AMT gearbox: features, device, principle of operation

So, in order to understand what the pros and cons of the AMT gearbox are, what it is and how it works, you first need to remember the operating principle of a manual transmission and classic hydromechanical automatic transmissions.

- In cars with “mechanics”, the driver himself selects and engages a lower or higher gear depending on a number of conditions and factors (starting from a standstill, vehicle speed, load on the internal combustion engine, the need to accelerate sharply, maintain a certain driving pace, etc.). At the same time, to change gear “up” or “down” you also need to constantly squeeze the clutch when moving from step to step.

- Naturally, the load on the driver increases, and driving a manual car is more difficult. However, a manual transmission provides complete control over the car, is structurally simple and well studied, as well as reliable and maintainable. Moreover, if you learn to drive a manual “correctly”, you can achieve good fuel efficiency.

- In the case of torque converter automatic transmissions, gears are switched automatically, which significantly facilitates the driving process. At the same time, such boxes have reduced efficiency, resulting in an increase in fuel consumption (on average by 15-20%).

Also, an automatic transmission is less reliable, has a complex design, requires regular maintenance, repair of automatic transmissions and/or gas turbine engines is quite expensive and cannot always be performed efficiently.

- Now let's get back to AMT. So, the amt robotic transmission provides the convenience of an automatic transmission and the efficiency of a manual one. Also, a “robot” is cheaper to produce, which reduces the cost of the car itself with this type of transmission.

In simple words, the robotic gearbox in its operation resembles a hydromechanical automatic (gear shifting occurs automatically), but is structurally more similar to “mechanics”. The result is high fuel efficiency, reliability, and the ability to withstand high torque and heavy loads.

AMT box structure and types of robotic boxes

So, having figured out how the AMT gearbox differs, what type of transmission it is compared to its analogues, you can move on to the design of this type of gearbox.

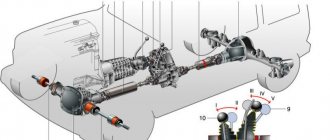

If we talk about a robotic gearbox, the design of the robotic gearbox from different manufacturers may have a number of certain differences. However, the general structure requires the presence of the following basic elements:

- clutch;

- manual box;

- special clutch and gear drive;

- electronic control system;

As for the clutch, in the AMT box this element is of a friction type. The gearbox itself is similar in design to a manual transmission. Also, robotic boxes can be equipped with an electric or hydraulic clutch drive.

In the first case, the solution has an electric motor and a mechanical transmission, while in the second, hydraulic cylinders controlled by solenoid valves are involved. The second circuit forms the electro-hydraulic clutch drive of the robotic box.

If we compare the two types of drives, the electric drive is simpler, but changes gears more slowly (up to 0.5 seconds). The hydraulic drive is more complex and works faster (0.05 sec.), while consuming more useful energy.

We also recommend reading the article about what a manual transmission is. From this article you will learn about the design of a manual transmission (“mechanics”), as well as the principles of operation of a manual (mechanical) transmission in a car.

It is quite obvious that initially the electric clutch drive was installed only on cheaper car models. Hydraulic was installed, as a rule, on business and premium cars, powerful sports cars, etc.

Let us add that today on some middle-class cars you can also find a “robot” with a hydraulic drive, although in most cases a preselective robotic gearbox with two clutches is used.

This type of robotic gearbox (for example, the well-known Volkswagen DSG) has a high switching speed (about 0.2 seconds), while a simpler electric clutch drive is used. This significantly reduces the cost and simplifies the overall design.

The control system for the robotic box is electronic. It is based on a control unit, sensors, and actuators. The transmission ECU receives signals from electronic sensors (for example, rotation speed at the input and output of the transmission, selector position, etc.). The block is also closely connected to the ECM.

Next, the block analyzes the received information and sends control signals to actuators. If the clutch drive is electric, then the signal goes to the electric motor. If a hydraulic drive is used, the unit controls the operation of the solenoid valves.

Double clutch robotic gearbox: preselective robot and its features

As mentioned above, the main disadvantage of a “single-disk” robot with an electric clutch is the slow gear shift speed.

As a result, when driving there is a noticeable gap in power, the dynamics of the car deteriorate, gears (especially when compared with automatic transmissions) are switched “hard”, jerkily, and gear shifting is very delayed.

Variations of spare parts used

Absolutely all AMTs are equipped with one of two types of drives that control the clutch and are responsible for timely switching of the desired gear. They can be either electric or hydraulic. As for the first type, a special servomechanism is used; it consists of a simple electric motor and mechanical transmission.

What about hydraulics?

, then, as you might guess, hydraulic cylinders are used there, the control of which is taken over by electromagnetic-type valves. Due to such an unusual mixture, they are also called electrohydraulic. The most obvious representative of such a system was Eastronic from Opel, as well as Durshift EST from the manufacturer Ford.

Tips and tricks for riding an AMT

To get used to the robot box and increase its service life, you can follow little tricks to make driving enjoyable and not cause negative emotions.

