Purpose, device, operating principle of pxx

The idle speed sensor functionally plays the role of a stabilizer, an automatic engine speed controller in modes without traction (in neutral gear, when shifting gears).

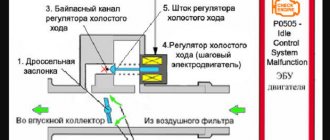

The mass flow sensor analyzes the amount of incoming air and transmits information to the electronic control unit, which dispenses the required volume of fuel through the nozzles. The crankshaft position sensor provides the number of revolutions. The electronic unit processes the message and generates control signals for the idle speed controller. The increase in revolutions of a cold engine occurs due to IAC. The engine is warming up. Starting movement (not recommended) without raising the temperature to normal is possible due to the participation of this regulator.

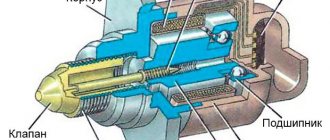

What does the pxx sensor on the VAZ 2114 consist of: 1 - valve; 2 — regulator body; 3 - stator winding; 4 — lead screw; 5 — plug terminal of the stator winding; 6 — ball bearing; 7 — stator winding housing; 8 - rotor; 9 - spring

The adjustment device is made in the form of a cylinder with two mounting ears. A spring-loaded conical needle is built into one end. Inside the housing there is a DC stepper motor containing two windings. Supplying control signals to the first circuit extends the conical needle, and retracts it to the second circuit. There is a detachable block on the side surface.

The device is located on the throttle body body, under the air duct hoses. Adjacent to the throttle position sensor.

Where is the pxx on the VAZ 2114

If you don’t know where the pxx sensor is located on a VAZ 2114, then I hasten to describe the situation to you in the photo below.

Where is the pxx on the VAZ 2114

Idle speed sensor VAZ 2114: signs of malfunction - Auto-Moto24.ru

At the moment when the gas pedal is released and the car is in neutral gear, engine speed is maintained by a device such as the idle air control (IAC) . When operating a vehicle with this part, problems often arise that have a direct impact on the operation of the power unit. In this article, we will look at the signs of a malfunction of the idle speed sensor of a VAZ 2114 , thanks to which you can quickly and efficiently fix the problem in engine operation. In addition, you will learn the design and operating principle of the IAC, as well as methods for checking it.

Symptoms of a problem

It is worth noting that the ECU , as a rule, does not report a malfunction of the idle air regulator, so CHECK may not indicate problems with this part. The need for repair (replacement) of the IAC can be determined by the following signs:

- Idle speed is too high

- Too low speed , which leads to significant vibration of the motor or its complete stop;

- Inability to start the engine without pressing the gas pedal;

- Lack of stability of engine speed. The revolutions are floating;

- When accelerating and changing gears, the moment you release the gas pedal, the speed increases significantly and only after a few seconds returns to normal ;

- When you turn on additional equipment (lamp, radio), the engine stalls .

Design and operating principle

The 14th VAZ uses an idle speed sensor with a stepper-type electric motor . Also in its design there is a conical needle that works in tandem with a spring. This needle ensures the dosage of incoming air into the throttle valve assembly.

1-valve; 2-body; 3-stator winding; 4-screw; 5-pin stator winding terminal; 6-bearing; 7-winding body; 8-rotor; 9-spring.

When the car's ignition is turned on, valve (1) is fully extended and closes the hole located in the throttle channel. Next, the regulator calculates the steps, returning the valve to its original position.

The initial position of the idle air control valve on VAZ depends on the type of firmware installed in the ECU . It is 50 steps Bosch firmware and 120 steps for firmware type JANUARY 5.1 .

As the number of steps of the sensor changes, the amount of air passing through the throttle channel decreases or increases. An extended valve has more steps and less air flow. The retracted valve is the opposite.

For a VAZ 2114 , the distance from the valve head (stem) to the body flange is no more than 23 millimeters . This must be taken into account when purchasing a new regulator.

We make sure that this distance is no more than 23 mm.

