TASKS AND RESPONSIBILITIES

"Haldex" is an electronically controlled clutch. It is installed in front of the rear cross-axle differential and transfers traction to the rear wheels - naturally, when there is a need for it. For example, on a slippery road. Or when starting from a stop - in order to more efficiently realize the torque.

The Haldex control unit collects data from the entire vehicle - from engine sensors, gearbox, anti-lock braking system, steering. By issuing a command to the clutch actuators, the computer takes into account not only wheel slip, but also speed, lateral acceleration, steering wheel position, and movement under traction or coasting. Such a large amount of information is needed so that the all-wheel drive transmission reacts in advance to situations that arise on the road. For example, when the clutch is locked, you can transfer maximum torque to the rear axle - in order to pull out a car that has fallen onto a slippery surface with its front wheels. Or, conversely, remove traction from the stern and thereby help other systems stop the resulting skid when the front wheels slip.

Operating principle of the Haldex coupling

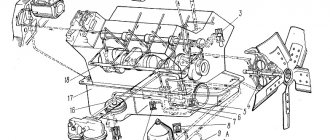

The mechanical part of the Haldex coupling consists of a cylindrical input shaft with an axial piston pump and working piston, a driven shaft with a drive head and a disc cam, and a set of friction discs. The outer disks are connected to the drive shaft, and the inner disks are connected to the driven shaft through longitudinal gearing.

Rice. Haldex coupling diagram: 1 – driven shaft with cam washer; 2 – working piston; 3 – multi-disc clutch; 4 – pump piston; 5 – discharge valve; 6 – inlet valve; 7 – clutch control pressure regulator; 8 – drive shaft

When one of the wheels of the car slips, a difference in rotational speed occurs between driven 1 and driven 8 shafts, and either the protruding or descending part of the cam washer is directed to the piston 4. As a result of the reciprocating movement of the piston, the oil pressure in the hydraulic system increases and the working piston presses on the pressure plate of the friction disc set. A set of friction discs are compressed, and thus a clutch is created between the input and output shafts.

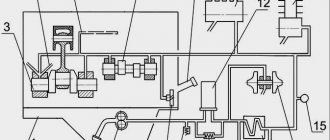

The hydraulic part of the Haldex coupling consists of an electric charging pump 9, an oil filter 10, inlet 11 and discharge 3 valves, a pressure regulator 5 with a control valve, a safety valve 4 and a hydraulic accumulator 6. In order for the system to operate quickly, the electric charging pump 9, starting from a rotation speed of 400 rpm, it pumps up a feed pressure of 4 kgf/cm2 into the clutch hydraulic system. The replenishing pressure is maintained by a hydraulic accumulator 6 and acts on both the pistons of the pump 12 and the working piston 13. The advantage of this arrangement is that, on the one hand, the pump piston is adjacent to the disc cam and, on the other hand, due to the light back pressure, the backpressure is eliminated clearance from a set of friction discs.

The hydraulic accumulator, along with maintaining the make-up pressure, has another task - to equalize pressure fluctuations in the system. If there is no pressure in the supply line, the accumulator spring is maximally compressed and oil is not discharged from the supply line through the accumulator. The increase in pressure in the supply line is limited to a predetermined level by transferring oil from it through the accumulator to a reservoir for collecting it. As the pressure decreases, the accumulator spring expands, reducing or completely stopping the release of oil into the container.

Safety valve 4 prevents the control pressure from rising above 100 kgf/cm2, protecting the coupling parts from overloads. The valve opens if the pressure acting on its shut-off element overcomes the force of the pre-compressed spring. When the pressure increases to 100 kgf/cm2, the valve opens, passing oil into the supply line and into the reservoir through the hydraulic accumulator, as a result of which the oil pressure in the system decreases to a predetermined level.

Rice. Hydraulic part of the Haldex coupling: 1 – cam washer; 2 – pushing rollers of pump pistons; 3 – discharge valves; 4 – safety valve; 5 – clutch control pressure regulator; 6 – hydraulic accumulator; 7 – working fluid reservoir; 8 – mesh oil filter; 9 – electric pump; 10 – filter; 11 – intake valves; 12 – pump pistons; 13 – working piston; 14 – disk package

The main hydraulic element is the pressure regulator control valve, which determines the amount of pressure on the discs and is controlled by the actuator motor, which in turn operates according to signals from the control unit.