- One of the most unpleasant things that can happen on the road with an AMT is clutch overheating. To prevent this from happening, in a traffic jam, when stopping for longer than 10 seconds, you can put the gearbox in the “neutral” position, and during a long climb, force a manual downshift. If the box is overheated, an icon will appear on the panel. You need to stop, turn off the car and wait until the AMT cools down.

- To avoid jerking when changing gears during acceleration, you need to press and then slightly release the gas pedal at the moment when you feel the gears changing soon. After switching, you can continue to gradually pick up speed.

- At each maintenance, calibrate the box, this will increase its service life.

Some have heard negative reviews from friends and acquaintances and do not want to buy, others have tried to drive older models of a robotic gearbox.

But with the development of technology, when AMT is gradually replacing both mechanics and automatic transmissions, a robotic gearbox can become the best and most economical option for a car.

Characteristic

So, our proposed car has an AMT gearbox. What it is? This transmission is a manual gearbox. In it, gear shifting is carried out using an eclectic control unit.

The system reacts to sensor signals and generates a response impulse, thanks to which the gears are switched. What is the characteristics of an AMT gearbox? Reviews from car owners note that this transmission combines the convenience of an automatic transmission and the reliability of a manual transmission. Unlike an automatic transmission, such a gearbox requires less load, thereby reducing fuel consumption.

In terms of cost, cars with AMT are an order of magnitude cheaper than the same models with automatic transmission, and in the same configuration. This is a kind of cheap analogue of an automatic transmission. Recently, AMT has been installed even on budget cars. And we’re not just talking about foreign cars, which almost have an AMT gearbox as standard.

What cars can it be installed on?

The first car under the Lada Priora brand, equipped with AMT, was released in 2014; the installed gearbox was modified AMT-2182. After running in and finalizing the mechanisms and program elements, automatic manual transmissions began to be equipped with the Lada Granta, this happened in March 2015, and the Lada Vesta in 2021. The Lada Kalina and Lada Xray cars were equipped with the same gearbox.

Later modifications of the gearboxes are structurally similar to the first gearbox released by the company. The difference lies in the improved program of the latest version, which was developed by the German company ZF Friedrichshafen AG. The principle is based on the use of a new transmission switching algorithm and improved functional logic. AMT has a number of operational features and is characterized as a simple, reliable, economical unit.

About double clutch

Earlier in the article we mentioned German Volkswagen cars with their selective gearboxes. Recently they have become very popular. And all thanks to the use of a dual clutch system. This device allows you to quickly change gears with minimal loss in dynamics. And all this without the use of an expensive hydraulic drive. They were called preselective due to their special operating principle.

When the car is moving in one gear, the second disc is already engaged with the next one. Thus, when the car needs to switch to higher speed, this process is carried out as quickly as possible. Moreover, the system works not only to upshift, but also to downshift. The car “resets” them very quickly when braking. The design of such AMTs is very compact, which is especially important for small cars. There are two types of clutch used here. It's wet and dry.

Let's look at the technical characteristics using the example of a 7-speed AMT. An electric pump is installed here. The oil volume in the system is 1.7 liters. The peak torque of this transmission is 250 Nm.

This is quite enough for passenger cars. But as for SUVs, they lack such characteristics for acceleration. Therefore, a wet clutch type is used here (oil volume is 6.5 liters). But the torque here is much higher – 350 Nm. In any case, the use of a double clutch allows you to change gears without noticeable dips in dynamics.

Now this type of gearbox is used on German-made cars, in particular on Volkswagens. Also, Skoda cars are equipped with an AMT gearbox.

six-speed robotic transmission with two clutches. The manufacturer gives it a five-year warranty.

5 AMT transmission service

According to the manufacturer, the 5 AMT transmission does not require maintenance, its elements are protected from dust and moisture, which in turn has secured the transmission’s reputation as a simple, reliable, trouble-free mechanism.

However, it is recommended to adhere to the following rules:

- Monitor the oil level; mechanical damage to the box may cause it to leak;

- Adapt the robotic gearbox clutch in a timely manner.

The box is a set of gears controlled by a ZF actuator. The clutch of the box wears out over time and needs to be adjusted to the actuator, this process is called adaptation, it is designed to eliminate jerks and shocks when moving.

Adaptation is carried out:

- Every 15,000 km of vehicle mileage;

- In case of clutch replacement;

- When updating the on-board computer settings.

The process is simple and takes a few minutes: the car is connected to the AvtoVAZ computer through a special diagnostic connector, the electrician turns on the program and directly communicates with the manufacturer’s server. The data is downloaded to the server, after which the engine starts and adaptation occurs within a few seconds.

It is advisable to have the box diagnosed by an official representative, since the work will require special equipment and trained personnel.

Let us remind you that today in cars and off-road vehicles there are three main types of gearboxes (Gearboxes) used - mechanical, automatic and robotic. Continuously variable transmissions (variators) are also known, but their use is very limited, and today we will talk about the advantages and disadvantages of automatic and robotic gearboxes.