The amount of air that has passed through the throttle assembly is checked by the mass air flow sensor. The ECU processes this information and supplies a certain amount of fuel accordingly. In this way, the fuel mixture necessary for engine operation is formed. The ECU also receives signals from the crankshaft position sensor about engine speed and accordingly transmits control signals to the idle speed controller. In this method, the power unit is provided with the required amount of incoming air.

The important role of a small device in a serious unit

Participating in the general algorithm of operation of the vehicle’s electronic system, the IAC is designed to automatically supply a certain amount of air when the throttle valve (DZ) is closed. Thus, it maintains the set idle speed (ISR) of the engine, preventing it from stalling when the gas pedal is released and the gearshift lever is in neutral position. The operating principle of the UDS is as follows:

- the amount of air entering through the remote control is controlled by a mass (total) air flow sensor - mass air flow sensor;

- receiving information from it, the controller (electronic control unit) regulates the supply of the required amount of fuel to the fuel injectors (Fuel Injection) of the car;

- he, using the data from the crankshaft position sensor (DPKV), controls the IAC in accordance with the required speed;

- automatically sets the speed when the engine warms up.

Having safely got out of the intersection, you need to make sure that this regulator is working. Since it does not have a self-diagnosis system, the VAZ 2114 computer may not generate errors. You will have to check it using a general analysis of engine operation.

Symptoms of a malfunctioning idle speed sensor

If the idle speed sensor fails, the driver will be notified of this by the Check Engine light (“Check engine”). However, if it lights up and the car has problems idling, this does not mean that the malfunction is definitely related to the sensor. Without checking the regulator, it is difficult to say for sure whether it is working or not.

We can identify a number of signs that are “beacons” that there are problems with the idle speed sensor:

- The car stalls at idle or its speed “floats”;

- In order for the engine to run smoothly, it requires significant warm-up time;

- When the gear lever is moved to neutral, the engine stalls.

The problems described above occur due to a lack or excess of air supplied to the engine when idling. However, it is not only the idle speed sensor that can cause such symptoms, which is why it needs to be diagnosed before choosing a new one to replace it.

Main functions of IAC

The device is designed to control the crankshaft speed in the engine.

- This is a valve with a cone-type shut-off needle that can be moved using a stepper motor.

- The valve is located in the throttle channel.

- The IAC determines the required amount of air and supplies it bypassing the throttle valve.

- In this way, the engine speed is adjusted.

- Depending on the operating conditions of the engine, the sensor in question increases or decreases the engine speed to optimal values for idle mode.

In addition to the main functions of the device, this sensor also indirectly affects the reduction of engine exhaust emissions.

The process looks like this:

- When engine braking occurs, the throttle valve closes sharply.

- The sensor works to increase the supplied air bypassing the damper.

- The result of this is the combination of the fuel mixture with air, which reduces the toxicity of exhaust gases.

The idle speed sensor is located next to the throttle sensor and is secured with two screws or simply fixed with glue.

Idle air control on VAZ 2114: signs of IAC malfunction

If instability occurs in the idle speed, the first thing car owners are advised to do is check the condition of the idle speed sensor. Instability of the operation of the DXX or the XX regulator is manifested in the following:

- When driving, the car stalls when changing gears;

- The revolutions then drop sharply, then begin to increase again.

If you find one of these problems, the IAC will most likely have to be replaced. But first, let’s figure out what kind of device this is.

Appearance and location

DXX is responsible for adjusting the idle speed. Hence the other name - idle air control. Externally, the device is a miniature electric motor, at the end of which there is a small cone-shaped needle.

Where is he located? The IAC is attached to the throttle body using two screws or regular varnish. Next to the DHW there is a throttle position sensor. Therefore, there should be no problems finding the sensor.

Idle speed regulator (sensor) VAZ 2114

At its core, the idle speed sensor is a valve equipped with a shut-off needle, through which the amount of air supplied to the combustion chambers bypasses the throttle valve is dosed. That is, when the damper is completely closed, and the controller comes to the conclusion that it is necessary to increase the idle speed, the idle speed controller (IAC) slightly opens or completely opens the intake port and thereby leans the fuel mixture. As a result, the car does not stall at idle even when driving on a cold engine. A stepper motor integrated into the regulator is responsible for driving the valve needle.

