Checking the compression of engine cylinders is recommended in almost any instructions when troubleshooting: when the engine has oil, when it stalls under any circumstances, when the car is idling poorly, or simply when its power drops. In many cases, the cause of such problems can be poor compression in the engine, and in order to identify the cause, you need to know what the compression should be specifically in the engine of your car model and how to check this very compression. Compression is the pressure of compressed air in a cylinder at the very end of the compression stroke, when this pressure is maximum.

We decided to write this instruction because measuring compression in cylinders is a very simple task. You will need to measure the compression in each cylinder in turn, while the engine is rotating from the starter drive, but not running on fuel on its own. Then all you have to do is compare the pressure readings in all cylinders with each other and with the pressure indicated in the characteristics of your car (operating instructions or any other reliable source of advanced engine characteristics of your car).

How to check engine compression?

To check, you will definitely need an indispensable attribute of our work - a compression tester, and you will have to buy it at the nearest auto store or simply ask a familiar auto mechanic, a thrifty or avid car enthusiast, or rent it. A compression gauge is a very inexpensive thing and costs a little more than a pressure gauge, although prices for the former vary much more. In general, the cheapest compression meter will cost you 400-1000 rubles, but there are also more professional devices that cost up to 10-15 thousand rubles, but you are unlikely to need them.

When choosing a compression gauge, you need to make sure that its tip is screwed into the spark plug channel (there are those that mercilessly get clogged there), so that the tip and the pressure gauge itself are connected to each other with a flexible hose and not a tube, since in the latter case you may have to remove something else from under the hood, since it will simply get in our way when installing the compression gauge. Also, see that the maximum pressure jackal reaches at least 20 kg/cm2. If the car needs the hands of a master, then use the rental car https://rentamur.ru/ while your car is at the service station.

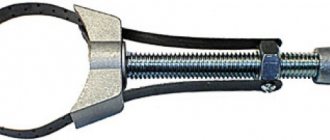

Compression gauge with adapter attachments for different types of spark plugs

In addition to the compression gauge, you will need an assistant who will turn the starter using the ignition key from the passenger compartment, and a spark plug wrench. Also, your car must have a working starter and, most importantly, an excellent battery condition, since it will have to work quite a lot.

For accurate and correct measurements, you will need to take the following steps:

- First, start the engine and let it run until it reaches normal operating temperature (90º), then turn it off and remove the wires from all spark plugs. When you remove them, mark each wire and its corresponding spark plug with paint (marker, felt-tip pen) of a different color for each spark plug, so as not to confuse them.

- Now you need to prevent fuel from entering the engine. The easiest way to do this is to disconnect the fuel pump from it. Remove the wire plug by grasping the caps without pulling on the wires, which could damage them. Label the test leads if necessary to avoid confusion when putting them in place.

- Clean the areas around the spark plugs to prevent dirt from entering the engine. Unscrew the spark plugs using a socket or a special spark plug wrench.

- Each compression tester has a pressure relief valve - be sure to reset the tester before testing each subsequent cylinder. Screw the tip of the compression gauge into the first spark plug hole.

- Have a helper depress the accelerator pedal all the way to open the throttle fully and begin cranking the starter by turning the ignition key for about 6-10 seconds. At this time, the pressure in the compression gauge will rise with each engine revolution and reach a certain maximum level - then it is necessary to turn off the starter.

- Be sure to record the result of the cylinder compression test. You need to record what compression was obtained as a result of the compression test and approximately how long it took in seconds to reach the maximum pressure on the pressure gauge.

- Check all other cylinders in the same way, also recording the compression readings in the engine on a piece of paper.

The procedure for connecting a compression gauge to check compression in the engine: remove the high-voltage wires from the spark plugs; unscrew all the spark plugs; screw in a compression gauge instead of spark plugs one by one

The compression rate for each engine is different, but in general it is considered normal for a gasoline engine to be about 10-12 kg/cm2. However, check this information for your vehicle model and specification.

