Types of idle speed sensors

Today, automobile manufacturers present several types of IACs:

- Solenoid sensor. It works based on electromagnetic force. After voltage is applied to the coil, the core is hidden. The valve flap allows air to flow freely inside. Once the solenoid is turned off, the peripheral channel is blocked.

The operation of the sensor is monitored due to the dynamics of the frequency of command signals. A certain amount of air has its own frequency equivalent, which allows you to clearly regulate the operation of the IAC.

- Stepper. The technical structure of such a sensor includes a ring magnet and windings. Due to the stepwise supply of voltage to each element, under the influence of a magnetic field, the main rotor rotates. The executing mechanism, depending on the position of the rotor, controls the opening of the air duct.

- Rotary sensor. Control occurs through alternating frequency pulses. It is very similar in structure to the solenoid IAC, but the main place in the design is occupied by the rotor itself.

The process of cleaning the idle speed sensor

To stabilize the operation, a cleaning process is required, especially if during inspection you find a clogged needle or throttle valve. To clean the contacts, use a cotton pad: after dipping it in alcohol, wipe them off.

Clean the cone needle with carburetor cleaner or WD-40. After generously spraying the needle, let it dry, after which you can install the part back.

Cleaning the throttle body will take a little more time, but will also not be labor intensive. You will need any cleaning agent: gasoline, solvent, carburetor cleaner, WD - 40. Also use a rag and a brush. Be sure to remove the air filter bell before cleaning, and do not forget to clean the damper on both sides.

Purpose of the IAC regulator

The idle air regulator is used exclusively in electronic ignition systems:

- the proportions of the fuel mixture in the injector are determined by the on-board computer;

- the amount of gasoline or diesel fuel for each cylinder is measured by the ECU;

- sensors are installed in the electronic ignition

DPKV(crankshaft),

TPDZ

(throttle valve),

Mass air flow sensor

(air), DD (detonation), based on the signals of which the fuel pump is activated and the ignition is distributed to specific cylinders;

- when the gas pedal is released, the fuel damper is completely closed, the proportions of the fuel mixture are violated, combustion products are sucked back into the combustion chamber due to the pressure difference between

intakeAnd

exhaust manifold

Purpose of the IAC

Based on the results of the air sensor signals, the controller makes a decision to further enrich the fuel mixture with air, ignoring the readings of the throttle sensor at this moment.

The chip on the IAC transmits a signal from the ECU; a bypass channel opens in the idle air regulator, through which air passes in the injector or additional fuel in the diesel engine. Engine speed is leveled, piston and crankshaft wear is reduced

Selecting a new idle speed sensor

There are no particular difficulties in choosing a new device. There are also no special nuances in selecting a sensor depending on the country of assembly of the car. When choosing a device, you should pay attention to the manufacturer, about which a little later. To be sure that the regulator will fit your engine, you should consider one of the following when choosing:

- Vehicle data: make, model, as well as internal combustion engine parameters, year of manufacture;

- Code of the existing idle air control;

- Vehicle VIN code.

Today, more and more car enthusiasts are looking for spare parts based on their vehicle data. This search method has become incredibly convenient thanks to the development of online stores . However, they also implement search by codes. As stated above, preference should be given to regulators from well-known manufacturers . For example: Bosch, Valeo, Continental, VDO/Siemens. Cheaper devices from Era, LCC and other lower-tier companies have a significantly shorter service life, so there is little point in saving. You should only be wary of fakes.

Operating principle

In carburetor engines, the problem of enriching the mixture when starting the internal combustion engine was solved by a starting handle and shims. With the advent of electronic ignition, this is done by the idle air regulator in conjunction with other sensors and the computer. Its operating principle is as follows:

- IAC calibration is performed by the ECU controller automatically after detecting this sensor in the system;

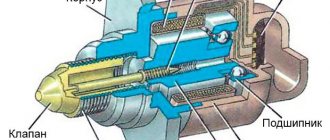

- in fact, the IAC is a stepper motor with a conical needle in a special hole in the throttle valve bypass channel;

- The IAC contact does not transmit any signals to the “brain” of the machine, but receives them from the controller, therefore it is not a sensor, but an actuator - an electric valve;

- in turn, the on-board computer “sees” that there is not enough air in the fuel mixture based on the signals from the mass air flow sensor, compared with the signals from the air flow sensor;

- Voltage is applied to the XX regulator, the needle leaves the channel, and the missing amount of air enters the mixture for mixing.