Signs of malfunctions of the VAZ 2114 px

Manufacturers of the VAZ 2114 did not provide diagnostics for the idle air regulator.

The on-board display will not display a message indicating an error in the operation of this mechanism. Inscriptions about low and high speeds do not guarantee breakdown of the IAC. The driver may notice changes in engine operation and suspect a malfunction based on indirect signs. The following symptoms are usually called:

- the engine suddenly “stalls” at idle;

- idle speed “floats” (randomly increases or decreases);

- when starting a cold engine, it is not possible to increase the speed;

- at the moment of changing gear, switching to “neutral” gear.

Such signs are caused by the unstable functioning of several sensors that take a direct or indirect part in preparing the fuel mixture (for example, a throttle position sensor).

Checking the RXX multimeter on a VAZ 2114

If you have a question about how to check the pxx multimeter on a VAZ 2114 car, then you have come to the right place. You need to take a multimeter and take several measurements; see the photo for what conclusions you need to check.

Checking the RXX multimeter on a VAZ 2114

Check engine

Modern injection engine control systems are capable of recording some malfunctions of the idle speed sensor. As an example, let’s look at the recorded deviations indicated in the error mask (list of malfunctions that cause the Check engine to light up) of the VAZ M7.9.7 engine control unit under EURO III toxicity standards:

- P1509 - IAC control circuit overload;

- P1513 - IAC control circuit, short to ground;

- P1514 - IAC control circuit, open or shorted to +12 V.

Also, when decrypted, the error code may appear as “IAC malfunction.” In this case, you should not immediately buy a new regulator, as the problem may be in the power wires.

Error codes can be read through the diagnostic connector using a special scanner. Decoding codes can be easily found on the Internet. In most cases, thorough cleaning will help delay replacement. The most accurate and quick way to determine a faulty idle speed control is by monitoring its operation in real time. This will require an oscilloscope, as well as diagnostic skills. It will not be possible to apply voltage to the sensor terminals to observe the movement of the rod. The IAC is controlled by Pulse Width Modulation (PWM). There are special devices on sale for quickly checking the IAC of VAZ cars. But their cost is too high if we talk about the frequency of use when repairing a personal car. On amateur radio forums you can find testers made by yourself.

Checking the sensor circuit

- Before you start checking the sensor, make sure that the multimeter is working and ready for use.

- The idle speed sensor and its “wires” are below the throttle sensor. The throttle sensor is marked with an arrow. The block has been removed from the idle speed sensor.

- Next, open the hood and disconnect the power supply from the sensor.

Please note that on cars equipped with a 1.6-liter engine, it is necessary to remove the throttle assembly mount and move it away from the receiver itself by about a couple of centimeters.

Take a multimeter

- Then, on the multimeter, set the “voltmeter” test mode.

- We connect the black probe to ground, and fix the red one to the terminals of block A - D.

- With the help of an assistant, turn on the ignition and look at the parameters given by the multimeter. The readings must be at least 12 volts . If the voltage is lower, then there are problems in the battery, and when there are no values at all, then the problem should be looked for in the wires or the motor control unit.

If after checking it is determined that the circuit is working properly, then you can proceed directly to the sensor.

Troubleshooting

The difficulty in diagnosing the idle speed sensor lies in the fact that its problems will not be shown by the on-board computer, and its functionality can only be checked manually. The same cannot be said about the throttle position sensor, because they have the same symptoms of malfunctions, and the most ordinary on-board computer can identify the latter.

Checking the sensor circuit

- Before you start checking the sensor, make sure that the multimeter is working and ready for use.

The idle speed sensor and its “wires” are below the throttle sensor. The throttle sensor is marked with an arrow. The block has been removed from the idle speed sensor.

- Next, open the hood and disconnect the power supply from the sensor.

Please note that on cars equipped with a 1.6-liter engine, it is necessary to remove the throttle assembly mount and move it away from the receiver itself by about a couple of centimeters.

Take a multimeter

- Then, on the multimeter, set the “voltmeter” test mode.

- We connect the black probe to ground, and fix the red one on the terminals of block A - D.

