Which VAZ engines do not bend valves

Home » News

Published: 09/19/2018

There were no problems with valves bending when the piston and valve met on VAZ engines - the timing chain did its job perfectly. But the emergence of front-wheel drive models required new engines, since the Zhiguli engine had a chain in the block and its dimensions were not suitable for transverse installation. With the help of Porsche specialists, a 1.1 liter engine was developed. with a timing belt and an aluminum block mounted transversely. It all started with him.

With the use of a timing belt, there was a risk of it breaking, which means that a “stick” could occur. But on the first engines corresponding to Euro 2, there was no such problem - the belt sometimes broke, but without consequences. The distance between the valves and the piston was sufficient, and when desynchronized, the piston did not reach the valve.

With the advent of Euro 3 standards, a broken belt began to lead to a “meeting” of valves and piston: the engine, “strangled” by eco-standards, needed to compensate for the loss of power. This can be achieved by increasing the compression ratio. The piston at its top dead center (TDC) has become closer to the valves. It turns out that as a result of the race for better ecology and power, almost all cases of belt breakage began to lead to bending of the valves.

This happens as follows: the timing belt breaks - the camshaft stops, but not immediately, and the crankshaft rotates as before. The piston goes up and meets the stuck valve at TDC. Impact - the valve bends in a weak spot, under the “plate”. The car cannot move any further.

At best, 1-2 valves suffer, but at worst, all of them. Repair involves dismantling the cylinder head and replacing damaged valves. The pleasure is not cheap, and most importantly - unpleasant, because who likes to open a generally serviceable engine?

Often “stick-free” is achieved by using non-standard pistons with special milled areas on the bottom of the piston to match the shape of the valve. VAZ has such engine modifications. As a rule, these are eight-valve engines. Also, milled pistons from third-party manufacturers are used.

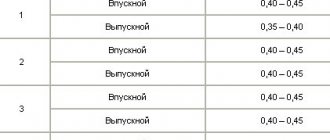

The inevitable increase in the combustion chamber, which can cause the engine to stall and consume more fuel due to a decrease in the compression ratio, is compensated by stamping at the bottom of the piston. However, as practice shows, this measure does not always prevent the piston and valve from “meeting”. We list those engines that, according to the manufacturer, are free from the risk of collision between the piston and valves:

But the only reliable remedy is timely replacement of the timing belt. It’s just that in the case of a VAZ it’s worth doing this more often than the manufacturer recommends. By the way, foreign cars also have “risky” internal combustion engines, but proper operation and timely service nullify the negative statistics of “stickings”.

Reasons why valve bends

The following main reasons can be identified:

- Condition of the timing belt (cracks, worn teeth, the belt is overtightened or loose)

- Failure to comply with the timing of belt replacement (high mileage of the vehicle).

- Entry of a foreign body (check that the protective cover is installed correctly)

What happens in the engine when the belt breaks?

Today, engines with 8 and 16 cl are most often used. They are responsible for compression of the cylinders and for the release of exhaust gases. They move because of the camshaft, which unwinds and presses on the valve. The engine operating cycle is a periodically repeating series of sequential processes occurring in each engine cylinder. The engine operating cycle occurs in 4 strokes or 2 revolutions of the engine crankshaft. (such engines are called 4-stroke; there are also 2-stroke engines, but they are not used in cars now). So you:

- Inlet

- Compression

- Extension

- Release

The valves open and close at the right time. The drive is carried out by cams located on the camshaft. When the cam rotates, its protruding part presses on the valve, causing it to open. Cl. the spring closes it.

The cam is an integral part of the gas distribution shaft (drivers call it the camshaft). The camshaft has bearing journals and cams. Torque from the crankshaft to the camshaft is transmitted by a chain or timing belt.

If the drive belt breaks while the engine is running, the camshaft is no longer connected to the crankshaft. And it can stop arbitrarily in a position in which one of the valves is completely open. In this case, when moving upward, the piston may collide with the valve, which in this case bends. And as a result, the engine faces serious repairs. The engine will need to be disassembled, the valves need to be replaced, and in some cases the “Head” of the block may also be damaged, so much so that it will need to be completely replaced.

On what cars do valves bend?

On most cars, when the timing belt breaks, the problem of valve bending occurs

It doesn’t even matter whether the engine is idling or driving along the highway. They can still bend

It is important exactly how much the gear is turned when the belt breaks. The bend can occur at 8, 16 and 20 cells. engines, on diesel and gasoline engines, small cars and cars with large displacement. Therefore, it is very important to promptly replace the timing belt. But a timing belt break does not always lead to bending.

On what cars does the valve not bend?

