Created in the late 90s of the 20th century, the NZ family of engines from the Toyota manufacturer received an alloy block, a plastic intake manifold and a timing chain drive. Within this family, the 1NZ FE engine received the maximum operating parameters - torque of 141 Nm at medium speed and power of 108 hp. With. with a compression ratio of 10.5 units.

ICE 1NZ FE

Initially, a prototype internal combustion engine was tested in the 1NZ-FXE hybrid engine, only after which it entered production. During the period 2000 - 2006, the motor received 10 international awards and was recognized as the most technologically advanced, environmentally friendly and economical power drive in the world.

Technical specifications 1NZ FE 1.5 l/108 l. With.

The developers of the Toyota concern took as a basis a standard engine design - 4 in-line cylinders, made of cast iron wet liners inside an aluminum block. The intake manifold in the engine is plastic, that is, it does not have casting defects or rough surfaces.

Most 1NZ FE models feature VVTi variable valve timing, but only on the intake camshaft. At first, the valve lift height was adjusted by mechanical pushers. In 2004, modernization was carried out, hydraulic compensators appeared, now users do not need to adjust the thermal valve clearances at a service station every 30,000 km.

1NZ FE design

Initially, the series had small volumes of combustion chambers and was intended for light class Toyota cars. The basic version has only 108 liters. pp., it will not be possible to significantly increase power.

Similar design solutions made it possible to obtain the technical characteristics of 1NZ FE:

| Manufacturer | Kamigo Plant |

| Engine brand | 1NZ FE |

| Years of production | 1997 – … |

| Volume | 1497 cm3 (1.5 l) |

| Power | 79.4 kW (108 hp) |

| Torque moment | 141 Nm (at 4200 rpm) |

| Weight | 112 kg |

| Compression ratio | 10,5 |

| Nutrition | injector |

| Motor type | in-line petrol |

| Ignition | DIS-4 |

| Number of cylinders | 4 |

| Location of the first cylinder | TVE |

| Number of valves on each cylinder | 4 |

| Cylinder head material | aluminum alloy |

| Intake manifold | plastic |

| An exhaust manifold | steel welded |

| Camshaft | original cam profile |

| Cylinder block material | Aluminium alloy |

| Cylinder diameter | 75 mm |

| Pistons | with LFA coating |

| Crankshaft | forged steel 4 counterweights |

| Piston stroke | 84.7 mm |

| Fuel | AI-92/95 |

| Environmental standards | Euro 5 |

| Fuel consumption | highway – 6.6 l/100 km combined cycle 9.5 l/100 km city – 13 l/100 km |

| Oil consumption | 0.2 – 0.4 l/1000 km |

| What kind of oil to pour into the engine by viscosity | 5W30, 10W30 |

| Which engine oil is best by manufacturer | Liqui Moly, Toyota |

| Oil for 1NZ FE by composition | synthetics, semi-synthetics |

| Engine oil volume | 3.7 l |

| Operating temperature | 90° |

| ICE resource | declared 150,000 km actual 250,000 km |

| Adjustment of valves | pushers |

| Cooling system | forced, antifreeze |

| Coolant volume | 5.7 l |

| water pump | Aisin WPT-063 |

| Spark plugs for 1NZ FE | BKR5EYA-11 from NGK or Denso K16R-U11 |

| Spark plug gap | 1.1 mm |

| Valve train chain | 13506-21020 |

| Cylinder operating order | 1-3-4-2 |

| Air filter | AMC TA-1678, Nipparts J1322102, Stellox 7101052SX, Miles AFAD094 |

| Oil filter | Mann W68/3, VIC C-110, C-113, DC-01 |

| Flywheel | 32101-52020, lightweight, 6 bolt holes |

| Flywheel mounting bolts | M12x1.25 mm, length 26 mm |

| Valve stem seals | manufacturer Goetze |

| Compression | from 13 bar, difference in adjacent cylinders maximum 1 bar |

| XX speed | 750 – 800 min-1 |

| Tightening force of threaded connections | spark plug – 25 Nm flywheel – 108 Nm clutch bolt – 64 Nm bearing cap – 22 Nm + 90° (main) and 15 Nm + 90° (rod) cylinder head – four stages 29 Nm, 69 Nm + 90° + 90° |

The engine characteristics are adjusted solely to ensure Euro-4 regulations and the current legislation of the countries to which Toyota cars are planned to be exported.

