Repost and the information will always be at hand ✅

The transmission serves to transmit torque from the engine crankshaft to the drive wheels, as well as to change the magnitude of the torque and its direction.

A car transmission is a set of mechanisms whose purpose is to transmit torque from the engine to the drive wheels. This causes the wheels to rotate, causing the car to start moving.

In addition, this important mechanism can distribute torque between all wheels, as well as change the direction of rotation and magnitude. Various parts and mechanisms help with this, without which it would be impossible to operate the car normally. For example, these are transmission units such as main gear, automatic and manual transmission (gearbox), clutch, differential.

The transmission design has evolved gradually. At first, the emphasis was on the comfort and controllability of the vehicle, and then they began to increase the life of the car itself by improving the efficiency of the transmission.

In the article, in simple language, I will tell you what a transmission is, what it is responsible for, what the main components are, how it works, classification by type of drive and operating principle, what breakdowns happen and how to identify them. I promise it will be interesting!

What is this in the car?

What is a car transmission in simple words? Let me say briefly - these are certain assembly mechanisms that are connected into a single whole in order to transfer the “flow” of energy from its source to the wheels of the car. If it were not for this design, it would be impossible to instantly activate the brake system, drive in reverse and control in traffic.

This term translated from Latin sounds like this: “transmissio”. This word literally translates as transfer or forwarding. Only the best automotive engineers design parts in the transmission.

Where is this structure located? Under the bottom of the car, it starts from the gearbox and ends in the area of the rear wheels.

Transmission photo

What requirements must the transmission meet?

- Reliability and safety.

- Light steering, especially when cornering.

- The highest possible power transfer rate.

- Minimum weight of all components.

- Low noise level during operation.

- High efficiency.

The more correctly and efficiently the components of the transmission work, the higher the safety of the driver, the lower the fuel consumption and wear of rubbing parts. Of course, this directly affects those characteristics that are indicated in the technical data sheet and guaranteed by the manufacturer.

There is also such a thing as transmission efficiency (transmission efficiency). It is calculated as the product of the efficiency of the mechanisms included in its composition. This is an effective characteristic indicating the ratio of useful energy to expended energy. Simply put, if the efficiency is low, it means that a lot of effort has been expended, but there is no result. The transmission efficiency of modern cars varies from 0.82 to 0.94.

This transmission parameter is not constant throughout the entire life of the machine . When operating a new car, the mechanisms grind against each other and efficiency increases. This value then remains for a long period of time, and when the moving parts wear out, the value drops. After a major overhaul, the efficiency increases, but never reaches its maximum value.

Also, many people ask the following question: “Gearbox and transmission are the same thing, what’s the difference?” I answer. The gearbox is one of the many parts of the transmission.

Purpose

All parts that affect the transmission of torque from the engine flywheel to the drive wheels are part of the transmission. The car starts moving without much effort and moves at the desired speed.

Why is this system of mechanisms necessary?

The main function of the transmission is to transmit, distribute and change torque from the engine to the drive wheels of the car. What is the purpose of the transmission? This is an intermediary between the engine and the drive wheels, without which it would be impossible to start the car moving.

What else does the transmission affect?

- Ensuring the required traction and speed of the vehicle when driving and turning.

- Ease of driving. This reduces the driver's fatigue and stress during long trips.

- Increased vehicle safety and reliability.

- Extending the “life” of the engine, removing excess load from it.

Without the transmission, it would not be possible to take turns.

Also, some people are interested in the question, what function does the transmission not perform? Here is the correct answer: it does not ensure the movement of the vehicle in a given direction.

What is a car transmission

An automobile transmission is a type of transmission that allows the vehicle to move and be controlled by the driver. In general, a car transmission includes:

- clutch or torque converter;

- Transmission;

- main gear;

- constant-velocity joint.

Optionally, the transmission may also include a transfer case and cardan drive.

The classification of automobile transmissions is based on various principles of gear shifting and transmission of torque to the working part of the car, that is, the wheels. The following types of automobile transmissions are distinguished:

- mechanical;

- automatic;

- robotic;

- CVT type transmission.

Device

As a rule, automakers use automatic and manual transmissions in their cars. Additionally, cars can be front-, rear-, or all-wheel drive. It depends on which wheels the torque is supplied to. Therefore, the type of drive directly affects which elements are included in the transmission.

