5 / 5 ( 1 voice )

The attitude of drivers towards robotic gearboxes is ambiguous. Some people categorically do not want to buy a car with such a transmission, while others consider the “robot” to be an excellent compromise between a manual and an automatic transmission. If we talk about the DSG-6 DQ250, then this 6-speed gearbox with a “wet” clutch is more reliable than its “dry” counterparts. Due to the fact that the parts are in an oil bath, it is not so susceptible to overheating, and the clutch wears out less quickly. With timely maintenance, this gearbox will delight you with a comfortable ride for a long time. Let's figure out how and when to service the DSG-6 DQ250 and how much it costs.

What reduces transmission life?

The service life of a robotic transmission largely depends on driving style and its operation. To ensure that the gearbox lasts a long time, follow the following recommendations:

- Avoid jump starts. When you start driving suddenly, the clutch closes very quickly and therefore wears out a lot.

- When driving in traffic jams, use manual or sport mode.

- Avoid jerks and frequent lane changes at a flow speed of 40-50 km/h.

- To control speed in traffic jams, press the brake pedal firmly, only in this case the clutch discs open. When you press the pedal lightly, they slip and wear out.

- Overloads lead to overheating and breakdown of the mechatronics.

- Don't shift into neutral too often. This reduces the resource of mechatronics. At traffic lights, just press the brake pedal hard, then the discs open. Engage neutral only when stopping for a long time.

- When parking on a slope, use the parking brake. This takes the load off the gearbox.

- To carry out timely repairs, diagnostics of mechatronics and clutch clearances must be carried out every 30-50 thousand km. This will allow you to eliminate minor faults in a timely manner and avoid costly repairs.

If you take these simple recommendations as a rule, you can significantly increase the transmission life.

Check before purchase

Buyers of cars with DSG often wonder how to recognize that the gearbox is dying. There are more than enough tips and general recommendations, but the question is: are they true?

Experts recommend turning on mode “D” and releasing the brake pedal. The car should start moving on its own without pressing the gas pedal, and the transmission should shift smoothly and without jerking to second gear. There should be no rough jerks either while driving or during acceleration.

However, a more accurate state of the box will be shown by a complete diagnosis of its electronics, in particular, the data in the measured value block. Any deviations from the norm are visible here, so a real specialist can easily determine the real condition of the DSG. It is noteworthy that in Western Europe, good sellers quite often show buyers an extract from a block of verified values.

Average parts life

Each car owner must know the service life of individual transmission components and parts, and prepare for their replacement in a timely manner. The average clutch life is 110-120 thousand km. But if you do not follow the basic recommendations for operating the “robot,” then this unit will have to be replaced much earlier.

Mechatronics breakdowns occur due to clogging of the electromagnetic valves with metal shavings. This usually happens after 90-100 thousand kilometers. If you change the oil in the box more often, you can drive it much longer without repairs.

The mechanical part of the DSG-6 DQ250 is quite reliable and usually lasts more than 150-200 thousand km. But if used incorrectly, craftsmen have to deal with problems such as breakage of forks and destruction of the housing on the side of the input shaft.

Automatic transmission DSG6/02E/DQ250. general review

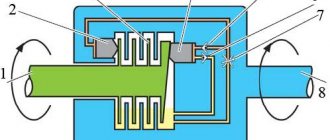

Automatic transmission of the VAG concern DSG6 02E (aka DQ250) is a robotic transmission with a double clutch located in a “wet” bath.

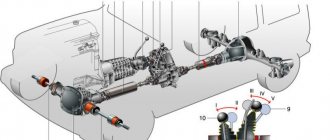

This unit was developed jointly with the American company Borg Warner and was installed from approximately 2003 to 2015 on a large line of cars: - Audi: TT, Q3;

— VW: Scirocco, Sharan, Touran, Golf, Golf Plus, Golf GTI, Passat, Passat CC, Jetta;

— Skoda: Octavia, Octavia RS, Superb, Yeti;

— Seat: Leon, Toledo, Alhambra, Altea;

There are cars with both front-wheel drive and all-wheel drive. In terms of service life and reliability, DSG6 showed comparable results regardless of the type of drive.

