When the engine idles intermittently, this is a clear sign that it is time to check the performance of the IAC. It is likely that you will need to replace this unit, because such a part cannot be repaired.

Initially, it is important to check the reason for the unstable operation of the internal combustion engine; perhaps the problem does not lie in the sensor. But this situation rarely occurs, and to solve the problem it is enough to replace the regulator with a new element.

All work can be done independently with a minimum of financial costs.

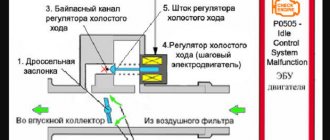

Main functions of IAC

The device is designed to control the crankshaft speed in the engine.

- This is a valve with a cone-type shut-off needle that can be moved using a stepper motor.

- The valve is located in the throttle channel.

- The IAC determines the required amount of air and supplies it bypassing the throttle valve.

- In this way, the engine speed is adjusted.

- Depending on the operating conditions of the engine, the sensor in question increases or decreases the engine speed to optimal values for idle mode.

In addition to the main functions of the device, this sensor also indirectly affects the reduction of engine exhaust emissions.

The process looks like this:

- When engine braking occurs, the throttle valve closes sharply.

- The sensor works to increase the supplied air bypassing the damper.

- The result of this is the combination of the fuel mixture with air, which reduces the toxicity of exhaust gases.

The idle speed sensor is located next to the throttle sensor and is secured with two screws or simply fixed with glue.

Checking the serviceability of the sensor

If you notice unstable engine operation at idle, you should not immediately go to the store for a new device. First you need to check the functionality of the node; perhaps the problem does not lie there. To do this, do the following:

- Turn off the ignition.

- Disconnect the connector with wires from the sensor.

- Take a multimeter and check the resistance between pins A and B, C and D.

- Acceptable resistance values range from 40 to 80 ohms.

- If you get different indicators at the output, then the regulator is faulty, therefore, this unit needs to be replaced.

- Is the resistance within normal limits? Then measure the same indicator between pairs of contacts B and C, as well as A and D.

- The tester will show infinity or open circuit.

- If there are other indications, the device may be considered faulty.

Using these simple steps, it is easy to determine the functionality of the idle air control on your VAZ-2115. If the element is broken, then proceed to consider the process of replacing the device.

Principle of operation

Turning on the ignition, the on-board computer begins to test the system. You can hear the fuel pump starting and all the lights on the instrument panel light up. At the same time, the idle air control completely blocks the air flow, and the control unit calculates the required number of steps and removes the needle, slightly opening the channel to the desired position.

The distance to the air flow can be different and depends on the parameter: hot or cold motor. For example, for warming up a rich mixture is required, which means the needle is extended as much as possible, but for operation on a hot engine the mixture is lean, that is, the regulator removes the lead screw, increasing the air supply.

For reference! The number of steps of the idle speed sensor on the VAZ 2115 depends on the type of software (firmware). For example, on a hot engine with a “January 5.1” controller the usual distance is 110 shg, and on a Bosch it’s 50 shg. (The maximum stroke reaches 250 shg.).

How to change the IAC on a VAZ-2115

As we mentioned earlier, the idle speed sensor cannot be repaired; it only needs to be replaced.

The price of a new part is about 350 rubles. To carry out the work, prepare the following:

- Sensor.

- A small amount of oil.

- Cross screwdriver.

Now you can start replacing:

- Park the machine on a level surface.

- Pull the handbrake.

- Open the hood and locate the idle air control valve. It is located on the throttle body.

- Turn off the ignition and disconnect the terminals from the battery. This is necessary in order to avoid a short circuit in the engine electronic system.

- Disconnect the connector from the sensor.

- To simplify the replacement process, you can remove the entire throttle assembly.

- The throttle regulator is secured with three bolts; they need to be unscrewed with a Phillips screwdriver.

- After this, remove the entire assembly.

- Now you can remove the regulator. Use extreme caution during this step.

The regulator installation process is as follows:

- Before installing a new part, clean the seat, the air channel in the throttle assembly and the place where the sealing ring is inserted from various contaminants.

- If cracks are found on the ring, then it is better to replace this element.

- Before installing the O-ring, lubricate it with engine oil.

- Install the ring on the surface of the throttle assembly.

- Then install the sensor in the same place (all the way), and then tighten the fixing bolts.