We recommend: What are the markings for xenon and halogen headlights?

If any cylinder has lost compression

If one or more cylinders give a compression reading that is significantly lower than the others, we will need to perform additional testing to determine whether the low compression is due to leakage from worn piston rings or other microscopic holes or cracks in the piston. cylinder.

- Pour a tablespoon (about 10 ml) of clean engine oil into the suspected cylinder.

- Connect the compression gauge and, according to the above instructions, crank the engine again.

- If this results in a noticeable increase in engine pressure, it most likely means that the piston rings are worn out or there is some other air leak in the cylinder, and you will need to go to a mechanic. The fact is that with such a leak, engine oil will rush to the leak site, and, once there, clog it and prevent air from escaping.

- If the compression readings have not changed during the test, then most likely the leak is so large that the engine oil simply failed to “seal” it. This could be due to engine valves or severely leaky gaskets.

To check the valves, the cylinder head must be removed, and this is also not an easy procedure. A leaky gasket, however, will show symptoms other than loss of compression. A leak between the cylinders will cause the engine to run rough, and there may also be a loss of coolant into the crankcase, which will show up as a white emulsifying foreign fluid on the oil dipstick and an overall high oil level.

Table: compression deviations and possible engine malfunctions

| Compression in the engine, kg/cm2 (with the gas pedal fully depressed/throttle open) | Possible malfunction | Possible additional symptoms |

| 12-15 | (Increased compression) Carbon deposits in the combustion chamber of the cylinders due to worn oil seals | Blue exhaust gases and increased oil consumption |

| 10-12 | Normal compression | — |

| 6,5-9,5 | The piston rings or pistons themselves are worn, there is damage to the cylinder walls | Blue exhaust gases and increased oil consumption |

| 7-8,5 | There is damage to the camshaft cam, which may cause the valve to open/close incorrectly | Complete or partial failure of the cylinder |

| 6-8 | The piston bridge has cracked | Blue exhaust gases, increased oil consumption, increased oil pressure |

| 5-8 | Failure to return the valve to its original position | Complete or partial failure of the cylinder |

| 4,5-6 | The piston overheated and burned out | Unstable engine operation at idle, increased oil consumption |

How to check it yourself

Having a compression gauge and an assistant at hand, measuring compression will not be difficult.

- Warm up the engine to operating temperature.

- Shut off the fuel supply to the cylinders. For carburetor engines, disconnect the hose that goes from the carburetor to the fuel pump; for injection engines, remove the fuel pump fuse and let the engine run until the fuel is used up from the system.

- Disconnect all high voltage wires from the spark plugs.

- Unscrew the first spark plug and insert the compression gauge fitting in its place.

- Have a helper run the starter for a few seconds until the pressure gauge needle stops moving up.

- Take pressure gauge readings and compare them with standard values.

- Carry out the same procedure for all cylinders. Compare the compression ratios in the cylinders.

Checking with a compression gauge

To measure the pressure in the engine cylinders, it is necessary to use a special tool - a compression gauge. The cost of such a device is low, so any car owner can purchase it. In addition to it, you will need a spark plug wrench and an assistant - he will have the important task of rotating the starter using the ignition key.

- The machine warms up to operating temperature.

- Carefully unscrew all spark plugs.

- The throttle valve opens, that is, the assistant presses the accelerator pedal all the way, while simultaneously turning the ignition key and thereby setting the starter in motion.

- The compression tester plug is tightly inserted into the spark plug well. The starter starts and the engine “cranks” for two to three seconds - this time is enough for the pressure gauge readings to stop increasing.

- The starter stops and the measurement data is recorded. Compression is measured in all engine cylinders.

- The compression gauge is completely emptied of air before each subsequent measurement. If the results obtained deviate from the norm, the readings are taken again.

Measuring engine compression using a compression meter video:

Compression values measured in different cylinders should be about 10% of the maximum pressure value indicated on the instrument scale. A decrease in results below 15% of the maximum indicates wear of parts - piston, valves, piston rings or cylinder. Operating a car engine in this condition risks its complete failure, major repairs, or complete replacement in the future.

