Many car enthusiasts like to carry out tuning of various kinds. Recently, the installation of a crankcase gas oil separator has become widespread. It is especially popular among fans of fast driving. In stores, they will ask for 2000 rubles for such a device, if not more. However, why pay if you can make such a necessary device yourself?! But first you need to figure out why it is needed at all. Maybe the engine is fine without it? But there are some peculiarities that this article is devoted to.

A little theory

First, a little theoretical part. In any car engine, even a modern model, each system performs its duties, and there is nothing superfluous. Here we can draw a parallel with a person whose all organs are important and necessary. The main thing is to maintain a healthy lifestyle. Any car in this regard also needs regular maintenance.

The functions of all engine components and assemblies are constantly dependent on each other. And if a part breaks down in any system, the efficiency of the power plant is significantly reduced. The same applies to the crankcase ventilation system, in which a crankcase oil separator is simply necessary.

Engine crankcase ventilation system

As a rule, pistons fit tightly to the cylinder walls of the engine due to compression and oil rings. Despite this design of the piston group elements, it is impossible to ensure complete sealing of the combustion chamber. And some of the gases from the burned fuel still break into the crankcase, which is why they are called crankcase gases.

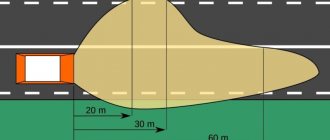

Moreover, depending on the design of the engine, 10-30 liters of gas can flow into the crankcase from just one cylinder in one minute. Due to the fact that the pistons move at high speed, the crankcase gases are constantly enriched with oil particles 0.1-2 microns in size. Oil mist is also formed due to the rotating crankshaft, which is immersed in an oil bath.

The problem itself is that the accumulation of gases in the crankcase leads to an increase in pressure that is exerted on the lubricant consumable. And in the absence of an oil separator for crankcase gases, this leads to an increase in pressure inside the lubrication system, and the oil puts pressure on weak areas, which are oil seals and seals. As a result, oil leakage cannot be avoided, and the engine becomes oil starved.

Methods for filtering crankcase gases

Crankcase ventilation system diagram

Domestic cars and some foreign cars do not have a crankcase gas filter.

The problem of filtering crankcase gases to ensure cleanliness in the combustion chamber and crankcase can be solved in several ways.

- Disconnecting the crankcase gas pipe from the throttle assembly. In this case, gases will escape into the engine compartment, polluting it. When pressure changes, air with dust and dirt can be sucked into the crankcase, thereby contaminating the oil. Simply disconnecting the pipe is not a solution to the situation, so a filter is attached to the pipe. The inlet to the throttle body should also be plugged to prevent dirt from entering the intake manifold and combustion chamber.

- Installing a filter element between the crankcase and the throttle assembly, in opposition to the pipe. This option is preferable, since it solves the issue of filtering crankcase gases and preventing the access of air from the external environment into the crankcase and throttle assembly. At the same time, oil vapor is partially supplied in minimal volumes to lubricate the units in the inlet manifold (throttle).

Here are photo instructions for implementing the first method:

The end of the hose circled in blue is disconnected

A filter is installed on the free fitting

The hose is cut and plugged with a champagne cork.

Into this hose.

. insert a metal ball for sealing

Since the manufacturer does not provide crankcase gas filters in the design of the car, it is impossible to purchase the recommended filter. It is not prohibited to use filters designed for modern foreign cars, but financial resources must be spent on this. An alternative to the factory filter is to use a simple fuel filter element. True, it is significantly inferior to the factory ones in terms of its consumer properties. It will quickly become clogged with oil droplets, resulting in the need for frequent replacement.

Conventional fuel filter in ruptured pipes

Filter after 2000 km

Some car owners decide differently with the filter element. You can make a crankcase gas filter with your own hands. The process of making it at home is not difficult, and the cost of homemade filter elements is minimal.

Homemade filter option

Homemade filter circuit

For self-production you will need:

- Sewer connection coupling made of propylene with a diameter of 50 mm, a length of 10 cm, which has protective rubber cuffs at the edges on both sides.

- two plugs for sewer pipes with a diameter of 50 mm made of propylene. They are necessary to turn the coupling into a hollow cylinder.

- two plastic pipes for connecting to a hose. The size must match the inner diameter of the hose. You can use plastic or metal threaded fittings.

- metal sponges for washing dishes. They will be used as a filter element and oil catcher.

- hoses, according to the size of the pipe outlets from the crankcase and the entrance to the throttle assembly.

Use a sewer coupling and metal brushes

Oil separator operation

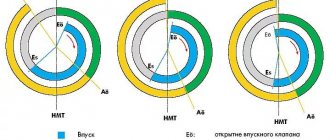

The oil separator, which is an important element of the crankcase gas recirculation system, can operate according to one of two basic principles:

- labyrinthine;

- cyclical.

