Hydraulic motors of the MP 40 series are gerotor drive mechanisms for universal use. This design makes it possible to provide high torque values at low and medium shaft speeds without the need to use additional drive stages. Their important advantages are:

- increasing equipment reliability;

- reducing the weight of the structure;

- reducing the cost of hydraulic drive.

In addition, these are self-lubricating devices, which require almost no additional maintenance if the oil in the system is regularly changed.

Features of work

The MP series equipment is a gear motor that operates using internal gearing, which allows the hydraulic energy of the fluid to be converted into mechanical rotational energy. The principle of operation is based on the use of a distribution device necessary to direct liquid flows to the working cavity of the desired power unit from the pump and its subsequent removal from the non-working cavity into the tank.

The distributor design includes valves that serve to protect hydraulic equipment from exceeding the maximum permissible forces.

- Serial variants

- MP-40/1

- EMP-44

- MP-41 True "Schmeisser"

MP-40

Mass production of MP-40 submachine guns began between March and July 1940, but the development of these weapons was completed in 1939 and the first small batch was released at the same time. Information about the MP-40 was first published in a book with the short title “Merkblatt fur die Ausbildung mit der Maschinenpistole 38 und 40 (MP38 u.40)”, published on December 4, 1939. The first since the release of MP-38 submachine guns for MP production -40 was transferred to the Steyr plant; after a few months, the production of the MP-38 was discontinued by the Erma and Haenel factories in favor of the production of the MP-40.

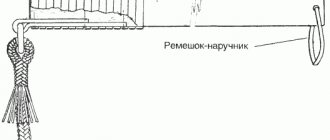

Photo: Early production MP-40 submachine gun with a leather safety strap installed. Such straps were extremely rare. The strap prevented the bolt from spontaneously moving back, which could lead to an accidental shot.

The MP-40 had a number of advantages over its predecessor, especially in terms of production technology. The design of the MP-40 featured stamped steel parts more widely; in particular, the pistol grip frame was made from stamped steel. Welding was used on a much larger scale to connect parts together. And an American wartime report noted:

“...the weapon is perfectly adapted to mass production, the number of operations requiring machining is reduced to a minimum. The structure is assembled from a large number of subassemblies, which makes it possible to involve a large number of subcontractors in production.”

In the first half of 1940, tests of a new fuse design were carried out. At least two types of new fuses are known. In the photo of SS soldiers, early production MP-40 submachine guns are visible, equipped with the so-called “universal bolt safety” located on the right side of the weapon. The second experimental type was later introduced into mass production. It was also located on the right side of the submachine gun. The new fuse fixed the bolt in the forward position. Such fuses went into mass production in the second half of 1940. Researchers note the obvious similarity of the fuse with the fuses of the Soviet PPD and PPSh assault rifles, noting that the Germans copied the Soviet design. A large number of previously manufactured MP-38 and MP-40 submachine guns were modified to accommodate the new fuses.

Serial variants

Several serial versions of the MP-40 submachine gun are known, all of them retained the basic differences between the MP-40 and the MP-38. The MP-40 was distinguished by a pistol grip frame made integral with the trigger guard, a smooth top of the body without ribs, a different magazine mounting device, a magazine socket without a hole, and a number of other features.

Unlike its predecessor, the MP-40 submachine gun was produced not in one, but in several versions. The design of weapons was constantly simplified in order to reduce the labor intensity of manufacturing. Experts count at least five modifications of the MP-40. It should be understood that the “purity” of modifications is relative, because changes to the design were made gradually and not simultaneously at all factories, in addition, at the front, parts were often rearranged from one submachine gun to another, and at the end of the war, “new” serviceable ones were often assembled submachine guns from several old and faulty ones. For example, in May 1944, an order appeared to increase the production of MP-40 by using parts from warehouses and stocks.

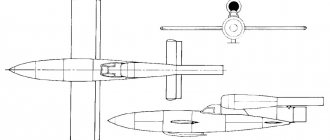

Photo: MP-40, 1st production version. Characteristic differences: the magazine socket is made of sheet metal with a smooth surface; handle with bracket - made of sheet metal (two stamped halves are connected into one part); Manufacturer coding - 660, 40.27 and 40. This sample is marked “Nnr.504” - 504th submachine gun of the Northern Fleet.