Operating principle of the IAC

In addition, the ECU receives signals about the temperature of the coolant and oil in the system. When starting in the cold season, it is necessary to warm up the engine to operating temperature in order to reduce wear on friction parts, so the IAC channel opens slightly to enrich the mixture for the injector, even without the driver pressing the gas pedal.

At the moment of start, the operating algorithm is as follows:

- the key turns, the ignition turns on;

- the rod extends all the way, the needle blocks the bypass channel;

- at the moment the rod rests against the calibration hole, the computer counts the steps backward;

- voltage is applied to the windings, the valve returns to the open position.

The number of reverse steps is programmed in the device firmware. For example, for Basch modifications on a warm internal combustion engine it is 50 steps, January – 120 steps, respectively. In total, the stroke of the rod is divided into 250 steps; the further it extends from the windings of the stepper motor, the greater the number of steps the ECU will count. When purchasing a new IAC, the distance from the mounting flange to the rod needle should be exactly 23 mm.

How to replace the idle speed sensor

Before starting work, remove the negative terminal from the battery. Disconnect the four-pin connector from the sensor to be replaced by first pressing the plastic latch (if available). Remove the pair of screws securing the regulator. Take a new device, lubricate the o-ring, spring and rod with engine oil: this will increase the life of the regulator.

Now you need to calibrate the newly installed product. To do this, put the negative battery terminal in place and turn on the ignition for 15 seconds without starting the engine. During this time, the control unit will calibrate automatically. Next, start the engine and check how the sensor functions on a running power unit. If the idle speed is higher than normal, then the procedure must be repeated (possibly more than once). With the idle speed control operating normally on a cold engine, the tachometer will show approximately 1000 rpm. After reaching operating temperature, they will drop to around 800 rpm. It is worth noting that discrepancies with these indicators may be caused by the use of low-quality fuel.

Signs of a malfunctioning idle speed sensor

The main problem will be that this part is not equipped with any type of self-diagnosis. On the control panel you will not see a flashing light or an inscription that will indicate a malfunction of the IAC. Everything will depend on your attentiveness and how you feel and hear your car. Signs that indicate that a part is worth checking include:

- the car began to stall at idle (uneven idle speed);

- a sharp drop or increase in speed during idle;

- when driving on a cold engine, the speed does not increase;

- When changing gear, the car stalls.

There are few reasons why the IAC failed. As they said earlier, this is a fairly reliable part, but it can still fail. There may be several reasons for the malfunction:

- The guide needle is worn.

- Broken contacts inside the part.

- The needle is clogged due to poor quality fuel.

As we all know, fuel is one of the most important components of the operation of both the engine and the car as a whole, and the idle speed sensor is no exception. Most of the reasons for part failure are the use of gasoline with impurities.

A malfunction and inadequate operation of the XX sensor is indicated by any changes in the engine speed. If the part fails completely, you will not be able to start the car without using the gas pedal. And such a procedure will negatively affect the operation of the vehicle as a whole. Manufacturers do not recommend this practice for nothing.

Operating principle of the idle speed sensor (IAC)

The moment we turn on the ignition, the rod on the idle speed control fully extends and rests against a special calibration hole in the throttle pipe. Afterwards, the sensor counts the steps and returns the valve to its original position. The position of the initial valve depends on the firmware: for example, January 5.1 - 120 steps on a warm engine, Bosch - approximately 50 steps on a warm engine.

On a warm engine at the time of adjustment, the sensor is at around 30-50 steps. As the steps increase or decrease, the volume of air passing through the calibration hole constantly changes. Moreover, if the rod is extended, then the steps increase and vice versa. The stroke of the rod is 250 steps.

At the time of purchasing an idle speed sensor for a VAZ, the distance from the rod head to the flange should be no more than 23mm. Carefully measure the length of the protruding head.

The engine receives a certain amount of air necessary for normal engine operation, thereby regulating the idle speed.