Using the labyrinth method, the speed of crankcase gases decreases. Due to this, larger drops of oil remain on the walls of the device, and then fall back into the engine crankcase.

Passing through the cyclic oil separator, the gases begin to rotate. Thanks to the centrifugal force generated in the device, oil drops settle on the walls of the oil trap, after which they flow by gravity into the crankcase. And to eliminate gas turbulence, a labyrinth crankcase oil separator is used, in which the oil becomes completely separable from the gases.

Cyclone oil separators (oil separators)

To get rid of the shortcomings of synthetic fiber filter fabric, cyclonic oil separators .

Rice. Operating principle of the engine crankcase ventilation system with a cyclone oil separator: 1 – cyclone oil separator; 2 – pressure regulation valve; 3 – charge air cooler; 4 – turbocharger; 5 – gases breaking through the piston rings

Crankcase gases are supplied through a channel inside the engine into a cyclone oil separator. The cyclone oil separator causes the air to rotate. Due to the resulting centrifugal force, the oil mist hits the wall of the oil separator. Drops of oil form there, which flow through a channel in the crankcase into the oil pan. The air, cleared of oil mist, is supplied to the air intake duct through the pressure control valve.

The cyclone oil separator is equipped with a special valve that limits the vacuum in the engine crankcase, since a strong vacuum can damage the engine oil seals and other rubber seals.

Rice. Diagram of operation of the cyclone oil separator pressure control valve: 1 – crankcase gas supply pipeline; 2 – air intake pipeline; 3 – membrane; 4 – compression spring; a – open position of the valve; b – valve closed position

The pressure control valve is located in the cover of the cyclone oil separator. It consists of a diaphragm and a compression spring and regulates the pressure when air is removed from the crankcase. The pressure control valve closes when there is a strong vacuum in the intake channel. When there is a slight vacuum in the intake channel, it opens by the force of a compression spring.

The operating principle of an internal combustion engine is that the pressure energy from the combustion of the fuel-air mixture in the chamber is converted into mechanical energy. The power of energy obtained from fuel combustion depends on many parameters, including the composition of the fuel-air mixture, its purity, chamber volume, compression ratio, and the presence of pollutants on the walls of all elements of the combustion chamber. Part of the unburned fuel mixture, soot particles, and combustion products, one way or another, enter the crankcase through the piston rings, in the space of which oil vapors are suspended. These oil vapors enter through the pipe into the throttle assembly of the injection engine or into the carburetor. Crankcase gases, which contain oil molecules, are designed to lubricate the elements of the carburetor or throttle assembly, followed by combustion in the engine. However, fuel quality, heavy engine operating conditions, wear of piston rings and cylinder walls allow contaminants to enter the crankcase. These elements, one way or another, again end up in the intake manifold. The process is repeated in a spiral, increasing the degree of contamination of all surfaces in the combustion chamber and the fuel-air mixture. These processes lead to loss of power.

Read also: The car was taken away by a tow truck and fines

In modern imported cars, crankcase gases are purified through a centrifugal filter element. The filter separates contaminant particles, traps excess oil vapor and returns it to the crankcase, preventing it from entering the intake manifold.

Serious damage to the engine

Burnt gases have a negative impact on the oil and reduce engine efficiency. In fact, crankcase gases are unburnt fuel residues and contain many harmful impurities that have a detrimental effect on the environment. The presence of water evaporation in gases leads to the formation of an emulsion, due to which foam is observed in the oil. Because of it, the rubbing elements do not receive a sufficient amount of lubrication, due to which they wear out faster and fail. And the vapors themselves that fall on the oil dilute it. Various impurities are formed, which have the most destructive effect, reducing the durability of almost all parts with which the oil comes into contact. As a result, the engine life is reduced several times.

A wise decision

The increased pressure that is constantly applied to the oil worsens the properties of the lubricant over time. Without a crankcase gas oil separator on the Polo, for example, the lubricant itself ages faster and its service life is significantly reduced, which entails frequent replacement of consumables. To avoid unnecessary pressure in the engine crankcase, a special exhaust gas ventilation system is provided. However, the standard separator, which is installed by many manufacturers on cars, does not completely clean the crankcase gases from oil particles. Therefore, some car enthusiasts install an additional device.

Most drivers of domestic and foreign cars with impressive mileage have often encountered sticky oil deposits on various parts of the engine. Often this is:

- intake tract;

- throttle valve;

- intake manifold;

- idle control valve;

- air filter - oil can get here through the mass air flow sensor (MAF).

By interacting with the mass air flow sensor, the oil can cause its failure, and replacing it costs 2500-3000 rubles. Isn't this a reason to take care of an additional measure in the form of a crankcase oil separator on a Citroen-Picasso or any other car?

