What is TPDZ

The throttle position sensor monitors the position of the throttle valve. The throttle valve is a valve that is located between the air duct pipe and the intake manifold. The damper regulates the air supply to the manifold. Position sensors are installed on all vehicles that have electronic fuel injection control.

The main purpose of the position sensor is to let the ECU know what position the damper is in. Thanks to this information, precise dosing of the mixture occurs, optimizing the flow rate relative to the position of the accelerator pedal. To put it simply, the TPS sets the amount of fuel injected into the cylinders by the injectors. Fuel consumption depends on the serviceability of this element. If there are suspicions about an increase in fuel, then it is necessary to resort to checking the TPS on Lanos.

How to adjust the throttle position sensor?

After replacing the throttle position sensor, it is adjusted, this will ensure proper operation of the TPS.

You need to adjust the new controller like this:

- The corrugated line connected to the inlet manifold device is dismantled. After disconnection, a visual diagnosis of the condition of the damper itself is performed. It is necessary to wipe this element, as well as the intake manifold, using a rag soaked in fuel.

- Then the damper thrust bolt is released. The element itself opens all the way and is sharply released; when this task is completed, a click should be heard when it hits the stop.

- The tension of the thrust bolt is adjusted; in the process, you need to click the damper. When this component stops “biting” and moves freely, the screw must be secured with a nut.

- Then the bolts that secure the controller are loosened. One tester probe is connected to the idle speed contact element, and the second is connected between the thrust bolt and the damper itself. The controller body is rotated until the voltage parameter begins to change with the opening of the damper.

- When this happens, the bolts can be secured.

Dmitry Maznitsyn spoke in detail about the procedure for adjusting the throttle position controller using the Volkswagen Passat as an example.

Type of damper sensors

Manufacturers produce two types of devices in question. Both options are used on Lanos, so let’s look at their features. There are film-resistor and non-contact throttle position sensors. They differ in design and operating principle.

A film-resistor TPS or contact one consists of tracks that are variable resistance.

The element is based on a movable slider, when moved, the resistance increases. The sensor design has three contacts - plus, ground and engine control. The device is supplied with a constant voltage of 5V.

A non-contact TPS or magnetoresistive on Lanos is a potentiometer that works on the principle of changing the influence of a magnetic field.

The design of the element contains a permanent magnet, and changes in the position of the damper are recorded using an electronic unit. A distinctive feature of contactless devices is their durability. Such devices are more expensive than contact devices.

Operating principle of damper position sensors

Knowing the types of throttle sensors, let's consider their design features and operating principles. First, let's consider a contact sensor or film-resistive sensor.

This element received its name film due to the use of a structural part in the form of a film. There is a track on the film along which a moving element—the slider—moves. The components of a contact potentiometer are:

- Housing made of plastic

- Film resistance. A positive charge is applied to the steel plate on one side, and a negative charge on the other.

- The moving element is a slider that is connected to the throttle valve

The principle of operation of the part is that a constant voltage is supplied to the track when the ignition is on and the engine is running. When the throttle is closed with the engine running at idle, the voltage at the output of the third contact does not exceed 0.5V. As soon as the driver presses the gas, the throttle position changes. As the damper moves, the slider moves along the resistive track. When the damper opens, the resistance increases, which means the voltage at the third signal contact of the sensor increases. With the throttle valve fully open, the voltage on the signal wire is 4-4.5V.

The voltage measured is sent to the ECU via a signal wire. The controller adjusts the fuel supply depending on the throttle opening value. Over time, the slider and film resistive element wear out, so the sensor fails and needs to be replaced. This part cannot be repaired, and if it breaks, replacement is required.

This is interesting!

Most often, the sensor fails due to abrasion of the track.

In this case, the voltage may not change at all when the engine is running or may change with sudden changes, which depends on the nature of the malfunction. The contact throttle position sensor has a different design, and therefore a different operating principle.

The functioning of non-contact type TPS is based on the Hall effect. By using this, the element in question lost its contacts, which is where it got its corresponding name. Instead of a contact plate, the design uses a permanent magnet. An integrated circuit operating on the Hall effect principle is built into the sensor body. The job of this chip is to sense changes in the magnetic field, which is achieved by changing the position of a permanent magnet.