Some engines have small protection - grooves, which are small notches. These grooves are installed so that at high speeds the piston does not catch up with the closing valve. But when the timing belt breaks, they also help reduce the negative consequences, and in some cases they do not bend the valve at all.

Sometimes car owners grind them themselves, but this is not always correct. Since the presence of these recesses leads to a decrease in the engine, an increase in fuel consumption, and the content of nitrogen oxides in the exhaust gases. Many auto companies have now abandoned such protection.

The most reliable method of combating valve bending is timely replacement of the belt.

Bent valve signs

124 and 126 engines on which valve bending.

124 does the engine bend the valves? When the belt breaks, there is no point in simply changing the timing belt, hoping that everything went without consequences and you will start the engine. Especially if the engine is on the list of those on which the valves bend. Yes, there are cases where the bend was not large and several valves no longer fit snugly in the seat, then you can turn it with a starter, but often such actions will further aggravate the situation. Since with minor damage everything will work and spin, but the engine will shake, and the consequences will only get worse.

It is best if you remove the “head” in order to check this visually or fill it with kerosene, however, there are several ways to check whether the valve is bent without disassembling the engine.

Main symptom

if the valves are bent, there is little or

no compression

. Therefore, it is necessary to measure the compression in the cylinders. But, such actions are relevant if the crankshaft can be turned and nothing rests anywhere. So the first thing you need to do is install a new belt, manually, using the bolt on the CV, turn the entire gas distribution mechanism a few turns (you need to unscrew the spark plugs).

How to check if a valve is bent

To determine whether any valve stem is bent, literally five turns of hand turning the crankshaft bolt with a wrench will be enough. If the rods are intact, the rotation will be free; if the rods are bent, the rotation will be heavy. There should also be clearly perceptible 4 points (with one revolution) of resistance to the movement of the pistons. If such resistance is imperceptible, then screw the spark plugs back in, unscrew them one by one and turn the crankshaft again.

Based on the manual torsion force, with one of the spark plugs missing, it is relatively easy to understand in which specific cylinder the valve(s) were bent. However, this method will not always help to accurately determine whether the valve is bent or not.

If the crankshaft rotates freely, then you can check it with a compression gauge

.

Don't have such a tool? This means doing a pneumatic test

, and checking the tightness of the cylinders is the most correct way, which will give an answer to how the valve plates fit in the seats, without additional consequences when cranking with the starter and without installing a new belt.

How to check if the valve is bent yourself?

For a pneumatic test, there is no need to take the car to a service station; you can find out for yourself whether the cylinder is sealed or not. The easiest way is:

- select a piece of hose according to the diameter of the spark plug well;

- unscrew the spark plug;

- set the cylinder piston to top dead center (valve closed) one at a time;

- insert the hose tightly into the well;

- Trying with all your might to blow into the combustion chamber (air passes through - it’s bent, doesn’t pass through - “blown away”).

The same test can be done using a compressor (even a car compressor). True, you will have to spend a little more time, as you need to prepare. Drill out the central electrode in the old spark plug, and put a hose on the ceramic tip (fix it well with a clamp). Then pump pressure into the cylinder (provided that the piston in it is at TDC).

The hissing sound and pressure on the pressure gauge will tell you whether the valve caps are seated or not. Moreover, depending on where the air goes, determine the inlet bent or exhaust. When the exhaust outlets are bent, air goes into the exhaust manifold (muffler). If the intake valves are bent, then into the intake tract.

avtoexperts.ru

One of the scary topics in the conversations of motorists is why valves bend, on which cars this breakdown is possible, and how to prevent it. Today we will talk in detail about the reasons why engine valves fail and measures to prevent this malfunction.

What are the valves in the engine responsible for?

First, a little theory. Surely every car enthusiast knows how many cylinders are in the engine of his car, but how many valves are in it - not everyone will answer this question. Most modern engines have from eight to sixteen valves (two or four per cylinder); there are power plants (eight or twelve cylinders) in which the number of valves is from 24 to 32.

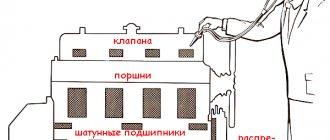

The valve is an important part of the gas distribution mechanism (GRM) of a car engine, which is located in the cylinder head and is responsible for the timely supply of air into the cylinder and displacement of exhaust gas from it.

Moreover, the same valve cannot perform these functions, and therefore each cylinder is equipped with two types of valves - inlet valves, which supply air to the combustion chamber, and exhaust valves, which squeeze out the combustion products of the air-fuel mixture from this chamber.