As conceived by German automakers, the DSG robot replaced “classic automatic transmissions” and CVTs.

During the production process there were several modifications to the DSG6 in terms of mechatronics and other components. The reason is the initial design flaws, which VAG consistently corrected.

Initially, 02E was installed on powerful 300-horsepower engines. It turned out that this automatic transmission cannot withstand such power in terms of resource. Therefore, VAG subsequently reduced the power of the engines on which the 02E gearbox was installed.

In 2009, the 02E was replaced by the more powerful DSG7 DQ500 (0BT/0BH).

Design features of DSG6 (02E/DQ250).

The entire transmission is completely in one oil bath, like a wet Powershift 6DCT450.

Structurally, the automatic transmission can be divided into two halves: hydraulic and mechanical. Hydraulic elements: mechatronics, clutch and pump. Mechanical elements: differential, shafts and gears. Like all “robots,” the main failures are mechatronics and clutch. This also includes the differential.

Basic malfunctions of DSG6/02E/DQ250.

- Differential.

Due to the high engine power, the differential cannot withstand loads. Much depends on the nature of the vehicle's operation. When it experiences loads in the form of sudden starts and accelerations, the life of the differential and clutch quickly decreases.

Differential DSG6 02E

Differential wear is expressed in the form of play and parasitic movement of the “finger”. Subsequently, the “finger” is completely broken, and chips are formed as a product of differential wear. Chips get into the pump and mechatronics, causing them to fail.

When the pump becomes clogged with wear products, it begins to jam. The pump has a rod that eventually shears off.

Pump DSG6 02E

It also clogs the oil supply tube for shaft lubrication with shavings. When one of the oil channels becomes clogged, oil is not supplied to the shaft - oil starvation occurs and the shaft fails.

Oil supply pipes DSG6 02E

A faulty differential 02E makes itself felt by noises and crunches. At the same time, due to the wear products of the differential, the mechatronics begins to work incorrectly, which is expressed in jerks, jolts and slipping of the automatic transmission. The noise of the DQ250 differential can initially be observed only at certain speeds - the satellites do not fit perfectly and begin to make noise.

The service life of the differential depends on the operating conditions and driving style of the car owner. The average resource in megacities is from 130,000 km. mileage

If the differential breaks down, it is either replaced with a used one in working condition or with a rebuilt one. There are no new DSG6 differentials on sale. Therefore, specialized services always have a certain number of differentials in stock for their prompt use during repairs.

- Mechatronics.

Symptoms of mechatronics malfunction:

- shocks, jerks, slipping;

- crunches;

- vibrations;

- emergency mode.

Crunches appear due to improper operation of the forks. Accordingly, the synchronizers do not engage the transmission.

Mechatronic DSG6 02E. The board (control unit) is visible from above

The transmission goes into emergency mode as sensors detect improper operation of the mechatronics.

Vibrations occur due to improper operation of the clutch, which in turn is caused by improper operation of the mechatronics. Thus, along with the mechatronics, the clutch also begins to fail.

On board the mechatronics there is an electronic control unit (mechatronics board 02E) and electromagnetic valves (hydraulic part of the mechatronics).

Much less often than the hydraulic part, the mechatronics board fails. A board malfunction makes itself felt by electronic errors. In very rare cases, the board fails, but no errors appear. Here the malfunction can be determined by the method of elimination, checking the performance of the hydraulic part of the mechatronics, clutch and mechanical part (differential, shafts and gears) and relying on the symptoms.

The average service life of the DSG6 board in traffic jams in megacities is from 150-200 thousand km. mileage

If the DQ250 board malfunctions, replace it with a new one or a used one. Board repair is not applicable.

Hydraulic part of mechatronics DSG6 02E

If the board is replaced, the new board is flashed using the vehicle's VIN number. Also, if possible, the software is “merged” from the old board and “poured” into the new one. There are no difficulties with selecting a board. There are difficulties with the equipment that allows flashing boards.

The resource of the hydraulic part of the mechatronics turns out to be less than the resource of the board. This is both a consequence of the natural wear of the mechatronics itself and the wear of the differential, as mentioned above.