The main difference between the process of measuring compression on an injector and a carburetor is the mandatory disconnection or removal of the crankshaft sensor. Experts advise doing this in order to protect the ECU from damage and completely shut off the fuel supply.

Measurement procedure

It all starts with preparation, as the basis for the competent conduct of any operation. In this case, it includes checking the condition of the engine, since the correctness of the measurement depends on this. For example, if even slight deviations are noticeable in the operation of the motor, they can affect the compression indicator during measurement.

Preparation also includes selecting the necessary tools:

- fully functional battery;

- pipe wrench;

- actually, the compression meter itself.

In some cases, especially for beginners, it is recommended to use the help of an assistant.

The measurement process itself looks like this:

- the motor initially heats up to a temperature of 50-60°;

- the spark plugs are unscrewed from the machine (using a pipe wrench or spark plug wrench);

- The crankshaft sensor is disconnected from the connector;

- the meter lead is screwed into the spark plug hole;

- the assistant turns on the ignition and presses the accelerator pedal;

- after the arrow on the meter stops, you need to write down the data;

- repeat the same procedure on all cylinders.

Why is the sensor disconnected? It's simple. This is done to prevent the controls on the computer from going wrong. In addition, in this way you can turn off the fuel supply to the injectors.

Compression can be measured on both a hot and cold engine.

| Hot engine | 1 cylinder | 2 cylinder | 3 cylinder | 4 cylinder |

| Open throttle and injectors disabled (ODZ) | 12.5 | 12 | 12 | 12 |

| Closed throttle and injectors disabled (ZDZ) | 11 | 10.05 | 10.05 | 11 |

| Open throttle connected injectors (fuel enters cylinders) | 12 | 11 | 11 | 11 |

| Cold engine | ||||

| Open throttle and injectors disabled | 12.3 | 11.5 | 11.5 | 11 |

| Closed throttle and injectors disabled | 12 | 11 | 11 | 12 |

| Open throttle connected injectors (fuel enters cylinders) | 13 | 12 | 12 | 12 |

However, correctly carried out measurements should also take into account leaks that inevitably occur on an injection-type engine. They are measured with another tool - a pneumatic tester.

To eliminate various errors on the injector, it is necessary to carry out measurements based on the position of the throttle assembly.

- First you need to turn off the fuel supply by removing the fuel pump from the system or removing the chips from the injectors.

- Open the throttle valve.

- Rotate the starter until the needle no longer rises.

Thus, the instructions on how to correctly measure compression on an injector tell us the following. It is necessary to measure compression with both the ODZ and the 3DZ. Both measurement methods provide indicators that help identify certain groups of defects.

Let's start with the fact that with ZZZ less air enters the cylinders. This means the pressure will be low. When measuring compression, this must be taken into account, because the parameter can be equal to 0.8 MPa. It turns out that air enters the cylinder in the same quantity as it is lost. Therefore, there is a noticeable drop in compression, even if there is a small leak.

A different picture is visible with ODD. There is much more air flow and less leakage. Therefore, the pressure does not drop much - to a maximum of 0.9 MPa. Diagnostics with ODZ makes it possible to detect gross defects observed in the engine.

You can check compression not only using a meter, although it is a compression meter together with other equipment that gives a complete result. You can diagnose the compression ratio using regular engine oil (using a meter, of course).

- Pour about 30 grams of lubricant into the hole from the removed spark plug.

- Check compression.

If it increases sharply, and the difference in its values between the cylinders disappears, it means that not everything is in order with the rings or seals.

How often should compression ratio be measured?

The exact frequency of checking compression of power units has not been established. There are symptoms that indicate the need for measurements:

- one or two cylinders are not working well, causing the engine to shake and “trouble” even at idle;

- there was a significant consumption of engine oil (over 100 g per 1 thousand kilometers);

- engine power has dropped;

- bluish or white smoke comes out of the exhaust pipe;

- Cold starting is difficult.