Rice. Control valve: 1 – drain hole; 2 – control valve; 3 - adjusting pin; 4 – drive motor; 5 – gear

When the control valve is closed, the difference in rotational speed between the input and output shafts creates a working pressure, the value of which is limited by the safety valve. Torque is transmitted through the clutch to the rear axle.

Rice. Operation of the control valve: a) the valve is closed; b) the valve is partially open; c) the valve is fully open

When the control valve is partially open, the clutch allows a certain amount of slip, i.e. torque is only partially transmitted to the rear wheels. When the control valve is fully open, no operating pressure can be generated and no torque is transmitted through the clutch. However, the pressure is not reduced completely, but partly due to the hydraulic accumulator to the level of replenishment pressure.

FATHERS AND SONS

The fourth Haldex was initially installed on all-wheel drive Skodas. The transmission of the new models has a more advanced fifth-generation clutch. The main changes have occurred in the hydraulic system, which, under electronic control, compresses and releases the discs.

In the fourth Haldex, the electric pump created a working fluid pressure (up to 30 bar), and the control solenoid valve limited its flow to the annular piston compressing the disk pack. The more fluid the valve bypassed, the more tightly the discs were pressed against each other and the more torque could be transmitted to the rear axle.

In the fifth generation coupling, the pump was equipped with a centrifugal regulator, which measures the required operating pressure in the system. When rotating, the regulator levers diverge under the action of centrifugal force and block the channels through which the oil drains into the pan. At the same time, the pressure in the system increases, the piston begins to compress the disks. If it is necessary to unlock the clutch, the automation reduces the speed of the electric motor, the levers return to their original position, the valves open and the pressure drops.

Essentially, the centrifugal regulator replaced two parts: the control solenoid valve and the hydraulic accumulator necessary to maintain pressure.

True, for insurance, a compact safety valve was introduced - it opens and bleeds excess oil into the reservoir when the pressure rises above 44 bar.

The struggle for millimeters and kilograms (by the way, the fifth Haldex is 1.7 kg lighter than its predecessor) is justified only if it does not come at the expense of reliability. I'm not sure there was any point in abandoning such an important part as the oil filter. After all, the fourth Haldex had a filter - but the fifth does not! It is unlikely that discs and other rotating parts began to be covered with some magical material that completely eliminates their wear. Where should the wear products go? “Shavings” accumulated in the oil can disrupt the operation of delicate hydraulic mechanisms, and repairing the clutch is expensive. In addition, it is now recommended to change the lubricant not every 60,000 km, but once every three years. During this time, many motorists reach 100 thousand! We hope the developers haven't forgotten about this.

Generations of Haldex couplings

There are currently five generations of the Haldex coupling. Let's note the features of each generation:

- First generation (since 1998). The basis of the clutch is a mechanism that determines the difference in rotation of the shafts that go to the front and rear axles of the machine. The mechanism is blocked when the drive axle slips.

- Second generation (since 2002). The operating principle has not changed. Only technical improvements have occurred: integration into one unit with the rear differential, an electrohydraulic valve replaced the electromagnetic one (the system started working faster), the electric pump was updated, a maintenance-free oil filter was installed, and the working oil volume was increased.

- Third generation (since 2004). The main change in the design is the installation of a more efficient electric pump and check valve. It is now possible to pre-lock the device electronically. In 150 milliseconds the mechanism is completely locked.

- Fourth generation (since 2007). The principle of operation has not changed. Design changes: the pressure in the hydraulic system of the mechanism now forms a powerful electric pump, the clutch is controlled only electronically, the fourth generation device can only be installed on cars with an ESP system. The main difference is that different speeds on the front and rear axles are no longer a condition for engaging the clutch.

- Fifth generation (since 2012). The operating principle has not changed. Design features of the latest generation Haldex coupling: the pump runs continuously, the clutches are electrically/hydraulically controlled, the mechanism can be replaced separately. The main difference is the higher quality of the elements.