The valves are brought into working condition by the camshaft, which, rotating around its axis in the cylinder head, raises some and lowers other valves into the cylinders - these are the so-called gas distribution phases. In turn, the camshaft is driven by the crankshaft - both of these timing elements are interconnected by a drive, which can be geared, belt or chain. A gear drive rotates the camshaft in the cylinder block, and a belt or chain drive rotates in the cylinder head.

Currently, the most widely used engines are those that use a belt or chain in the gas distribution mechanism. The belt drive type is simpler in design, but less reliable than the chain drive. The chain drive type, in turn, is more complex - its mechanism includes tension rollers and dampers. It is no coincidence that we paid so much attention to the details of the gas distribution mechanism - understanding the principle of its operation will help us in the future to determine the reasons why the valve bends.

Why do valves bend?

With both a timing mechanism with a belt drive and a timing mechanism with a chain drive, there may come a time when the belt or chain drive fails. A broken timing belt or stretched timing chain links that are unable to engage the teeth of the camshaft gears (slippage) causes the camshaft to stop abruptly while the crankshaft continues to move.

At this moment, the valves are recessed into the cylinder, and the piston rises towards them. The lifting force of the piston is much greater than that of lowering valves, so the piston hits the valve plate, and the rod, unable to withstand this impact, bends or even breaks. The engine stops completely, and it is not recommended to start it again, so as not to provoke a more serious breakdown - failure of the pistons, which can lead to costly repairs to the cylinder head.

How to determine if the valves are bent

It is impossible to determine by eye that the valves are bent if the belt breaks or the timing chain slips. To do this, you need to carry out two simple operations.

To begin, install a new timing belt on the rollers according to the marks and slowly rotate the crankshaft. Two to five turns are enough to determine that the valves are bent: if the rotation is free, then the valve stems are intact; if it is difficult, the valves are bent.

It happens that the crankshaft rotates, but the valves are still bent. How to determine the breakdown in this case? It is necessary to measure the compression in the cylinders by first unscrewing the spark plugs. If there is no compression in the cylinder, the valves are bent.

How to prevent valve failure

Let's look at the reasons why the belt could break in order to understand how to prevent such a breakdown.

Reason 1: The timing belt has expired. Like any other consumable, the timing belt has its own service life. The car manufacturer indicates in the operating manual the timing belt replacement period - for most engines it occurs after a mileage of 100-120 thousand kilometers. Of course, you can hope that until this moment the belt will serve faithfully, but to be sure, we recommend that at each scheduled maintenance you inspect the condition of the belt and, if necessary, replace it. In this case, we will not allow it to break, and, as a result, we will not deal with problems with bent valves.

Installation

Types of internal combustion engines, what internal combustion engines exist

Remove the standard side mirrors (pry off the mirror triangle with a screwdriver and remove the three mounting screws). Install the new mirror in the reverse order.

We stretch the turn signal wires to the mirrors:

- Remove the door trim.

- Remove the turn signal from the fender and disconnect the block. We install plugs instead.

- Pull the wires out of the fender and into the interior. To do this, unscrew the sill trims in the cabin, peel back the carpet and felt and pull the black wire in the engine panel. We determine which of the two +12 V wires using a multimeter or a test lamp. We insulate the second wire.

- Route the wire from the passenger compartment to the car door through the corrugation.

Broken timing belt main reasons

Lada Granta engines Lada Granta

If we compare modern engines with their predecessors, today's engines have more power and shorter service life. Regarding the problem of valve bending, it is precisely to achieve greater efficiency from the engine that the distance from the piston to the valve is minimal. Even a slightly open valve bends as the piston rises to TDC. It turns out that various technical innovations in engine building did not in any way affect the well-known problem, which is inherent in the vast majority of engines, regardless of the type of motor and manufacturer. We are talking about bending of valves when the drive belt or timing chain breaks.

An important rule when operating a car is to monitor the condition of the timing belt and replace it in a timely manner. The belt should not have any delaminations, cracks or other defects. Also, various technical liquids are not allowed to come into contact with its surface. The appearance of squeaking, creaking and other extraneous sounds will require the owner to check the tension and condition of the timing belt, as well as the tensioner and other rollers.

To answer the question of when to change the timing belt, you need to study the operating instructions for a particular car. Often on new cars, the belt is changed after 60 thousand kilometers traveled or after 2-3 years (whichever comes first). A planned replacement with an original belt involves the next replacement every 50 thousand km

It is advisable to select non-original belts with caution and change them every 40 thousand km

Now a few words about the chain drive. The timing chain requires less attention, since replacing the chain on average is necessary once every 150-200 thousand km. and more. In this case, it is necessary to monitor the chain tension, the condition of the tensioner and chain guide. Increased noise during engine operation, the appearance of a metallic clang and other signs will indicate the need to immediately check these elements.