If you are used to checking and changing spark plugs every 20-50 thousand kilometers, then measure the pressure in the cylinders at the same frequency. This will help monitor the condition of the CPG and prepare in advance for possible repairs.

How to determine the pressure in diesel cylinders

To organize the procedure, you will need to prepare a well-charged battery and a compression gauge for working with diesel engines (it has special attachments and a measurement limit of up to 60-70 atmospheres). Engine compression is measured after it has warmed up. Following actions:

- remove the glow plug;

- screw the compression gauge into the vacated hole;

- turn off the diesel fuel supply (remove the power plug from the solenoid valve);

- ask a friend to press the accelerator (if the diesel engine has a valve that creates a vacuum used in the vacuum brake booster and regulator) and turn on the starter with the “start” button;

- remember (write down) the data obtained using the device;

- check the obtained values with those recommended by the car manufacturer (the necessary information is in the service book).

We recommend: Oil leakage from under the crankshaft oil seal: causes and troubleshooting

The compression value in a diesel engine depends on the brand of engine and is in the range of 28-40 kg/sq.m. see. An interesting dependence of compression in a diesel engine on the possibility of starting it at a certain outside temperature. Below are the compression values when the engine starts without problems:

- up to 28 kg/sq. cm: air temperature not lower than minus 15 degrees;

- up to 30 kg/sq. cm: normal start at minus 20;

- up to 32 kg/sq. cm: the engine will start at minus 25;

- up to 36 kg/sq. cm: start-up can be done at minus 30;

- up to 40 kg/sq. cm: diesel is able to start at 35 degrees below zero.

A drop in compression in diesel engines is accompanied by the appearance of a bluish exhaust from the muffler pipe, which is associated with incomplete combustion of fuel due to low temperature. Another consequence of a decrease in pressure in the cylinders is poor atomization of diesel fuel in the chambers, leading to a drop in power of the power unit.

How to check compression on gasoline and diesel engines

Checking compression in engine cylinders using various methods allows you to more accurately determine the problem area where you should concentrate your efforts. You can take measurements in your own garage, without resorting to the services of specialists. If you decide to measure this extremely important indicator yourself, then you need to arm yourself with the following arsenal:

- The measuring device itself is a compression meter.

- Charged car battery.

- Candle key.

- Defective starter.

We recommend: Electrolyte for batteries

Experts often carry out measurements on a cold engine. If you do not have proper experience in carrying out such work, then you must first warm up the engine. After which the air filter is dismantled and the low-voltage wires are disconnected.

A compression gauge is a regular pressure gauge with a special adapter. The device is connected to the spark plug hole and thus a measurement takes place in each cylinder while simultaneously starting the engine at idle. The compression gauge is held for several seconds. As soon as the arrow stops growing, the device is disconnected. It is advisable to perform this procedure several times, and then display the average value. It is a completely normal situation when the data obtained differs from those certified by the manufacturer. After all, during the operation of the car, natural wear of the piston group parts occurs, which helps to reduce compression. A discrepancy within 10% is considered acceptable.

If some deviations from the norm of compression of a gasoline engine are acceptable, then for a diesel engine everything is much more serious. It is worth taking measurements of a diesel engine not only to determine the condition of the piston group, but also to obtain the temperature range at which stable operation of a “cold” diesel engine is possible. In order to measure the pressure in the cylinders of a diesel engine, it is necessary to turn off the power, leaving only the starter in working condition. When measuring, it is necessary to observe, perhaps, the most important condition - the crankshaft must make 200-250 revolutions per minute.

To measure this parameter in the cylinders of a diesel engine, the following conditions must be met:

- Turn off the fuel supply;

- Unscrew one nozzle;

- Make sure the battery and starter are working properly.

It is necessary to de-energize the fuel supply solenoid valve along the line. After which the compression gauge is connected to the nozzle hole. The device must have a measurement limit of at least 60 atmospheres.