The incoming air is analyzed by the mass air flow sensor (MAF) and, in accordance with its quantity, the Controller supplies the required amount of gasoline to the engine through the fuel injectors. Using the crankshaft position sensor (CPS), the controller monitors the engine speed and controls the idle speed control. This is how the process of supplying the required volume of air occurs.

On a cold engine, the controller increases the speed due to the idle speed sensor (IAC) and increases the engine speed when warming up. This mode allows you to immediately start moving without warming up.

It is recommended to install an idle speed sensor from the Omega group with the number 2112-114830. Also quite good RXX 2112-1148300-04 “KZTA”. It is worth noting that when purchasing you need to pay attention to the end mark 04. Sensors are produced with mark 01 02 03 04, so look at the mark of the old sensor and purchase the same one. If you put, for example, a sensor labeled 04 instead of 01, the sensor will not work. The following replacement is allowed: 01 to 03, 02 to 04 and vice versa.

Preventive measures

In order not to encounter a complete malfunction of the regulator in the future, it is worth periodically carrying out the cleaning process described above.

How often to carry out the cleaning process depends on how actively you use your vehicle. If the car is a work vehicle, it is recommended to check and clean the sensor once a year; if you use it only for yourself, once every two years will be enough. But, of course, do not forget about the signs of a part malfunction; if they appear, do not delay. This will help you avoid complete failure of the part and enjoy a high-quality ride. Together with you, we come to the conclusion that the part is unpretentious, simple in its functionality and use. Don’t forget: timely detection of a malfunction is the key to overall vehicle productivity. The full operation of the engine depends on the serviceability of each of its components, and if you neglect any part, including the idle speed sensor, this can lead to more labor-intensive repair processes and failure of the entire car.

Checking the idle speed sensor

Diagnosing the part is quite easy, but pay attention to a few points. The first problem may be removing the part; most manufacturers attach the XX sensor to screws, and in extreme cases they can be drilled out, but in some variations the part is mounted on varnish. If your regulator is secured with varnish, be careful not to forcefully remove it, as this may damage the intake part of the car. In your case, it would be correct to completely dismantle the throttle assembly and only then disconnect the IAC.

The easiest way to check is, of course, visual inspection. During a visual inspection, the first thing you should pay attention to is whether the needle is dirty. Also pay attention to the condition of the contacts and the throttle valve itself.

If broken wires are found, they must be returned to their place. Solder them and, to avoid corrosion, treat them with varnish.

It would be appropriate, if possible, to check the IAC with a multimeter or a homemade tester. You can check the resistance with a multimeter, and use a homemade tester (you can make one from a mobile phone charger) to check the stroke of the regulator rod.

If you find that the motor is damaged, the rod is completely worn out, or the cone needle is worn out, the part will need to be replaced. Don’t be too upset about this, the cost of the part will only be about 1000 rubles.

Sensor diagnostics

You can check the idle air valve yourself. Its faults can be divided into two parts: mechanical and electrical. There are several verification methods.

Visual inspection

First you need to conduct a visual inspection. In this way, you can detect body defects, needle wear, and carbon deposits. If deposits form, you can clean them with carburetor cleaner. It is also recommended to clean the entire throttle body as it is in a similar condition.

Using diagnostic programs

The operation of the IAC can be checked using a diagnostic adapter and special programs. For example, you can use the simplest ELM327 adapter and the OpenDiagMobile program. In the program menu you need to select the desired position of the XX regulator and watch the operation of the valve. It is better to set it at least 20 steps more than the current position.

Wiring check

For this we need a multimeter. With the engine off, remove the connector from the sensor. We set the measurement limit on the measuring device to 0-20 V DC voltage. We measure the voltage at the connector. Normally it should be 12V.

Checking the regulator resistance

To do this, we will need to measure the resistance between terminals A, B, and C and D after disconnecting the sensor terminal. We move the multimeter to the position of measuring resistance at the limit of 0-200 Ohms (Ω).

The normal value is within 50-55 Ohms. The resistance between A and C, B and D must be infinity.

Checking with throttle assembly

There is another way to diagnose IAC. To do this, you will need to remove the throttle assembly from the studs along with the sensor.