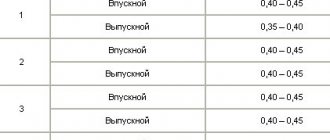

How to adjust valves on a 1nz fe engine

k) Determine the size (thickness) of the new pusher. — Using a micrometer, determine the thickness of the pusher being replaced. — Calculate the thickness of the new pusher using the formula so that the clearance in the valve drive is within the recommended range,

For inlet valves N=T + (A -0.20) mm For exhaust valves N=T + (A -0.30) mm

where: N is the thickness of the new pusher, T is the thickness of the removed (used) pusher, A is the measured gap in this valve.

Nominal clearance in the valve drive (on a cold engine): intake 0.15 - 0.25 mm; graduation 0.25 - 0.35 mm

Note : pushers are available in 35 sizes in 0.02 mm increments, with thicknesses ranging from 5.06 mm to 5.74 mm.

m) Install the valve lifters (see the “Engine - General Repair Procedures” section).

i) Turn the crankshaft pulley and align it with the “O” mark on the timing chain cover.

o) While holding the chain, install the intake camshaft and sprocket assembly,

p) Align the marks on the chain and the camshaft sprocket,

p) Install the two camshafts and sprockets assemblies (see section “Cylinder Head”).

c) Remove the rod from the timing chain tensioner. r) Make sure the timing marks on the sprockets are facing up as shown in the illustration.

y) Make sure that the timing marks and chain marks are aligned as shown in the illustration.

f) Install two new plugs into the cylinder head cover.

Tightening torque 15 Nm

x) Check the clearance in the valve drive (see above).

Install the cylinder head cover (see section “Cylinder Head”).

Source

Design Features

The NZ series turned out to be long-lasting:

- 2000 – 2005 – 105 l. s., 138 Nm, assigned index NZE124;

- 2005 – 2007 – 109 liters. s., 141 Nm, NCP90 index;

- 2007 – 2013 – 110 l. s., 140 Nm, index NZT260;

- 2013 – … – 109 liters. s., 136 Nm, index NZT.

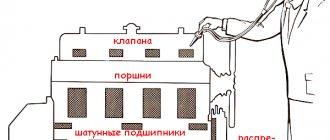

The 1NZ FE naturally aspirated in-line petrol engine includes design features of the ZZ/AZ family and fresh developments from Toyota designers:

- cast iron liners are poured directly into the aluminum block, so overhaul of the cylinders is impossible;

- the cast crankcase serves as an oil pan and ensures block rigidity;

- the axis of the forged steel crankshaft is offset relative to the cylinders by 12 mm;

- lightweight piston skirt with polymer coating, press-fit pins;

- a feature of the intake camshaft is the presence of a VVTi clutch for adjusting valve timing;

- the cylinder head is equipped with standard mounting holes for injectors and valve seats;

- the oil pump is located in the crankcase and has a separate drive from the crankshaft;

- heated throttle valve, “cold” thermostat 84 degrees, mechanical type;

- the pump is driven by a common belt, like all other attachments;

- Double-shaft timing belt, DOHC 16V type, driven by a single-row chain on the exhaust camshaft;

- the manifolds have changed location - inlet at the front, exhaust at the rear, so do-it-yourself boosting was made easier by the designers from the very beginning;

- there is no return line in the fuel system, fine-dispersion multipoint injectors;

- mechanical throttle valve, DIS-4 ignition with separate coils for each spark plug.

Crankshaft axis offset

Gas distribution mechanism

Lubrication scheme

The performance of hydraulic compensators and the VVTi clutch depends on the quality of the oil. The manual contains a detailed description of the maintenance and repair operations of the power drive.

List of internal combustion engine modifications

The 1NZ FXE version arose during the development of the main 1NZ FE engine, became part of a hybrid engine (ICE plus electric) for the Toyota Prius, and has the following characteristics:

- compression ratio 13 - 13.4 units;

- power 74 – 76 l. With.

Hybrid engine 1NZ FXE

Instead of the Otto cycle, the Atkinson method is used here. At low speeds, the wheels of the car are rotated by an electric motor; on large internal combustion engines, from which the battery is charged at the same time. Complex and varied attachments are used, which are not available in the basic version.

Advantages and disadvantages

Initially, Toyota management included a disposable cylinder block in the power drive, the overhaul of which is impossible. The piston pins cause trouble because they are pressed rather than floating. When a chain breaks or jumps several links after stretching, pistons without counterbore bend the valves when they encounter them.

