What to do if your car has symptoms of a “dead” air flow sensor? Before going to a service station or store for a new expensive sensor, try checking it yourself.

The mass air flow sensor (MAF or MAF-sensor) controls the volume of incoming air into the intake system of the internal combustion engine to create a fuel-air combustible mixture. This allows you to get maximum engine power with minimal fuel consumption. The correct operation of all other interconnected engine systems depends on the readings of the mass air flow sensor.

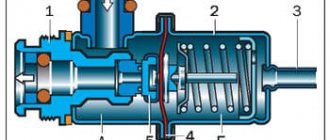

The principle of operation of the mass air flow sensor

Most mass air flow sensors have two highly sensitive heating filaments (thermistors). The filaments are made of platinum or tungsten, and an electric current is applied to them to heat them to a certain temperature.

One sensor thread is located directly in the air line, and the second is protected by a special screen from direct air flow. When the engine is running, the air flow passing through the sensor cools the exposed filament more. As a result, a temperature difference arises between the thermistors, and an open thread requires more current to restore the required temperature.

Taking into account the cooling intensity of the thermistor and the difference in readings between the threads, the electronic control unit (ECU) calculates the amount of air entering the intake tract and determines the required amount of fuel for stable engine operation. Many mass air flow sensors additionally have a built-in air temperature sensor entering the intake tract, which allows you to take more accurate readings.

Some MAF sensors use either a sputtered ceramic heating element or a semiconductor film instead of highly sensitive filaments. But the principle of operation of the sensor remains the same.

Where is the MAF located?

The mass air flow sensor is located in the vehicle's intake tract, between the air filter and the throttle valve, and is mounted directly on the air filter housing.

The presence of a malfunction and its absence

Using the instructions, you can easily test the mass air flow sensor. Let's look at a couple of options and start with the most optimal one. While the engine is running, it is necessary to disconnect the sensor connection connector on the on-board system. If the engine is turned on, the system will begin to operate in emergency mode. Now the volume of air supplied does not matter, but how the throttle valve is located, on the contrary, is important. After disconnecting the sensor, try to drive the vehicle. When you feel an increase in dynamics, it is recommended to take a serious approach to solving this problem. The next step will be a visual check of the DMVR. You need to check all corners and crevices for dried oil, liquid on the surface and dirt. If you find something like this, clean the equipment as soon as possible and resolve the issue with leaking oil. To ensure accurate results, purchase a multimeter. The 2V reading is a DC voltage measurement. When you see a green and yellow wire, connect your multimeter to them, but often the colors are different. The connector sequence is one and three. If the ignition is turned on and the engine is turned off, the sensor voltage will be from 0.996 to 1.01 V. You need to beware of a value that sets the bar too high. There are frequent cases when with an indicator of 1.05 you can say goodbye to the mass air flow sensor, and flushing is powerless here. Isn't it true that such sensor control is effective? Having received an analysis of the results, you can safely begin further work.

Symptoms of a faulty air flow sensor

If the mass air flow sensor begins to produce incorrect data, then a failure occurs in the system for preparing the fuel-air mixture, and the proportions of fuel and air are disrupted. This results in the following symptoms of a malfunction:

- Unstable idle speed

- Violation of the smooth running of the car

- Difficulty or impossible to start the engine

- Noticeable deterioration in vehicle dynamics

- Increased fuel consumption

- The yellow "Check Engine" light on the instrument panel does not go out

Check engine light on the instrument panel

If the Check Engine light is constantly on on the instrument panel, the easiest way to check, if you have a diagnostic tool, is to read the error codes, which will allow you to pinpoint the problem. One of the most common DMRV errors is error p0100. Explanations of diagnostic codes can be found in the technical literature for a specific vehicle.

None of the above symptoms are a 100% guarantee that the mass air flow sensor has failed. Other vehicle systems may also be to blame. But all these symptoms together, or each one separately, give reason to check the flow meter for performance.

How to determine a faulty air flow sensor

The easiest way to check the functionality of the air flow sensor is to disconnect it from the system. As a rule, this method shows almost 100% whether the element is working or not.

First you need to start the car and warm up the engine a little by accelerating. After about 3 minutes, turn off the engine and remove the sensor terminal. We return to the salon and start the car again. If the speed increases noticeably, then the mass air flow sensor is faulty.