By connecting the valve connector and turning the ignition on/off, you can observe the operation of the IAC live. See how the needle works, if it is rubbing somewhere, check the evenness of the stroke, hear suspicious sounds.

Diagnostics of IAC on a carburetor engine

Locate the solenoid valve that is screwed into the side of the carburetor. Turn on the ignition and disconnect the wire from the valve, then connect again. Characteristic clicks should be heard. Their absence (provided there is a voltage of 12 volts on the wire approaching the valve) indicates a malfunction of the device.

Manual diagnosis

This is the simplest method and requires a helper to implement it. Algorithm of actions:

- remove the IAC plug from the socket;

- remove the regulator;

- reconnect the connector while holding the IAC in your hands;

- ask an assistant to start the engine: the rod of a working device will completely enter the solenoid at the moment of starting, and then extend back to a certain distance.

Using this method, you can check the functionality of the needle and the integrity of the coil windings. However, it is impossible to determine the consistency of the firmware: the needle must extend to a strictly defined distance. If we follow the principle “from simple to complex,” then the initial stage of testing is discussed above. What's next?

How to check the idle speed sensor using a multimeter

You will need a tester that measures resistance and voltage. To determine possible malfunctions of the idle air regulator, touch contacts C, D and A, B with probes: the tester should show 40-80 Ohms. Next, measure the resistance between pins A, D and C, D: it will be infinitely large. Now turn on the ignition and set the multimeter to voltage measurement mode. Between contacts A, B and C, D, the voltage should be between 12-20 volts.

IAC diagnostics on a homemade stand

If you have minimal experience in soldering radio components, then you can assemble the simplest circuit yourself. For this you will need:

- solder with flux;

- soldering iron;

- mobile phone charger;

- non-polar capacitor 10 µF for a voltage of at least 10 volts;

- plug block from IAC;

- 6 V light bulb;

- any switch with two positions.

This “stand” will help you check the device using impulses. Connect one of the “charging” terminals through the connector to contacts A and C of the idle speed sensor. Connect a light bulb in series to the second wire of the power supply - connect a toggle switch to its other contact. Solder a capacitor parallel to its terminals, which must be simultaneously connected to contacts B and D. Connect the unit to a 220 V network and click the toggle switch: a bright glow of the lamp indicates a malfunction of the regulator, but if it is lit at full intensity, the IAC is normal.

Folk method

Implementation of this method is only possible with an assistant:

- The sensor is being dismantled. To do this, it is usually enough to unscrew the fixing bolts.

- A four-pin connector is connected.

- A finger is applied to the end of the sensor needle; no serious effort is needed.

- The assistant gets behind the wheel and the ignition is activated. When turned on, the controller should extend the needle. If this happens, then the regulator is operational. Malfunctions should be looked for in the functioning of the throttle position controller.

Method for checking the sensor using a multimeter

The most reliable and common way to check the functionality of the sensor is to use a multimeter. But to do this, the regulator must first be removed. Typically, it is secured with several screws near the throttle sensor, but on some cars it can be secured with a special solution or varnish.

It is impossible to dismantle the IAC using force, since there is a high risk of damaging the intake system. In such a case, you will have to remove the entire throttle assembly.

To check the electric motor, it is necessary to measure the resistance of the windings. The multimeter contacts must be connected in turn to each of the windings A and B, C and D. If everything works properly, the data obtained will fall in the range of 40–80 Ohms.

As an additional check with a multimeter, the contacts can be swapped. The sensor, in this case, should indicate an open circuit.

IDLE SENSOR CONTAMINATION

Often the cause of improper operation of the idle air regulator is its contamination. In such a situation, you can replace the sensor (which is inexpensive) or clean it. Cleaning the idle speed sensor takes place in two stages: You need to moisten a cotton swab with a special product (for example, which is used to clean a carburetor) and use it to clean the contacts of the sensor. This must be done carefully so as not to damage them; The remaining parts of the regulator can be cleaned mechanically using the product indicated above. Moisten a toothbrush with it, for example, and carefully clean the needle, rod, spring, removing accumulated dirt.

