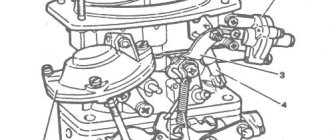

Carburetor device.

It consists of many elements such as a float chamber . Designed to store fuel in the required quantity, namely the floats regulate the level. To avoid increased consumption and flooding of spark plugs. Next, the mixing chamber . Necessary for the production of a combustible mixture, namely mixing gasoline with air. Diffuser , designed to pump the mixture, that is, increase the flow rate. A sprayer with a jet is necessary to supply the combustible mixture into the diffuser .

There are also two dampers , namely throttle and air . The throttle valve is designed to regulate the flow of the combustible mixture. Consequently, an increase or decrease in engine speed. And the air damper regulates the flow of air entering the carburetor through the filter. The idle system , namely the channels that bypass the throttle valve. Thus allowing the combustible mixture to constantly flow into the engine cylinders. Also, the suction of the combustible mixture , with the help of a handle in the car interior, opens the throttle valve. That is, making the mixture more enriched with gasoline. This allows you to start the engine in cold weather.

The principle of operation of a carburetor.

In principle, everything is very simple. First of all, gasoline enters the float chamber through the filter. Where, when the fuel level rises, the float rises and closes the valve. That is, closing the extra supply.

The fuel then enters the mixing chamber, where it is mixed with air. The one that does the same thing into the camera, but through the top. Further, thanks to the atomizer and diffuser, the mixture is pressurized through the throttle valve into the cylinder; the throttle valve opens when the gas pedal is pressed, increasing the flow of the mixture.

Additional carburetor systems

This primitive carburetor design works well only in a small range of engine speeds and throttle positions. When the load on the engine increases or the position of the damper changes, the composition of the air-fuel mixture no longer corresponds to the operating mode of the engine. As a result, power decreases, wear on engine parts and fuel consumption increases. To improve the performance of the carburetor in transitional and non-optimal modes, various systems are used that regulate the supply of fuel to the mixing chamber.

- Acceleration pump

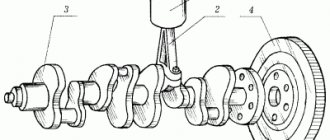

When you sharply press the gas pedal, the speed of air movement through the mixing chamber, as well as the volume of the air-fuel mixture entering each of the cylinders, increases sharply, but the “Venturi tube” does not have time to supply the required amount of fuel due to the high inertia of the entire system. Therefore, for a short period of time, until the vacuum in the nozzles forces the fuel to pass through the nozzles faster, the mixture will be very lean.

Such a mixture burns much faster than a balanced one, so instead of smooth combustion during the entire power stroke, an explosion occurs. With such combustion of the air-fuel mixture, the released thermal energy cannot be effectively converted into crankshaft torque, so the exhaust gases begin to seek exit from the cylinder. This leads to overheating and destruction of valves and pistons, the breakthrough of a large amount of gases into the crankcase and a decrease in engine compression.

To compensate for the lack of fuel, an accelerator pump is used, which injects fuel, the amount of which is directly proportional to the speed and opening angle of the throttle valve. Due to the fact that fuel is injected directly into the mixing chamber, it is effectively mixed with air and provides the required air-fuel mixture ratio.

- Engine starting system

When starting a cold engine, the air-fuel mixture burns slightly differently than in a warm engine, so a starting device is installed in the carburetor. It limits the air flow into the mixing chamber and increases the opening of the throttle valve, causing the mixture to be over-rich

- Idle system

When the engine is idling, the throttle valve is almost closed, so the formation of the mixture in this mode occurs differently than usual. Air and fuel flow through the idle jets through channels inside the carburetor into the space directly behind the throttle valve and are mixed in the intake manifold. A forced idle economizer is also installed on the carburetor, which cuts off the fuel supply when the engine speed exceeds 2,500 thousand per minute and the gas pedal is not pressed. Pressure on the gas pedal is detected using a microswitch connected to the throttle valve actuator. From the microswitch, the signal is sent to the ignition controller, which compares the engine speed and the position of the gas pedal and, if necessary, turns off the economizer, which causes the fuel supply to stop.

- Fuel level control system

In order to ensure the required air-fuel mixture ratio, it is necessary to adjust the fuel level. After all, the operation of the Venturi tube depends both on the air speed and on the fuel pressure in the area of the jets, which in turn depends on the fuel level in the float chamber. The fuel level control system consists of a float and a needle valve. The higher the fuel level in the chamber, the higher the plastic or metal float rises. The fuel pump supplies fuel to the chamber; when its quantity reaches the required level, the float closes the valve and the fuel supply stops. When the fuel level drops, the float lowers and opens the valve, resuming the flow of fuel into the chamber.