"HALDEX" AND COMPANY

02

The Haldex coupling first appeared on production vehicles in 1998. It was tried on by all-wheel drive Audis and Volkswagens with transversely mounted engines. Unlike its predecessor, the viscous coupling, the Haldex, with its electronic control, transferred power to the rear axle faster and more accurately. Driving has become not only more convenient and interesting, but also safer. From generation to generation, hydraulics and mechanics improved, electronics became more efficient and smarter, the unit lost weight and dimensions, which made life easier for assemblers. “Haldex” is installed not only on “Skodas” - a multi-plate clutch with electronic control is used in Audi, Volkswagen, Cadillac, Bugatti, Opel, Ford, Land Rover, Volvo models "

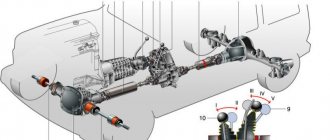

All-wheel drive transmission with Haldex V clutch: fifth rear

Advantages of the Haldex coupling

The Haldex coupling is widely used by Volkswagen for class A cars (Volkswagen Golf, Bora, Audi TT, Skoda Oktavia, Seat Toledo, etc.).

On the one hand, it offers the benefits of permanent all-wheel drive; on the other, it can be combined with anti-slip systems such as ABS, EDS, ASR, EBV and ESP. Unlike traditional permanent drive systems, the 4 motion system has a number of advantages:

- the car retains the characteristics of front-wheel drive

- clutch response time is very short

- different tire sizes (spare wheel) do not cause any problems

- jamming in the drive when parking or maneuvering no longer occurs

Structurally, the Haldex coupling is installed in the same place where the viscous coupling was previously located, namely, directly on the rear axle. Together with all components, including the control unit, it is a compact unit that is driven by a cardan shaft.

Rice. General layout of a vehicle with a Haldex coupling

Changing the oil in the 4th generation Haldex coupling using the Volvo XC70 as an example. Photo and video instructions

Today we will teach you how to change the oil in a 4th generation Haldex coupling using the example of a Volvo XC70.

To work, we need a filter, it comes complete with a lid, the lid has additional fastening screws (the cost of the set is 2500 rubles), a liter canister of oil (about 750 grams are filled in the system).

The oil filter is located at the top of the coupling; to get to it you need to unscrew the driveshaft and move it to the side. First, we apply marks so that we can then put the shaft in its original place:

Use a 8mm hex to unscrew the 6 bolts securing the shaft to the flange:

Using a 10mm wrench, unscrew the 4 bolts securing the propeller shaft support bracket:

Remove the cross member and unscrew the fastenings of the cardan to the bevel gear. At the back there is a hinge with a tight fit in the clutch cage, in order to pull it out without much difficulty, you need to help it with a mandrel, there are holes in the cage that are not threaded, we insert our mandrel there and with small blows of a hammer we push the hinge as the car moves:

Using a 24mm socket we unscrew the nut securing the cage, there are two options: make a mandrel to hold this coupling from turning, or, as in our case, use an impact wrench:

Using a copper mandrel we knock the coupling off the shaft:

In this case, a small amount of oil will leak out; prepare the necessary container for it in advance. Now we have free access to the oil filter cover. Remove the engine and drain the oil from the coupling. We unscrew the two bolts securing the motor, to do this we use a 4-point hexagon:

Take a flat screwdriver and pry the motor through the groove:

This will cause oil to flow out again. There is a mesh on the motor, it is clogged, it needs to be removed and washed, it is attached with Torx T10 screws:

Use a 4mm hex to unscrew the two bolts securing the oil filter cover:

Use some kind of hook to hook the plastic plug. Place the new filter in place until you hear a characteristic click:

Lubricate the sealing collar of the plastic plug and install it in the seat. At the end, we pour new oil into the coupling, the filler plug is 13 key, it contains approximately 650 grams, we check the level along the lower edge of the filler hole:

Now we need to start the engine so that the Haldex clutch pump turns on, it pumps oil through the system, fills the filter, after which we check the level again.

Video changing the oil in the Haldex coupling Volvo XC70:

Backup video on how to change the oil in a Haldex Volvo XC70 clutch:

Read times: 2,463; Today: 1

Haldex coupling maintenance:

Routine maintenance of Haldex couplings consists of 2 main stages: diagnostics of the operation of the coupling and its components, replacement of oil and filters. The oil pump must create a certain oil pressure for the friction discs to function properly. Over time, the pump motor, which has a conventional brush mechanism, may fail. The mesh filtering large particles can also become clogged and interfere with the normal operation of the pump.

If there is a loss of oil pressure in the system or a deviation from the standard value from the norm by more than 10%, first of all it is necessary to replace the Haldex pump with a new or restored one, check the condition of the filter and install a new one if necessary. With regular checks and oil changes, the Haldex coupling will last for the entire life of the vehicle. Read the operating instructions for your car for recommended oil change intervals!

05.10.2018 / Articles