How and what to measure

Compressometer

Compression is measured with a special device - a compression meter. It is a pressure gauge with a hose, at the end of which there is a fitting, either metal with a thread for a spark plug hole, or rubber in the form of a cone.

The process of measuring compression using a compression gauge involves placing a fitting in the spark plug hole and cranking the crankshaft with the starter until maximum pressure is reached.

Compression in a cylinder can also not be measured, but checked and compared with other cylinders.

To do this, unscrew all the spark plugs except one, and manually (using a wrench on the generator pulley nut) turn the crankshaft until the piston reaches top dead center.

Then they check the second cylinder, the third and the fourth in the same way, and compare the applied forces. Of course, this method is not comparable to measuring with a compression gauge, but it can help to understand which cylinder has a problem.

What should the compression be in VAZ cars?

The average compression rate for unboosted VAZ engines is 8-9 atmospheres, for forced ones with a reduced combustion chamber - 11-13 atmospheres.

In order to accurately determine the standard compression ratio, use the table that indicates the compression ratio in the cylinders of eight- and sixteen-valve VAZ engines.

| Number of valves | 16 | 16 | 8 | |

| Engine volume, l | 1,5 | 1,6 | 1,5 | 1,6 |

| Cylinder diameter/piston stroke, mm | 82/71 | 82/75,6 | 82/71 | 82/75,6 |

| Compression ratio | 10,5 | 10,3 | 9,9 | 9,6 |

Compression standards in engine cylinders

To assess the technical condition of the power unit, you need to know what compression values are considered normal, because engines are different. As a result of repeated practical measurements made over many years, the following relationship between the compression ratio and the measured pressure was revealed: when taking measurements on a car with a hot engine, a working starter and a fully charged battery, the minimum permissible compression value is equal to the nameplate compression ratio multiplied by a factor of 1 ,3.

In numbers for different engines this is expressed as follows:

| engine's type | Gasoline, old model with compression ratio up to 8.5 | Modern gasoline with a compression ratio of 9.3—10 | Diesel |

| Minimum permissible pressure, Bar | 11 | 12 | 22 |

| Optimal pressure, bar | 13 | 14—15 | 30 |

When the piston group of a car is severely worn out or the valves are burnt out, the compression in the “sick” cylinders drops below the permissible values indicated in the table. If, for various reasons, a large amount of motor lubricant gets into the CPG, then all the gaps become sealed, and the pressure rises above normal. This phenomenon can mislead an inexperienced motorist who undertakes diagnostics.

A difference in cylinder performance exceeding 1 bar is also unacceptable. It indicates that one or more components of the CPG are not operating at full capacity, or are even inactive, increasing fuel consumption by 10-25%.

Compressometer - a device for measuring pressure with your own hands

Measurements are carried out with a special device - a compression meter, consisting of the following elements:

- pressure gauge with threaded fitting;

- steel tube or flexible hose with built-in check valve and air release button;

- a nozzle for screwing into a cylinder, equipped with adapters for other threads or a rubber cone.

A compression gauge complete with various nozzles and adapters.

The pressure gauge is screwed into a tube (flexible hose), and a threaded tip is installed at the other end. The check valve serves to record the pressure gauge readings, because when checking, the piston “pumps up” pressure over several revolutions of the crankshaft (about 10).

To analyze power units running on gasoline and diesel fuel, pressure gauges with different measuring scales can be used. If for gasoline engines a device designed for 20-25 Bar is sufficient, then for diagnosing a diesel engine a scale of at least 50 Bar is required.

Engine compression: what is it and what is it used for?

Compression, in simple terms, is the pressure generated at the highest point of movement of the crankshaft during the compression stroke. Factors influencing changes in the compression ratio can tell a lot about the condition of the engine, its level of wear and possible problems that affect its normal functioning and the behavior of the car as a whole.