This is what the pin layout looks like on the IAC power supply block. - With the help of an assistant, turn on the ignition and look at the parameters given by the multimeter. The readings must be at least 12 volts . If the voltage is lower, then there are problems in the battery, and when there are no values at all, then the problem should be looked for in the wires or the motor control unit.

If after checking it is determined that the circuit is working properly, then you can proceed directly to the sensor.

Checking the idle speed sensor

When testing the sensor itself, you must connect the sensor to resistance test mode as follows:

- Regardless of polarity, connect the probes to the terminals first A And B, and then C And D. If the sensor is working, then the values should be about 53 Ohms.

The values are normal.

- Next, we connect them in the same way, only to outputs A and C , B and D , here the values should show “infinity”.

If the test readings were abnormal, you can try to clean it with carburetor cleaner, or purchase a new one.

What error codes appear when the IAC is faulty?

If the idle air control is faulty, the on-board computer may display the following errors:

- P1509 - IAC control circuit overloaded;

- P1513 - IAC control circuit, short to ground;

- P1514 - IAC control circuit, open or shorted to +12 V.

When deciphering fault codes via the Internet or in the vehicle's operating manual, you may sometimes encounter definitions indicating problems with the operation of the IAC. They often indicate a regulator failure. Errors can be seen not only on the on-board vehicle, but also when diagnosing a car using a scanner. Sometimes they indicate not sensor defects, but contact failure.

Symptoms of a problem

You can understand that the IAC has failed by the following signs:

- The engine is running at idle. With this phenomenon, shaking and rattling of the car is felt;

- The car stalls at idle. The engine may suddenly stall in neutral or when changing gears;

- When starting a cold power unit, the speed does not rise. If the valve is working properly, they grow quite quickly as they warm up. If it breaks down, the tachometer needle remains at the same low level for a long time;

- The revs fluctuate at XX. The instrument needle may rise and fall involuntarily.

These symptoms can sometimes signal not only the breakdown of a given unit, they can also be caused by other reasons. For example, a defect in the throttle position sensor (TPS). But when they appear, you should first check this valve. Another indicator of this malfunction is a drop in the speed of the power unit when the headlights or heater are turned on. The car may suddenly stall when starting, which sometimes also indicates this problem. But only diagnostics of the part will help to accurately identify the problem.

Diagnostic methods

Before proceeding with the replacement, we recommend that you really make sure that the cause of all problems with your VAZ 2114 is the faulty IAC. To do this, there are two main ways to check the status of the device.

Explore both to see which diagnostic option is best for you.

Visual inspection

First you need to conduct a visual inspection. In this way, you can detect body defects, needle wear, and carbon deposits. If deposits form, you can clean them with carburetor cleaner. It is also recommended to clean the entire throttle body as it is in a similar condition.

Using diagnostic programs

The operation of the IAC can be checked using a diagnostic adapter and special programs. For example, you can use the simplest ELM327 adapter and the OpenDiagMobile program. In the program menu you need to select the desired position of the XX regulator and watch the operation of the valve. It is better to set it at least 20 steps more than the current position.

Checking the regulator resistance

To do this, we will need to measure the resistance between terminals A, B, and C and D after disconnecting the sensor terminal. We move the multimeter to the position of measuring resistance at the limit of 0-200 Ohms (Ω).

The normal value is within 50-55 Ohms. The resistance between A and C, B and D must be infinity.

Checking with throttle assembly

There is another way to diagnose IAC. To do this, you will need to remove the throttle assembly from the studs along with the sensor.

By connecting the valve connector and turning the ignition on/off, you can observe the operation of the IAC live. See how the needle works, if it is rubbing somewhere, check the evenness of the stroke, hear suspicious sounds.

Wiring check

For this we need a multimeter. With the engine off, remove the connector from the sensor. We set the measurement limit on the measuring device to 0-20 V DC voltage. We measure the voltage at the connector. Normally it should be 12V.

Diagnosis of IAC mechanics

The mechanics may be broken. The main thing that is checked during diagnosis is the mobility (length) of the bolt cone. The 100% condition of the device can only be determined with a special stand or a special tester, but an eye check can also reveal the cause of the problem.