What about the transmission? The standard transmission kit includes the following components:

- Clutch.

- Gearbox - gearbox.

- Differential.

- Axle shafts are wheel drive shafts.

- Main gear.

- Constant velocity joints.

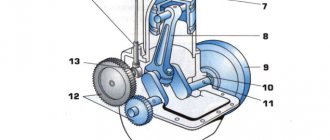

What a transmission looks like

Depending on the type of drive, the transmission assembly may include mechanisms such as a transfer case, driveline drive, and clutches. It is these basic parts of the car that the transmission connects to ensure the efficiency of the vehicle. Other components and mechanisms do not belong to the vehicle transmission.

What is included in the transmission of tracked vehicles?

- Final drive.

- Input gearbox.

- Rotation mechanism.

- Clutch or main clutch.

- Checkpoint.

Also, some people ask, “What goes into a truck transmission?” In addition to the main mechanisms, it additionally includes an intermediate middle drive axle, a transfer case, and a power take-off. In large road trains for driving on hard road surfaces, the transmission is only in the tractor. And when driving off-road, the transmission is also installed in the drive axles of trailers.

General diagram of a truck transmission

Such a complex mechanism is necessary in order to increase the life of the motor. Instead of constantly changing the operating mode of the internal combustion engine, the gearbox changes the torque ratio. And the clutch serves to protect the engine and gearbox from jerking loads.

What rotates fastest in a transmission? When driving a car, the crankshaft of the internal combustion engine rotates at a speed of up to 7000 rpm, and the wheels are 4 times smaller, and in bad conditions even slower.

Another good article: Crankshaft: what is it, where is it located, device, purpose, how it works, photo

Let's move on to a detailed description of all the parts included in the transmission.

Clutch

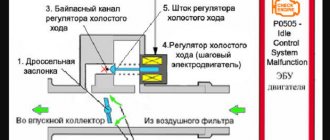

This is a set of parts (discs, flywheel, release forks, gearbox input shaft), the purpose of which is to briefly disconnect the engine from the gearbox. The clutch is located between the internal combustion engine and the gearbox. This is necessary to ensure that the car starts moving, as well as to smoothly change gear speeds. The clutch is found in a car with a manual or robotic gearbox. Therefore, it can be controlled by both the driver and the electronics, which automatically switches speeds.

An additional purpose of the clutch is that it helps protect engine and transmission parts from damage under sudden loads.

When the left pedal is pressed, the driven and driving discs are separated, and you can change the desired gear. And if the pedal is not pressed, then these same discs are tightly connected to each other. It is important to understand that this rather fragile mechanism is sensitive to incorrect driver actions. If you engage the clutch abruptly, it will break due to the “burning” of the rubbing parts.

As a rule, a friction clutch is more often used, the action of which is based on the force of dry friction . In cars with a manual transmission, dry friction is used without lubricating fluid. In the normal state, the disks are pressed against each other using springs. This helps transfer energy from fuel combustion to the transmission. If the driver presses the left pedal, the discs are separated and the transmission of energy flow is stopped without stopping the engine. When you need to start moving again, you need to smoothly release the pedal so that the discs connect again. Dry clutches are often used on vehicles with all-wheel drive.

And in cars with an automatic transmission, the clutch looks like two turbines, which are directly connected to the transmission and engine. The parts rotate in engine fluid. The leading torque converter transmits energy to the engine oil, from which the driven turbine begins to move. A wet clutch is more reliable, but its price is higher. There are also hydraulic and electromagnetic clutches, but they are not as widespread.

Gearbox (Gearbox)

This is the most complex mechanism in the transmission. The gearbox helps change the gear ratio for efficient engine operation in any road conditions. Thanks to this, the engine operates in a stable mode, without sudden jumps in speed, and the car moves at the speed that is necessary at a given time. Additionally, the gearbox switches the drive to reverse.

Thus, the gearbox changes the torque supplied to the wheels, the direction of movement of the vehicle, as well as its speed. In addition, the gearbox can disconnect the engine from the transmission for a long time.

Checkpoints can be of the following types:

- Automatic (“automatic”) Here the gear shift occurs automatically. The downsides are slow acceleration and increased fuel consumption.

- Mechanical (“mechanics”). Here, gear positions are changed manually using a lever. This type of gearbox is reliable and easy to operate.

