Injection cars use a large number of sensors that are responsible for the operation of the entire engine. Using their readings, the engine control unit receives the information necessary to adjust the mixture, supply a spark, etc. All injector sensors are interconnected and the failure of one of them seriously affects the operation of the internal combustion engine as a whole.

One of the most frequently broken sensors is the idle speed control. Due to its poor design, this part is susceptible to rapid failure, which leads to uneven operation of the internal combustion engine at idle.

In this article we will talk about the sensor that regulates the idle speed on a VAZ 2114 car. It describes in detail its design, purpose, location, signs of breakdown and methods of self-replacement.

Sensor design

The idle speed control of the VAZ 2114 is made according to the design of a DC motor; it would seem that such a part should be reliable, but due to its flimsy design, air leaks often occur in it.

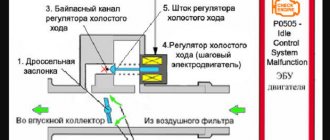

The IAC is an engine with a worm-type shaft, and at the end of the shaft there is a triangular valve that blocks or opens the air flow necessary for the internal combustion engine to operate at idle.

COST AND MANUFACTURERS

What is IAC or DAC? This is abbreviated as idle speed control or idle speed sensor - they are the same sensor. On the VAZ 2114, the idle speed sensor is installed exactly the same as on the VAZ 2115 or on the injection “eights” or “nines”.

Marking DXX - 2112-1148300 or with additional numbers at the end from 01 to 04. Mainly there is a production regulator:

- ZAO Omega (2112-1148300 Moscow),

- OJSC Pegasus (2112-1148300-01 Kostroma),

- KZTA (2112-1148300-02 Kaluga).

It is believed that all devices are interchangeable with each other, but 2112-1148300-01 has a winding resistance of 53 Ohms, and 2112-1148300-02 has a winding resistance of 51 Ohms. According to the characteristics, 2112-1148300-03 is equivalent to 2112-1148300-01, and 2112-1148300-04 is equivalent to 2112-1148300-02.

The sensor valves may have different tips that block the bypass channel of the XX system. The metal tip is universal - it is designed for gasoline and gas. With a plastic tip, it is better to use the sensor only for operating internal combustion engines on gasoline.

The quality of DXH varies; at one time, many defective spare parts came from factories. Therefore, car owners often take various sensors in stock. The cost of the regulators allows you to buy a spare part - they are inexpensive, the price is in the range of 400-500 rubles.

How the sensor works

The throttle assembly has special channels for air flow, which are used only when the engine is idling.

The main air flow into the engine enters through the throttle valve, but when operating at idle, it is closed and the air passes through a special channel, which is opened by the IAC valve.

The sensor receives signals from the ECU and opens the channel to the required amount, thereby regulating the air flow at idle and mixing air with fuel to form the fuel mixture necessary for the operation of the internal combustion engine.

Principle of operation

The idle speed sensor consists of several parts, namely: an electric motor, a valve, a rod, a shut-off needle and a spring. While the car is moving, the valve of the device is stationary. And as soon as the injector goes to idle and the throttle valve closes, the valve begins to work and pump air, bypassing the closed valve.

The electric motor forcibly drives the valve during idle. The rod serves to connect the electric motor to the valve and transmit reciprocating movements to it. The shut-off needle, in turn, blocks the air flow at the moment when the VAZ 2109, 21099 injector receives speed in a engaged gear.

Where is it located?

The sensor is located on the throttle body. You can find it by looking behind the remote control and you can see two adjacent TPS and IAC sensors. The IAC is mounted on two bolts using a Phillips screwdriver and has a special O-ring to seal the system.

It should be noted that the XX regulator is installed only on the VAZ 2114 with a mechanical throttle. If the car is equipped with an electronic throttle with the E-GAZ system, this sensor is not available in such a car.

