The constant improvement of the internal combustion engine in order to increase efficiency and improve fuel efficiency has forced engineers to seriously rework the timing structure of modern diesel and gasoline engines. Changes also affected the design of the piston group and combustion chamber. These modifications were made to maximize the efficient filling of the cylinders and their high-quality ventilation, that is, to obtain improved gas exchange.

We also recommend reading the article about what a variable valve timing system is. From this article you will learn about what types of these solutions are installed on different engines, as well as the operating principles and design features of such systems.

If in the early stages of development the most common engine was with two valves per cylinder (1 intake and 1 exhaust valve), today an increase in the number of valves per cylinder is everywhere observed. Such changes are well illustrated by the most common version of the automobile internal combustion engine with four cylinders. Previously, such engines were often 8-valve, with one camshaft. Today, such a unit is often a 16-valve version with two camshafts (for intake and exhaust valves), can be equipped with a variable valve timing system, etc.

Broken timing belt/chain: main reasons

If we compare modern engines with their predecessors, today's engines have more power and shorter service life. Regarding the problem of valve bending, it is precisely to achieve greater efficiency from the engine that the distance from the piston to the valve is minimal. Even a slightly open valve bends as the piston rises to TDC. It turns out that various technical innovations in engine building did not in any way affect the well-known problem, which is inherent in the vast majority of engines, regardless of the type of motor and manufacturer. We are talking about bending of valves when the drive belt or timing chain breaks.

An important rule when operating a car is to monitor the condition of the timing belt and replace it in a timely manner. The belt should not have any delaminations, cracks or other defects. Also, various technical liquids are not allowed to come into contact with its surface. The appearance of squeaking, creaking and other extraneous sounds will require the owner to check the tension and condition of the timing belt, as well as the tensioner and other rollers.

To answer the question of when to change the timing belt, you need to study the operating instructions for a particular car. Often on new cars, the belt is changed after 60 thousand kilometers traveled or after 2-3 years (whichever comes first). A planned replacement with an original belt involves the next replacement every 50 thousand km. It is advisable to select non-original belts with caution and change them every 40 thousand km.

Now a few words about the chain drive. The timing chain requires less attention, since replacing the chain on average is necessary once every 150-200 thousand km. and more. In this case, it is necessary to monitor the chain tension, the condition of the tensioner and chain guide. Increased noise during engine operation, the appearance of a metallic clang and other signs will indicate the need to immediately check these elements.

We also recommend reading the article about what can whistle under the hood when cold. From this article you will learn about the possible causes of squeaking and squeaking, as well as ways to identify and eliminate the problem.

So, let's return to the belt, which is less reliable compared to the chain. The timing belt most often breaks for the following reasons:

- belt wear as a result of long-term use or use of a low-quality product;

- jamming of the pump (water pump);

- jamming of the crankshaft, camshaft;

- tension roller malfunction, timing rollers jamming;

- destruction of the timing belt as a result of engine oil getting on its surface;

- mechanical damage after contact with sharp edges of the timing drive, camshaft gears;

Why do valves bend when the timing belt or chain breaks?

Despite the improvements, the general traditional principle of operation of the timing belt and engine valve mechanism remains unchanged. As you know, raising the piston to TDC (top dead center) means that at the specified moment the intake and exhaust valves are closed. This is necessary to create pressure and seal the combustion chamber.

If the timing belt breaks, then the valves simply do not have time to close, which means they collide with the rising piston. When the timing belt breaks, the camshafts immediately stop. This immediate stop occurs for two reasons:

- since the drive force from the belt or chain disappears;

- the camshaft cams themselves are retarded by return springs;

As for the crankshaft, this element of the crankshaft continues to rotate by inertia. The inertial rotation of the shaft does not depend on what gear and at what speed the car was moving, at what speed the engine was running, etc. The flywheel still turns the crankshaft. In other words, if the timing belt breaks, then the timing mechanism immediately stops and the valves remain open, while the crankshaft continues to rotate and the moving pistons hit the valves that are open at this time.

The result of a broken belt is that the piston meets the valves, after which the valves immediately bend. Often the valve stem is bent, although sometimes various deformations of the valve disc are also possible. Less common is damage to the piston itself, which is also a consequence of a broken belt and bent valves.

Engineers and car manufacturers are well aware of this problem. To prevent the consequences of a broken timing belt/chain, some old internal combustion engines had special grooves for the valves on the piston. These grooves actually provided the necessary free space, which allowed the open valves not to collide with the upward moving piston. In such motors, after the valve drive broke, the valves did not bend.

Modern engines also have characteristic recesses on the piston. It is worth noting that these grooves avoid the risk of damage to the valve while the engine is running. If the timing belt breaks on such engines, the indicated grooves do not prevent the valves from bending, that is, the valves still bend even if there are special grooves on the piston.

Auto parts and service stations

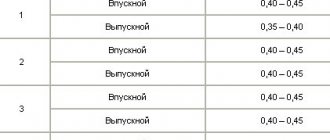

On what engines do valves bend?On cars with an 8-valve engine, it bends least often, but with 16 and 20 valves, be it gasoline or diesel, bending occurs in most cases. True, sometimes it can be one or more valves, and if the engine was idling, then trouble will come. But there are few such cases, mostly the consequences are irreversible. A table with a list of engines on which the valves of all popular cars bend when the timing belt breaks.