- Variable speed drive. There is a smooth change in torque here. This is the so-called continuously variable transmission.

- Robot. This is a manual transmission, where the clutch and gear shifts occur automatically.

Excellent article on the topic : Which is better: a CVT, a regular automatic or a robot, the difference, owner reviews, video

The gearbox helps the engine “adapt” to the desired conditions. For example, when driving off-road in a low gear, the engine works harder and the wheels rotate slowly, which helps to overcome even difficult sections of the road. And when driving on the highway, when you engage a high gear, the engine runs in economical mode and the wheels rotate faster.

Main bridge

Transmission axles are the supports to which the vehicle frame is attached. The drive axle receives torque from the transmission, which sets the wheels in motion. The driven axle is just a support. Axles can be rear, front, or middle (they are installed in trucks).

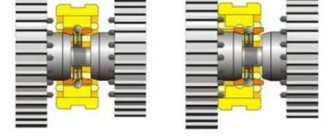

Differential

A differential is a set of gears that rotate with 2 degrees of freedom. What is it for? In order to divide the torque into 2 streams, which makes the wheels spin. In simple words, it distributes the rotation speed along the axle shafts of the drive axle depending on external conditions . And it works together with the main gear.

For example, when turning left, the left wheels move along a shorter trajectory than the right ones. Thus, the left wheels move slightly slower. The presence of a differential lock in cars allows two wheels to move on the same axle at the same speed. The device keeps the rotation of the wheels under its control, changing their speed to prevent them from slipping on uneven road surfaces (this is especially important when driving on slippery roads).

The most important characteristic of a differential is the locking coefficient, which indicates the ratio of the torque of one wheel to the same indicator of the other. Roughly speaking, cross-country ability depends on the blocking coefficient. The higher this indicator, the better the cross-country ability. For standard differentials it is equal to 1, and for more complex mechanisms it can be with a value of 5.

The location of the differential directly depends on the type of drive:

- Full - in the transfer case;

- Front - in the gearbox;

- The rear one is in the crankcase.

Transfer case

In common parlance this part is called a “transfer case”. This part is installed only in all-wheel drive vehicles to distribute rotation between all wheels. The transfer case may contain a range of multipliers, which increases the torque many times over when passing through difficult sections of the road.

Cardan shaft (transmission)

The driveshaft is a mechanism that transmits torque from the gearbox to the rear wheels. Typically, this part is installed in all-wheel drive or rear-wheel drive vehicles to transmit rotation between different axles. For example, in front-wheel drive cars, engine rotation is transmitted to the drive axle by shafts from the gearbox cardan.

The shaft contains 2 parts, which are connected to each other at an angle. The cardan consists of couplings, shafts, hinges, splines, and an intermediate support. The cardan transmission looks like a pipe, and thanks to additional parts it can change its length and also bend. And this is very important when driving over bumps, when the wheels move up and down, and the distance from the gearbox to the main gear is constantly changing.

Another good article: Car spar: what is it, how many are there in a car, what it looks like, where it is located, what it is needed for, photo + video

The cardan is considered an important mechanism that helps smoothly transfer torque from the gearbox to the main gear when driving on uneven roads, even at a certain angle. Additionally, the cardan reduces body vibrations when the vehicle is moving.

The driveshaft helps transmit torque from the gearbox output shaft to the main gear shaft, which are at an angle to each other.

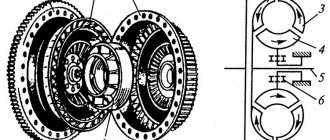

main gear

This is a unit that transmits torque directly to the drive axle. The device includes an axle shaft, gears, and satellites. One of the important functions of the final drive is to increase torque and reduce rotation of the drive wheels.

There is a single gear, as well as a double gear, which is available in trucks with a large gear ratio. And on rear-wheel drive cars, the so-called hypoid main gear is used, which is located in the axle housing. In front-wheel drive vehicles, the final drive is located in the gearbox near the differential.

CV joint

CV joint is a constant velocity joint, which is located on the drive axle shafts. It is the very last component of the transmission that is directly related to torque. This mechanism is necessary to accurately “transmit” rotation from the differential to the wheels, no matter what angle they are at. Internal and external CV joints ensure constant connection between the differential and the wheels when driving in any road conditions.