Causes of failure

The most common IAC breakdowns on the VAZ 2114:

- Air leaks from joints;

- Cap contamination;

- Failure of the IAC armature;

Air leaks from joints

This problem occurs due to a violation of the sealing of engine joints due to rivets falling out or the sealing ring becoming obsolete, which leads to the leakage of unaccounted air. Unaccounted air leads to an incorrectly composed fuel mixture and, consequently, to incorrect operation of the internal combustion engine intermittently.

Contamination of the cap (valve)

Contamination occurs due to crankcase gases entering the throttle assembly, which leads to the formation of carbon deposits on the IAC valve. Crankcase gases appear in the remote control due to a worn-out CPG, and small ventilation (breather) is connected to the intake corrugation.

Armature burnout

In a permanent motor, the armature has a winding, which, due to jamming, burns out and disables the IAC. This kind of breakdown occurs quite often.

Symptoms of a problem

There are a number of signs indicating that the idle speed regulator on a VAZ 2114 car has failed. Most often, such signs are reflected in the operation of the internal combustion engine.

Malfunctions characteristic failures of the IAC:

- Unstable XX;

- Spontaneous engine stop;

- The engine stalls when the gas is released;

- The engine speed jumps at idle;

Often, a breakdown of the IAC can be confused with a clogged throttle assembly, which becomes dirty due to crankcase gases. When replacing the IAC, if the choke has traces of dirt, oil or other deposits, it is recommended to remove the throttle and wash it with carburetor cleaner.

Idle speed sensor VAZ 2114: device and where the idle speed sensor is located

The principle of operation of the IAC VAZ 2114 with a stepper electric motor is to ensure the supply of the required amount of air necessary to stabilize the idle mode of the vehicle’s internal combustion engine.

This allows the car to start moving when the engine is not yet warmed up, and also for the engine to operate normally in transient conditions, etc. The idle speed sensor 2114 is externally a small device in the form of an electric motor with a cone-shaped needle at the end.

Main components of the sensor:

- idle air control;

- sealing ring;

- regulator fastening screw;

- idle air control needle.

More precisely, an IAC with a stepper motor, which drives the needle and is responsible for its movement, makes it possible to regulate the air supply. The XX sensor reads the amount of air volume passing through the regulator. Under the control of the controller, fuel is supplied through fuel injectors into the vehicle’s internal combustion engine.

The system in which the XX sensor is located, monitoring the engine speed and taking into account operating modes, dynamically increases or decreases the amount of incoming air passing bypassing the throttle valve. This allows the engine to operate stably in idle mode (minimal maintenance of combustion processes of the fuel mixture so that the engine does not stall).

The idle speed control is attached to the throttle body using two screws. In some cases, the screws may be seated on the varnish, which makes servicing and repair of the IAC difficult (the sensor is removed along with the throttle valve).

Examination

To check the IAC, you will need a multimeter with which you will measure voltage and resistance.

Checking the circuit

First you need to check the sensor's power circuit. To do this, remove the connector from the IAC and turn on the ignition on the car, set the switch on the multimeter to measure a DC voltage of 20V. We connect one multimeter probe to the motor housing, and the other to terminal A on the connector, the multimeter should show a voltage of at least 12V. Then we connect the probe to terminal D; the multimeter should also show at least 12V.

Sensor check

Checking the sensor involves measuring the resistance of the regulator itself. To do this, switch the multimeter switch to measure resistance with a limit of up to 200 Ohms. We connect the probes to terminals A and B, D and C, the resistance on them should be approximately 50 Ohms. Then we connect the probes to terminals A and D, B and C, the resistance between these contacts should be infinite.

If any of these parameters differ when checking your IAC, it must be replaced.

Malfunctions

The peculiarity of the idle speed sensor is that it is impossible to trace the occurrence of a malfunction due to the operation of the on-board computer. The system does not recognize a breakdown, so everything has to be done manually.

There are several characteristic signs that can tell you about problems with the XX sensor:

- The car often stalls when idling;

- A phenomenon called floating speed occurs;

- There are no increased speeds when starting a cold engine;

- If the gear is switched off, the engine may stall spontaneously.