Also, having removed the sensor, you will notice a faster increase in speed when accelerating with the pedal than was the case with the sensor. If the mass air flow sensor is not replaced in time, the fuel mixture will be too rich, which will lead to oil dilution and engine overheating.

Dismantling, cleaning and assembly

I would like to say right away that the opinions of professionals differ. Some people think that this process is very useful, while others say that this type of repair will make the problem worse. However, do it carefully and everything will be fine. The following is not permitted:

3. Cotton swabs.

4. Compressed air.

In almost every market you can buy a solution for cleaning WD40 and carburetors. Now we will tell you how to properly clean the equipment so that you don’t have to buy a new one, since a mass air flow sensor costs about 2,000 rubles. If you do not remove the pipe, you will not be able to properly clean the sensor. You need to have star keys of various sizes with you. Next, after unscrewing all the screws and bolts, remove the sensor from the pipe. Don't be alarmed or surprised; there will be a lot of oil on the surface of the sensor. This is great, since you have every chance to repair the equipment yourself without purchasing a new one. With the solution we mentioned earlier, spray the sensor wires that are held in place by the resin. We are waiting for everything to dry. If necessary, repeat the process one more time. Without carburetor fluid, you can use alcohol. When you have cleaned the sensor, move to the mesh of the pipe, and then to its inner surface. Change the air filter and proceed to assembly. At the end of this process, the sensor readings may change.

Now you have an idea of how the mass air flow sensor is cleaned and you have seen that this equipment is fragile and significant. By performing systematic checks, frequent malfunctions can be eliminated.

The price of a mass air flow sensor (MAF) stands out among other car spare parts and is about 2000 rubles. If the diagnostics revealed an error in the mass air flow sensor, then do not rush to change it, try to restore the mass air flow sensor yourself .

First you will need to remove the pipe from the mass flow sensor (instructions). Next, you need to remove the mass air flow sensor from the pipe, otherwise it will not be possible to perform high-quality cleaning. To remove the sensor, you will need a set of sprocket wrenches. Unscrew the screws and pull the sensor out of the pipe. You can often find that the inside of the sensor itself is covered with an oil coating; our task is to make everything perfectly clean. To clean the air flow sensor from this deposit, a carburetor cleaner is suitable. On the inside of the film there are 2-3 sensors, which are small wires that are attached using a special resin. We carefully spray this sensitive element so as not to damage it. We wait a while for the product to dry. We repeat this procedure several times, depending on the contamination of the air flow sensor. To speed up drying, you can use a compressor/can of compressed air, but the point is not in high pressure, but in blowing for drying. Flushing the air flow sensor can also be done using other means, for example, alcohol. In addition to the sensor, it is worth paying attention to both the mesh of the pipe and its inner surface. If necessary, clean the air flow sensor pipe from dirt, debris and dust. This the MAF repair . We perform the assembly in reverse order and change the air filter.

As practice shows, out of 10 sensors, 8 can be restored by cleaning. In any case, it’s worth a try, because the price of a cleaning agent is 10-15 times less than the cost of a new sensor.

Video on cleaning the air flow sensor :

By the way, before you buy a new sensor or try to repair the mass air flow sensor . It would be better to diagnose it first.

How to check the air flow sensor (3 ways to check)

In some cases, to check the mass air flow sensor, it must be removed from the car. Dismantling procedure:

- Loosen the clamp

- Remove the air pipe,

- Unscrew the screws securing the sensor to the air filter housing.

- Before disconnecting the electrical connector, you must remove the negative terminal from the battery. This must be done so that the electronic engine control unit does not generate an error and the check lamp does not light up.

Method number 1. Visual control

To do this, you need to remove the sensor and carefully inspect it for mechanical damage or foreign objects or debris. It is also worth visually assessing the integrity of the heating filament sensors or heating film.

Such problems can arise due to a leaky air filter housing, or due to a poor-quality air filter.

If visible damage is detected, the sensor must be replaced. And if there is debris or dirt in it, the air flow sensor can be cleaned with special products or a carburetor cleaner (alcohol-based spray). Mass air flow sensors are very fragile, so be careful not to clean them mechanically. The sensor cannot be repaired!