Hydraulic

The design has a special fluid reservoir, as well as additional cylinders (almost like in a brake system). Here, thanks to the use of hydraulics, the gear shift speed is about 0.1 seconds.

On some sports cars this figure can be 0.05 seconds, which is faster than a manual transmission. But, due to the use of a hydraulic drive, the system requires more energy. Accordingly, the design becomes more complicated. Therefore, such boxes are not installed on budget cars.

Automatic AT or AMT: gearbox features

First of all, initially cars were equipped with only two types of gearboxes: traditional mechanics and hydromechanical automatic transmission (aka AT). However, later CVT variators appeared, as well as, relatively recently, robotic gearboxes (AMT and preselective manual transmissions).

As for AMT, we immediately note that a robotic transmission of this type is actually a manual transmission that operates without driver participation, that is, gears are switched automatically. It is noteworthy that attempts to automate mechanics were made quite a long time ago, but only thanks to modern technologies and the active introduction of electronics was it possible to implement such a task.

If we talk about AT, this type of gearbox appeared a little later than manual transmission. For a long time, such a box remained the only type of automatic transmission, thanks to which, to this day, it continues to be one of the most common types of automatic transmission.

- Now let's look at the classic automatic transmission and the relatively recently appeared robots such as AMT in more detail. Let's start with a traditional slot machine.

So, a hydromechanical automatic transmission is a complex and expensive device that combines elements of hydraulics, mechanics and electronics. An automatic transmission, unlike a CVT, is a step-type gearbox, that is, it has fixed gears.

Such a box did not receive the usual mechanical clutch, since the torque from the internal combustion engine is transmitted to the transmission through a special device (“donut” automatic transmission or torque converter).

ATF (automatic transmission oil) plays an important role in such machines. This liquid is not just a lubricant, but a working fluid. The torque converter converts torque and then transmits it to the gearbox through liquid.

Also, transmission oil is supplied to the automatic transmission under pressure through the valve body channels, that is, ATF acts on the actuators to engage gears. Redistribution of fluid flows occurs by opening and closing valves (solenoids), the operation of which is controlled by the automatic transmission ECU.

The advantages of automatic transmission include fairly high comfort, smooth operation and reliability of the box. A working AT gearbox changes gears almost imperceptibly, operates quietly, without unnecessary noise or vibration.

At the same time, a classic automatic transmission (taking into account the peculiarities of its design and operation) requires a large amount of transmission oil and is sensitive to the quality of ATF and the condition of the fluid. Also, the unit is not designed for constant high loads, it is “afraid” of prolonged slipping, sudden starts, and driving at high speeds.

The presence of a torque converter also means that the efficiency of such a box is slightly lower compared to analogues (by 10-15%), which means increased fuel consumption and losses in acceleration dynamics.

The average service life of such automatic transmissions is 200-250 thousand km, but only subject to timely and high-quality maintenance, as well as compliance with a number of rules within the framework of the operation of vehicles equipped with an automatic transmission of this type. Let us also add that repairing automatic transmissions is also often difficult and expensive.

Content

- Varieties

- Variations of spare parts used

- Advantages and disadvantages

The most important difference is the type of clutch itself. In AMT

special friction clutch discs are used, and their number may vary in different modifications. The innovative part of such a device is the so-called double clutch. Its main advantage and feature is that it allows you to transmit torque without interrupting the power flow.

All this became possible precisely thanks to the presence of a second clutch, that is, the robot pre-selects the next gear and sends this data to the second disk, while the first one is still working in the current gear at engine speed. It’s very convenient, and most importantly gentle on both RGG itself

, and for the engine as a whole.

Our verdict

Compared to the previous version, the new AMT has become clearer for the driver and more comfortable for everyone in the car. If you don’t treat the robotic Vesta as a racing car, then your impressions of the car are extremely positive. The robot is still for those who are not in a hurry. Well, for those who are used to driving, there is a manual Lada Vesta Sport.

Automated manual transmission, or AMT for short, is quickly conquering the market and is in great demand among consumers. What helped the box gain popularity was its ease of use and comfort when driving a vehicle.

Car manufacturers also pay a lot of attention to the mechanism and rely on further use and improvement of the box. It's all about a large number of positive nuances, these are: simplicity and reliability of the design, relatively small dimensions and weight, low production price and the main feature is decent fuel economy. It is no coincidence that this type of box is actively installed on Lada cars produced by AvtoVAZ PJSC.

What it is

AMT – Automatic-manual transmission, literally deciphered . It is based on conventional mechanics. Only the correct gear shifts on a manual transmission are carried out by the driver, and in it - the electronic unit. It “sorts out” speeds based on its operating algorithm. Therefore, depending on the quality of the unit’s firmware, the operating characteristics of the AMT box depend - fuel economy, vehicle response, shift speed, etc.

This transmission combines the reliability of a manual transmission, the efficiency and convenience of automatic transmissions. An important factor in choosing a robot is its price. It is an order of magnitude cheaper than a machine gun. For this reason, many car manufacturers are moving away from classic automatic transmissions towards robotic gearboxes.