Measuring engine compression using instruments

Such factors include timing defects, wear of the piston group, coking of parts and many others. Deterioration of the technical parameters of the power unit, a sharp jump in fuel consumption - all these are the consequences of changing the compression value up or down, regardless of what specific reasons were the impetus for this.

Pressure is measured in atmospheres. Some pressure gauges use other units of measurement - bar, Megapascal.

Factors affecting internal combustion engine compression

The compression level directly depends on the volume of incoming air flow, which, in turn, depends on the problems and defects listed above. Separately, it is worth mentioning the throttle valve, which has a significant impact on compression in the cylinders: its position is regulated by air flow. Its intensity, in turn, depends on the air filter: drivers often forget to clean and change it when it gets dirty, which leads to a deterioration in its capacity.

A dirty air filter reduces engine compression

We recommend: How to reupholster a steering wheel with leather yourself?

Compression values can vary greatly depending on the set gas distribution phases: if errors are made during their installation, the closing moment of the intake valve changes, which moves the cylinder in a certain direction.

The compression ratio can vary depending on the width of the clearances in the valve actuator. For example, the pressure may decrease if the gap is too small, causing the closing of the intake valves to be delayed. At the same time, valve overlap increases - the angle at which the valves open at the same time. This also has a negative impact on compression levels.

Due to the low temperature of the internal combustion engine, the air flow entering a cold engine does not have time to expand and warm up sufficiently, without subsequently creating the required pressure - accordingly, the compression value of the cylinders also drops.

One of the reasons for reduced compression is valve clearances

The presence of valve clearances leads to air leaks. Their intensity is influenced by certain factors that have a similar effect on the amount of compression:

- Motor temperature. As it increases, compression also increases, since the distance between the parts decreases;

- Engine oil supply. A tighter fit of the engine's rubbing parts to each other is ensured by an oil layer on their surface, which also makes it possible to reduce gaps and reduce air leaks through them;

- Fuel supply. The oil film formed on the inner surface of the cylinders when fuel drops enter is quickly washed away, which can stall the operation of the entire internal combustion engine, increases friction and reduces the density of contact of surfaces to each other;

- Depressurization of pressure gauge hoses, check valve, high force applied by springs;

- Increase in crankshaft speed.

What does engine compression affect?

The engine compression level affects various processes and engine parameters:

- Completeness of fuel combustion;

- Engine oil consumption;

- Ease of starting the engine. A decrease in pressure below normal makes it much more difficult to start the engine, especially in the cold season;

- Correct operation of the cylinders. Low compression can increase the risk of engine stalling;

- Power. The lower the compression, the lower the power.

What does a compression test show: main faults

Before considering how to measure compression, it is necessary to understand the definition itself. It is often confused with the compression ratio. In fact, the compression ratio is the ratio of the volume of the entire cylinder to the volume of the compression chamber (the space above the piston when it is at top dead center).

This is a constant value, and it changes when the parameters of the cylinder or piston change (for example, when replacing a piston from a convex to a flat one, the compression ratio decreases as the volume of the compression chamber increases). It is always indicated by a fraction, for example 1:12.

Compression (more accurately defined as pressure at the end of the compression stroke) refers to the maximum pressure that the piston creates when it reaches top dead center at the end of the compression stroke (both intake and exhaust valves are closed).

Compression depends on the compression ratio, but the second parameter does not depend on the first. The pressure value at the end of the compression stroke also depends on additional factors that may be present during measurements:

- pressure at the beginning of the compression stroke;

- how the valve timing is adjusted;

- temperature during measurements;

- leaks in the cylinder;

- crankshaft starting speed;

- dead battery;

- excessive amount of oil in the cylinder (if the cylinder-piston group is worn);

- resistance in the intake manifold pipe;

- motor oil viscosity.

Some mechanics try to increase engine power by increasing the compression ratio. In fact, this procedure only slightly changes this parameter. You can read about other ways to add “horses” to the engine in a separate article.