- Clutch.

Symptoms of a faulty clutch:

- vibrations when starting;

- shocks of 1-2 gears;

- slippage.

These symptoms are more likely to occur when the transmission is not warmed up. Mechatronics, on the contrary, shows its malfunctions more when the box is warmed up.

Clutch DSG6 02E

The average clutch life of the DSG6 in traffic jams in megacities is from 120 thousand km. mileage Again, a lot depends on the operation.

Solution options: buy a new clutch, buy a refurbished clutch, buy a used clutch. Nowadays, the optimal solution in terms of price/quality ratio is a rebuilt clutch. The resource and warranty for the restored clutch are the same. For example, in our technical center the warranty will be 1 year without mileage limitation. Therefore, there is no particular point in buying a new 02E clutch.

As with all robotic automatic transmissions, mechatronics works in tandem with the clutch. Therefore, the failure of one node automatically leads to the failure of another node. With a command from the mechatronics, oil pressure is applied to the clutch and it is squeezed, transmitting torque to the input shaft. The shaft transmits torque to the differential and, accordingly, to the drives.

- Shafts and gears of the mechanical part of DSG6.

It can be noted that mechanical wear is relatively rare, provided that the oil supply tube is not clogged. Average resource – from 200 thousand km. mileage Typically shafts fail due to oil starvation.

Shafts and gears DSG6 02E

Diagnostics DSG6/02E/DQ250.

Robotic transmissions use a large amount of electronics. Therefore, if the symptoms and error codes are known, an experienced technician can immediately determine the source of the malfunction.

To determine clutch wear, you can do mechanical diagnostics by taking an oil sample to check for burning.

Differential wear is determined by the presence of chips after dismantling the DSG6 housing cover.

The results of the initial diagnosis of DQ250 will be as follows:

- automatic transmission faulty: yes/no;

- mechatronics faulty: yes/no;

- mechatronics board faulty: yes/no;

- clutch faulty: yes/no;

- mechanical part is faulty: yes/no.

If there are chips in the transmission and the box operates with kicks/jerks, then the automatic transmission will be completely disassembled, at least to repair the mechatronics and mechanical parts. When disassembled, the clutch will look the same. If the clutch is in good condition, then there is no need to change it.

Pallet DSG6 02E

Repair of DSG6/02E/DQ250.

There are no particular difficulties with installation/disassembly of this box. The complexity is comparable to conventional mechanics. A good mechanic will remove the DSG6 in half an hour.

The timing of DSG repair depends on the amount of work to be done. Mechatronics can be repaired in 1-2 days. The clutch can also be replaced in the same 1-2 days. Overhaul of the 02E robot takes about three days. There is no shortage of spare parts.

The repair of such a transmission is provided with a 1-year warranty without mileage limitation.

The mechatronics can be removed separately without removing the box itself.

Tow truck.

If there are slight minor kicks/jerks, you can get to the service center on your own.

If the transmission goes into emergency mode, then there are no special options other than a tow truck.

If a faulty clutch slips, or when there are crunches/noises, it is better not to risk it and immediately call a tow truck. Each slip is accompanied by a push, and accordingly a huge load is transferred to the differential.

Is it worth buying a used DSG6 automatic transmission?

DSG6 must be selected by letter designation on the body (for example, POU), or in a special selection program by VIN number.

You should try to look for a used 02E with minimal mileage. A specific instance can be checked by the condition of the drained oil (by unscrewing the drain plug), if the seller of the box allows this. If the oil is clean, you can buy this automatic transmission at your own risk. But again, it will be unknown what condition the mechatronics, clutch and differential are in. Otherwise, you can buy an automatic transmission 02E and get these components repaired in the very near future. Again, a used DSG6 is quite expensive - about 80 thousand rubles. only for the box.

After purchasing a used DQ250, you will also need to flash the control unit, or install software from the old unit. Don't forget about the costs of removal/installation, oil and filters.

Filter cartridge DSG6 02E

DSG6 service.