Checking the sensor for mechanical service involves removing it. Procedure:

- We put the vehicle in handbrake.

- Remove the “–” terminal from the battery.

- Disconnect the block from the valve.

- We clean, wipe the place where the product was located, the fastenings.

- Unscrew the fasteners and remove the part.

Instructions on how to check the idle speed sensor on a VAZ 2110 (injector, 8 or 16 valves) after removing it:

- We connect the sensor to the block.

- We connect the battery.

- We activate the ignition - the cone shutter should move forward. If this is not observed, there may be a malfunction of the rod (possibly coking) or the motor. The norm for the protrusion of the needle (cone) from the body of the product is 23 mm. When operational, if power is supplied, the rod changes position.

Cleaning, repair or installation of new

To carry out any of these activities, you will have to partially disassemble the UDS.

Before starting work, you need to prepare consumables and tools:

- carburetor cleaning fluid;

- WD-40 lubricant;

- rags and cotton swabs;

- slotted screwdriver;

- 13 mm socket wrench with ratchet;

- dismantle the VAZ 2114 engine casing;

- remove or loosen the fasteners of additional commutations that are located on the UDS; air filter pipe;

- throttle cable;

- in case of a critical malfunction, replace it with a new one, similar to the faulty one;

- when disassembling the IAC, it is necessary to monitor the integrity of the electrical wiring connections;

On the VAZ 2114, like on any other car, there are no insignificant or unnecessary parts and components. When carrying out repairs or maintenance of some of them, you should not miss the opportunity to check the serviceability of other mechanisms and devices that are functionally related to them.

Homemade IAC tester

In some cases, checking the idle speed control with a multimeter is borderline useless. For example, on injection VAZs. In this case, the multimeter data will not be informative, since the main problem is coking of the screw pair. This problem leads to the sensor becoming stuck, causing it to simply not provide a constant flow of air.

Some craftsmen independently manufacture devices for checking IAC in such a situation. For a homemade tester, you need to have a 6V AC phone charger transformer on hand. If you use the controllers alternately, you can check the forward and reverse stroke of the regulator. The working device will illuminate the indicator light with a dim light, and the opposite effect will indicate jamming and the need for repair.

Calibrating a new IAC

What should I do if the test reveals that the sensor needs to be replaced? It needs to be calibrated.

- We check the distance from the end of the rod to the mounting plate, it should be no more than 23mm.

- We disconnect the minus from the battery, de-energizing the ECU.

- Install the regulator.

- We connect the battery back.

- Turn on the ignition for 5 seconds without starting the engine. At this time, the IAC calibration occurs.

- Turn off the ignition to complete the calibration.

- We start the engine and observe the idle speed.

Now you know how the idle air regulator works, how to check it and, if necessary, replace it. As you understand, there is nothing complicated about this and all operations are accessible even to a novice car enthusiast.

How to remove the idle speed sensor

Replacing the idle air control valve on a VAZ is very simple

To remove the sensor, you need to put the car on the handbrake and disconnect the negative terminal from the battery. Next, you need to disconnect the wiring harness from the sensor and clean the place where the IAC connects to the throttle pipe body - so that dirt and sand do not get into the mounting hole. The sensor is secured with two screws, which must be unscrewed with a screwdriver or ratchet.

Replacing pxx on a VAZ 2114

Replacing pxx requires preliminary preparation, eliminating possible surprises.

To replace pxx you need:

- perform a preparatory inspection,

- determine the essence of the problem,

- explore possible repair methods,

- stock up on the required spare parts, tools, and consumables.

Required Tools

To work you will need:

- working regulator;

- Phillips screwdriver;

- M13 head, ratchet driver;

- can of VD-40;

- rags;

- liquid for flushing carburetors;

- multifunctional measuring device;

- source of air flow (compressor, industrial hair dryer, special spray can).

Repair procedure for idle speed sensor

Typically, repair work is carried out in several ways. The reasons for the differences may be the vehicle’s equipment, level of training, style, habits of the mechanic, unforeseen breakdowns that occur along the way.