Changed compression ratio

What does pressure at the end of the compression stroke affect? Here are just a few factors:

- Cold engine start. This factor is especially important for diesel engines. In them, the air-fuel mixture is ignited due to the temperature of highly compressed air. For gasoline units, this parameter is no less important.

- In some cases, a decrease in compression causes an increase in crankcase gas pressure. Because of this, a larger volume of oil vapor enters back into the engine, which leads to increased exhaust toxicity, as well as contamination of the combustion chamber.

- Vehicle dynamics. As compression decreases, engine response drops noticeably, fuel consumption increases, and the oil level in the crankcase drops faster (if lubricant leaks through the oil scraper ring, the oil burns, which is accompanied by blue smoke from the exhaust pipe).

There is no universal value for the pressure at the end of the compression stroke, since it depends on the parameters of the individual power unit. In view of this, it is impossible to name a universal compression value for all power units. This parameter can be found in the technical documentation of the vehicle.

When a change in pressure is detected during measurements, this may indicate the following malfunctions:

- Piston wear. Since these parts are made of aluminum, they will wear out over time. If a hole forms in the piston (burns out), compression in that cylinder can be greatly reduced or practically disappear (depending on the size of the hole).

- Burnout of valves. This often happens when the ignition is set incorrectly. In this case, combustion of the air-fuel mixture occurs when the valve is open, which leads to overheating of its edges. Another reason for the valve seat or “plate” to burn out is a lean air-fuel mixture. A decrease in compression can also be a consequence of the fact that the valves do not sit tightly in the seats (deformed). Gaps between the valve and its seat cause premature leakage of gases, causing the piston to push out with insufficient force.

- Damage to the cylinder head gasket. If for some reason it bursts, gases will partially leak into the resulting crack (the pressure in the cylinder is high, and they will definitely find a “weak spot”).

- Wear of piston rings. If the rings are in good condition, they regulate oil flow and seal the sliding movements of the piston. Another of their functions is to remove heat from the piston to the cylinder walls. When the tightness of the compression pistons is broken, exhaust gases penetrate to a greater extent into the crankcase rather than being removed into the exhaust system. If the oil scraper rings wear out, more lubricant enters the combustion chamber, which leads to increased oil consumption.

Also, during measurements, it is worth paying attention to the extent to which the pressure in the cylinders has changed. If the procedure showed a uniform decline in the indicator in all cylinders, then this indicates natural wear of the cylinder-piston group (or some of its parts, for example, rings).

When the pressure at the end of the compression stroke of one cylinder (or several) differs significantly from the compression in others, this indicates a malfunction in this unit. Among the reasons are the following:

- Burnt out valve;

- Sagging piston rings (mechanics call this “stuck rings”);

- Burnt out cylinder head gasket.

What to do if diagnostic results are disappointing

When the pressure in one or more cylinders deviates from normal, you are dealing with a malfunction of the power unit. As a rule, such problems require partial or major repairs of the “heart” of the machine. If the indicators are too low, the following breakdowns are possible:

- Wear of rings, pistons and liners (with the same values on all cylinders). The “diagnosis” can be clarified if a second measurement is taken with the addition of 4-5 ml of motor oil to the cylinders. Increasing the compression will confirm the result. If the readings do not change, then the following problem occurs.

- The presence of leaky valves in the chambers (at different values).

- One of the valves or pistons is burnt out (no pressure at all).

Piston burnout in the center (left) and side (right)

A pneumatic tester can provide more accurate results. The breakdown is detected as follows: if air goes into the crankcase, then the pistons pass, and if it goes into the manifold, the valves. Malfunctions associated with a drop in compression below normal are eliminated by disassembling the power unit and replacing worn parts. There is no point in changing one valve, since over time the next one will fail. It is better to install a new valve group.

The same applies to pistons - a set is installed at once, and the parts are selected by weight so that the difference is no more than 5 g. Fitting is done by removing a thin layer of metal from the inside of the heaviest pistons with a scraper. If, after removing the block head, the measurement showed a large ellipse-shaped hole in the cylinders, then they should be bored on a machine to the next repair size.