- Don't forget about the bracket that secures the wires.

- In this step, reinstall the throttle assembly and screw it on.

- The final stage is checking the correct installation and tightness of all connections. Do this several times.

After all the work done, connect the terminals to the battery and check how the engine works.

If the idle speed has stabilized, then the replacement was carried out correctly. Please note that the new sensor is selected based on one parameter - the distance between the tip of the valve needle and the mounting flange (2.3 cm). The manufacturing company is determined independently - this is not so critical.

To summarize, we note that the idle speed controller is a fairly important unit that affects the stable operation of the internal combustion engine at idle. In the article, we told you how to determine the malfunction of this unit, as well as how to replace the sensor. There is nothing complicated in carrying out the work. It is important to be careful and perform all actions consistently. In this case, you can repair your VAZ-2115 without any problems.

Description of IAC

What is the IAC in the Four with an injector, what signs of malfunction are typical for it, where is the device located? You will find answers to these questions with photos and videos below; first, we recommend that you familiarize yourself with the basic information regarding this regulator.

Installation location and purpose

In VAZ 2114 and VAZ 2115 cars, the XX regulator is a device whose purpose is to stabilize the speed of the power unit at idle. The IAC is used to regulate the amount of air flow supplied to the fuel system when the throttle is closed. Accordingly, the engine speed is automatically adjusted. This regulator is located on the throttle body. The device is fixed in the seat using two bolts.

Operating principle

When you turn the key and turn on the ignition, the rod on the IAC extends to the end, as a result of which it rests against the calibration hole on the throttle line. After this, the regulator begins to count steps and returns the valve to its initial state. The position of the original valve directly depends on the firmware of the VAZ control unit. For example, in a car with a January 5.1 control unit on a fully warmed up engine, the number of steps is 120, and in a Bosch it is about 50.

When the power unit is warmed up, at the time of adjustment the IAC is located at around 30-50 steps. When the number of steps increases or decreases, the volume of air flow that passes through the technological opening changes regularly. When the rod extends, the number of revolutions increases, and when it retracts, it decreases. The stroke of the rod is about 250 steps. A certain volume of air is supplied to the motor, which is needed for optimal functioning of the power unit.

The amount of supplied air is regulated by the mass air flow meter in accordance with the volume, the control module supplies a certain amount of fuel to the engine through the injectors. This ensures an optimal ratio of air and fuel when forming a combustible mixture. If the engine is not warmed up, the control module increases the speed thanks to the IAC, which allows you to use the car for driving without warming up the internal combustion engine.

Which regulator is suitable for VAZ 2114 and 2115?

As for the most suitable regulator for the “Four” and “Fifteen”, judging by the reviews, the best option is the IAC Omega. The catalog number of these devices is 2112-114830. In addition, in practice, devices from the manufacturer KZTA, number 2112-1148300-04, have proven themselves well. When purchasing, be sure to pay attention to the mark (in this case 04, but IACs with marks 01, 02, 03 are also produced) on the old and new regulator, they must match.

If the marks do not match, the regulator will not be able to work. You can use 01 instead of 03, and also 02 instead of 04 and vice versa. When buying a regulator, you need to measure the distance from the rod head to the flange; it should be no more than 2.3 cm . Find out how to distinguish a fake IAC from the original from the video published by the AutoLife channel.

Possible malfunctions and ways to eliminate them

What are the symptoms that indicate that the device has failed:

- the number of engine revolutions is not controlled; it can spontaneously increase and decrease,

- the power unit may randomly stall for no reason at idle,

- on a cold engine the driver cannot increase the speed,

- when additional equipment (optics, heater, wipers) is turned on, the engine speed drops significantly, in particular, if the car is idling,

- The speed of the power unit may be increased, this is due to the development of the sensor cone.

If problems arise in the operation of the IAC device, the device must be cleaned or replaced.

Signs of a malfunctioning idle speed sensor

Modern cars with an injector have in their design a mechanism responsible for starting “cold” and running the engine at idle. This device is controlled by a controller. The regulator is reliable and simple, but problems still happen.

Causes of malfunction of the idle air regulator (abbreviated as “IAC”)

Sensor failures can occur due to the following factors:

- the stepper motor is broken (most often due to natural wear and tear);

- the power supply is broken or missing;

- the cone and rod are dirty (oil deposits tend to occur on a worn motor);

- ECU problems (related troubles - excessive fuel consumption, difficult engine starting, unstable operation of the car in different modes, etc.)