A permanent magnet is attached to the throttle valve. When the damper opens, the magnet moves simultaneously. Changes in the position of the magnet contribute to the induction of pulses, which are recorded by the microcontroller. The magnitude of the supply voltage is similar to the contact sensor. That is why the contact sensor can be completely freely and without modifications replaced with a non-contact one.

This is interesting!

Among the advantages of the contactless element is a long service life due to the absence of rubbing parts. Among the disadvantages, it should be noted the cost, which is 1.5 times higher than a conventional contact TPS.

What you need to know about TPS

Where is the TPS TPS located, what functions does it perform and what are the symptoms of problems? Before finding a breakdown, we suggest that you familiarize yourself with the main characteristics of the mechanism and its operating principle.

Purpose and location

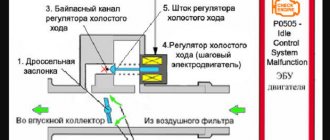

So, what is the purpose and where is the remote sensing position sensor located? The damper itself is a structural element of the engine intake system. It is used to regulate the volume of incoming air flow, that is, thanks to it, the correct composition of the combustible mixture is formed. The purpose of the throttle sensor is to transmit data to the manifold about the state of the bypass valve - it can be either closed or open.

Schematic structure of the mechanism

Where is the DPS located? Typically these devices are located in the engine compartment, directly on the throttle line. They are connected to the damper axis. If the throttle position does not change for some reason, this will lead to improper formation of the air-fuel mixture, which, in turn, will affect engine performance.

Design and principle of operation

By design, the throttle sensor is a type of resistive device. Inside the device there is a special movable slider, which is used to move along an arcuate plane. This plane is combined with the damper. When you press the gas, the damper assumes an open state, and the current collector itself rotates along the surface of the resistive device. At this moment, the resistance on the potentiometer changes.

The operating principle of the device is quite simple. When the damper is closed, the voltage on the TPS will be low, but when it opens, this value begins to increase. The highest TPS voltage appears when the damper is open. Taking this information into account, the car control unit selects the required volume of fuel to form the air-fuel mixture (the author of the video about the symptoms of breakdown and replacing the regulator is Ivan Vasilyevich).

Depending on the design, a magnetoresistive element may be used in the structure of the mechanism. Such a device includes a sensitive component in its design; a magnet is installed on it, connected to the shaft of the device. As a result of the fact that there is no contact between the resistive element and the magnet, the mechanism is non-contact.

The non-contact throttle position sensor operates on a slightly different principle. When the damper opens, the magnetic field in the mechanism changes, in turn, this also contributes to a change in the resistance of the sensitive component. Information about this is also supplied to the control unit, which forms the mixture itself.

Causes and first signs of malfunction

Before making adjustments, we recommend that you familiarize yourself with the causes and signs of sensor malfunction.

The main symptoms that indicate that the throttle position sensor needs to be adjusted or repaired are:

- The primary sign of a malfunctioning throttle position sensor is unstable operation of the car engine. The power unit may operate normally for a certain period of time, but then it will suddenly stall when changing gears or coasting at neutral speed. In general, the engine will function unstably at idle speed.

- When driving in first or third gear and pressing the gas, dips may be felt. Engine power may drop, and then it will recover on its own. These failures may not be felt systematically, but periodically.

- Another sign of a malfunctioning throttle position sensor is random over-throttle, which occurs when the driver presses on the gas. Also, in this case, the car may stall.

- The appearance of jerks, which is especially noticeable when accelerating. Like other symptoms, jerking may appear and disappear (the author of the video about diagnosing a device in a garage is the Alex ZW channel).

What malfunctions of the damper sensor occur

Problematic are contact-type sensors, the service life of which on Lanos does not exceed 50 thousand kilometers. If a non-original element is installed on a car, its service life does not exceed 10-20 thousand kilometers. There are three main types of faults found on contact-type devices:

- Wear of the moving film contact

- Oxidation of contacts

- Wear of the fastening joint or its play

Damper sensor connection diagram

During constant friction of the moving contact with the film resistance, wear of the metal layer occurs. The service life of the part depends on the quality of the product, as well as the style or nature of driving. Before you start replacing the element in question on a car, you should first diagnose it. The reason for carrying out a TPS check on Lanos is various factors, which we will learn about in detail in the next section.