Types of transmissions

Some widespread transmission designs have become classics, which allows us to highlight them for separate consideration.

Mechanical

Purely mechanical solutions are simple and inexpensive, while providing good fuel economy.

This transmission includes a dry single-plate clutch with a pedal drive, a manual gearbox with manual shifting, cardan shafts to drive axles or individual wheels, final drives with differentials integrated into the gearbox or axles.

The wheels are connected to the axle gearbox using axle shafts.

Automatic

Automation in the transmission is usually involved in the construction of the gearbox, although automatically operated clutches are increasingly being used in other areas.

The box itself can be organized in the form of classical hydromechanics with electronic control elements, a robot with switching solenoids and clutch control, or a variator, where a metal belt is used that works along cones of variable diameter.

Hydraulic

It is not very common to use a purely hydraulic transmission. Its composition is unique and has little in common with all the others.

A powerful hydraulic pump is driven from the internal combustion engine, and the pressure of a special fluid it creates is transmitted through lines to the actuators of the axles or individual wheels.

These mechanisms use hydraulic motors that perform the opposite role of pumps, converting the flow of liquid under pressure into rotation.

Hydromechanical

A characteristic feature of hydromechanics is the use of a torque converter (GTR) and a fluid pressure-controlled gearbox.

GTR softens shock loads and partially converts the transmitted torque due to the slipping of the pressure and driven turbine wheels, between which a reactor is placed to reorganize the fluid flow.

A mechanical box of a unique design is installed behind the GTR, where the gears are organized according to the planetary principle, and switching is carried out using clutches pressed by fluid pressure through the cylinders. Such boxes are widespread and are considered classic automatic machines.

Electromechanical

In order to eliminate massive parts, as well as optimize control, electric current can be used instead of mechanics. A generator is connected to the engine, and the electricity it generates is supplied through conventional wires to the executive electric motors, of which there may even be one for each wheel.

Regulating functions are reduced to the application of known principles of electronics and electrical engineering. This is especially true on vehicles with particularly heavy load capacity, and recently on all kinds of hybrids.

Front wheel drive

The most technologically advanced in production are front-wheel drive cars, where the engine, gearbox and main gear are combined into a separate module, from which driveshafts extend to the CV joints to the hubs of the driving front wheels.

This is how almost all budget passenger cars, crossovers and even some of the premium segment are now arranged. It is claimed that these machines are simple and reliable to operate, although in fact their main trump cards are manufacturability and low cost. The layout of such bodies is also quite simple.

Rear wheel drive

Rear-wheel drive cars have become automotive classics. The important principle of separating the drive and steered wheels is implemented here, as well as better performance with the loading of the drive axle during acceleration, the naturalness of the driver's reaction in difficult situations and the ease of implementation of all-wheel drive.

The engine can be in the front of the car, although on sports cars it is located within the base or even in the rear overhang. All shafts run along the axis of the body.

All-wheel drive

All-wheel drive can be organized either on the basis of front-wheel drive or classic rear-wheel drive. In any case, the car has a transfer case of varying levels of complexity, as well as sometimes electrically controlled viscous or friction clutches for connecting individual axles.

Such vehicles have better cross-country ability and controllability, but the cost of such transmissions is high, which limits their use.

On the subject: Which is better all-wheel drive, front or rear?

The situation will be radically resolved in the direction of all-wheel drive on electric vehicles, where it is even easier to implement than any single-wheel drive.

Principle of operation

Let's take a closer look at how the transmission works and what its operating principle is. How is the energy generated in the engine transferred to the wheels and thanks to this the car can move?

Transmission structure

Step-by-step operating principle:

- As a result of the activation of the ignition system, high voltage is created to form a spark, which ignites the air-fuel mixture. After fuel combustion, the engine crankshaft begins to rotate. This part is connected to the flywheel, and it is connected to the clutch. During normal operation, the clutch is always connected to the flywheel, and as a result, the gearbox is also always in the “on” state. Before changing gear, the clutch disconnects the permanent connection between the gearbox shaft and the flywheel. And when the switch is completed, the clutch restores this connection back.

- The gearbox can select the optimal gear ratio using a different set of gears. Each pair of gears has a different gear ratio, which allows you to change the value of torque and shaft speed. I note that only one pair of gears can engage at a time when selecting a specific gear. Other gears will simply run idle. The engine, clutch and gearbox are located in one housing and this trio is called the power unit.