It is quite easy to understand that a car owner is dealing with a malfunction of the idle air control. To do this, you need to start the engine and remove the connecting socket from the block. If there is no breakdown, the speed will quickly drop. At the same time, the internal combustion engine will stop thanks to a spring mechanism that pushes out the cone. This process is accompanied by complete closure of the bypass channel cross-section.

For minor changes in engine operation, additional diagnostics are required.

Idle speed control

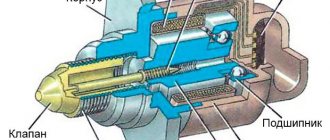

As in engines with a carburetor, the injection engine contains idle speed with the throttle valve fully closed. This is possible only under one condition - if the design of the throttle provides for a bypass channel, and it must have a variable throughput. To do this, a conical valve was introduced into the bypass air channel of the throttle body, regulating the air supply when the throttle valve is closed, and called it IAC, idle air regulator. It consists of a conical valve, a stem and a stepper motor. Depending on which winding the impulse is applied to, the motor rotates in one direction or the other, thereby changing the throughput of the bypass air channel. The unmarried ones either rise or fall as a result of the movement of the conical valve. The unmarried speed sensor on the VAZ 2115 has catalog number 1148300 02.

Video about the single speed regulator VAZ 2115 - symptoms of malfunction and replacement.

Signs of a malfunction

Lack of idle speed, floating idle speed, idle speed does not increase on a cold engine.

How to check

The most common failure of the IAC is the twisting of the stepper motor windings. To check the windings, you need a multimeter turned on in order to measure resistance. The resistance value between contacts A-B and C-D is within 45-80 Ohms. Otherwise, the regulator asks for replacement. There should be infinite resistance between pins AD and B-C. This means that the windings do not short circuit each other. If there is resistance on these contacts, the sensor is replaced. The nominal voltage of the tables is from 7.4 to 14.1 V.

Idle speed sensor malfunctions

The first step is to measure the voltage in the power supply of the node.

The next step in checking the IAC is to determine the supply voltage. It is performed according to the following algorithm:

- disconnect the connector;

- start the internal combustion engine;

- A voltmeter is used to measure the voltage of the contacts (for VAZ cars these are terminals marked A and D).

The basic principle for interpreting the results comes down to two options. The first one is a value below 12 V (check the wiring). Second (measurements are greater than the specified value) - you need to check the regulator itself.

Often the main symptom of idle speed problems is a lighted Check Engine light. Not all cars have this option, since the unit is an actuator.

If the speed “floats” at idle, a thorough diagnosis is necessary. First, check the regulator itself. A change in crankshaft rotation can occur due to a failure of the intake air sensors, a breakdown of the gas distributor, etc.

Common symptoms of a faulty idle speed sensor are listed below:

- “cold” knee rotations. the shafts do not increase (the motor is unstable and may stall);

- as the generator load increases, the idle speed drops (to create such conditions, headlights and electrical appliances are turned on in the car);

- while driving the car, the internal combustion engine periodically stalls when switching gears to a manual transmission;

- The speed drops and rises spontaneously.

If such problems are detected, you can try to find a malfunction of the idle air valve yourself. For example, by conducting an eye examination. This way you can detect needle wear, body defects and carbon deposits. The latter is easily amenable to carburetor cleaner. At the same time, inspect the throttle and bypass channel - clean them, if necessary, with the same special product. Why do car enthusiasts choose to have their “iron horse” repaired at a technical center? The main advantage is saving time (if done by professionals).

Symptoms and causes of IAC malfunction

Signs of a malfunctioning idle speed sensor appear as follows:

- during a cold start, the crankshaft speed does not increase, which is why the engine runs unstable and tends to stall;

- there is a drop in the number of idle revolutions after a significant increase in the load on the generator - turning on headlights, electric heaters, and so on;

- the engine periodically stalls when any gear of the manual transmission is switched off (the symptom manifests itself while driving);

- The speed “floats” - it spontaneously increases and decreases.

Important point! There is a misconception that a regulator failure is necessarily accompanied by the inclusion of the Check Engine indicator on the dashboard. Since the element is an actuator, the light warning option is not provided in all cars.