So, let's return to the belt, which is less reliable compared to the chain. The timing belt most often breaks for the following reasons:

- belt wear as a result of long-term use or use of a low-quality product;

- jamming of the pump (water pump);

- jamming of the crankshaft, camshaft;

- tension roller malfunction, timing rollers jamming;

- destruction of the timing belt as a result of engine oil getting on its surface;

- mechanical damage after contact with sharp edges of the timing drive, camshaft gears;

Let's sum it up

VAZ cars can hardly claim to be the optimal and best solutions even in their price range. But today Granta or Kalina often turn out to be the only possible purchase for a Russian family. The sharp increase in prices for other new cars is reflected by the need to buy domestic developments. It should be noted that AvtoVAZ is doing a tremendous amount of work to update its equipment, but even this work has not yet given the desired results.

In modern VAZ lines there is only one own engine that does not bend the valve. This is a 98-horsepower unit on the Priora. However, here everything is arranged in such a way that you may not be lucky, so 16 valves will have to be replaced after a belt break. In other engines, valves and other parts will definitely have to be changed after a belt break. It is much cheaper to monitor the condition of the roller and belts by replacing all these parts in a timely manner.

Why does the valve bend when the timing belt breaks?

The valve mechanism works as follows: when the piston reaches top dead center, both valves in the combustion chamber close and a certain pressure is created in it. A broken belt means that the valves do not have time to close in time before the piston arrives. Thus, their meeting occurs - a collision, which directly leads to the fact that the valve bends. Previously, in order to prevent a similar problem, special grooves were made for the valves on older engines. On new generation engines there are also similar notches, but they are intended only to avoid valve deformation during engine operation and in the event of a belt break they do not help at all.

From a physical point of view, from the moment the timing belt breaks, the camshafts immediately stop, under the action of return springs that brake its cams. At this moment, the crankshaft inertially continues to rotate (regardless of whether the gear was engaged or not, whether the speed was low or high, the flywheel continues to spin it). That is, the pistons continue to work, and as a result, they hit the currently open valves. Quite rarely, but it happens when the valves damage the piston itself.

Causes of timing belt breakage

- wear of the belt itself or its poor quality (shaft gears have sharp edges or oil from the seals).

- crankshaft jams.

- pump jams (the most common phenomenon).

- Several or one camshaft is jammed (for example, due to one of them becoming unusable - however, the consequences here are slightly different).

- The tension roller unscrews or the rollers jam (the belt becomes loose or overtightened).

Modern engines, since they are more powerful compared to their predecessors, have much lower survivability. If we consider the cause based on the valves, this problem arises due to the small distance between them and the piston. That is, if at the moment the piston arrives the valve is slightly open, then it immediately bends. Since for greater compression and contraction in the bottom of the piston there is no groove under the valve of the required depth.

How to understand that the valve is bent

If the timing belt comes off or breaks, the engine will immediately stall. It won’t even occur to most people that the problem is serious. Well, it stalled, so I’ll start it again and go. It is important to listen to the engine here. If the starter rotates faster than before, there is no need to turn the key any more - the belt is definitely torn. Well, it’s better to open the hood and look under the casing.

A belt that is already “on the verge”

If the casing is tightly screwed on, you can go the other way - unscrew the oil filler cap and check whether the camshaft cams rotate when starting (of course, you can’t do this without an assistant).

Unknowing drivers crank the starter until the last moment in the hope that the engine will start. At this time, the pistons simply chew through all the valves in turn. Therefore, if the car suddenly stalls, we look under the belt cover or at the first start, when we hear the “free flight” of the pistons, we immediately turn off the engine. Listen to how an internal combustion engine starts with a broken belt in the video.

Now about the valves. It doesn’t always bend them, but sometimes only a part breaks. This can be determined by measuring compression. At the slightest bend of the plate, the compression sags greatly. Such a motor can even start, but it works extremely unstable - it stalls.

There is another way to check:

- a piece of thick hose 5-10 centimeters long is selected (the diameter must correspond to the spark plug well);

- the spark plug is unscrewed, the piston is set to the TDC position (at this moment the intake and exhaust valves are completely closed);

- a hose is installed and air from the compressor is pumped inside.

If the valve is bent, the consequences will be heard. The air will go either into the inlet or out the outlet (depending on which rod is broken). And sometimes the air goes both ways. Experienced mechanics advise disassembling the head and doing a complete troubleshooting. After all, it is unknown how badly the rods were bent, whether the guides were damaged and whether the pistons were intact. This is the safest and most accurate way.