Types of TPS faults

Problems with the operation of the throttle sensor are associated with its design design, and are generally characteristic of most variable resistors. Car enthusiasts identify three main problems:

- Wear of the moving contact or film resistance.

- Backlash of fastenings.

- Oxidation of active contacts.

During the operation of the moving contact and interaction with the film resistance, constant friction arises, which, with prolonged exposure, wears out both the resistive layer and the surface of the active contact itself. Practice shows that the degree of wear directly depends on driving style and manifests itself extremely unevenly. Because of this, only in some places places are formed where the active contact does not reach the resistive layer, causing the voltage to disappear at the output of the throttle position sensor.

Oxidation of working contacts occurs exclusively under conditions of high humidity under the hood. As a result, the resistance may increase and the electrical contact may be completely broken.

What are the causes and signs of TPS failures on Lanos?

If you suspect a malfunction of the TPS, then the first thing you need to look for is the presence of a number of the following symptoms:

- Reduced engine power

- Increased fuel consumption

- Delayed engine response to pressing the accelerator pedal

- Jerking occurs when accelerating hard

- Problems starting the engine

- The “Check Engine” indicator lights up, indicating an engine error.

The described symptoms do not indicate 100% that the cause of the malfunction is the damper sensor. That is why it is additionally recommended to check the device. Absolutely every driver can perform a TPS check on Lanos, and for this it is not at all necessary to visit a car service center. How to check the damper sensor on Lanos, we will find out in detail.

How to check contact TPS on Lanos

If there are signs of a malfunction of the throttle position sensor, it should be checked before replacing. To check, you will need a device such as a multimeter. With its help it is necessary to measure the voltage in the power wire that is connected to the part. To do this you will need to do the following:

- Disconnect the chip with the wire from the sensor

- Connect the multimeter probes to the positive and negative contacts of the device

- Turn the tester into DC voltage measurement mode up to 20V

- Start the engine and check the readings on the instrument

- The device should show values of 5V. If the multimeter shows a lower value or even zero value, then damage to the core of one of the power wires is likely. This conclusion can be made if the multimeter probes are correctly connected to the contacts on the chip

If there are readings on the multimeter, then we proceed to directly checking the sensor itself. To do this, you need to connect the chip to the sensor, and using two pins, connect the multimeter probes to the output contact and ground (second and third contacts). When the throttle is closed and the ignition is on, the voltage value should be 0.7V, and when it is opened to its maximum (pressing the gas pedal), the value should increase to 5V.

The last test option is to measure the sensor resistance. To do this, you need to disconnect the power supply and connect the multimeter probes to the sensor contacts. They are connected to the second and third contacts, that is, the output signal to the ECU and ground. The device switches to resistance measurement mode. When the damper is closed, the multimeter should show a high resistance value of up to 2.5 kOhm. When the damper opens, the resistance drops to 1 kOhm. Moreover, it is necessary to open the damper slowly, and at the same time observe the readings. The readings should decrease smoothly and without jerking. If this is the case, then the sensor is working and does not need to be replaced.

This is interesting!

To more accurately check the throttle position sensor, you will need to conduct computer diagnostics.

With its help, you can determine the serviceability of the TPS. If Lanos has a contactless element, then special equipment will be needed to check its serviceability. You can independently check only the output voltage supplied to the computer when the damper position changes. It should also be noted that most often contact sensors fail if they have a manufacturing defect. Otherwise, they last almost forever.

DIY diagnostics

How to check the throttle position sensor? To make sure that the device needs to be replaced, when the first signs appear, you need to diagnose it.

Checking the throttle position sensor is carried out using a voltmeter:

- First you need to turn on the ignition and, using a tester, use probes to determine the voltage between the “-” contact and the slider. If the device is working, this parameter should be no more than 0.7 volts.

- Then you need to fully open the damper; to do this, turn the plastic sector and check the voltage again. In this case, the voltage must be at least 4 volts.

- Having done this, turn off the ignition and remove the plug. Between any output and the slider contact, resistance diagnostics is performed.