- Main dosing system

The composition of the air-fuel mixture at a stable throttle position and not at full engine load depends on the main metering system. It consists of air and fuel jets, channels, an emulsion tube (on some carburetor models, the air jet and emulsion tube are combined) and a sprayer. The composition of the air-fuel mixture and engine operation in most modes depend on the condition of all elements of the main metering system. Two-chamber carburetors use two metering systems - the first and second chambers. The second chamber is activated when the gas pedal is pressed more than 2/3, its main metering system supplies a richer air-fuel mixture, this is necessary to provide more engine power and prevent fuel detonation at high engine loads.

Do-it-yourself carburetor diagnostics and repairs.

As I said earlier, the system is quite capricious. Therefore, it requires due attention, namely timely diagnosis and repair. When I got a car with a carburetor. Firstly, I went to specialists to check and adjust everything. Because you need to understand how it should work.

After I saw and understood the whole point, I began to try repairs with my own hands. Because dust and low-quality gasoline simply kill the carburetor. And sometimes I had to repair it every week. Because due to the blockage, the car simply stopped driving. Yes, and starting the engine was a problem. But thanks to this, I was soon able to repair it practically with my eyes closed.

Carburetor filter.

So, let's start to figure it out. If the engine is very difficult or cannot be started at all. First, we look at the float chamber to see if there is gasoline there or not. If it is missing, then you need to unscrew the filter. Next, carefully remove and wash the mesh. Subsequently, install everything in place.

Carburetor valve and float.

If this procedure does not help, then check the fuel valve and the float itself. For example, if the valve is dirty. Then we wash it and also blow it with air pressure using a regular pump. The float should move easily without touching the walls of the body. If you find that the float is damaged or there is gasoline inside. It needs to be replaced with a new one or try to seal it. But you need to be careful with the glue so that gasoline doesn’t simply dissolve it.

Throttle valve and carburetor jets.

However, if the float chamber is full, and the engine still does not want to work. Here you need to check the throttle valve, as well as all the jets. We check the entire damper drive so that the movement is smooth. Since due to dirt it can generally jam. In this case, we will need to rinse everything thoroughly. Same with jets. We unscrew it, wash it, and also blow out all the channels with air pressure.

Fuel line.

To diagnose the fuel line, you need to check the gasoline pressure. If the stream is weak or does not exist at all, then we check the following. Fuel filter, for dirt. Since in most cases it is made of transparent plastic. As a result, if it becomes dirty, it must be replaced with a new one. Also, the reason for the lack of pressure may be due to the pump. It's quite easy to check. You need to press the manual drive lever a couple of times. If, as a result of this procedure, gasoline spurts out, then everything is fine. But if not, then the problem is internal. Then you will have to change the pump or try to repair it. Replacing damaged parts.

Carburetor solenoid valve.

The solenoid valve is designed to prepare a combustible mixture at idle. If it malfunctions, the car will constantly stall. And also work intermittently. However, at high engine speeds there will be no problems. Since the solenoid valve begins to operate only at engine speeds below 1700. It is very easy to check its serviceability.

Firstly, it must be dismantled. Connect the electromagnetic valve terminal to the battery positive. And connect the ground using a regular piece of wire to the valve body. If everything is working properly, you should hear clicking sounds. However, if there is a malfunction, the valve will have to be replaced with a new one.

How to profitably exchange a used car

To guarantee the legality of the used car exchange service and its objective cost, the purchase and sale process should be carried out at a trusted auto center. Here the client will be offered:

- Diagnostics of the old model, on the basis of which its cost will be determined;

- Selection of cars for exchange, completely new or with a clean mileage history: all cars undergo forensic examination, therefore the car dealership will never sell a car with a “dark past”;

- Legal support of the transaction: the client enters into a notarized agreement and, if necessary, can use the credit services of the car dealership’s partner bank;

- Efficiency of the service: the client does not need to look for buyers for his vehicle; he does not need to settle issues with the traffic police or the bank. The listed functions are the task of the auto center.

Read here! Carburetor design

Thus, with minimal documents, it is possible to buy an improved car within one to three days. The used car exchange service makes it possible to regularly change the owner’s vehicle fleet by purchasing its best models.

Do-it-yourself carburetor flushing.

Washing with your own hands is quite a jewelry job. Since there are a large number of small parts. Purchase a repair kit first. Since this kit contains all the gaskets, and in some I also saw jets. Regarding the liquid in bolognese, you can also buy it. But I always washed with solvent. Of course, many are against this washing, but I’m not complaining. If you dry it well, there will definitely be no problems.