The advantages of the 1NZ-FE motor are:

- high service life from 300,000 km;

- independent chip tuning to increase power;

- lack of adjustment of valve thermal clearances after 2004.

Cooling system

The power drive uses budget AI-92 fuel economically and is not difficult to maintain and repair.

Specifications

The parameters of the power plants made them popular throughout Japan, the CIS countries and Europe. For American consumers it is underpowered.

| Cylinder volume | 1500 cc |

| Number of cylinders | 4 |

| Number of valves | 16 |

| Maximum power indicator | 107 hp |

| Torque indicator | 141 Nm at 4200 rpm |

| Timing mechanism type | DOHC |

| Valve setting system type | VVT-i |

| Compression level | 10.5:1 |

The material used to manufacture the engine is aluminum alloy. Toyota power plants produced at that time had thin walls, so they did not have repair dimensions.

Despite this, the resource of the power plant reaches 300,000 - 400,000 km.

A prerequisite for long service life of the engine from the 1NZ line is the use of high-quality lubricants, as well as timely maintenance. The chain drives the gas distribution mechanism. Thanks to this, there is no need to periodically change the belt element. However, expert opinion suggests that it also needs to be replaced every 100,000 kilometers of the car.

List of car models in which it was installed

The naturally aspirated in-line four-cylinder engine 1NZ FE, operating on the classic Otto cycle, was installed on Toyota modifications:

- Corolla Fielder/Axio – station wagon for Russia and 11th generation sedan;

- Ractis – subcompact van with a glass roof;

- Succeed – right-hand drive minivan with all-wheel/front-wheel drive;

- Probox – family minivan;

- Will – a youth car with an original design;

- Sienta – minivan with sliding doors;

- Allion – a sedan with a sporty exterior;

- Premio – a sedan for the older generation;

- Fun Cargo – a compact van with an original exterior;

- Auris – family hatchback, new generation of Corolla;

- Platz – classic sedan;

- Porte – subcompact van with doors of different types of opening;

- Raum – subcompact van with automatic transmission;

- Vios – sedan;

- bB – subcompact van in English style;

- Yaris/Echo is a classic sedan.

Toyota Fun Cargo

Additionally, these engines were installed in the Scion xB and xA/ist, and the initial version was used exclusively in the Toyota Prius.

Maintenance schedule 1NZ FE 1.5 l/108 l. With.

The factory manual indicates maintenance periods and replacement operations for consumables that the 1NZ FE engine has in its design:

- the manufacturer provides for replacement of the roller-type timing chain after 120 - 150 thousand mileage;

- the manufacturer recommends changing oil that has lost its properties after 7,500 km, and antifreeze after 20,000 km;

- It is recommended to change the air and fuel filters after 10,000 and 30,000 mileage, respectively;

- adjustment of thermal clearances of engine valves is carried out once every 2 years (mileage 30,000 km);

- the service life of spark plugs in the DIS-2 system is 30,000 km, when using iridium modifications 60,000 km;

- the exhaust tubular manifold begins to burn out after 50 - 70 thousand mileage.

Replacing the timing chain

Periodically, carbon deposits deposit on the valves and pistons, the crankcase ventilation becomes clogged, and the throttle valve becomes clogged. The above systems need to be flushed and purged and sensors replaced.

Typical problems and causes

As for a small-volume engine, the 1 NZ FE engine has good characteristics and service life. However, the unit is characterized by some problems that appear due to long-term operation.

- Oil consumption.

Increased consumption appears after engine mechanisms and parts reach significant mileage. Basically, the problem is typical after traveling 150,000 km or more. A solution to high consumption may be to carry out a procedure for cleaning the combustion chamber, or replacing the oil scraper piston rings and caps.

Piston rings:

- Engine operation is accompanied by knocking and noise.

The main reason for this manifestation is stretching of the motor chain. The behavior is often observed in units that have traveled 150,000 kilometers. To solve, it is necessary to replace the drive chain of the gas distribution mechanism. The mechanism that tensions and calms the chain may need to be replaced.

Timing drive chain:

- Unstable idle speed.

The problem manifests itself when the engine throttle body is dirty and can be solved by cleaning the mechanism. In addition, the condition of the sensor and valve responsible for idling the engine is checked.

Throttle:

- The engine operation process is accompanied by vibrations.