Where is the timing belt located?

First, let's remember where the timing belt is located and what it looks like. Its location is in front of the engine, but do not forget that motors come in longitudinal and transverse locations. In most cases, gas distribution mechanisms use a toothed rubber belt, but in a considerable number of car models from different manufacturers, a steel chain is also used for this.

Engine cylinders can be equipped with two or four valves with one and two camshafts (CV), respectively. The kinematics of the gas distribution mechanisms of such engines differ. We will show them using the example of 8- and 16-valve power units for the VAZ 2110, 2111 and 2112.

The scheme with two shafts is more complicated, and in it, in addition to the pulley of the second RV, a support roller is added. This also complicates the belt replacement procedure. It is most difficult to perform this operation after a break or severe stretching of the belt, when the factory timing settings can be completely lost. Replacing in normal mode is not so difficult that you can’t try to do it yourself.

Signs that a valve is bent

show to car service

check the compression if the engine does not stand up tightly

check the compression

won't start

Elementary! You pull out the spark plugs, stuff a bright LED into the cylinder and inspect the pistons for marks from the valves.

If there is no compression, an experienced mechanic will hear it even just when cranking the engine with the starter. But there may be no compression even with bent valves and with coked (stuck) rings. Then pour 50 grams of oil into the cylinder, crank the engine with the starter and measure the compression. And a miracle! Compression has appeared. Feel free to disassemble the engine. If it doesn’t appear, remove the head and change it, grind the valves.

Which VAZ engines bend valves and which don’t?

On which VAZ engines does the valve bend, and on which ones does not?

Welcome, friends, to the DIY auto repair website. Experienced car enthusiasts know that a broken timing belt can lead to dire consequences. In particular, there is a high risk of “meeting” valves that have already come out of their seats and pistons rising by inertia.

Which VAZ engines bend valves

The result is deformation of vital engine elements, as well as an urgent need to visit a service station and carry out major repairs. But does the valve always bend when the timing belt breaks? Should we be afraid of this?

A little history

The new “tens” were immediately equipped with 8-valve engines with volumes of 1.5 and 1.6 liters. The first power units (from the perspective of the problem we are describing) were ideal, and the valves did not bend. Although earlier models like eight and nine with a volume of 1.3 had this problem. The reason was that the piston structurally could not “meet” the valves.

Over time, a more modern VAZ 2112 model appeared in the “ten” family, equipped with a one and a half liter engine with a 16-valve engine. It was from this moment that the problems began. Many car enthusiasts and specialists could not understand why the valve bends.

In fact, the reason was in the design of the power unit. On the one hand, the appearance of a 16-valve head made it possible to increase the car’s power to 92 “horses,” and on the other, a broken timing belt invariably led to a collision of pistons and valves, as well as deformation of the latter.

After that, I had to go to a service station and have the car undergo expensive repairs. The design fault lay with the pistons themselves, which lacked the necessary recess. As a result, the timing belt break always ended in the same way.

Updated car engine

A similar oversight was taken into account and more advanced 16-valve 1.6-liter engines were installed on new VAZ 2112 cars. Structurally, the power units were not very different, but one feature was still present. In the new engine, the pistons had certain recesses, so the problem described above was eliminated.

Over the next few years, car enthusiasts began to forget about bent valves and became accustomed to the reliability of the new 16-valve engines. But the updated Priora model with a 1.6-liter power unit was an unpleasant surprise - the valves also bent when the timing belt broke.

At the same time, the final repairs were much more expensive. On the other hand, the developers made the belt as wide as possible to minimize the likelihood of the belt breaking. The only unlucky ones were those car enthusiasts who received a defective belt or those who did not take care of their “iron horse” at all.

Unfortunately, even on the new 1.4-liter Kalina engines with 16 valves, repairs cannot be avoided if the belt breaks while driving. So monitoring the state of this node is mandatory.

On which VAZ engines does the valve bend, and on which ones does not?

Let’s draw intermediate conclusions and also highlight the most “dangerous” and “safe” models from the perspective of probable valve deformation in the event of belt damage:

1. Which VAZ engines bend valves? This category includes car engines of the following model range - 21127, 21116, 2112, 1194.

2. Which VAZ engines do not bend valves? More reliable are the engines of such VAZ models as 1183, 21114, 21083, 21124, 21126 (they bent until 2013, but not now), 21128.

The current problem has caused a lot of controversy among car enthusiasts. Many owners of “problem” VAZs are interested in what to do to prevent the valve from bending. In fact, there are several recommendations.