There are also a few errors on the on-board computer, but you shouldn’t rely solely on them.

| Error code | What does it mean |

| 0505 | DXX error |

| 0506 | Low idle speed |

| 0507 | Increased idle speed |

Many people confuse the signs of IAC failure with the throttle position sensor. The symptoms are indeed very similar. But the point is that the on-board computer signals a breakdown of the position sensor, but regarding the IAC it is silent.

Diagnostic methods

Before proceeding with the replacement, we recommend that you really make sure that the cause of all problems with your VAZ 2114 is the faulty IAC. To do this, there are two main ways to check the status of the device.

Explore both to see which diagnostic option is best for you.

First way

- Get a tester if you haven't had one before.

- Disconnect the DXX from the block with wires.

- If you have a 1.6-liter engine, then be sure to disconnect the throttle assembly fasteners and move it from the receiver about 1 centimeter.

- Use a voltmeter to check if voltage is being supplied to the regulator. The minus is connected to ground, and the plus goes to the block - use the AD pins.

- With the ignition on, the tester should show at least 12 W.

- If there is no voltage, then there is a problem in the power circuit or electrical unit of the car.

- If there is voltage, but it is significantly less than 12W, then this indicates a low charge level of your battery. Be sure to recharge the battery.

- After checking the circuit for efficient operation, proceed to study the DXR itself. At this stage the ignition is turned off.

- In turn, connect the terminals to the tester to pairs A-B and CD. The normal resistance should be approximately 53 ohms.

- Change the pairs to AC and BD. When measuring them, the resistance should turn out to be infinitely large.

If the check shows that the readings do not meet the standards, then several actions can be taken:

- Clean the contacts, throttle body, needle needle and other sensor components using carburetor cleaner. It is not difficult to find, and it is cheaper than specialized cleaners;

- If possible, try to repair the IAC;

- If it is impossible to carry out repairs, replace the old sensor with a new regulator.

Faulty sensor

Second way

For this testing option, you will need a simple tester that you can easily make yourself. We offer corresponding video instructions

Now we proceed as follows.

- Unscrew the fastening screws of the regulator and remove it from its seat. The location of the DXX is already well known to you.

- Disconnect the regulator from the main block, and apply the finger of your right hand. And the index finger. You don't need to put a lot of effort into creating a set.

- The nuance of placing a finger lies in the features of the regulator itself, at the end of which there is a cone-shaped needle.

- If the engine stops working, then if the IAC is working properly, the needle comes out completely.

- Your finger will allow you to feel a slight jolt when you turn on the ignition.

- If this push is absent, then the device has failed.

The maximum distance from the protruding rod head to the flange is 23 millimeters. When buying a new IAC, be sure to take this fact into account.

A Question of Choice

When checking the sensor, we found out that the device was faulty and needed to be replaced. But what should we choose in its place?

Today, two types of devices from different manufacturers are in particular demand for the VAZ 2114 - OMEGA and KZTA.

In the case of OMEGA, pay attention to number 2112-114830. If you decide to choose KZTA, then the option that suits you has catalog number 2112-1148300-04.

The last two digits may be different, and this is a very important point. If your IAC number ends in 01, you should not change it to 03, otherwise you will simply waste your money. The device is replaced with a similar one or with a subsequent number - 01 is changed to 01 or 02, etc.

The cost of the IAC is around 300-400 rubles, depending on the region and the specific store. Be careful, as there are now an impressive number of fakes on the market.

Replacement

Replacement is quite simple and does not require special skills in car repair. You just need to prepare a Phillips screwdriver with a short shaft and you can start replacing.

- Remove the connector from the IAC;

- Unscrew the two IAC fastening bolts using a Phillips screwdriver;

- We take out the IAC

- We install the new IAC in the reverse order, not forgetting to put a new O-ring on it;