If the car shows signs of IAC malfunction in the form of floating engine speed at idle, advanced diagnostics may be needed. A spontaneous change in the crankshaft rotation speed occurs for many reasons - failure of a sensor, air leaks, gas distribution malfunctions, and so on. It is better to start troubleshooting by checking the regulator.

IAC failure occurs for three main reasons:

- Open or poor contact in the power supply circuit. Simply put, there are problems with the wiring.

- Breakdown of the stepper motor due to natural wear and tear. In this case, only replacing the idle speed sensor will help.

- Contamination of the rod and cone with oil deposits.

There is a fourth reason - problems with the electronic control unit. The problem is quite rare and is accompanied by additional symptoms - increased gas mileage, unstable operation in all modes, difficult starting, and the like.

Oil deposits reach the rod thanks to secondary gases sent by the crankcase ventilation system for re-combustion. The more worn out the engine, the more deposits accumulate on the working cone. As a result, moving the rod becomes difficult; in advanced cases, the mechanism simply jams.

Idle Air Control Malfunction - Check Engine Signal

A dictionary of error codes is easy to find on the Internet.

Control systems in cars with an injector record deviations in the operation of the fuel regulator. Below are some possible IAC failure codes with decoding:

- P1509 (control circuit overload);

- P1513 (short to ground);

- P1514 (open circuit or other problems at 12 V).

If you receive information about a problem, check the wiring - perhaps the problem lies there. Test codes are received through a special connector using a scanner. You can decipher the obtained values yourself using special tables (search online). If you can't quickly check the system, a thorough cleaning will help delay replacement for some time.

You can determine the serviceability yourself, but this will require skills and an oscilloscope.

Idle valve. Why urgent action is necessary when signs of malfunction are detected

This element directly affects the operation of the motor by regulating the air supply (it passes by the throttle). When electrical appliances are turned on in a car, the load on the generator and, accordingly, the engine increases significantly (including the temperature). To maintain a stable idle voltage and battery voltage when the power unit is warm, the device partially opens the channel. Result: more air enters the internal combustion engine.

The most common cause of idle speed problems is a dirty rod. If you neglect to regularly clean the throttle valve, carbon deposits may appear on the elements of the control system. This can also lead to failure of the ECU resistor due to overload of the control channel. Dirt on the unit in question leads to increased load, which prevents the rod from moving. The resistor is inexpensive, but add to the total amount the time and money costs for diagnostics.

By design, the system comes in three types.

The search for the source of the problem when signs of a malfunction of the idle air control appear begins with the “materials”. There are three types of stabilizing XX systems (the number of contacts in the diagnostic connector is indicated in parentheses):

- solenoid (2);

- rotary (3);

- stepper (4).

The third option is more common. It consists of four windings and a ring magnet, which are located perpendicular to each other. Rotation of the rotor is provoked by voltage on certain windings. It is transmitted through a worm gear, driving the “curtain”. To check the electrical windings, you need to measure the resistance on the first and second two contacts (use a multimeter).

Often, signs of a malfunctioning idle speed sensor on the injector appear due to a dirty air filter. To prevent such a problem in winter, experienced car owners recommend changing the gas more often, which will allow:

- remove condensate from the exhaust system;

- develop a stock.

To minimize risks, do not reuse the old filter. Wash the throttle valve and pipes only with special products (as we already mentioned, a carburetor cleaner is suitable).

How to find the idle speed sensor when detecting signs of malfunction? We will give an example on the domestic car “Priora”. Under the hood, find and remove the plastic engine casing. Find the throttle element with your eyes.

If you look “in the direction” of the car’s movement, the desired mechanism will be on the right.

Clean it, remove it and test it if necessary.

Methods for eliminating floating engine speeds

Malfunctions of video recorders of video surveillance systems and ways to eliminate them

When starting to find and eliminate the reasons that cause unstable operation of the engine in idle mode, first of all you need to check:

- Condition of the air filter and spark plugs. If they become critically dirty, they need to be replaced.

- Integrity of insulation of high-voltage wires. If damage is found, they must be replaced.

Checking the tightness of the intake manifold (video guide)

Let's consider the remaining elements of the car, the malfunction of which can affect the smooth operation of the VAZ 2114 engine in idle mode.