1. First, try to periodically assess the condition of the timing belt and replace it at the first sign of damage. The appearance of cracks, contact with engine oil on the surface, excessive stretching, peeling of the edges - all this is a reason to install a new timing belt and not wait for a break.

2. Secondly, if the engine is expected to be repaired, then you can change the pistons, and in some cases, the crankshaft. In addition, some experts recommend (as a solution) installing a new camshaft.

But here, of course, you can’t do without consulting specialists. After this, flashing and removal of the catalyst may be necessary.

If you got a car with a bent valve, then don’t despair ahead of time.

The ideal solution would be to pay maximum attention to the engine and replace the timing belt more frequently. Even this will be enough to minimize risks

As for replacing components and expensive repairs, these costs, as a rule, are not justified. Good luck on the roads and of course no breakdowns.

https://remontavtovaz.ru

avtoexperts.ru

One of the scary topics in the conversations of motorists is why valves bend, on which cars this breakdown is possible, and how to prevent it. Today we will talk in detail about the reasons why engine valves fail and measures to prevent this malfunction.

What are the valves in the engine responsible for?

First, a little theory. Surely every car enthusiast knows how many cylinders are in the engine of his car, but how many valves are in it - not everyone will answer this question. Most modern engines have from eight to sixteen valves (two or four per cylinder); there are power plants (eight or twelve cylinders) in which the number of valves is from 24 to 32.

The valve is an important part of the gas distribution mechanism (GRM) of a car engine, which is located in the cylinder head and is responsible for the timely supply of air into the cylinder and displacement of exhaust gas from it.

Moreover, the same valve cannot perform these functions, and therefore each cylinder is equipped with two types of valves - inlet valves, which supply air to the combustion chamber, and exhaust valves, which squeeze out the combustion products of the air-fuel mixture from this chamber.

The valves are brought into working condition by the camshaft, which, rotating around its axis in the cylinder head, raises some and lowers other valves into the cylinders - these are the so-called gas distribution phases. In turn, the camshaft is driven by the crankshaft - both of these timing elements are interconnected by a drive, which can be geared, belt or chain. A gear drive rotates the camshaft in the cylinder block, and a belt or chain drive rotates in the cylinder head.

Currently, the most widely used engines are those that use a belt or chain in the gas distribution mechanism. The belt drive type is simpler in design, but less reliable than the chain drive. The chain drive type, in turn, is more complex - its mechanism includes tension rollers and dampers. It is no coincidence that we paid so much attention to the details of the gas distribution mechanism - understanding the principle of its operation will help us in the future to determine the reasons why the valve bends.

Why do valves bend?

With both a timing mechanism with a belt drive and a timing mechanism with a chain drive, there may come a time when the belt or chain drive fails. A broken timing belt or stretched timing chain links that are unable to engage the teeth of the camshaft gears (slippage) causes the camshaft to stop abruptly while the crankshaft continues to move.

At this moment, the valves are recessed into the cylinder, and the piston rises towards them. The lifting force of the piston is much greater than that of lowering valves, so the piston hits the valve plate, and the rod, unable to withstand this impact, bends or even breaks. The engine stops completely, and it is not recommended to start it again, so as not to provoke a more serious breakdown - failure of the pistons, which can lead to costly repairs to the cylinder head.

How to determine if the valves are bent

It is impossible to determine by eye that the valves are bent if the belt breaks or the timing chain slips. To do this, you need to carry out two simple operations.

To begin, install a new timing belt on the rollers according to the marks and slowly rotate the crankshaft. Two to five turns are enough to determine that the valves are bent: if the rotation is free, then the valve stems are intact; if it is difficult, the valves are bent.

It happens that the crankshaft rotates, but the valves are still bent. How to determine the breakdown in this case? It is necessary to measure the compression in the cylinders by first unscrewing the spark plugs. If there is no compression in the cylinder, the valves are bent.

How to prevent valve failure

Let's look at the reasons why the belt could break in order to understand how to prevent such a breakdown.

Reason 1: The timing belt has expired. Like any other consumable, the timing belt has its own service life. The car manufacturer indicates in the operating manual the timing belt replacement period - for most engines it occurs after a mileage of 100-120 thousand kilometers. Of course, you can hope that until this moment the belt will serve faithfully, but to be sure, we recommend that at each scheduled maintenance you inspect the condition of the belt and, if necessary, replace it. In this case, we will not allow it to break, and, as a result, we will not deal with problems with bent valves.

Reason 2. Using a counterfeit timing belt. Some car enthusiasts, wanting to save money, buy non-original, cheap timing belts, which break at low mileage - 5-7 thousand kilometers. Advice - be responsible when purchasing a timing belt; it is better to pay more for this consumable than to later fork out for expensive repairs to the cylinder head.