- The torque is then transmitted to the final drive (directly or through the driveshaft). The main gear reduces the high rotation speed (it is too high for the wheels) and transfers the rotation to the differential.

- The differential distributes torque to the axle shafts of the drive wheels. The axle shafts receive that long-awaited energy that will be transferred to the drive wheels. CV joints help maintain the desired speed when driving on uneven roads. The car begins to move.

- A driveshaft has been added to the rear-wheel drive transmission, which transmits rotation from the rear axle to the front. And a transfer case has been added to the all-wheel drive vehicle, which ensures that all wheels “transform” into drive wheels.

Video: Car transmission. General structure, principle of operation and structure of the transmission in 3D

Types

Let's take a closer look at how transmissions are classified according to energy transfer methods.

- Mechanical . Transfers mechanical energy from the engine.

- Electric . It converts mechanical movement into electrical energy. Then it “turns” it back into a mechanical one and transfers it to the drive wheels. Most often, such a transmission is used on powerful trucks.

- Hydraulic . Converts mechanical energy into fluid flow pressure, and then converts it back into mechanical energy and supplies it to the wheels. Rarely used in mechanical engineering. This type is used on mobile vehicles (excavators, etc.).

- Combined (hybrid) transmissions. For example, these are hydromechanical and electromechanical. These are combinations of 2 different types of transmissions.

Let's look at each type in this transmission classification in more detail.

Mechanical

This is the most popular type of transmission, which is used in most passenger cars. The device operates only with the help of mechanical parts (clutches and gears).

The mechanical transmission is reliable and durable, which can be easily repaired. Also, this type of mechanism has high efficiency, is small in size and weight.

The disadvantages are that gear shifting is not entirely smooth, which in turn leads to irrational use of engine power. It will also be difficult for novice drivers to get used to driving cars with a manual transmission using a lever (this does not apply to sports cars, where shifting occurs automatically).

Interesting! Mechanical transmission was used during the Soviet era when designing the T-55, T-62, T-64, T-72, T-80 tanks.

What kind of transmission is called onboard and where is it used? Tractors, combine harvesters, road equipment and some high-speed tracked vehicles are equipped with an onboard transmission (with final drive or wheel drive). These units are placed in front of the drive wheels or in them themselves. This is done in order to transmit maximum torque to the drive wheels.

Hydromechanical

This is an increasingly popular transmission that is used in cars with automatic transmission. Both hydraulic and mechanical parts are used here. Mechanical energy is “converted” into oil movement in a torque converter (analogous to a clutch). Torque is transmitted without jerks or distortions, stepwise, without the participation of the driver in this process.

The car moves smoothly, the service life of the engine and other transmission elements increases . The use of a hydromechanical transmission helps to pass difficult sections of the road (snow, sand) more efficiently due to constant traction and low rotation speed of the drive wheels.

The disadvantages include increased weight of the structure, complex repairs, and high price of the car. The engine efficiency also decreases.

This type of transmission is also used in railway vehicles, tractors, tanks (Leopard-2, M1 Abrams).

Hydraulic

Synonyms for this type of transmission are hydrostatic, hydrostatic, and oil-hydraulic power. In this type of transmission, engine energy is transmitted using axial plunger mechanisms - hydraulic machines. When transmitting torque, the fluid is compressed. At the same time, it is possible to place transmission parts at a large distance from each other with a high number of degrees of freedom and torque. This requires strict control over the quality of the fluid used and the installation of a fluid coupling for each gear.

Another good article: Webasto: what is it in the car, how does it work, principle of operation, types, prices, photos + video

As a rule, “flexible” transmissions are used in motor ships, construction rollers, machine tools, railway and aviation equipment.

Electromechanical

This is the most modern type of transmission, which became popular after the mass production of electric cars. The most important element here is a traction electric motor (one or more), as well as additional parts - an electric current generator, an electrical control system, as well as wires that connect parts of the transmission. This system is powered by a traction battery.

The advantage of an electromechanical transmission is an instant response to changes in the torque parameter, the arrangement of elements at a large distance from each other, which allows you to create convenient designs. Cons: high price, low engine efficiency, large weight and size.

Some people ask, “What types of transmissions are used in mining vehicles?” Most often, electromechanical transmission is used in mining dump trucks.