Solenoid valve diagnostics

Cars with engines equipped with a carburetor are equipped with idle speed solenoid valves. Devices are checked as follows:

- Disconnect the power cord.

- Start the engine to warm up.

- Connect the wire. If a clear click is not heard, the part must be replaced.

Adjusting the idle speed on a carburetor engine (with video)

Note that the main reason for the appearance of floating idle speed in engines of this type is the incorrect operation of the carburetor. The device is adjusted by rotating the fuel quality and quantity screws.

Is the EGR system on the injector working?

"Floating" speed can be caused by jamming of the exhaust gas recirculation (EGR) valve, which is installed in the exhaust manifold. It is necessary to periodically remove dirt from the valve seat and its seat using a carburetor cleaning aerosol, avoiding liquid getting on the sensor diaphragm.

Keep the valve seat clean

Is the idle air control valve working correctly?

The IAC is checked by measuring the electrical resistance at the contacts - to diagnose the device you will need a tester (multimeter) set to the “ohmmeter” operating mode. To check the details:

- Let's turn off the ignition.

- Disconnect the connection block.

- Let's measure the resistance on contacts A - B and C - D of the device. The optimal readings of the device vary from 40 to 80 ohms.

- Let's repeat the measurements with contacts B - C and A - D. In this case, the multimeter should show “infinity” or an open circuit.

Any violation of the normal resistance values means a malfunction of the regulator. IAC failure is a common cause of floating engine speed at idle, and if a malfunction is detected, the device must be replaced. Before you begin dismantling the part, you must disconnect the negative wire from the battery. After installation, the new IAC is calibrated - the removed terminal is returned to its place, the ignition is turned on and after 5-10 seconds (there is no need to start the engine).

IAC failure is a common cause of floating engine speeds.

Serviceability of the mass air flow sensor

To diagnose the mass air flow sensor, you need to switch the tester operating mode to “voltmeter” (20 V). We check the part by following these steps:

- Let's turn off the engine and turn on the ignition.

- Let's measure the voltage at the connection connector between the contacts of the green and yellow wires. The multimeter reading should be in the range of 0.99 - 1.02 V.

The device can be cleaned by “blowing” with a carburetor cleaning aerosol

Video: Checking the mass air flow sensor

Cleanliness of the damper assembly

The throttle valve assembly is diagnosed by visual inspection for contamination. Clean the part with cotton swabs and a toothbrush moistened with a cleaning solution. For ease of work, the device is dismantled. After cleaning, it is recommended to blow out all channels and pipes of the unit with compressed air using a tire inflator.

To clean the part, it must be dismantled

Video: How to clean the throttle body

Is it possible to diagnose DPKV and DSA?

A breakdown of the DPKV and DSA (Hall sensor) is indicated by the Check Engine indicator that lights up on the car’s dashboard. Testing these devices is only possible using special instruments (oscilloscopes). You can first check the integrity of the wiring; if it is broken, the damage should be repaired.

- The DPKV sensor is installed on a bracket located in close proximity to the generator drive pulley.

- The DSA is located on the speedometer drive mechanism of the gearbox.

For a more detailed introduction to methods for detecting faults associated with engine malfunction in idle mode, it is recommended to watch the following video.

Finding the cause of the malfunction of the idle speed sensor on VAZ cars

Using a tester, professional or homemade, you will discover the root of the problem.

For quick self-diagnosis, there are special devices on sale, but they are quite expensive. Some car owners use testers made at home (you can find out how a “home” one is made on car forums). We recommend turning to professionals, but the final decision is yours.

The Uremont.com aggregator offers tools for identifying a suitable service station and connecting with professionals. An interactive map with addresses of partner car services and user reviews will speed up the search for a car repair shop. The online application form presented on the website is a universal way to solve almost any problem with a car (for example, you can call a tow truck).

Sensor layout

The sensors under the hood of the VAZ 2115 are located as follows.