Reason 3. Timing pump failure. In the design of the gas distribution mechanism of some engines, the pump comes into contact with the belt, and if this unit fails, it jams, as a result of which the belt rubs against the pump and frays, which leads to its breakage. The pump wears out at the same mileage as the timing belt, so when replacing the belt, we recommend installing a new pump.

Reason 4: Camshaft wear. This breakdown occurs over long engine runs (150 thousand km or more), and therefore does not occur so often. A seized camshaft can cause the timing belt to break. That's why when buying a used car with high mileage, we strongly advise you to look at the condition of the camshaft.

Reason 5. Malfunction of the timing drive attachment. The timing belt moves on rollers, which can also wear out and jam, which leads to the belt breaking and the valves bending.

We recommend checking the condition of the tension rollers at each maintenance, regularly lubricating and tightening their fastenings, and, if necessary, replacing them with new ones.

Although engines with a timing chain drive are considered more reliable, it happens that valves bend in them too. This happens for two reasons: the chain links stretch or the drive attachments (tension rollers and dampers) fail. The main reason why timing chain links stretch is the poor-quality material from which it is made. Such a disaster happened to Volkswagen TSI engines in the mid-2000s: the German automaker ordered chains from an unscrupulous contractor, and they began to fail at 20-40 thousand kilometers, causing the valves to bend. To prevent valves from bending in such engines, the timing chain and attachments should be periodically diagnosed and, if necessary, replaced with new ones.

Timing belt replacement infographic

To enlarge the image, just click on the picture.

The gas distribution mechanism (GRM) synchronizes the operation of the piston group, the fuel injection system and the exhaust of combustion products. If you are wondering how to change the timing belt, we will provide the necessary minimum information that will help present this procedure as a whole. This will make it easier to decide whether replacing the timing belt is worth your own efforts, or whether it is better to entrust this work to specialists.

The timing belt is the most responsible and important belt drive in a car. Its breakage is a big nuisance. You'll be lucky if the problem is limited to bent valves. Therefore, the answer to the question of how to replace the timing belt should be given immediately as soon as you suspect a problem with its operation. In this case, it is better to play it safe than to have serious repairs in the future.

Useful tips on the topic

Following the recommendations will make life easier for the driver and the engine of his car:

- find out whether the valve in your car’s engine will bend from a table, from a reference book, or with your own hands;

- when buying a used car from a stranger, it is recommended to change the timing belt, even if the former owner claimed to have recently replaced it;

- periodically check the belt tension and carry out a visual inspection for cuts, scuffs, and rope detachment;

- buy a good quality belt (it’s always better to use the same brand);

- carry a spare timing belt;

Let's say I have everything I need. Now I can replace the timing belt myself

If you are confident in your car repair skills, then absolutely. Please note that replacing the timing belt is one of the most time-consuming maintenance procedures. That is, if you were able to change the oil or air filter yourself, this does not mean that you will get it right the first time and change the timing belt yourself.

In addition, the details of the procedure are quite different on different engines. Most likely, the experience of replacing the engine of one car will not be very useful when working with an engine of another type. Therefore, it makes no sense to recommend any tools, nut tightening torques or timing marks, since you need to look individually for your engine in the car repair manual.

In general terms, the instructions for replacing the timing belt look like this:

- Jack up the right front wheel and remove it.

- Remove the top timing belt cover.

- Remove the lower protection of the timing mechanism.

- Place the crankshaft at TDC and align the mark on the engine housing and the marks on the crankshaft and camshaft pulleys on the same line.

- Check that the TDC mark on the flywheel matches the marking.

- Fix the position of the shafts (the method and tool depend on the brand of engine).

- Loosen the tensioner roller.

- Remove the belt.

- Remove and replace the tensioner and auxiliary rollers (if equipped).

- Remove/replace the pump (if necessary).

- Replace the timing belt.

Video on replacing the timing belt using the example of Lada Priora

VAZ 2110 engine valves, video of valve adjustment, which engine bends the valves

The VAZ 2110 engine valve is the most important structural element of the “ten” engine, as in other models of internal combustion engines. A malfunction of the valve mechanism inevitably leads to breakdown of the entire VAZ-2110 engine. Today we will tell you the main thing about the valves of the power unit of a domestic car.