How to check the idle air control

The malfunction of this device in cars equipped with an on-board computer can be determined by the error code it produces. For example, for a VAZ2114-15 it is 0505 (IAC malfunction). The numbers 0507 indicate excessively high crankshaft speeds, and 0506 indicate low ones. The ideal option is to test the idle air control at a special stand in a car service center. However, this is quite expensive, especially considering the relatively low cost of the IAC itself. Therefore, it is worth considering the available verification methods.

Diagnostics of IAC on a carburetor engine

Locate the solenoid valve that is screwed into the side of the carburetor. Turn on the ignition and disconnect the wire from the valve, then connect again. Characteristic clicks should be heard. Their absence (provided there is a voltage of 12 volts on the wire approaching the valve) indicates a malfunction of the device.

Manual diagnosis

This is the simplest method and requires a helper to implement it. Algorithm of actions:

- remove the IAC plug from the socket;

- remove the regulator;

- reconnect the connector while holding the IAC in your hands;

- ask an assistant to start the engine: the rod of a working device will completely enter the solenoid at the moment of starting, and then extend back to a certain distance.

Using this method, you can check the functionality of the needle and the integrity of the coil windings. However, it is impossible to determine the consistency of the firmware: the needle must extend to a strictly defined distance. If we follow the principle “from simple to complex,” then the initial stage of testing is discussed above. What's next?

How to check the idle speed sensor using a multimeter

You will need a tester that measures resistance and voltage. To determine possible malfunctions of the idle air regulator, touch contacts C, D and A, B with probes: the tester should show 40-80 Ohms. Next, measure the resistance between pins A, D and C, D: it will be infinitely large. Now turn on the ignition and set the multimeter to voltage measurement mode. Between contacts A, B and C, D, the voltage should be between 12-20 volts.

IAC diagnostics on a homemade stand

If you have minimal experience in soldering radio components, then you can assemble the simplest circuit yourself. For this you will need:

- solder with flux;

- soldering iron;

- mobile phone charger;

- non-polar capacitor 10 µF for a voltage of at least 10 volts;

- plug block from IAC;

- 6 V light bulb;

- any switch with two positions.

This “stand” will help you check the device using impulses. Connect one of the “charging” terminals through the connector to contacts A and C of the idle speed sensor. Connect a light bulb in series to the second wire of the power supply - connect a toggle switch to its other contact. Solder a capacitor parallel to its terminals, which must be simultaneously connected to contacts B and D. Connect the unit to a 220 V network and click the toggle switch: a bright glow of the lamp indicates a malfunction of the regulator, but if it is lit at full intensity, the IAC is normal.

Cleaning the needle and bypass channel

To provide access to valve parts, removal of the IAC is required using the following technology:

- disconnecting the block from the connector;

- cleaning the connector contacts and plug with a cotton swab soaked in WD-40;

- unscrewing screws with a curved screwdriver;

- removing the regulator to check the condition.

IAC cleaning

Attention: There is no need to disassemble the regulator, just spray the spring and rod with needle with WD-40 spray, wait for it to dry, and at the same time clean the throttle bypass channel.

The adjustment is made by the on-board network controller itself. However, for stable operation of the engine, you should check the distance from the mounting flange to the protruding needle cone. By default it should be 23 mm.

Nuances of choosing an idle speed sensor

The original idle speed sensor is marked as XX-XXXXXXXX-XX. The last two digits indicate the compatibility label:

- odd (01 and 03) are interchangeable, even (02 and 04) are also interchangeable;

- These groups are not interchangeable with each other, that is, instead of the “native” 02, valve 01 or 03 cannot be used.

Even with original regulators, it wouldn’t hurt to additionally lubricate the IAC with a mixture of lithol and WD-40 (spring and rod). Since replacing IACs with your own hands is in demand among car enthusiasts, there are counterfeit regulators that can be identified by the following characteristics:

- there are no distinctive marks on the packaging;

- yellow sticker on the body without frame;

- dark needle tip;

- thin black o-ring instead of thick red seal;

- body rivets do not have heads with a diameter of 3 mm;

- a white spring instead of a black product with frequent winding;

- the body is 1 mm shorter.

An example of a counterfeit IAC

Since installation is always done on your own, additionally lubricate the rod and spring to increase the service life of the IAC and the entire engine.