Method number 2. Power off

The easiest way to check the mass air flow sensor is to disconnect power from it. With the engine not running, disconnect the electrical connector on the mass air flow sensor. Then we start the engine.

In this situation, the engine control unit switches to backup mode and replaces the readings of the disabled sensor with those programmed by the manufacturer.

In this case, engine operation should normalize and idle speed should increase. For additional checking, you can drive a car with the MAF connector disconnected - 100-200 meters. If all symptoms of a malfunction of the mass air flow sensor have disappeared, then the sensor is transmitting incorrect data - it is considered inoperative and requires replacement.

When checking the mass air flow sensor in this way, after disconnecting the electrical connector from the sensor, the “Check” engine error lamp will light up on the instrument panel. After completing the check or replacing it, you will need to reset the error! To do this, you can disconnect the negative terminal of the battery for a few minutes (carefully, absolutely all settings will be lost). In some car models, the error can only be reset at a service center using a special scanner connected to the car’s diagnostic connector.

Method number 3. Checking with a multimeter

To check the air flow sensor with a multimeter, you need to know which parameters to measure and from which contacts of the electrical connector. They may differ for each car brand. The location of the sensor wires and terminals can be found in the vehicle's electrical diagram.

For example, on Bosch sensors that are installed on VAZ and GAZ cars, you can check the voltage (V) between the incoming signal and ground at the mass air flow sensor connector. To do this you need:

- Turn on the car ignition, but do not start the engine,

- Connect the red (+) probe of the multimeter to the yellow wire,

- The black (-) probe goes to the green wire of the connector.

- We set the mode switch on the multimeter to measure the minimum direct current.

The voltage at the contacts should be between 1.00-1.04 Volts . If the readings are higher, the sensor requires replacement.

Additionally, you can remove the sensor without disconnecting the electrical connector and apply a stream of air to the sensor from the air filter side. The voltage should increase to 1.3 Volts , in which case the air flow sensor is considered working.

Depending on the sensor design, it is still possible to measure the resistance on the resistors. Moreover, the measurement results at different air temperatures will be different. Accurate data on the optimal values of resistance readings, measurement temperatures and the location of contacts on the connector are usually indicated either in special technical literature or in the car repair instructions.

The most popular DMRV malfunctions

The main signs of a malfunction of the mass air flow sensor:

- Problems with the flow meter can be reported by the Check Engine indicator, which appears on the dashboard inside the car.

- Depending on the type of device and machine, an icon may appear on the control panel indicating a low level of the air flow sensor signal.

- The power unit began to work intermittently. When the sensor is disconnected, the car stalls or the engine speed begins to jump up or down. The power of the internal combustion engine decreases, the car has difficulty accelerating, especially when moving uphill.

- Increased fuel consumption.

- When changing gears on the gearbox, the engine randomly stops.

A faulty sensor can be determined by the integrity of the housing. The presence of damage on it, as well as on the corrugated line, may indicate problems with the controller. We are talking about the pipe that connects the regulator to the throttle valve. If the engine randomly stalls during operation, this may indicate a malfunction in the power line.

If the air quantity and distribution control device is faulty, then the symptoms of the breakdown may be similar to errors in the operation of the air filter.

Reasons why the device fails:

- the sensor is not connected to the machine's power supply;

- break or damage to the power supply circuit;

- malfunctions in the operation of the controller can be caused by malfunctions in the functioning of the engine control unit;

- incorrect connection of signal cables or their breakage;

- oxidation or damage to contact elements.

If all else fails, buy a new air flow sensor

All testing methods showed the same result - “Sensor to be replaced.” The mass air flow sensor is quite expensive, and you should approach its purchase consciously.

Using the example of the same manufacturer Bosch for LADA and GAZ (article 0280218037) - according to the search results on the GisAuto portal as of September 18, 2021, 568 offers from different cities were found in Russia. The cost of this sensor varies from 2,490 rubles. up to 6,676 rub. Such a range in prices may depend on various reasons: availability, delivery time, purchase cost, etc.

You can select a mass air flow sensor for your car on the GisAuto portal - you can use the part number, make and model of your car, and also create a request using the VIN number of the car, and then the sellers themselves will send you their offers. All you have to do is choose the option that suits the price and time frame.