The valve mechanism works as follows: when the piston reaches top dead center, both valves in the combustion chamber close and a certain pressure is created in it. A broken belt means that the valves do not have time to close in time before the piston arrives. Thus, their meeting occurs - a collision, which directly leads to the fact that the valve bends. Previously, in order to prevent a similar problem, special grooves were made for the valves on older engines. On new generation engines there are also similar notches, but they are intended only to avoid valve deformation during engine operation and in the event of a belt break they do not help at all.

From a physical point of view, from the moment the timing belt breaks, the camshafts immediately stop, under the action of return springs that brake its cams. At this moment, the crankshaft inertially continues to rotate (regardless of whether the gear was engaged or not, whether the speed was low or high, the flywheel continues to spin it). That is, the pistons continue to work, and as a result, they hit the currently open valves. Quite rarely, but it happens when the valves damage the piston itself.

Causes of timing belt breakage

- wear of the belt itself or its poor quality (shaft gears have sharp edges or oil from the seals).

- crankshaft jams.

- pump jams (the most common phenomenon).

- Several or one camshaft is jammed (for example, due to one of them becoming unusable - however, the consequences here are slightly different).

- The tension roller unscrews or the rollers jam (the belt becomes loose or overtightened).

Modern engines, since they are more powerful compared to their predecessors, have much lower survivability. If we consider the cause based on the valves, this problem arises due to the small distance between them and the piston. That is, if at the moment the piston arrives the valve is slightly open, then it immediately bends. Since for greater compression and contraction in the bottom of the piston there is no groove under the valve of the required depth.

How do you know if a valve is bent?

Checking the engine to see if the valves are at risk of bending after a timing belt break

Neither a visual inspection nor the numbers given in the “valve bend” tables will help you in this matter. Even if you have information from the manufacturer about damage in the event of a broken belt, it is unknown how reliable it is.

If you want to check for the possibility of the valve piston bending when the timing belt breaks, you need to remove the belt, set the first piston at TDC, and rotate the camshaft 720 degrees.

If everything went well and it didn’t get stuck, you can continue checking - move on to the second piston. When everything is fine there, then a possible belt break will not lead to negative consequences for the engine of your car.

To avoid this problem (bending valves when broken), it is necessary to constantly monitor the condition and tension of the timing belt. If the slightest unfamiliar noise appears during operation, you should immediately try to find out the cause of its occurrence and inspect the condition of the rollers and pump.

When purchasing a used car, replace the timing belt immediately, regardless of what the dealer tells you. And then such a pressing question as whether the valve bends when it breaks will not bother you.

Bent valve signs

When the belt breaks, simply changing the timing belt, hoping that everything went without consequences and you will start the engine, is not worth it. Especially if the engine is on the list of those on which the valves bend. Yes, there are cases where the bend was not large and several valves no longer fit snugly in the seat, then you can turn it with a starter, but often such actions will further aggravate the situation. Since with minor damage everything will work and spin, but the engine will shake, and the consequences will only get worse.

It is best if you remove the “head” in order to check this visually or fill it with kerosene, however, there are several ways to check whether the valve is bent without disassembling the engine.

Main symptom

if the valves are bent, there is little or

no compression

. Therefore, it is necessary to measure the compression in the cylinders. But, such actions are relevant if the crankshaft can be turned and nothing rests anywhere. So the first thing you need to do is install a new belt, manually, using the bolt on the CV, turn the entire gas distribution mechanism a few turns (you need to unscrew the spark plugs).

How to check if a valve is bent

To determine whether any valve stem is bent, literally five turns of hand turning the crankshaft bolt with a wrench will be enough. If the rods are intact, the rotation will be free; if the rods are bent, the rotation will be heavy. There should also be clearly perceptible 4 points (with one revolution) of resistance to the movement of the pistons. If such resistance is imperceptible, then screw the spark plugs back in, unscrew them one by one and turn the crankshaft again.

Based on the manual torsion force, with one of the spark plugs missing, it is relatively easy to understand in which specific cylinder the valve(s) were bent. However, this method will not always help to accurately determine whether the valve is bent or not.

If the crankshaft rotates freely, then you can check it with a compression gauge

.

Don't have such a tool? This means doing a pneumatic test

, and checking the tightness of the cylinders is the most correct way, which will give an answer to how the valve plates fit in the seats, without additional consequences when cranking with the starter and without installing a new belt.

How to check if the valve is bent yourself?

For a pneumatic test, there is no need to take the car to a service station; you can find out for yourself whether the cylinder is sealed or not. The easiest way is:

- find a piece of hose along the diameter of the spark plug well;

- unscrew the spark plug;

- set the cylinder piston to top dead center (valve closed) one at a time;

- insert the hose tightly into the well;

- Trying with all your might to blow into the combustion chamber (air passes through - it’s bent, doesn’t pass through - “blown away”).

The same test can be done using a compressor (even a car compressor). True, you will have to spend a little more time, as you need to prepare. Drill out the central electrode in the old spark plug, and put a hose on the ceramic tip (fix it well with a clamp). Then pump pressure into the cylinder (provided that the piston in it is at TDC).

The hissing sound and pressure on the pressure gauge will tell you whether the valve caps are seated or not. Moreover, depending on where the air goes, determine the inlet bent or exhaust. When the exhaust outlets are bent, air goes into the exhaust manifold (muffler). If the intake valves are bent, then into the intake tract.

On what engines do valves bend? — (MS Word document *.docx)

Source: https://etlib.ru

Author of the material: Ivan Matieshin.