It is better to change the oil in DSG6:

- first replacement at 60 thousand km. mileage;

- second replacement at 120 thousand km. mileage;

- subsequent replacements every 40 thousand km. mileage;

When changing the oil, the filter cartridge is changed and 6 liters of the oil itself are drained. The total filling volume of 02E is about 9 liters.

There is also an internal filter in the box itself, but it is changed only if the entire automatic transmission is overhauled (replacing the clutch and/or repairing the mechanical part).

When replacing the clutch, it is also advisable to replace the heat exchanger (chips and clutch wear products accumulate in it), located on the transmission housing. For preventive purposes, it is better to change the heat exchanger every 150 thousand km. mileage

You can also remove the heat exchanger and install an adapter plate with leads on an additional radiator (purchased separately). There is also a composite plate to save both the heat exchanger and install an additional radiator. This heat exchanger (our unique development), unlike the standard one, can be removed and cleaned of wear products.

Keep an eye on cooling. The box is cooled by a flow of oncoming air passing through the radiators and entering the engine compartment. The DSG6 only has a heat exchanger that serves to heat the transmission in winter. When radiators (internal combustion engines and air conditioners) are clogged, air flow through them is difficult, and at best only the radiators themselves are cooled. In megacities traffic jams there is no air flow at all. Therefore, one of the factors leading to breakdowns of DSG transmissions is overheating caused by insufficient cooling due to clogged radiators. The transmission overheats, the mechatronics overheats, the valves begin to jam, and then the clutch fails. In one summer season in such conditions you can completely destroy the box. Therefore, in the spring, it is better to come to a specialized service center for an initial diagnosis of the automatic transmission, in order not only to assess the performance of the box, but also to look at the condition of the radiators and give a general assessment of the possibility of overheating of the DSG6.

Internal filter DSG6 02E

Checking DSG6 when buying a used car.

You should do a test drive in all transmission operating modes (hot, cold, in traffic jam mode) and pay attention to the symptoms: vibrations at start, jerking, extraneous noise.

It is advisable to stop by the service center and do an initial diagnosis of the automatic transmission: read the errors, look at the condition of the radiators, take an oil sample.

If everything turns out to be in order and the car is purchased, then the new owner should change the oil and filters. In the future, if you have the slightest complaints about the operation of the DSG, it is better to immediately contact a specialized service for repairing such transmissions.

Clutch 02E should also be adapted periodically. The approximate schedule for this procedure is every 60 thousand km. mileage But you need to take into account that if the clutch is seriously worn, the transmission may not undergo adaptation. In this case, you will have to change the clutch. To determine whether the adaptation procedure will help, or whether the clutch needs to be replaced, diagnostics of the box will be required.

If you have any questions, write comments under this article, or call our specialist directly. The phone number is listed in the “Contacts” section. Also, through any messenger you can send the technician photos of spare parts, error codes, etc., or you can also call and consult on any issue.

How often to adapt

If the box starts to “kick” and vibration appears, the first thing to do is adaptation. This procedure costs 1500-2000 rubles. and in the absence of other malfunctions gives excellent results. During adaptation, the gear shift points are synchronized and the clutch is precisely calibrated.

Adaptation must be carried out when replacing the engine with a more powerful version, as well as after chip tuning. Otherwise, the checkpoint will not work correctly.

Even if there are no problems with the gearbox, it is recommended to carry out adaptation every 30-60 thousand km. This will make the operation of the transmission more precise, avoid jerking when moving, and incorrect gear shifting.

Practice shows that many drivers come for adaptation only after unpleasant symptoms appear. This can happen even during the first 15-20 thousand of the car's mileage. Service center technicians recommend carrying out adaptation according to the regulations, and not waiting for signs of malfunctions. Clutch discs wear out, so the gearbox settings need to be adjusted periodically. This will extend the life of the transmission.

Do I need to clean the radiator?

The DSG-6 DQ250 does not suffer from overheating as often as “dry” gearboxes, but this possibility cannot be ruled out. The cooling efficiency of parts largely depends on the cleanliness of the radiator. If it is clogged with dirt, dust, poplar fluff, then at the slightest load the transmission will overheat.