Oil washer. What, why, and do you need

In general, it is correct to call it an “oil catcher”. But you must admit, it’s much more brutal to casually throw out “Yes, I’m thinking about installing an oil sump.” “But in order to install it, you need to understand what it is, where it is placed and why, in fact, it is needed. Today we'll figure it out. And first, a little theory.

Where does the oil in the intake come from?

Let me start by saying that in this article I have already explained in detail and in simple words what crankcase ventilation

(VKG) and why it is needed. It also describes step by step why oil can burn due to a clogged system and how to fix it. But constant topping up to the level is only an external manifestation of the disease. It becomes much more fun when the speed starts to fluctuate, errors in mixture formation and throttle appear, and traction deteriorates. And all this because the oil flying into the intake throws everything it passes through in its path: the throttle itself, the idle air regulator, sometimes even the mass air flow sensor. Well, I’m not talking about carbon deposits on valves and pistons, due to the constant bathing in oil mist.

Thus, we already know (those who don’t know, follow the links above and find out) that the root cause of “Shrovetide” in the intake tract is, as a rule, inadequate ventilation. Why she can’t cope is, again, explained in my other articles, but today we’re talking about dealing with the consequences.

So what should we do?

Well, everything is transparent here. No matter how anyone makes excuses, a healthy engine won’t throw spoonfuls of oil into the intake

.

And if you’re too lazy to start repairing the engine, but the oil pumping is already bad, we’ll treat it with poultices. And for this, caring manufacturers of various tuning

have long come up with special fo-yu!

As you may have guessed, we are talking about a device called an oil trap

(the notorious oil washer).

By the way, do not confuse it with the membrane oil separator

of the same ventilation system. So, the name fully reflects the simple-as-a-log essence of the miracle device: to catch the liquid component from the mixture splashing with oil, accumulating it in a reservoir. If very schematically, then take a ventilation tube (the so-called breather), pull it out of the inlet pipe and insert it into the oil trap. Profit! And then there are possible options.

A)

The outlet from the oil trap (MU) is inserted back into the inlet. That is, with this scheme, the MU serves as a separator embedded in the line, separating the liquid and then returning crankcase gases to the intake tract (as it was from the factory). Only without oil. The most correct scheme. Accordingly, almost no one does this.

b)

The exit from the MU is not inserted anywhere, but goes out stupidly outside, into the atmosphere. The hole in the inlet pipe is plugged with a plug. Even a plastic bottle can be used as an oil separator body. A method for those who “I’ve been working on cars for 40 years!” and the right guys on the humiliated Devyatyny with a Chinese turbine.

Why is option "a" better?

There are a couple of objective reasons for this.

- The crankcase gases are also drawn out by the vacuum in the intake, whereas in the second option they come out only under pressure in the crankcase itself. Actually, this is how the engineers intended it: there should always be a vacuum in the ventilation system

. Otherwise, its effectiveness decreases. Well, that is, if the cart is not only pushed from behind, but also additionally pulled from the front, it will move much easier. The analogy is clear. - An unforgettable and chronic exhaust smell in the cabin is sure to await users of the second option. Of course, many people install “vapor suppressors” in the form of fuel filters and other gadgets at the atmospheric outlet of such an oil trap, but all these are half-measures and help little.

Relevance

Why do you need to install such a clever device? Due to high crankshaft speeds, oil flies through the crankcase ventilation breather and can end up on the carburetor assembly, and in the case of injection engines, on the throttle unit. And to prevent this from happening, just such a device is installed. Moreover, it is advisable to install it not only for those drivers who do not mind pressing the accelerator pedal to the floor. Those owners who have been using their car for quite a long time should also think about it. After all, during this period, the rings have most likely already worn out and do not provide proper sealing of the combustion chamber.

What might you need?

There is no need to immediately run to the store in search of a miracle device, because you can make it yourself, unless you buy the necessary “ingredients”. So, for home production of a crankcase gas oil separator on a VAZ-2109 (for example), you cannot do without:

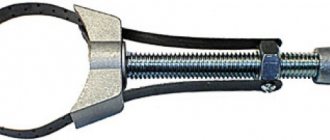

- repair coupling;

- plugs for the socket (2 pieces);

- plastic pipes (also 2 pieces);

- metal sponge.

A repair coupling is sold at any hardware store and is used when carrying out sewer work. It is a plastic cylinder, which at both ends has a small thickening on the outside with a rubber seal. The remaining components can also be purchased both at construction sites and in stores selling household goods. As for the cost, it is quite affordable and affordable for any family budget. The metal sponge will serve as the main element of the entire system.

Is it possible to install an additional oil separating filter?

