack of lubrication

Insufficient lubrication occurs due to narrowing of the oil channel with sealant or gasket. Characterized by a strong discoloration of the turbine shaft.

A complete lack of oil has a very negative effect on all elements of the turbine and completely disables the turbocharger in a short period of time.

Self-diagnosis based on symptoms of turbocharger and engine operation

In the tables below you can independently assess possible damage and malfunctions of the working unit. All known symptoms and assumptions about breakdowns are collected here.

Is it easy to diagnose damage to turbine blades?

If you suspect wear on the turbine components, you must first diagnose the internal wheels of the turbocharger. For example, you can visually inspect the condition of the turbine compressor wheel; this can be done quite easily. To do this, you need to disconnect the air supply module from the turbine itself. As a result, you will be able to closely examine the wear on the compressor blades.

But in order to diagnose the turbine wheel from the engine exhaust system, you will have to completely remove the turbocharger from the engine and completely disassemble it.

True, the compressor wheel that receives air from the street is most often damaged. Damage to the wheel from the exhaust system can only occur if foreign objects from the engine enter the turbine.

For example, in the event of a timing belt break (in the case when the engine valves meet the pistons), as a result of which the engine fails. In this case, after poor cleaning of the engine from chips and other components of destruction, starting the engine can lead to damage to the turbine.

| Signs of turbocharger malfunctions | ||

| Symptom: | Manifestations: | What to do: |

| Turbocharger whistle | When the speed increases, you can hear the whistle of the turbine. The turbine shaft itself may be damaged. The whistle is caused due to metallic friction. | Turbocharger replacement / Repair. |

| Blue smoke | Oil leak in turbocharger. There may be chips (wear) on the shaft. Oil enters the exhaust system. | Turbocharger replacement / Repair. |

| Increased fuel consumption | Damage to turbocharger bearings. The oil supply line to the turbine is faulty or clogged. | Check the turbocharger oil lines and replace them if necessary. |

| Black smoke | Perhaps the turbine does not have enough air to supply to the engine. As a result, an incorrect mixture of fuel and oxygen is formed in the combustion chamber. As a result, black smoke is produced during fuel combustion. Most likely the car has a leak in the air supplied to the engine. | Check the hoses and connections of the air intake system. Also check the compressed air supply line for leaks and replace the damaged component if necessary. |

| Power loss I | Lack of constant power. The compressor may be damaged. For example, due to broken blades, the turbine can no longer supply enough air to the cylinders. | New compressor wheels are needed. It is also necessary to protect the air supply system to the turbine from foreign objects. |

| Power loss II | The VTG unit is dirty. As a result, the operation of turbine blades with variable geometry is not effective. For example, due to contamination of the blades, there may be insufficient exhaust gas pressure. | Disassemble the turbine and clean the blades from soot formation. |

| Excessive boost pressure | The boost pressure control valve is faulty. Malfunction of the vacuum valve control unit. | Replacing the vacuum unit, cleaning or replacing the exhaust gas valve. |

| Turbocharger noise | The back pressure in the exhaust system is too high. Damage to the compressor wheel or turbine wheel. Exhaust gas leak. | Check the exhaust system for damage. Check the turbine compressor for damage. Fix the problem by repairing the turbocharger. |

What should you pay attention to?

Signs of a malfunctioning engine turbine can vary. Let's look at some of them.

For example, the emission of blue smoke from the exhaust pipe of a warm engine indicates an oil leak in the turbocharger and its entry into the engine cylinders.

If black smoke is emitted , there is an air leak in the injection lines or intercooler.

And if white smoke , then most likely the turbocharger oil drain line is clogged.

If the machine has increased oil consumption , this indicates a clogged air supply channel or oil drain line.

If you observe a sharp increase in fuel consumption , it is likely that the air supply channel or air filter is clogged.