- Next, slowly turning the damper, you need to monitor the voltmeter readings; when the device is working, they will change, and the arrow on the tester should move smoothly. If it moves jerkily, this indicates that the TPS is not working (the author of the video about diagnosing the regulator resistance is the AndRamons channel).

Where is the TPS located on Lanos?

Having understood the design, types and principle of operation of throttle position sensors, it remains to find out where it is located. Finding it will not be difficult, since it is located in the most visible place in the area where the throttle is located.

On Lanos, the TPS is located under the idle speed control. The photo above shows what the sensor looks like and where it is located. It is secured with two screws with a Phillips head screwdriver.

How to replace the throttle position sensor on a Chevrolet and Daewoo Lanos

If diagnostics show that the TPS on Lanos is faulty, then it should be replaced. There are no difficulties with the replacement, but we will consider this process step by step. Before removing the old sensor, you need to remove the terminal from the battery. This is done in order to prevent the occurrence of a short circuit, as well as to reset the ECU error

. If this is not done, then after replacing the TPS, you may find that the Check Engine will light up on the instrument panel.

Instructions for replacing TPS on Lanos are as follows:

- After removing the negative terminal from the ECU, you should disconnect the chip with the power wire by prying the clamp with your fingers

- Unscrew the bolts securing the device and remove the part from the car

- Install a new one in place of the old sensor and secure it with bolts. Connect the chip with wires

The replacement instructions are not difficult, but it is important to know some nuances:

- Lanos produces different types of sensors, which have corresponding article numbers or catalog numbers. The table below shows device part numbers for cars with different types of 1.4/1.5/1.6 liter engines

- It is necessary to configure the TPS, which is described in detail in the next section

- Mounting form - it is important to pay attention to the type of holder or damper axis. They are different, so before purchasing it is better to remove the sensor and see what type of mount is used on it

The table shows that Chevrolet and Daewoo Lanos with engine sizes of 1.5 and 1.6 liters use devices with article number 3102.3855. Lanos with 1.4 engines, as well as Sens, use elements with catalog numbers 3202.3855 and 3302.3855.

This is interesting!

It is recommended to install contactless sensors, as they not only last longer, but also work much better.

Adjusting the TPS or how to adjust the damper position sensor with your own hands

After installing a new TPS on Lanos, it is necessary to adjust the device. Setting (also called calibration) is needed to ensure the correct functioning of the element. The adjustment features are based on the following steps:

- First, we check the element and make sure that it needs adjustment. To do this, we measure the voltage at the sensor contacts. The value should be 0.7V with the damper closed. If this is not the case, then the TPS needs adjustment

- To do this, loosen the fastening screws and turn it clockwise. If there is no free play when loosening the screws, then you need to increase the diameters of the sensor holes. This can be done with a file or a drill bit.

- Having enlarged the mounting hole, you need to reinstall the element in place and measure the voltage with the ignition on. The value should be 0.65-0.7V

- Having set the appropriate voltage value, it is recommended to reset the ECU by removing the negative terminal for 15-20 minutes

- After connecting the terminal, you need to turn on the ignition for 15 seconds and then turn it off

- The ignition is turned on again and the engine starts

Now you understand what adjusting the TPS on Lanos is, and why you need to perform this procedure. After installing a contactless throttle sensor, you can notice improvements in your car such as improved engine responsiveness when you press the gas pedal, the disappearance of twitching and jerking in 1st and 3rd gear, reduced fuel consumption, etc. Reviews show that it is better to overpay and buy a contactless damper position sensor than to replace contact devices every 2-3 years.

Replacing TPS

Replacing the auto sensor takes place in several stages, it is quite simple, even a novice car enthusiast can do it. First you need to turn off the ignition and disconnect the wire from the negative terminal on the battery. Then you should press the plastic latch and also disconnect the block with the existing wires from the sensor. To completely remove the device being replaced, unscrew the two bolts using a Phillips screwdriver.

Foam rubber is used as a seal between the throttle pipe and the sensor. It is a component and also needs to be replaced. When installing a purchased device, you need to carefully tighten the mounting screws until the ring is completely compressed.

After installing the sensor, you should connect the wires. Since no further adjustment is required, the work can be considered complete. The entire process of changing the device takes no more than a quarter of an hour.