Adjusting valves on a VAZ 2110 engine

You will immediately feel the malfunction of the VAZ 2110 engine valves. For example, if you notice a metallic rattling sound coming from under the valve cover, this is a reason to check the valve clearance. Especially if the sound does not disappear even when the engine is warm. The valve mechanism diagram in the “tenth” engine is as follows. The camshaft (5 in the figure), rotating, runs into a special “glass” (3), which pushes the valve (2) down, opening it. The valve clearance is adjusted by selecting washers or “nickels” (6) of various thicknesses. These washers are located at the bottom of the valve cup and over time, under the mechanical influence of the camshaft cams, the gap (A) between the “penny” and the camshaft “cam” changes. It is the increased valve clearance that causes the unpleasant sound. But a reduced clearance can also cause problems, because the valve will not be fully pressed by the return springs, will not sit tightly on the valve seat and will not maintain sufficient compression. Therefore, adjusting the valves of the VAZ-2110 engine must be taken very seriously.

Video of valve adjustment on a VAZ 2110 engine

Next is a video of valve adjustment on an 8-valve “tens” engine. The video is short, clearly and clearly explained, with all the necessary illustrations, watch it.

Why and on which VAZ 2110 engine does the valve bend?

Let's say right away that the valve bends mainly when the piston meets the valve. In most cases, this occurs when the timing belt breaks. After all, it is the belt that synchronizes the rotation of the crankshaft and camshaft, respectively, the stroke of the pistons and the stroke of the valves. If the belt breaks, the piston goes up, and the valve can go down, which can result in a problem like the one in the photo below.

But not all VAZ-2110 engines are guaranteed to bend valves when the belt breaks. This problem mainly affects the 16-valve injection engine with a displacement of 1.5 liters. The index of this engine is VAZ-2112. On a 1.6-liter engine with 16 valves, AvtoVAZ designers provided special recesses for the valves in the piston bottoms, in case the belt breaks. See the photo of the piston with recesses below.

Why does the VAZ 2110 engine smoke?

Actually, why does the engine smoke and what does the valve have to do with it? The fact is that with a high mileage of the power unit, oil begins to enter the combustion chamber through the valves, as a result, smoke comes out of the exhaust pipe, and carbon deposits form in the combustion chamber. It is carbon deposits that are the main enemy of stable engine operation, since it interferes with the normal combustion of the fuel-air mixture and clogs the gaps in the piston grooves, blocking the compression rings. Since compression rings cannot fully perform their function, this leads to a drop in compression, which means a decrease in power and an increase in fuel consumption. In addition, carbon deposits can cause corrosion between the valve chamfer and the seat, which also negatively affects the operation of the engine, since the surfaces do not meet tightly.

How to avoid the appearance of carbon deposits in the combustion chamber? First, you need to understand where the oil gets into the cylinders. For the most part, engine oil ends up there penetrating through the valve mechanism, or more precisely through the valve stem seals of the VAZ-2110 engine. Next is a diagram showing valve stem seals numbered 4 in the next picture.

The caps are installed on valve bushings, which are inserted into the cylinder head; there is a spring-return mechanism on top, which is blocked by crackers (9). The fact is that the valve stem seals are made of an elastic material that is resistant to temperature changes and tightly compresses the valve stem without allowing oil to pass along the valve stem into the combustion chamber. But nothing lasts forever, and when the caps are no longer able to tightly press the valve stem, the oil flows down the valve straight into the combustion chamber. Therefore, timely replacement of valve stem seals in the VAZ-2110 engine is necessary. Because it is much cheaper than carrying out serious repairs to the power unit by disassembling the engine and cleaning it from oil soot and deposits in the combustion chamber.

Ways to solve the problem

Since the collision of pistons with valves has quite serious negative consequences, many car enthusiasts are interested in whether it is possible to influence this situation.

There are several methods that allow you to convert a valve-bending motor into a “plug-inless” one.

The simplest of them is installing pistons with grooves. By the way, on some VAZ engines this is how the problem with “sticking” is solved.

On the bottom of such pistons there are special recesses for valve plates. Due to this, the latter in the open position do not come into contact with the pistons installed at TDC.

But not all engines can be modernized in this way, for the reason that it is not always possible to find pistons with factory-made grooves to replace the “original” ones.

The second method is to independently make grooves on the piston. This method is suitable for those who have not found replacement “non-stick” pistons. But this method has a significant drawback - it is very difficult to make identical recesses on all pistons. As a result, an imbalance in the weight of the pistons may occur, which will affect the service life of the crankshaft. Also, grooves of different sizes can cause different compression in the cylinders, and this problem cannot be eliminated.

The third method is to increase the height of the combustion chamber. This is done by installing 2-3 gaskets under the head of the block. This method has a negative side - an increase in the volume of the combustion chamber, which entails a drop in compression, and as a result - a decrease in power and an increase in fuel consumption.