Changing the sensor can be done in two ways:

- with disconnection of preparation elements, air supply,

- without detailed disassembly.

Below we will consider the second option, which includes a minimum number of technological operations. If it is not possible to provide convenient access to the dismantling site, there will be an additional need to service, replace, or clean other adjacent parts, it is worth using the first method.

Step-by-step instructions for replacing the idle speed sensor on a VAZ 2114

- Raise and secure the hood.

- Turn off the power to the car - loosen and remove the negative terminal of the battery.

- Remove the engine casing.

- Carry out an external inspection of the fastening hardware, if necessary, clean it, treat it with a penetrating agent, and wait for the rust to break down.

- Unscrew the nuts securing the throttle assembly.

- Remove the remote control from the studs and carefully move it slightly to the side, freeing access.

- Disconnect the connector from the IAC block.

- Use a screwdriver to unscrew the screws and pull out the idle air control. There are cases of rigid fixation of mounting screws (cross-shaped grooves are painted over and drilled). This option will require dismantling the entire assembly, followed by continued disassembly on a table or workbench.

- Inspect the sensor. Check the windings with a tester to make sure there is a malfunction. Replacing a working device with a new one will not bring success. We'll have to look for another culprit for the car's unstable behavior.

- The wires of the first winding go to contacts A, B of the connector block, the second - C, D. The normal resistance AB (CD) is 53 Ohms. There should be no electrical communication between the two circuits (AC) - the device will show infinity.

- The serviceability of the device will raise suspicions about the integrity of the wiring. With the ignition on, measure the supplied voltage at the cable connector suitable for the IAC. The value should be at least 12V. Absence is a sign of a wire break or a problem with the control unit. Understatement - the need to charge the battery.

- Clean, rinse with carburetor fluid, wipe the assembly seat. Dry with air flow - no moisture should get inside the regulator.

- The surface of the cone should be flat, smooth, excluding bumps, sagging, and dirt. Otherwise, the calibration hole in the housing will not close tightly, and the fuel mixture will receive excess air.

Attention! On the new sensor, the spring-loaded needle can be extended to its full length. Before installation, the needle should extend to a distance of no more than 23 mm from the edge of the housing.

Trying to push the needle in manually is strictly prohibited. Such actions will cause the mechanism to malfunction. It is logical to use a special stand at a service station. Fans of radio engineering and electronics will be able to independently assemble an electronic device that supplies step control pulses to the sensor windings, extending and retracting the needle. You should first test the assembled device on an old sensor.

- Lubricate the O-ring on the device body with engine oil (for example, using a dipstick).

- Insert the working sensor into the seat.

- Reassemble in reverse order, lubricating the threaded connections.

- Reinstall the battery terminal and tighten it.

- Turn on the car's power with the ignition key. Wait 5 seconds. The on-board electronic control system will calibrate the needle extension.

- Start the engine and let it run without pressing the gas pedal. Observe the instrument arrow on the panel. As the engine warms up, the speed changes smoothly, without jerking.

- A negative result indicates the presence of an arc fault.

- The physical performance of components and mechanisms leads to the need for computer diagnostics, settings, and programming of engine operating modes.

Removing a faulty device

- Place the car on a flat surface with the handbrake on;

- Raise and secure the hood cover;

- Turn off power. This moment is not on duty - it is mandatory!

- Remove the motor protective cover;

- Loosen the clamp and remove the rubber tube coming from the air filter;

- Remove the fastening of the VF pipes and the corrugation;

- Unscrew the mounting bolts and pull out the cable running from the throttle valve to the gas pedal.

Designation of the idle speed sensor - Clean the entire surface around the throttle assembly with a rag;

- Lubricate the mounting screws of the remote control and idle air control with WD-40 so that they can be easily unscrewed;

- Unscrew the nuts by 13 mm and pull out the throttle assembly;

- Disconnect the IAC and remove it from the terminals;

- If there is dirt in any places, it must be wiped off thoroughly;

- Use a screwdriver to unscrew the mounting bolts of the remote control and IAC;

- Remove the valve from the mounting socket.

