Signs of a faulty distributor cap

Distributor

is an ignition distributor, a mechanism designed to create high-voltage pulses in the ignition system in order to distribute ignition among the cylinders. In other words, the task of the distributor is to supply a spark in the selected sequence to the spark plugs of different cylinders synchronously with the operation of the camshaft.

These devices are used in gasoline carburetor engines. Diesel engines do not have an ignition system, and injection systems do not use a breaker.

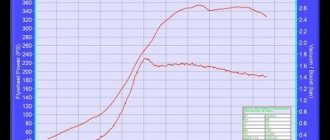

Diagnostics of the ignition system using an oscilloscope

Often, when professionally checking a car's ignition system, they use a device called a motor tester. Its main task is to monitor the high voltage waveform in the ignition system. In addition, using this device you can view the following operating parameters in real time:

A complete set of motor testers for car diagnostics

- spark voltage;

- spark lifetime;

- spark breakdown voltage.

All information is displayed in the form of an oscillogram on the computer screen, which gives a comprehensive picture of the performance characteristics of spark plugs and other elements of the car’s ignition system. Depending on the ignition system, diagnostics are carried out using different algorithms.

In particular, classic (distributor), individual and DIS ignition systems are checked using an oscilloscope in different ways. You can find detailed instructions about this in a separate article on checking the ignition with an oscilloscope.

conclusions

Malfunctions in a car's ignition system can sometimes turn into big problems at the most inopportune moment. Therefore, we recommend that you periodically inspect its main elements (spark plugs, high-voltage wires, ignition coil). This check is simple, and even an inexperienced motorist can do it. And in case of complex breakdowns, we recommend that you seek help from a service station in order to carry out detailed diagnostics using a motor tester and other diagnostic equipment.

Distributor design

The distributor circuit assumes the presence of such elements as:

The distributor circuit is designed so that at a certain moment the breaker opens the primary ignition circuit, as a result of which a high voltage current is created in the secondary winding of the ignition coil. Through the distributor, this current is transmitted to the spark plugs in certain cylinders. The regulators automatically adjust the ignition timing, which depends on the current operating mode of the engine.

The distributor breaker is an electromechanical part and consists of the following parts:

The breaker shaft consists of two main parts. On one of them, depending on the type of breaker, cams are installed, the number equal to the number of cylinders in the engine. This distributor device is not very reliable, since a large number of contacts, as well as the presence of moving parts, lead to regular problems with this unit.

The distributor device, as well as its use in general, are outdated from the point of view of modern electrical equipment, but in our country there are still a lot of carburetor engines, so the problem of the performance of this unit is currently relevant.

As for where the distributor is located in the car, most often it can be found under the hood next to the engine, near the cylinder head or on it. Although the exact location of the node depends solely on the model of the machine.

Distributor purpose

The distributor is a unique mechanism designed to determine the moment when high-voltage pulses begin to form in the ignition system. This device is used to distribute electric ignition among the cylinders of two types of gasoline internal combustion engines - injection and carburetor.

The distributor, by its nature, differs from other components in that its structure has a fairly large number of parts that wear out quickly. But the condition of this mechanism has a direct impact on the efficiency of the engine, as well as its starting characteristics. In addition, how efficiently the distributor works also affects the overall dynamics of the car and the toxicity of the exhaust.

As for the functions of this mechanism, there are two main ones:

- Interruption of the primary ignition circuit - in this way, the distributor provides current fluctuations in the primary winding of the coil, as a result of which a high level voltage appears in the primary part.

- Distribution of energy between the cylinder spark plugs in the required quantity and sequence.

The described mechanism is also indispensable because in its structure it has a number of mechanisms whose task is to change the ignition timing, which depends on the operating mode of the engine.

It should be noted that some cars, namely those with glow, diesel and compression engines, do not need a distributor for the simple reason that they have a different principle of ignition of the fuel-air mixture.

Distributor malfunctions

The following signs indicate that the distributor is malfunctioning:

When there is a spark on the central wire, but not on the spark plug wires, this indicates a breakdown of the slider.

In most cases, the causes of distributor failure are:

Breakdown of the roof and ignition coil occurs due to large gaps in the contacts of the distributor cover and slider, spark plugs and bad candlesticks.

In each of these cases, replacement is required. But at the same time, for almost any car, it is possible to change not the entire distributor, but only its failed part, which is an advantage, since it significantly reduces the cost of repairs.

The most basic check of the distributor is a visual assessment of the condition of the slider, contacts and cover.

In a contactless distributor, the main malfunction is the failure of the hall sensor or inductive sensor.

To check the ignition system and distributor, among other things, observe the spark on the unscrewed spark plug after starting the engine. In garage conditions, you can also check using measuring instruments or indicators.

The distributor capacitor is also one of the parts that often fail. It helps to increase the voltage supplied to the spark plugs when the engine starts. And in order to check it, you need to disconnect it and touch the “ground”, and if a characteristic crackling sound is heard and a voltage drop is observed, the capacitor is working, if this does not happen to the replacement part.

A distributor is always a dismountable unit that can be disconnected, removed from the car, disassembled into components, a problem can be detected and eliminated by replacing the damaged part.

Subscribe

to our channel in

Index.Zen

Even more useful tips in a convenient format

Operating principle of the distributor

In many ways, the operating principle of the distributor remained unchanged for many years. In VAZ cars, such as VAZ 2109, 2106, 2107, 2108, an ignition system of this type was used almost until the end of the last century.