So, let's get to the point. To wash it, we need to completely disassemble it. That is, unscrew everything that is there. As a result, freeing all the channels for cleaning. We begin to wash away all the dirt and sand, thereby achieving sterility. We also use a tire inflation pump to blow out all the channels. I recommend doing this procedure on a clean and illuminated surface. As a result, after washing, it is necessary to dry the carburetor. Then assemble in reverse order. Carefully placing everything in its place.

Carburetor flushing

It is best to use cans called “carburetor cleaner” for cleaning. Unscrew all the jets, including the idle jets, remove the accelerator pump, place both halves of the carburetor, all sprayers, emulsion tubes and jets in a bath filled with 1 cm of gasoline. Carefully fill all channels with “carburetor cleaner” and leave it for 5 – 6 hours. After this, use a toothbrush and gasoline to wash the outside of the carburetor body, remove it from the bath and blow it with compressed air. Then thoroughly blow out the channels with compressed air. Using “carburetor cleaner”, wash off all deposits from the throttle body and flush and blow all passages, nozzles, tubes and jets several times. Do not use matches or toothpicks to clean the nozzles; use only “carburetor cleaner” and, if necessary, thin copper wire. Dry the passages and throttle valve using compressed air. Replace the gaskets between the carburetor and the intake manifold. Install the lower part first (this makes it much easier to tighten the nuts), then insert all the jets (do not mix them up), the accelerator pump, the gasket and the top part of the carburetor. Tighten the bolts and connect all the pipes and rods.

The VAZ 2101 is a fairly old car and problems with the Weber carburetor are common. Auto mechanic Nail shows how to sort out and repair a VAZ 2101 carburetor You will have the opportunity to visually see the entire process of repairing a VAZ 2101 carburetor on video, from disassembly to installation and adjustment. If your car behaves inappropriately and has standard complaints such as: fuel consumption, jerking and the like, then this VAZ 2101 carburetor repair video is just for you.

Subscribe

to our channel in

Index.Zen

Even more useful tips in a convenient format

Apparently there is a problem with the inlet valve of the overrunning pump, there is one channel there, in which there is a ball. This channel could have become coked and the ball along with it, so the carb does not splash fuel.

Adjusting the carburetor with your own hands.

There is nothing scary, much less complicated, about adjusting the carburetor with your own hands. Since all procedures are performed with conventional tools. Unlike the injector, where computer diagnostics are required. So, let's start by adjusting the fuel level.

Adjusting the float mechanism.

The float mechanism is adjusted after washing, before assembly. For this procedure we will need to visually inspect the entire mechanism. Because if the bracket is bent, the system will not work correctly. This will cause the floats to skew and touch the walls of the chamber. But this problem can be corrected manually. We just bend the bracket. And finally, we lower the float to the lower position, thereby opening the fuel valve. Then we measure the distance. There should be 15mm between the float and the valve.

Idle speed adjustment.

Idle speed adjustment is performed with two screws. The screw is “quality”, and the second is “quantity”. First, let's figure out “who is who.” Tighten both screws until they stop. Then back three turns and start the engine. If everything works out, the revs will start to jump. The engine will not run smoothly. If the car does not start, then unscrew both screws one more turn. Then we begin to tighten one of the screws smoothly and slowly. If the engine speed begins to increase, then this is a “quality” propeller. If you tighten the “quantity” screw, the engine will start to stall.

So let's start adjusting. This work is carried out only on a warm engine. We unscrew both screws, find the “quality” from them and begin to tighten them slowly. The engine speed will begin to rise and become more even. At the same time, we also begin to slowly tighten the “quantity” screw, thereby lowering the engine speed. As a result, we need to achieve 800 - 900 rpm and stable operation. And at the end we tighten the “quality” screw a little until the operation becomes unstable. And back one turn. Carburetor adjusted!

DAAZ 2107 carburetor design

A carburetor produced by DAAZ is installed on some models of Zhiguli cars. In particular, on VAZ 2105, VAZ 2107, Oda, Moskvich, etc.

Carburetors for equipping vehicles are produced here

The unit has two internal combustion chambers that operate sequentially, depending on the opening/closing of the throttle valves. The carburetor structure is determined by the following components:

- first and second chambers;

- fuel mixture dosing systems;

- idle system;

- fuel pump;

- econostat;

- motor starting device;

- economizer (forced idle).

Each of these elements is responsible for a specific area of work:

- dosing systems supply the required amount of fuel to the engine in a timely manner to ensure smooth engine starting;

- The idle system supports the operation of the carburetor power unit when driving at minimum speed or when parked;

- the pumping mechanism ensures a sharp supply of fuel to the cylinders if the road situation requires it (acceleration, overtaking, sudden starting from a standstill);

- The econostat as a device is designed to enrich the air-fuel mixture at maximum engine load;

- The economizer controls the moment of shutting off the fuel supply through the idle system.