1. Phase sensor; 2. Coolant temperature sensor; 3. Knock sensor; 4. Oil pressure sensor; 5. Oxygen sensor; 6. Crankshaft position sensor; 7. Speed sensor; 8. Idle speed sensor; 9. Mass air flow sensor; 10-11. Gasoline level sensor; 12. Antifreeze level sensor; 13. Throttle position sensor

VAZ 2115: replacing the idle speed sensor with your own hands

Idle speed sensor (XX)

If the engine of your VAZ 2115 idles intermittently, you need to make sure that the sensor responsible for idling the engine is working properly. You may need to replace the idle speed sensor on the VAZ 2115, since it cannot be repaired. First, it is important to make sure what the reason is; maybe it’s not the sensor. The easiest and cheapest way is to replace it yourself, with a minimum of tools and a minimum of costs. Nowadays it is difficult to imagine a car that does not have idle speed. When driving around the city, it is simply necessary. This mode allows you not to turn off the car engine at every stop or at a traffic light.

Signs of IAC malfunction

Unfortunately, the 2110 VAZ DXX is NOT equipped with a self-diagnosis system, therefore the “CHECK ENGINE” light signal will not indicate a malfunction. Loss of performance on the VAZ 2110, 2112 is determined by the following main signs:

- the engine “stalls”, for no apparent reason, at idle;

- The idle speed “floats”;

- when a “cold” VAZ 2110, 2112 engine is started, there are no overestimated speeds at all;

- The engine stalls, specifically, after turning off the gear while driving.

The symptoms completely coincide with the failure of the VAZ 2110 TPS, but in the case of this sensor the “CHECK ENGINE” indicator will light up.

SENSOR (XX) IDLE SPEED

This is a special device that controls the crankshaft speed:

- It is a valve that has a conical shut-off needle that is moved by a stepper motor

- The valve of the sensor we are considering is located in the channel of the throttle pipe.

- It controls the required amount of air, which is supplied bypassing (bypassing) the throttle valve.

- It is thanks to this functioning that the speed of rotation of our crankshaft is regulated.

- Depending on the nature of the engine operation, the installed sensor provides adjustment for decreasing or increasing engine speed (to optimal) when idling.

In addition to the described main function, it also affects the reduction of engine exhaust toxicity. How does this happen:

- During engine braking, the throttle valve closes (quite sharply).

- At the same time, the sensor increases the supplied air volume, bypassing this damper.

- Thus, the process of depleting the fuel mixture by adding air occurs, which minimizes the toxicity of emitted exhaust gases.

Where is the sensor located

It is installed on the throttle body, not far from the throttle sensor, screwed with two screws, or simply glued.

How is its performance checked?

So:

- Turn off the ignition;

- Disconnect the block with wires from the regulator;

- Using a multimeter, check the resistance between pairs of contacts: A and B; C and D;

- The permissible resistance ranges from 40 - 80 Ohms;

- If other resistance readings are received, the regulator is faulty and requires replacement;

- If the resistance is normal, move on to the next paragraph (item);

- Using the same multimeter, now we measure the resistance between pairs of contacts B and C, A and D;

- The multimeter indicator will show either infinity or an open circuit;

- If the readings are different, then the regulator is faulty.

IDLE REGULATOR. Sensors (VAZ 2108-2115) Diagnostics, compatibility, operating principle

The idle speed controller (IAC) is used to maintain the set engine speed at idle by configuring the amount of air supplied to the engine when the throttle is closed. The IAC is located on the throttle pipe and is an anchor-type stepper motor with 2 windings. When an impulse is applied to one of them, the needle takes one step forward to the other. step back. Through the worm gear, the rotational movement of the stepper motor is converted into the translational movement of the rod. The conical part of the rod is placed in the air supply channel to regulate the idle speed of the motor. The regulator rod extends or retracts depending on the control signal from the controller. The idle air control regulates the crankshaft speed during idle and controls the amount of air supplied bypassing the closed throttle valve. In the fully extended position (the fully extended position corresponds to “0” steps), the conical part of the rod shuts off the air supply bypassing the throttle valve. When opening, the valve provides air flow proportional to the movement of the rod (number of steps) from its own seat. A one hundred percent open valve position corresponds to a 255 step movement of the stem. When the engine is warmed up, the controller controls the movement of the rod and maintains a constant crankshaft speed at idle, regardless of the state of the engine and the load configuration. In Mikasa systems, a slightly different name is often used. Additional Air Regulator (ADV). The RDV has a different design: instead of a stepper motor, a torque motor is used, which rotates the locking element to a certain angle, proportional to the voltage.