Photo: MP-40, 2nd production version. Stiffening ribs are made on the magazine socket; handle with bracket - made of sheet metal (two stamped halves are connected into one part); Manufacturer coding - auf41, auf42, bnz41, bnz42, fxo41, fxo42. The second production version was the most widespread.

Photo: MP-40, 3rd production version. Stiffening ribs are made on the magazine socket; handle with bracket - made of sheet metal (two stamped halves are connected into one part); Manufacturer's encoding is auf43. This version was distinguished by a nut on the barrel with only two turnkey flats. The body is marked “SA” - Suomen Armeja, Finnish army.

Photo: MP-40, 4th production version. Stiffening ribs are made on the magazine socket; the handle with bracket is made of sheet metal in one piece; Manufacturer's coding: bnz43. This option is characterized by a thicker trigger guard. There is no manufacturer code on this particular example, but all 4-series variants were assembled only by Steyr. The Wa623 Waffenamt marking is typical for the Steyr company, and it is present on this submachine gun.

Photo: MP-40, 5th production version. Stiffening ribs are made on the magazine socket; the handle with bracket is made of sheet metal in one piece; Manufacturer coding - bnz43, bnz44. In this type, the handle with a bracket was tightly attached to the lower part of the body by welding.

MP-40/1

The MP-40/1 submachine gun was distinguished by a system for mounting two magazines at once, a very intriguing and extremely mysterious version of the MP-40! This weapon is one of the rarities: now only five copies have survived in the world. Very few MP-40/1 submachine guns were produced. There is almost no reliable information about the MP-40/1. The most reliable: the weapon was really designated MP-40/1.

Photo: MP-40/1 with two magazines is a very rare weapon. This specimen was assembled at the Erma plant in 1942.

Obviously, the system with two stores was invented with the aim of increasing the total capacity of the stores, but the emergence of the concept of two stores is not clear. In any case, this concept made the MP-40/1 an extremely interesting model of small arms, albeit an unsuccessful one. It is believed that the variant was intended to arm special forces units. In fact, it’s unlikely: special forces needed more reliable weapons with better characteristics.

Obviously, the development of a variant with two stores began after understanding the experience of combat operations on the Eastern Front in the initial period of the war. Until June 1941, German submachine guns were superior to the enemy's manual automatic weapons in all respects; moreover, often the enemy did not have weapons of this class at all. The situation took a different turn after the collision of the German military machine with the Red Army. As it turned out, the Red Army was armed with a large number of machine guns, which were superior to German submachine guns in terms of characteristics, magazine capacity and, moreover, were simpler and cheaper to produce. Most of all, German gunsmiths were struck by the simple and reliable PPSh-41 assault rifle, equipped with a disk-type magazine for 71 rounds. German soldiers greatly valued such machine guns, considering them the most desirable trophy. There are many photographs of German soldiers armed with PPSh-41 machine guns. To a large extent, the popularity of the PPSh among the Germans was facilitated by the capacious magazine of the Soviet machine gun.

In October 1942, the commander of the SS Viking division even came up with a proposal to establish mass production of PPSh in the Reich, because the machine gun was significantly superior to German submachine guns. The division commander noted in his report the advantages of the Soviet assault rifle over all known German models, especially pointing out the large capacity of the disk magazine.

“Russian machine guns are widely used in our division; they have proven themselves to be very reliable even in the most unfavorable conditions.”

In the second half of the war, an unspecified number of captured PPSh-41 assault rifles were converted to fire 9 mm Parabellum cartridges. During the modification process, the assault rifles received new 9 mm caliber barrels and a magazine socket for German MP-38 and MP-40 submachine guns with a capacity of 32 rounds. The exact number of converted Soviet machine guns is not known, but the scale can be estimated. On July 5, 1944, the army command ordered the production of a batch of 9-mm barrels for PPSh assault rifles “in addition to the 10,000 already delivered.”

The popularity of PPSh in the German troops was explained primarily by the large magazine capacity; in this light, the development of the MP-40 in a version with two magazines seems quite logical, but this path did not eliminate a significant drawback of German weapons - the sensitivity of the weapon itself and its magazines to the slightest contamination. That is why the fairy tale about the development of the MP-40/1 at the order of saboteurs seems to be just a fairy tale and nothing more. It would be easier to equip small special forces with captured weapons that are more adequate than the MP-40/1.