The carburetor is equipped with many small elements.

Principle of operation

The DAAZ 2107 carburetor operates in various modes. Depending on the operating mode, certain system components will be used:

- Starting the engine “cold”. The procedure is carried out by enriching the air-fuel mixture, which comes from the dosing system. At the same time, the position of the air damper is adjusted to create the necessary air flow into the chamber.

- Idling. After the propulsion system warms up, the air damper closes, leaving only the necessary gap for air to enter the combustion chamber of the mixture. In this mode, gasoline is actively transferred from one jet to another, which ensures constant fuel pressure in the engine. The engine will be ready to increase speed at any time.

- Medium loads. As the throttle valve opens, the air-fuel mixture is supplied to the second chamber. This reduces the fuel pressure in the system, due to which the engine produces the necessary power to move the car.

- Increased loads. In this mode, all components of the motor operate. The pump operates at an accelerated pace to provide the required amount of fuel to the engine. The air damper continuously draws in air for an optimal ratio of the components of the combustible mixture.

Eventually.

As a result, after repairing, washing and adjusting the carburetor with your own hands, a check is necessary. Press the accelerator pedal and release quickly. The engine should run smoothly. No failures and of course no stalling. If you find any deviations. Then simply unscrew the “quality” screw another half turn. Repairing a carburetor with your own hands is not the most difficult job, but it involves a lot of emotions. When you hear how quietly and smoothly the engine runs after your repair. I hope you found a solution to your problem in this article. Thank you for your attention, see you soon!

I also advise you to look at: REPAIR OF INTERIOR HEATER

K-151 carburetor design

Most domestic cars are equipped with a carburetor:

- passenger cars "Volga" and IZH;

- UAZ SUVs;

- light trucks "Gazelle" and "Sobol".

Its main purpose is to prepare and adjust the composition of the fuel-air mixture for an internal combustion engine.

The carburetor is designed to prepare and adjust the composition of the fuel-air mixture for the engine

The design of the K-151 carburetor is quite complex. It consists of the following elements:

main body with float chamber;

a second housing or throttle body which is turned by actuator from the accelerator pedal;

the top cover of the float chamber, which contains a locking mechanism that prevents the chamber from overfilling with gasoline, and an air damper for starting a cold engine;

main dosing system (GDS), consisting of jets and fuel lines for preparing the fuel-air mixture;

idle system, necessary for stable engine operation at idle speed, consisting of a bypass channel, jets and adjusting screws, as well as an economizer valve with a membrane mechanism;

accelerator pump mechanism, which allows the car to move without failure during sudden acceleration and consists of additional channels in the main body, a ball valve, a diaphragm mechanism and a fuel sprayer;

econostat - a system designed to enrich the engine with a fuel-air mixture with a sharp increase in speed;

a transition system consisting of fuel and air nozzles and ensuring a smooth increase in speed at the moment the throttle valve begins to open in the secondary chamber.

The design of the K-151 carburetor is quite complex

K-151 has two cameras. The throttle valves open alternately during operation. This guarantees an uninterrupted fuel supply. When entering the carburetor, fuel passes through a fitting in which a mesh filter element is mounted. This mesh cleans gasoline from impurities and dirt. Excess fuel flows back into the gas tank through the fuel hose. All this allows you to maintain the required pressure in the fuel system.

I became acquainted with the Pekar K151 carburetor after purchasing a Volga (Gaz 2410) car. Well what can I say? The carburetor is produced by Pekar JSC (St. Petersburg Carburetors) and is intended for installation on Volga and Gazelle cars (modification K-151). The Volga, I’ll tell you, is of course a prestigious car of domestic production, but not economical when it comes to fuel... And the carburetor plays an important role in this. Of course, the K151 is more economical than the K-126, which was produced earlier, the power has increased, but of course there are disadvantages, in my opinion they are present in all domestic products. The jets tend to get clogged, and therefore you have to clean them (at least once every two months). And for a domestic car, it’s a completely normal carburetor.

Mikhail74

https://otzovik.com/review_728025.php l

A serious advantage of the K-151 is the presence of suction. The engine cold start control system on vehicles with K-151 operates separately. Therefore, cold starting can sometimes be difficult. To avoid such problems, a wire is stretched between the crescent of the starting device and the adjusting heel of the throttle valve. This wire creates adhesion between two separate mechanisms and guarantees quick engine starting.

In this case, the suction can be adjusted by setting the desired values depending on weather conditions.