It is imperative to clean the radiator when changing the oil. It is also recommended to carry out this procedure during the poplar flowering season, after long trips in dirty weather. It is better to remove contaminants once again than to face overheating of the gearbox.

Most common problems: DQ250

Most often, breakdowns of the Mechatronic electronic unit occur in this box:

as well as parallel clutch drum No. 131550A:

After changing the settings of computer programs, drivers’ capabilities associated with sudden maneuvers on congested city highways received significant restrictions. Now the technical characteristics and operational capabilities of the DSG 6 DQ 250 gearbox are almost no different from their competitors - CVTs, as well as multi-stage automatic transmissions like GM.

The service life of the DSG DQ250 gearbox on average does not exceed 2–5 years of service. During this period, people most often contact service stations with the following problems:

- increased transmission vibrations;

- box shaking;

- jerking of the vehicle when changing gears;

- failure of the double clutch mechanism;

- speed sensor failure;

- clogging of hydraulic system channels as a result of failures of electromagnetic solenoids;

- the presence of suspensions, chips and metal dust in the gearbox housing;

- failures of electronic devices and sensors Mechatronics.

To change or not to change the oil?

The DSG-6 DQ250 instruction manual says that there is no need to change the oil. But this recommendation is relevant for ideal European roads and countries where few people drive cars with a mileage of more than 100-150 thousand km. In Russian realities, it is still necessary to change the transmission fluid. The official dealer recommends doing this every 60 thousand km, but practice shows that when operating a car in large cities, where there are often traffic jams on the roads, the optimal replacement interval is 40-45 thousand km.

Technicians who often drain transmission fluid and repair gearboxes see the condition of the oil. After 50 thousand mileage, there are quite a lot of metal shavings in it, which clog the mechatronics solenoid valves.

The conclusion is simple: if you want to drive your car longer, you need to change the oil more often. This is quite an expensive undertaking, but repairs will cost even more.

6-speed preselective robot DSG-6 DQ250

This gearbox first became known in 2003. Immediately after its appearance, they decided to equip the fifth generation Volkswagen Golf with a robot. The transmission is also known under another designation - 02E DSG-6. It was originally designed for cars with an engine of up to 3.2 liters and a torque of no more than 350 Nm. Later, the permissible torque began to be reduced, since in practice the box caused problems. It works on the double clutch principle: when the first clutch operates at an odd speed, the second shaft prepares the next even speed. This is where the name preselective comes from, which in other words is “prediction.” That is, in fact, the box anticipates the need to switch to another speed. This ensures instantaneous gear changes (less than 0.01 sec), and, most importantly, without any actual loss of power.

How much does an oil change cost?

It is recommended to use only original oil G 052 182 A2. Non-original oils are 1.5-2 times cheaper, but dubious analogues from unknown manufacturers can lead to transmission failure, so it’s not worth the risk. For a complete replacement, you need about 7 liters of transmission fluid, the purchase of which will cost about 9000-9500 rubles. You will also need an oil filter 02E.305.051.S, its cost is about 1,500 rubles. It is also recommended to replace the filter seal and plug; these consumables will cost 200-250 rubles. You can use a quick gearbox cleaner, the price of which is about 300 rubles. Thus, if you decide to replace the transmission fluid yourself, this procedure will cost an amount not exceeding 11,500-12,000 rubles.

The cost of changing the oil from an official dealer is 2000-2500 rubles. At many official service stations you can purchase original consumables at a substantial discount, so you will save time and overpay quite a bit.

At different service stations they can perform an oil change for 1000-1500 rubles. and also offer transmission fluids at prices starting from 800 rubles. per liter But whether there is any point in such savings is up to you to decide, because no one gives any guarantees in this case.

Bottom line

Servicing the DSG-6 DQ250 is far from cheap, but repairs will cost even more, and it is inevitable if you do not pay due attention to the robotic gearbox. If you plan to drive the car just a little and then buy a new one, you can follow the manufacturer's recommendations and not change the oil. But if you want the box to last for a long time, listen to the recommendations of the official dealer and do not skimp on consumables.

DSG-6 DQ250

Original oil G 052 182 A2

Oil filter 02E.305.051.S

Oil filter gasket N 91084501

edit this post