Supply voltage range V: 7.5-14.2 for РХХ212-1148300-02 (Creation of KZTA) and РХХ212-1148300-01 (Creation of Pegasus OJSC, Kostroma)

testing Turn off the ignition. Disconnect the harness connector from the regulator. Using a multimeter, check the resistance of the IAC windings. The resistance between the contacts of the idle speed control system A and B, and C and D should be 40-80 Ohms. If not, change the IAC. If yes, check the resistance between contacts B and C, A and D. The device should demonstrate infinity (open circuit). If not, change the IAC. If so, the IAC circuit is ok.

Signs of a malfunction of the idle speed sensor (IAC) Unfortunately, the idle speed control is not equipped with a self-diagnosis system, therefore neither the on-board vehicle (BC) nor the illuminated check engine will tell us about this. But if you encounter subsequent problems, then the sensor must be checked (How to check the IAC?), cleaned (How to clean the IAC?) Repaired (How to repair the IAC?) Or replaced (How to change the idle speed sensor?) In case of a malfunction.

1) Stalls at idle

2) Idle speed fluctuates

3) When starting a cool engine, there are no high speeds

4) Stalls when the gear is removed from the box

In principle, all the symptoms of the death of ICH are identical to the symptoms of TPD. But the difference is that if the TPS dies, the on-board vehicle will show an error or the check engine will light up.

YOU CAN READ MORE CAREFULLY HERE

Like 10 Rating

Only registered users can participate in discussions.

Full version of the website

Where is the Idle Air Controller (IAC) located?

The idle speed sensor is located on the throttle body. The idle speed sensor is located next to the throttle position sensor. The DXX is secured with 2 screws. It also happens that the sensor is mounted on the varnish.

Photo of the idle speed sensor (IAC)

The idle speed sensor is located at number 3. Next to number 4

HOW TO REPLACE THE IDLE SENSOR VAZ 2115

If a sensor malfunction is detected, it is recommended to replace it with a new one. After repair, no one guarantees a long service life, and the price of a new one is about 350 rubles. What is needed to replace the sensor on a VAZ 2115:

- New sensor;

- A little oil;

- Crosshead screwdriver.

Step-by-step instruction

So:

- First, we place the car on a level surface.

- Then tighten the handbrake.

- We open the hood and find the XX regulator located on our throttle body.

- Turn off the ignition and disconnect the terminals from the battery, otherwise a short circuit may occur in the entire electronic system of the engine.

- Disconnect the block with wires from the sensor.

Disconnect the block with wires

- To simplify the work of replacing the sensor, we dismantle the entire throttle assembly.

- The regulator assembly is secured with three bolts.

- Unscrew them using a Phillips screwdriver.

Unscrew the screws securing the unit using a Phillips screwdriver

- Remove the throttle assembly.

Removing the knot

- After this, carefully remove the regulator.

Carefully unscrew the regulator

- Before installing a new engine XX sensor, it is necessary to thoroughly clean the air channel inside the throttle assembly and the surface where the sealing ring is installed from dust and dirt.

- If you find cracks on the o-ring, abrasions or damage, then it is better to replace it.

- Before installation, lubricate the O-ring with engine oil.

- We install the ring on the surface of the throttle assembly (see photo above).

- Then we install the new sensor there all the way and carefully tighten the fastening screws.

- Also, don’t forget about the wiring harness mounting bracket.

- We install the throttle assembly back and screw it on.

- We carefully check the tightness and correct fit of all sections several times. We put the terminals on the battery and then check the smooth operation of the engine.

How to choose a new one

We select a new sensor based on one important parameter - the distance between the mounting flange and the tip of the valve needle, it should be 2.3 centimeters. The manufacturer can be any, here you can guide yourself based on experience.

Replacing the Idle Air Controller - step-by-step instructions with photos

Idle speed sensor for VAZ 2107 injector

As we wrote above, pxx is located on the throttle body. Remove the decorative engine cover.

Disconnect the tube inserted into the air duct as shown in the figure.

Next, loosen the clamp and remove the air duct from the throttle valve.

Carefully remove the throttle cable as in the photo

Now you need to unscrew the throttle assembly, if you manage to get to the sensor this way, then you don’t have to remove the throttle.

The throttle assembly is secured to two 13mm bolts

Now after removing the throttle, we can easily remove the rcx and install a new one.

Before installing the new px, clean the mounting hole. It is advisable to lubricate the O-ring with oil.

After installing the pxx, we reassemble in the reverse order.