As a rule, the reason lies in the failure of the engine mounts. Most often, the front product fails. The problem is resolved by replacing the part. In addition, a possible cause may be clogging of the injectors due to the use of poor quality fuel. In this case, cleaning is carried out with the obligatory replacement of the fuel filter.

Fuel injectors:

In addition to these problems, the lubricant pressure sensor often fails and the rear crankshaft oil seal leaks. To prolong the operation of the unit, it is recommended to carry out timely maintenance of the motor and use high-quality consumables. The engine core cannot be restored and after a run of 200,000 kilometers the unit is replaced with a contract engine.

Review of faults and methods for repairing them

Due to its design features, the 1NZ FE motor is guaranteed to bend the valve during a timing chain break. However, other faults are more relevant to the user:

| Uncontrolled engine oil consumption | 1) worn valve stem seals 2) coked or worn-out rings | 1) replacing caps 2) replacing rings |

| Third party sounds | 1) chain stretch 2) wear of liners 3) carbon deposits on the valves 4) development of rollers/pushers | 1) replacing the chain with a kit 2) replacement of liners 3) decarbonization with special detergents 4) replacement of rollers, pushers |

| Floating speed | 1) IAC breakdown 2) damper clogged | 1) replacing the XX regulator 2) cleaning the throttle |

Repair 1NZ FE

All attachments are driven by one belt, so a whistle often occurs, indicating slippage or, conversely, too much tension. Weak points are also the crankshaft rear oil seal and the oil pressure sensor.

Malfunctions

Malfunctions characteristic of the 1NZ FE engine begin to appear after a significant mileage. Moreover, all of them are caused by the fact that the developers of this power unit used almost all known methods of reducing its durability. This was caused by the need to solve a more complex problem - creating the shortest possible (along the length of the crankshaft) motor.

The most common ones are:

| FAULTS | CAUSES | REMEDY METHODS |

| Noise and knocking in the engine. | Stretching the timing chain. | Replace the chain. At the same time check and, if necessary, replace the chain tensioner and guide. |

| Engine speed fluctuates in idle mode. | Clogged: Ÿ idle speed sensor; Ÿ throttle valve block. | The malfunction can be eliminated by cleaning clogged units. |

| High consumption of engine oil. | Worn oil scraper rings or caps. | 1. Decarbonize the oil scraper rings. 2. Replace oil seals and/or rings. |

| The oil pressure indicator light on the instrument panel lights up. | The engine oil pressure sensor is clogged or faulty. | Replace the engine oil pressure sensor. |

| Whistle in the engine. | The alternator belt has become unusable. | Replace the alternator belt. |

| Strong vibration of the motor. | The fuel filter and/or fuel injection system injectors are clogged. | 1. Clean the injectors. 2. Replace the fuel filter. |

A design feature of the 1NZ engine is the impossibility of major repairs (if necessary). After a run of 200...250 thousand km, the power unit, as a rule, must be replaced with a contract one.

Engine tuning options

It is theoretically possible to boost the 1NZ FE engine in seven stages:

- exhaust modernization - forward flow, “spider” and ECU correction to produce 145 hp. With. maximum;

- modification of the fuel system - the use of high-performance injectors and Apexi Power FC “brains” to provide 150 hp. With.;

- supercharging - turbine plus intercooling, installation of a high-performance brake system, power increases to 180 - 200 hp. With.;

- supercharger - usually Supercharger

Tuning 1NZ-FE

Thus, the 1NZ FE engine is distinguished by an aluminum block and a timing chain drive according to the DOHC 16V scheme. It is used in almost the entire model range of the Toyota manufacturer, which came off the assembly line from 1997 to 2005, and in some modern cars.

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them

Where was the unit installed?

Due to its versatility, the engine was installed on a wide range of Toyota cars:

- Yaris, Echo;

- Scion xA as well as xB;

- Ist, bB;

- Vios;

- Raum;

- Belta;

- Porte;

- Platz;

- Auris;

- Premium;

- funcargo;

- Allion;

- Sienta;

- WiLL VS;

- Ractis;

- Probox;

- Corolla (Axio/Fielder, RunX, Allex).

Also, under license, the engine was installed on the Chinese Geely CK and MK, Great Wall C10.

Over many years of operation in a wide variety of vehicles, including commercial ones, the 1NZ-FE engine has established itself as a reliable, but quite demanding unit.