Thus, it is better to have an IAC solenoid valve costing 300 - 500 rubles in stock in order to replace it in the field to normalize the idle speed of the internal combustion engine. These diagnostic methods will allow you to determine a malfunction of the regulator and a clogged bypass channel of the throttle valve.

Operating principle of the idle speed regulator (sensor)

Let's consider the principle of operation of the idle air control (IAC) using the example of the IAC (idle air sensor) of the ECM of VAZ 21083, 21093, 21099, 21102, 2111 cars.

The principle of operation of the idle speed controller and the order of its operation in different modes

Based on a signal from the controller (ECU), at different engine operating modes, the idle speed regulator, by moving the rod tip, changes the size of the flow area of the bypass channel through which air is supplied to the throttle valve. The maximum extended position of the rod is the initial position (zero step). It can be observed with the engine not running and the ignition off. In this position, the cross-section of the bypass channel is completely blocked by the tip, and air does not flow under the throttle valve. A fully retracted rod corresponds to 255 steps of travel and a fully open bypass passage.

— IAC operation when starting the engine

When starting and warming up the engine, when the throttle valve is completely closed, the controller, based on the readings of the temperature sensor, using the IAC, slightly opens the access of the required amount of air to maintain increased idle speed. As the engine warms up, it reduces the amount of incoming air - the speed drops to normal.

— IAC operation at idle speed

On a warm engine, with the throttle valve closed, the controller, using IAC, provides the required idle speed. The regulator rod is retracted, the bypass channel is completely open.

— IAC operation in medium and full load modes

When you press the gas pedal and open the throttle valve, air begins to flow into the engine intake manifold through the throttle valve section, and the IAC is set to a position in which, when the gas is released and the throttle valve is abruptly closed, a smooth reduction in engine speed to normal would be ensured. To determine the number of IAC steps in a given situation, the controller uses the readings of the crankshaft position sensor (crankshaft rotation speed), throttle position sensor (current throttle position), speed sensor (the car is moving or standing), etc. .

IAC operation in power modes

— IAC operation with increasing load

When the load increases (turning on the cooling system fan, air conditioning compressor, etc.), the controller, using the IAC, increases the required volume of air entering the engine to ensure its power characteristics and prevent “failure” of speed in idle mode.

Notes and additions

— The idle air control is an element of the engine control system (ECM). This is an actuator. With its help, the control unit (ECU) regulates the amount of air entering the engine cylinders.

Twokarburators VK - More information on the topic in our VKontakte group, on Facebook Twokarburators FS and on Odnoklassniki - Twokarburators OK

More articles on the principle of operation of elements of the electronic engine control system (ECM)

— Checking the idle speed controller ECM VAZ 21083, 21093, 21099

Where is the idle speed sensor located?

The location of the sensor may vary slightly depending on the make of your car. In order not to describe for a long time, it is best to understand where the idle speed sensor is located, it is better to look at the picture below.

Typically, a bad or faulty idle air control valve will cause several symptoms that alert the driver to a potential problem:

- Irregular idle speed

One of the most common symptoms associated with a problematic idle air control valve is an irregular idle speed. The idle air control valve is programmed to regulate and maintain a constant engine idle speed. If the valve fails or has any problems, it can cause the idle speed to reset. This can result in an unusually high or low idle speed or, in some cases, a high idle speed that continually rises and falls.

- Check if the engine light comes on

Another sign of a potential problem with the idle air control valve is the check engine light coming on. If the engine control module detects a problem with the idle air control valve circuit or signal, it will turn off the check engine light to notify the driver that there is a problem. The Check Engine Light can also turn off due to a variety of problems, so it is recommended that you check your vehicle's computer for trouble codes.

- The engine stalls

Another more serious sign of an idle air control valve problem is the engine stopping completely. If the idle air control valve fails completely, it may leave the vehicle because there will be no air source to maintain a proper idle. This can cause the engine to stall while running, and in some cases can cause the engine to not idle at all and stall when starting.

If your car has any of the symptoms listed above, or you suspect that your idle air control valve may have a problem, it is better to contact a specialist or check it yourself, more about checking the idle air control valve below.

Advice

If the engine speed is too high, too low, or too short, the problem may not be with the idle control system, but with engine leakage. First, check your vehicle for vacuum leaks to rule out this possibility.