In many foreign-made engines, the installation of repair parts is not provided. There you need to change the entire set at once - liners, pistons and rings.

If you do not respond to a drop in compression below normal in a timely manner, the consequences may be as follows:

- cold starting the engine will become more difficult, and then completely impossible, without injecting oil into the cylinders;

- consumption of motor lubricant due to waste will increase to 1-1.5 liters per 1000 km, which may cause spark plugs to fail and rings to become coked;

- due to the large difference in compression in the cylinders, the engine will operate unstably and vibrate;

- fuel consumption will increase significantly;

- the power of the power unit will drop to such an extent that driving will become impossible.

This is what a burnt valve on the side looks like

The reason for excessive compression is the presence of motor oil in the combustion chambers in large quantities, which leads to compaction of all gaps. The problem arises due to unsuitable oil reflecting caps, when lubricant enters the chambers not from below, but from above, through the valves. This problem is considered relatively harmless: oil deflectors are replaced in 2-3 hours, depending on the make of the car.

Compression measurement continues to be one of the simplest and fastest methods for diagnosing power units. When engine problems occur, the first thing you need to do is check the pressure. And based on the test results, you should decide on the further sequence of actions: carry out more in-depth diagnostics or disassemble and repair the motor.

Why add oil to the cylinders?

A problem with rings, pistons, valves or gaskets is more accurately diagnosed by filling the cylinder under test with about 3-5cc. see butter. An immediate increase in compression after adding oil already on the first stroke will indicate piston ring failure. If the compression is initially low, then oil was added, but it was not possible to increase the compression, then leaks through the cylinder head gasket are likely.

Most often, compression drops in only one cylinder. About 5 “cubes” of clean engine oil should be poured into this cylinder with the lowest compression. During the filling process, the oil should not fall on the piston bottom, but on the walls of the cylinder liner. Next, the compression measurement is repeated. If the pressure increases relative to the readings in other cylinders, it is likely that the piston rings are coked, stuck or destroyed.

Also, the absence of changes in the readings after adding oil may indicate that the valves are not completely seated against the seats. The valve may burn out or the valve seat may be damaged; the valve clearances may be incorrectly adjusted.

To diagnose cylinder head gasket damage, piston burnout or cracks in the piston body, it is necessary to install the piston closer to top dead center (TDC), which corresponds to the compression stroke. Next, you need to supply a portion of air into the cylinder under a pressure of about 2 - 3 atmospheres.

If the head gasket is damaged, then the sound of air escaping from the spark plug well located nearby will be heard. Air escaping through the carburetor means the intake valve is not seated properly. Additionally, the oil filler plug is removed. If air comes from there, a burnout or crack in the piston is likely. Air in the exhaust tract will indicate a loose or burnt exhaust valve.

For maximum accuracy, it is recommended to use a combined method of measuring compression (measuring “cold” and “hot”, with the throttle valve open and closed). At the initial stage, you need to measure the compression in the cylinders of a gasoline unit with the throttle open. Then the spark plugs, glow plugs or diesel injectors (depending on the type of internal combustion engine) are put in place and the engine starts. It is necessary to warm up the engine, and then measure the compression (with the throttle closed for gasoline engines).

You need to measure compression on a cold engine when you cannot start the engine. The engine does not start “when cold” due to critical wear of the CPG, as well as as a result of stuck piston rings. On a cold internal combustion engine, the pressure in such cases drops by two or more times. Warming up the engine allows you to increase compression, after which the unit is acceptable.

It is separately recommended to carry out compression measurements on a cold diesel engine. The measurement indicator in a diesel engine depends on the presence of oil in the cylinders. Before measuring diesel compression, the engine must sit for at least 2 hours.

This time is necessary for the remaining oil to completely drain back into the engine crankcase. A drop in the compression rate for a cold diesel engine below 18 atmospheres will mean that starting such an engine is almost impossible. If the indicator after warming up does not rise above 24 atmospheres, then the engine must be repaired.