Electromechanical transmissions are additionally used in tractors, military equipment, diesel locomotives, buses and marine vessels. Some types of transport “turn on” the engine only after reaching a certain speed, and until this time the wheels move using electric current.

Now let's move on to a description of the types of drives and the features of the transmissions used in them.

Dependence of transmission on drive

Design features vary for different types of transmissions. In total there are the following drive types:

- Front wheel drive.

- Rear wheel drive.

- All-wheel drive.

There is such a thing as a car wheel formula, which includes 2 digits. Explanation: the first is the total number of wheels, and the second is the number of drive wheels. So front- and rear-wheel drive are designated 4×2, and all-wheel drive – 4×4.

Let's look at them in more detail.

Front wheel drive

They use a classic transmission, the operating principle of which was indicated above. Rotation from the engine is transmitted only to the front axle through the gearbox, final drive and axle shafts.

The differential and final drive are housed in the gearbox in a single housing.

Rear wheel drive

All elements of a front-wheel drive transmission are present here. Here the driving axle is the rear one, and torque is transmitted using an additional element - the driveshaft. It is located between the gearbox and the main gear and is an intermediary in the transfer of energy.

All-wheel drive

Torque is transmitted simultaneously to the front and rear axles. The transmission additionally includes a transfer case, which transmits rotation to all axle shafts. And the center differential is responsible for the distribution of torque between the wheels.

The truck's transmission includes an additional axle to reduce pressure on the asphalt and reduce wear.

Types of all-wheel drive:

- Permanent all-wheel drive. All wheels are driven at all times. Thanks to this, acceleration and controllability are improved, wheel slip is reduced due to the uniform distribution of traction.

- Connectable. The driven axle becomes the driving axle when the driver forcibly engages all-wheel drive.

- Automatically connected. Activated when the drive wheels slip.

Why does a car have a transmission?

Based on the functional purpose, we can identify several specific tasks that transmission mechanisms solve:

- connection and prompt disconnection of torque transmission units with the engine output shaft, usually with a flywheel installed there;

- change in the overall transmission ratio, that is, the ratio of the engine shaft speed to the speed of the drive wheels;

- additional increase or decrease in the gear ratio in special driving conditions, for example, off-road or when climbing uphill with a heavy load;

- distribution of torque between the axles when the car has more than one driving pair of wheels;

- transmission of rotation along the vehicle axis to the drive axles or across, directly to the wheel hub units;

- reversing the direction of torque transmission from longitudinal to transverse in drive axles;

- providing the ability for the wheels to rotate at different speeds while maintaining their constant load of torque;

- disabling one or more functions when necessary;

- additional functions related to the specifics of a particular vehicle, for example, parking braking, power take-off to external units, and the like.

Each function has its own mechanical, hydraulic or electrical device for its execution, sometimes the capabilities are combined in one unit.

Principle of operation

The transmission uses several characteristic techniques for transmitting rotational motion over a distance:

- possibility of disconnecting the power flow;

- shift of the axis of rotation in space;

- tilt of the rotation axis at a constant or variable angle;

- change in torque value with a proportional but opposite change in rotation speed;

- simultaneous use of different principles, for example in hypoid gears or more complex cases.

A variety of components and parts are used, from the simplest shafts and gears to computer-controlled power electronics devices.

The most common signs of transmission failure

Many transmission parts wear out or break over time. What common breakdowns can occur?

- The clutch is a so-called consumable item. This is where the driven disk breaks most often. This causes grinding, slipping and unstable clutch operation. In this case, the driven disk is replaced, and other parts are inspected for wear. Please note: clutch slipping can cause wear on the driven disc clutches. This leads to limited pedal free play, poor acceleration, reduced torque transmission, or the car may not move at all. The life of the clutch directly depends on the driving style of the car.

- Gearbox - the gearbox is the most complex mechanism in the transmission. A common cause of breakdowns is infrequent transmission oil changes. After all, it is precisely this that protects all gearbox components from wear. If the fluid is not replaced on time, it will increase wear on the gearbox. When the gearbox breaks down, extraneous knocks, noise, and rustling appear, even when the lever is moved to the neutral position, poor operation occurs when shifting gears, and oil leaks from the gearbox, the smell of which appears in the cabin. In these cases, you should immediately contact a car service center. It is recommended to strictly monitor the condition of the gearbox (change the fluid in the cooling system in a timely manner, diagnose the electronic control unit, etc.)