EMP-44

MP-40/1 was created between the end of 1942 and mid-1943. It first appeared in the Geratlist (list of weapons of the German army) in June 1943. All known copies were assembled by Steyr and Erma in the second half of 1942 and in the first half of 1943

The weapon supply system from two magazines was allegedly developed by specialists from the Erma company. This theory is confirmed by the appearance of the EMP-44 submachine gun, an experimental weapon also equipped with two magazines. Development of this submachine gun began in 1942 (the surviving sample has serial number 000015, assembled in February 1943).

Most likely, the submachine gun was intended to arm crew members of armored vehicles and crews of fortifications. The low mass of the weapon in this case was not a priority factor. In tanks and casemates, the threat of dust getting into weapons was also not as significant as in an open field. It was these factors that allowed the designers of the Erma company to offer systems with two magazines, using the much criticized magazines in the Reich from the MP-38 and MP-40 submachine guns. In tanks and casemates, stores functioned quite normally.

For unknown reasons, all work on the EMP-44 submachine gun was stopped after the production of several prototypes, after which, apparently, the company transferred the device for attaching two magazines to the MP-40. Most likely, this is how the MP-40/1 appeared, but why it was not included in Geratlist is a mystery.

MP-41 True "Schmeisser"

The submachine gun was a combination of elements from several types of small arms. The wooden stock with the butt, the guard and the trigger are almost like those of the MP-28/II, the mechanism itself is from the MP-40. As in the case of other variants of the MP-38 or MP-40, such as MP-38(L) and MP-40/1, information on the MP-41 remains esoteric and relates more to the realm of legends, or, as experts say in linguistics, to the field of “bylichik”. The MP-41 was never even intended to be included in the Geratlist, that is, this weapon was not intended to equip the German army. All surviving examples of MP-41 submachine guns are marked “M.P.41 Patent Schmeisser CG Haenel, Suhl”; they are equipped with magazines marked “M.P.41 Patent Schmeisser”, below which is the Haenel brand in the form of an arrow .

Photo: The MP-41 submachine gun is a true Schmeisser. The submachine gun was developed by Schmeisser and produced by Haenel, presumably on order from Romania. Unlike the MP-38 and MP-40, the MP-41 submachine gun had two firing modes: automatic and semi-automatic.

Another question: why did the Germans, in the middle of the war, need to produce on a limited scale a batch of submachine guns of dubious design, made up of components from old submachine guns? The markings on the magazine are also intriguing, because the design of the magazine is no different from the magazines for the MP-38 and MP-40 submachine guns, where does the “Schmeisser patent” come from?

Presumably, the MP-41 submachine guns were assembled by order of the Reich satellites.

The customer specified the presence of a wooden stock with a butt, which is why it was necessary to use the unused stock of butts for MP-28/II submachine guns. forces. Romania

Most likely, the customer of the strange weapon was Romania, which was a strategic ally of Germany. The Romanians were never able to establish mass production of submachine guns. During the war, the Romanian army used submachine guns very similar to the MP-41, developed and produced by the Romanian company Orita. They differed from German weapons in their stores, which, although similar to German ones, were still different. German and Romanian stores were not interchangeable. The Romanian order for the MP-41 is supported by a large number of famous photographs where Romanian soldiers are captured with MP-41 submachine guns in their hands. In addition to Romania, MP-41 submachine guns were most likely supplied to Croatia and other Balkan allies of Germany.

Obviously, the MP-41 submachine gun was a rare weapon, manufactured in very small quantities. On the other hand, analysis of the serial numbers of surviving samples allows us to talk about several tens of thousands of copies made. According to archival documents, the Haenel company manufactured 27,500 MP41 submachine guns. The first batch of 26,000 units was assembled in 1941; at the end of 1944, another 1,500 MP-41s were manufactured.

The city of Schul, where the Haenel plant was located, became one of the first German cities occupied by American troops, but then the city fell into the Soviet zone of occupation. Both the Americans and the Russians carefully examined the small arms factory and interrogated the company's designers, including such “stars” as Herbert Haenel, Hugo Schmeisser and Hans Schmeisser.

According to the information received, the Haenel company could assemble a maximum of 100 MP-41 submachine guns per day, and MP-40 - 300. That is, the MP-41 was three times more difficult to produce compared to the MP-40. An inventory of parts for the assembly of MP-41 submachine guns as of the summer of 1945 was discovered at the company.