As you can see, this is a useful thing, especially when there is no time or desire to clean the throttle, change spark plugs and clean the intake manifold. However, not many automakers install such filters on their cars.

If there is no oil trap, you can install it additionally by first purchasing a ready-made one in the store (experienced users claim that they are ineffective) or make it yourself.

For an example of how this can be done, see here:

Video taken from the YouTube channel “Denis MECHANIC”

And more on the topic:

Video taken from the YouTube channel “Yuri K”

As usual, each person must draw their own conclusions!

Source

Assembly process

There is no particular difficulty in assembly. The first step is to put a plug on one end of the coupling. The result will be something like a glass, but not for tea drinking. During operation of the most effective design of the crankcase gas oil separator, the plug will not have to be removed, and therefore for better reliability it is worth sealing it with a sealant. The next step is to place the metal sponge on the bottom of the cylinder. Just don't fill it out completely. In the upper part of the second plug, you need to drill two holes for the prepared plastic pipes. The edges of the tubes should be treated with silicone grease and installed in the prepared holes.

Looking at the inside of the plug, one of the pipes should be 1 centimeter shorter than the other. The longer one will be the intake one. Now all that remains is to fix the resulting cover in the rubber gasket. That's all - the homemade automotive gadget for catching crankcase gases is ready. If the owner has a delicate taste, then the product can be painted in the desired color and then allowed to dry thoroughly. Only after this can you proceed to further installation.

How to make an oil trap yourself

I decided to post my oil catcher, because there is a lot of incomprehensible information on the Internet. They show the finished version, but the most important thing is that it doesn’t show how it works inside. A more correct option is this. The exhaust gases must rise from below and pass completely through the scrapers. You can buy ready-made branded ones, but the cost is surprising.

They also put the tube outside, but you don’t want to breathe gases when the car is warming up, stuck in a traffic jam, or when you turn on the heater in winter.

I put it in my VAZ 2105, drove it 100 km and put it in for repairs, I need to do the engine. It is clear that oil was thrown into the carburetor before the oil sump was installed, now it will be interesting with the new engine how the oil catcher will work.

I created the diagram myself.

mesh so that the scrapers do not fall down into the emulsion

ordinary stainless steel scrapers

At the outlet of the oil catcher, I put a brush in the tube to make sure nothing gets into the carburetor.

Device installation

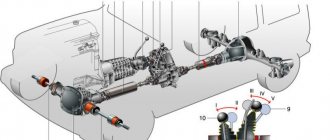

The crankcase gas oil separator is installed depending on the engine type:

- carburetor;

- injector.

In carburetor engines, the device is mounted directly in front of the air filter, which regulates crankcase gases. If it is an injector, the device is connected to the inlet pipe located close to the throttle valve and cylinder block cover.

The system is now ready for use. However, for its high-quality and productive functioning, installation alone is not enough; it is necessary to inspect the device from time to time and carry out regular maintenance. To do this, the device must be disconnected from the system and rinsed thoroughly, completely getting rid of any remaining accumulated oil. In this case, treatment with a solvent will not interfere.

After the maintenance procedure, the crankcase gas oil separator device is put into place and can be used for further operation. There is no need for frequent inspection and maintenance; the frequency can be at least once every two months.

As is already known, oil leakage not only has a negative impact on the efficiency of the engine, but also significantly reduces its service life. A homemade device allows you to eliminate this problem to some extent. However, the lubricant itself also plays a key role. Therefore, you should not save on purchases; it is better to purchase only high-quality products. No engine will put up with cheap oils whose quality is questionable.

Cheap and cheerful, but functional

Many drivers who have already managed to make a crankcase oil separator on their own are pleasantly surprised by the price. In some cases it is practically zero. Perhaps craftsmen make do with improvised means that they find in their own garage. But even if nothing suitable is available, the price of the crankcase gas oil separator is low, since all the parts from the instructions discussed above are cheap.

On the Internet you can find many ways to make a homemade device, for which different materials are used. However, everything is done according to the scheme described above. Differences may relate to the use of additional elements or the replacement of plastic pipes with metal fittings that are screwed into the oil separator cover.

At the same time, there is a positive trend in engine performance. Oil no longer accumulates, which means you can drive for a long time without problems. However, do not forget to look under the hood of the car and check the condition of the device.

Manufacturing process

- We make a hole in the plug for a plastic pipe or fitting. We fix it on the plug and seal it. This will be the filter outlet.

- At the end of the sewer coupling, closer to the edge, a hole is made for the second pipe. We fix it on the coupling and seal it. This will be the inlet pipe from the crankcase.

- We stuff metal sponges inside the coupling as a filter element. They will trap dirt and oil capillaries. You should not tightly pack the jaws inside the coupling, as this will complicate the passage of air.

- We insert the plugs from both ends into the coupling; the joint can be additionally sealed.