The basis of the work is the connection of the distributor with the engine crankshaft. When the piston in the first cylinder takes the position corresponding to TDC, the breaker contacts open, a high voltage appears in the ignition coil, directed through a slider located in the distributor cover to the spark plug of the first cylinder.

There the combustion of the fuel assembly occurs, and the crankshaft continues to rotate. In addition to moving the pistons, it causes the breaker cam to rotate. When in another cylinder another piston occupies a position corresponding to TDC, at this moment the breaker contacts in the distributor open again, and a high-voltage voltage is generated in the ignition coil and supplied to the desired spark plug.

This joint rotation of the crankshaft, the breaker cam and the distributor slider ensures that a spark appears where and when needed. However, this does not cover all aspects of how the distributor works. To understand its operation, it is necessary to touch upon such concepts as the angle of the closed state of contacts (UZSK) and the ignition timing angle (IAF)

UZSK

A concept such as UZSK characterizes the time when the breaker contacts are closed. In essence, this is an indirect characteristic of the accumulation of energy in the coil after the completion of spark formation. UZSK directly affects the amount of energy spent on sparking and, accordingly, on engine operation.

In cases where the distance between the contacts is small, the coil will not accumulate the necessary energy and the spark energy will be low, which will lead to interruptions in the operation of the motor. A large gap also leads to interruptions, since the contact breaking time is reduced and the coil does not have time to fully discharge.

Each ignition system has its own optimal UZSK, to ensure which, if necessary, the distributor must be checked and adjusted.

UOZ

This concept concerns the moment of ignition of a fuel assembly. The fact is that its combustion does not occur instantly, and often, to ensure optimal conditions for such a process, it must begin earlier than the piston reaches the TDC position. The OZ characterizes the time by which the appearance of a spark precedes the appearance of the piston in the TDC position.

It is constantly changing, and its value completely depends on the operation of the motor under specific conditions, i.e. depending on the load, vehicle speed, quality and type of fuel used. To ensure optimal combustion of the fuel assembly, the distributor contains a centrifugal regulator and is also connected to a vacuum regulator.

VACUUM REGULATOR

It is this device that can change the OZ if necessary. As soon as the motor load changes, appropriate adjustments are made to the operation of the distributor device parts.

Important! The load is determined using the throttle valve.

The vacuum regulator of the distributor is a closed cavity. To ensure better performance, the design is divided by a diaphragm. One cavity goes directly to the carburetor.

When a vacuum occurs, the diaphragm begins to move. As a result, pressure is exerted on the movable disk and the breaker cam. The response time of the latter is adjusted depending on the current situation.

Attention! The distributor changes the moment of spark formation, thereby affecting the performance characteristics of the motor.

OCTANE-CORRECTOR

This is a very important element in the distributor design. Without it, the entire system could not function normally. The unit changes the SOP depending on the fuel that is currently being used.

By its design, this distributor element resembles two plates with an arrow. The same arrow is installed on the engine. There are special lines on it, through which the ignition angle is adjusted. It is almost impossible to do without this part when refueling different types of gasoline.

We recommend: Design, principle of operation and types of DSG gearbox

CONTACTLESS SYSTEMS

Technologies do not stand still. Every year, the automotive world is rocked by new innovations. This is precisely what innovation became in its time, supplementing the distributor design with switches.

Attention! In switches, the signal is supplied to the control electronic module, and not to the coil.

The second name for non-contact systems in the distributor device is Hall sensors. The simple design of these devices ensures uninterrupted signal supply. The sensors themselves work due to changes in the magnetic field.

Malfunction of the contact distributor.

Malfunction of the distributor during contact ignition is due to a change in the gap in the contacts or their contamination. The operation of a contact distributor, in contrast to a non-contact distributor, is greatly influenced by the condition of the contacts, which must be checked after 10,000 km. Distributor malfunctions include wear of the shaft cams and the stop of the contacts sliding along them, wear of the bushings in which the shaft rotates, destruction of the bearing of the movable contact plate, weakening of the contact spring, jamming of the contacts on the axis, burning, erosion or contamination of the contacts.

All these faults lead to a change in the gap or a violation of contact between the contacts. As a consequence, loss of engine power, engine idling stops, throttle response decreases, jerking is possible when the gas pedal is sharply pressed.

In case of significant wear or destruction of the bearing of the movable contact plate, critical wear of the bushings, breakage of the negative shunt, a violation of the contact of the contact pair lever and the contact itself leads to popping noises in the intake manifold and muffler. This is also possible if the radio interference resistor located in the distributor runner burns out.

When the engine does not start, this may be due to a lack of contact or gap in the contact pair, or a breakdown of the slider. The absence, contamination or burnout of contacts is determined visually if there is no spark discharge on the high-voltage wire coming from the ignition coil. If there is a spark on the central wire and no spark on the spark plug wires, this indicates a breakdown of the slider. Malfunctions also include malfunction of the centrifugal and vacuum regulators. If there is a weak spark on the central wire and large sparking between the contacts, the capacitor is most likely faulty. Do not install additional capacitors or capacitors of larger capacity. The capacitance of the capacitor should be in the range of 0.15 - 0.35 µF.

Where is the distributor located?

Basically, the ignition distributor, regardless of its model, is located on the cylinder head cover. The reason is that the distributor shaft is driven into rotation by the rotation of the camshaft of the gas distribution mechanism.

To ensure that the electrical line from the distributor to the ignition coil and battery is not too long, the distributor-breaker is installed on the side of the cylinder head cover on which the battery is located.