Table of contents

Advantages of using MR hydraulic motors

- High speed stability at start-up and during operation at low speeds.

- Constant torque of the unit, regardless of external factors.

- Wide range of speeds in the equipment line.

- Increased overall reliability of the hydraulic motor design, which allows the equipment to be used in harsh operating conditions.

- Excellent ratio between the weight of the gerotor hydraulic motor and its strength.

- Serial connection is acceptable.

- Even in the case of high drain pressure, the device does not require the use of a drainage system.

MP 38 and MP 40: the main difference

Automatic MP 38

Automatic MP 38

- The MP 38 submachine gun did not have a single wooden part;

- a folding stock was used for the first time;

- the proprietary design of Geipel's colleague Heinrich Vollmer was used as a mainspring pushing the bolt after recoil - a telescopic tube combining the spring with the firing pin;

- The reloading handle was on the left side; the shooter could not remove his finger from the trigger.

See also the article MP5 submachine gun and its characteristics

On the lower section of the barrel there was a special protrusion - a bridle, which was supposed to prevent damage to the barrel when firing through the loophole of an armored personnel carrier and block the unintentional ejection of the muzzle during shooting if the shooter loses support.

German assault rifle MP 40

For all its innovations, the MP 38's parts were still largely milled using traditional machine technology, and although the army was pleased with it, the Wehrmacht demanded that the weapon be made more suitable for mass production.

Therefore, the MP 38 was critically analyzed and redesigned to make maximum use of dies and welded assemblies. The result became known as the German MP 40 submachine gun, which replaced the MP 38 as the standard submachine gun and became the de facto brand of the German army.

MP 40 submachine gun

The main difference between MP 38 and MP 40 was as follows:

- body - made of stamped sheet steel, formed and welded;

- the magazine body became ribbed, and not smooth, and the upper part of the PP body, on the contrary, became simple, and not ribbed;

- The MP 40 Schmeisser now has a safety lock that reliably holds the bolt in the forward position. The MP 38 had no safety at all, and to hold the bolt, special grooves were used in the receiver, into which the bolt handle was inserted, and the bolt could be fixed in both the front (cocked) and rear (lowered) positions;

- the surface of the magazine receiver became corrugated, which made it easier for the shooter to hold the barrel while firing.

MP 38 magazine receiver

MP 40 magazine receiver

Options

Options for hydraulic motors manufactured by M+S Hydraulic (Bulgaria):

- with a slide valve, which allows for the versatility of the equipment and wider possibilities for its additional configuration in accordance with the specific application;

- in wheel or flange design;

- with a needle bearing in the motor with maximum radial load capacity;

- with shaft seal designed for low and high pressures;

- with a conical, splined or keyed shaft design;

- with speed sensor.

The history of the creation of a submachine gun

In 1936, having considered the trends and tactics of the Spanish Civil War, the top of the Wehrmacht decided to mass produce the MP 40 submachine gun (hereinafter referred to as PP).

The PP models that existed at that time, in their opinion, did not meet modern requirements, and the leadership of the German army (Obercommando der Wermacht) instructed the director of the Erfurt arms concern ERMA Geipel to create a PP with the necessary characteristics.

See also the article Gun safe and tips for choosing

The new PP had to meet the objectives of the new mobile, lightning war (Blietzkrieg) strategy. ERMA Werke already had developments in this matter, and quite quickly, by mid-1938, the MP 38 PP model, innovative at that time, was designed.

MP 40 in computer games

The popular weapon could not help but be widely represented as a combat resource in computer video games, especially in the so-called shooter games, from Commandos of the 90s to Call of Duty and the latest versions of Sniper Elite.

The player armed himself with a pistol - an MP 40 submachine gun, Sniper Elite 4

Player takes aim with MP 40, Sniper Elite 4

MP 40 in cinema

The filmography of the legendary submachine gun is very extensive. The image of a German occupier with his sleeves rolled up, clutching a formidable symbol of the German military machine, has become an integral attribute of military themes. But often he ended up in the hands of good heroes.

Clint Eastwood as an English intelligence officer in the film "Where Eagles Fail"

Nikolai Merzlikin as partisan Levushkin in the film “No Way Back”

Arkady Svidersky as a disguised Soviet saboteur with MP 38 in the film “One Chance in a Thousand”