- in the propeller shaft may fail due to natural wear and tear. If there are malfunctions in the operation of the cardan transmission, then a creaking noise is heard and vibration is felt while driving.

- The differential and final drive often fail under extreme loads and oil leakage through the seals. If there is not enough lubrication, the gears will wear out quickly. When driving, there is noise, vibration or knocking when the vehicle starts to move.

- CV joints rarely break, despite the high load they bear. If water gets through worn boots into the angular velocity joints, a crunching sound will be heard while driving. Therefore, it is necessary to change the running gear consumables in a timely manner and check the condition of the suspension.

Video: General transmission structure

The transmission is a key mechanism in a modern car that transmits torque from the engine to the drive wheels. This is precisely its direct purpose. The type of device depends on the type of drive in the car and the method of energy transmission.

The most reliable transmission is a mechanical one, the operation of which depends only on regular maintenance. Most often the clutch disc fails, and the most expensive part is the gearbox, especially if we are talking about an automatic transmission.

New developments are increasingly being introduced into cars, where electronic components and gears are replaced by electric cables and electric motors controlled by an on-board computer. And the pinnacle of technical progress is an environmentally friendly car (for example, on hydrogen fuel), where such a mechanism as a transmission is completely absent.

Repost and the information will always be at hand ✅

3.1.1 Transmission classification

3.1.1 Transmission classification

Based on the method of energy transfer, transmissions are divided into mechanical, hydromechanical, electromechanical, and hydrostatic.

In mechanical transmissions, energy transfer occurs due to mechanical friction in clutches, as well as shaft connections, hinges and gears.

In hydromechanical transmissions, a torque converter or fluid coupling is installed between the engine and the mechanical part of the transmission, providing hydraulic connection between the engine and the transmission. Fluid couplings do not change the transmitted torque and always operate with the turbine wheel slipping relative to the pump wheel, and consequently with a loss of power. At high rotation speeds, slippage is 2...3%, at low speeds it approaches 100%. At idle, when there is no fluid supply, the fluid coupling transmits residual torque. The high moment of inertia of the fluid coupling wheels prevents the shock-free engagement of the gear wheels. Therefore, it is necessary to install a conventional friction clutch after the turbine wheel. Due to high fuel consumption, large weight, overall dimensions and cost, fluid couplings are not used on domestic cars.

In an electromechanical transmission, an engine (usually a diesel engine) rotates the rotor of an electric generator, the energy of which is transmitted through an electric cable to an electric motor and then through a gear reducer to the drive wheels or electric motors mounted in the drive wheels. The electromechanical transmission, if equipped with appropriate control equipment, has high transformative properties and automatically adapts to changing loads, and the engine operates in optimal mode. Due to the high cost, complexity of the design, the use of scarce materials and the large mass, electric transmissions are economically profitable to use on vehicles with a carrying capacity above 80 tons (BelAZ-7549, etc.).

In hydraulic displacement transmissions, the engine drives a hydraulic pump, which, under high pressure, pumps oil into hydraulic motors located in the drive wheels and causing them to rotate. Hydrostatic transmissions use hydrostatic fluid pressure. The torque and rotational speed of the drive wheels change either due to changes in the parameters of the hydraulic machines with a possible constant operating mode of the internal combustion engine, or as a result of regulating the engine power. The advantages of a hydraulic displacement transmission: a wide range of changes in the driving torque and speed of the vehicle, remoteness (units located in different parts of the vehicle are connected to each other by oil lines), simplicity and convenience of autonomous power supply to the drive wheels, complete replacement of a mechanical transmission, the ability to brake the vehicle. However, automatic torque change is not possible in hydrostatic transmissions, so they are equipped with control equipment that responds to load changes.

Disadvantages of hydrostatic transmission: complexity and high cost of the design. This transmission is installed only in special machines.

Low cost, high reliability and efficiency, simplicity of design, relatively small weight and overall dimensions have led to the widespread use of mechanical transmissions. However, they require manual control and do not always ensure the engine operates in optimal mode. The transmission and engine are not sufficiently protected from dynamic loads. In agricultural vehicles, general transport trucks and their modifications, mechanical transmissions are mainly used.