It also happens that the noise of the turbocharger increases . This often happens due to a clogged oil supply line. If an oil leak is noticed on the turbine housing, then most likely the turbine axle is coked or there is a violation in the coupling system.

The car began to accelerate worse - this indicates a malfunction of the turbine control system.

If you hear a grinding noise when the turbocharger is running , the cause may be deformation of the turbine housing.

And if a whistle is heard , this indicates an air leak between the compressor outlet and the engine.

In most cases, automobile turbines can be repaired

If you experience loss of power, or whistling noises from the turbo, or increased fuel consumption or smoke, then generally, if your car is equipped with a turbo, there is likely a problem. The turbine on the car is faulty. In this case, the car must be taken to a specialized workshop for diagnostics as soon as possible.

Remember the following; under no circumstances should you delay a trip to a car service center to diagnose the turbine. Otherwise, you risk losing a lot of money in the future, since the turbocharger may simply not be repairable after a breakdown. As a result, you will have to buy a new turbine, which costs a lot of money.

In addition, every owner of a turbocharged car should be aware that broken parts of the turbine can also lead to damage to the engine itself. If the turbine fails, another expensive component of the car can also suffer - the catalyst.

See also: How to replace spark plugs without any hassle

Fortunately, many problems associated with turbine operation can be eliminated by routine repairs. However, not all auto repair shops dare to carry out such work. In many car repair shops, in case of even minor problems with the turbine, they often advise buying a new one.

However, remember that most repairs on various types of turbochargers will significantly extend its service life. Therefore, a turbine failure does not always mean that it is time to buy a new turbocharger.

But turbine repair is not always justified. It all depends on the type and type of malfunction. For example, very often several important components in turbochargers fail, as a result of which repairing or overhauling the turbine will not be advisable, since it will be cheaper to purchase a new turbocharger.

An example of damage to bushings due to wear.

Everything about turbochargers, or the Supercharger

Many motorists are wary of repairing turbochargers. And for good reason. At the same time, manufacturers allow some turbines to be repaired and even produce original components, while others even engage in industrial restoration of units. The reason for the low service life of rebuilt turbines is often the notorious human factor.

Presumption of innocence

A turbocharger (TC) operates at the crossroads of several engine systems, and its health depends on the health of other components. Therefore, if any complaints arise about the operation of the TC, it is important to conduct a thoughtful diagnosis of the unit as part of the motor. Diagnostics is also necessary in the event of a turbine failure - it will serve as a guarantee that a new or repaired turbine will not fail after a couple of thousand kilometers.

Even a rag left in the intake system when servicing the machine can damage the shaft impeller, not to mention lost bolts or washers. |

One example of the characteristic destruction of a compressor wheel when a turbine is twisted. An experienced master can determine this detrimental regime by the particular wear of the blades and shaft. |

Complete coking of the oil supply tube is typical for gasoline turbines due to higher temperatures compared to diesel ones. |

A classic of the genre is overheating of the turbine shaft due to oil starvation. It cannot be processed or restored. |

First, using a computer, the engine management system as a whole and individual sensors are checked. The vast majority of turbines are equipped with a boost pressure control mechanism; its failure could easily be the result of a trivial malfunction - for example, an incorrect signal from the air flow meter. There are often cases when, due to ignoring such diagnostics, specialized TV repair companies deliver... serviceable units.

Is it possible to buy a used turbine with a guarantee?

Remanufactured used turbochargers are available for purchase on the Russian market. Unlike new ones, their cost is much cheaper. Moreover, most of these refurbished used turbines are sold with a warranty. True, such a guarantee is given for a short period. But, nevertheless, for owners of turbocharged cars, this is a good way to save money on buying a new turbine.

Typically, the process of purchasing a used remanufactured turbine consists of simply exchanging it with an additional payment. Typically you give away your broken turbine and pay a certain amount extra for the repaired one. As a result, by paying a much smaller amount of money for a turbine, you get, although not a new, but quite working turbocharger.