Sources

- https://provaz2114.ru/elektrika/priznaki-neispravnosti-rhh-na-vaz-2114.html

- https://vaz-remzona.ru/rhh-vaz-2114/

- https://ladaautos.ru/vaz-2115/gde-raspolagaetsya-datchik-xolostogo-xoda-vaz-2115.html

- https://www.vazzz.ru/zamena-rhh-vaz-2114-8-klapanov/

- https://ladafakt.ru/datchik-rhh-vaz-2114-priznaki-neispravnosti.html

- https://carfrance.ru/kak-proverit-datchik-xolostogo-xoda-na-vaz-2114/

- https://vaz-2114.info/9-priznakov-neispravnosti-datchika-holostogo-hoda-vaz-2114/

- https://elm3.ru/diagnostika/regulyator-holostogo-hoda-rhh

- https://osensorax.ru/rashod-uroven/datchik-holostogo-hoda-vaz-2110

- https://pricurivatel.ru/proverka-regulyatora-xolostogo-xoda-multimetrom.html

- https://remontvazov.com/rxx-zamena-remont-priznaki-neispravnosti

We check the idle speed sensor on a VAZ-2114 with our own hands: signs of a malfunction

If the idle speed of the car begins to “float”, and its operation as a whole has become unstable, then first of all you should check the idle speed sensor. In this article we will tell you in detail about this, and also tell you how to approach the issue of choosing this sensor.

Video with an overview of the main malfunctions of the idle speed sensor (+ replacement)

Main symptoms of a malfunction

Among all engine problems, “floating” idle speed is especially noticeable, and they manifest themselves in the following:

- The engine stalls when changing gears.

- The engine speed either rises sharply or drops to a minimum.

- The revolutions drop sharply at the moment of stopping with the engine running (at the moment of stopping at a traffic light - approx.).

If such symptoms are present, the idle speed sensor is usually faulty. However, before you start repairing it, you need to understand what it looks like and where it is located.

Sensor location on the engine

The sensor that regulates idle speed on a VAZ-2114 is usually fixed with two bolts next to the throttle assembly. It is easy to recognize by the presence of a power supply and its specific shape.

Idle speed sensor location

Now that we have figured out its location, we can begin diagnostics and, if necessary, repairs.

Troubleshooting

The difficulty in diagnosing the idle speed sensor lies in the fact that its problems will not be shown by the on-board computer, and its functionality can only be checked manually. The same cannot be said about the throttle position sensor, because they have the same symptoms of malfunctions, and the most ordinary on-board computer can identify the latter.

Checking the sensor circuit

- Before you start checking the sensor, make sure that the multimeter is working and ready for use.

The idle speed sensor and its “wires” are below the throttle sensor. The throttle sensor is marked with an arrow. The block has been removed from the idle speed sensor.

Please note that on cars equipped with a 1.6-liter engine, it is necessary to remove the throttle assembly mount and move it away from the receiver itself by about a couple of centimeters.

Take a multimeter

- Then, on the multimeter, set the “voltmeter” test mode.

- We connect the black probe to ground, and fix the red one to the terminals of block A - D.

This is what the pin layout looks like on the IAC power supply block.

If after checking it is determined that the circuit is working properly, then you can proceed directly to the sensor.

Checking the idle speed sensor

When testing the sensor itself, you must connect the sensor to resistance test mode as follows:

- Regardless of the polarity, we connect the probes first to terminals A and B , and then C and D. If the sensor is working, then the values should be about 53 Ohms.

The values are normal.

If the test readings were abnormal, you can try to clean it with carburetor cleaner, or purchase a new one.

Which sensor should you choose?

In order to correctly approach the selection of an idle speed sensor for a VAZ-2114, you should know that the last two digits on the sensor article number have a special meaning. Because if the article number of the old one ended with “ 01 04 will be replaced , then there will be no sense in this, because it simply will not work properly.

Native sensor and analogue

Sensors from numbers “ 01 ” to “ 02 ” and “ 03 ” to “ 04 ” are considered interchangeable, respectively.

When choosing this device, also pay attention to counterfeit goods, because there are plenty of them on the modern market.