Lubrication system on KamAZ

The KamAZ 740 engine lubrication system of Euro-2, -3 and -4 classes is a whole complex of equipment for storing and delivering oil to the elements of the power unit, cleaning and cooling the lubricant:

- Engine oil pan: a trough-shaped container, divided from the inside into two parts. An oil intake is provided in the deep part of the pan. To ensure that oil is delivered to the oil intake without interruption, the pan is equipped with a partition. The pan cools the oil due to contact with the walls and heat exchange between the walls and the environment. The pans of new engines are equipped with one drain hole, old ones - with two.

- Oil intake: this part is located in the deep part of the pan and is used to deliver oil to other components of the power unit. The oil intake is equipped with a coarse filter and a tube connected to the oil pump.

- Oil pump: equipped with a fine filter, provides an optimal level of pressure to deliver oil to the main line.

- Oil lines: through them, oil is delivered to the rubbing parts of the engine - the compressor, connecting rod bearings, etc.

- Oil cooler: this element of the system is responsible for cooling lubricants at air temperatures above 0 ° C. If the ambient temperature is below 0 °C, the oil cooler is switched off.

- Breather: Through ventilation, it removes the resulting fuel vapors and exhaust gases, preventing lubricant dilution.

- Monitoring equipment and sensors: this is modern equipment that notifies the driver about the pressure level in the lubrication system, its emergency drop and clogging of the full-flow filter.

- Centrifugal filter: cleans the oil from foreign components. Under pressure, the rotor causes the oil to move; after cleaning, it flows into the radiator or, through the drain valve, into the oil pan.

Modern KamAZ 740 engines use the following principle of the lubrication system: oil is delivered to parts with the highest load under pressure, to others - by gravity or injection.

Properly selected oil of the required viscosity and high quality will extend the life of KamAZ engine components and stabilize its temperature during overloads.

KamAZ-740 engine lubrication system. Diagram with explanations.

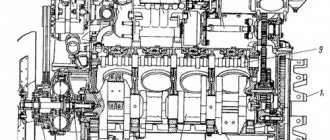

The engines of KamAZ vehicles use a combined lubrication system. Depending on the placement and operating conditions of the parts, oil is supplied either under pressure, splashing, or gravity. Oil is supplied to the most loaded parts under pressure, to the rest - by splashing and gravity flow.

The lubrication system is a series of devices and units for storing, supplying, cleaning and cooling oil:

- engine oil pan;

- oil intake;

- coarse oil filter;

- fine oil filter;

- oil pump;

- oil lines;

- oil radiator;

- instrumentation and sensors.

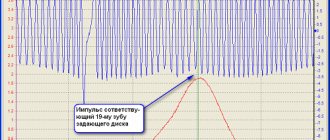

Oil from the sump flows through an oil receiver with a strainer into the oil pump sections. From the discharge section, oil is supplied through a channel to a full-flow filter, and from there to the main oil line. Then, through channels in the block and cylinder heads, oil under pressure is supplied to the crankshaft and timing parts, fuel injection pump and compressor.

Oil is supplied to the connecting rod bearings through the crankshaft channel from the main journal closest to them. The supports of the rods and pushers of the gas distribution mechanism are washed by a pulsating jet, and the remaining parts are washed by splashing or gravity flow of oil.

Oil removed from the cylinder walls by oil scraper rings is discharged through drillings in the piston grooves into the piston and lubricates the piston pin supports in the upper connecting rod head and piston bosses.

From the main lubrication line, oil under pressure is supplied to the thermal power sensor, and when the fluid coupling valve is open, it is supplied to the fluid coupling itself.

From the radiator section of the oil pump, oil is supplied to the centrifugal (fine) filter and through the open oil cooler valve to the radiator itself, and from it to the engine sump. If the oil cooler switch valve is closed, then oil flows from the centrifuge (centrifugal filter) into the sump through the drain valve.

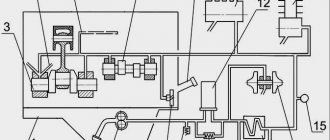

1 — centrifugal oil filter; 2 — oil radiator valve; 3 — bypass valve of the centrifugal filter; 4 — drain valve of the centrifugal filter; 5 — bypass valve of the full-flow oil filter; 6 - main oil line; 7 — full-flow oil purification filter; 8 — lubrication system valve; 9 — pressure section of the oil pump; 10 — radiator section of the oil pump; 11 — safety valve of the discharge section; 12 — oil radiator; 13 — safety valve of the radiator section; 14 - pallet; 15 — fluid coupling of the fan drive; 16 — thermal power sensor; 17 — fluid coupling valve; 18 — high pressure fuel pump; 19 - compressor; 20 — breather; 21 — oil level indicator; 22 - pressure gauge.

KamAZ engine fuel system

The KamAZ 740 engine is powered by a split-type fuel system. It includes the following elements:

- Fuel Tanks: Used to store fuel and prevent it from leaking and causing uncontrolled combustion. They are made of high-tech materials, equipped with a filler neck with a sealed cap and a filter mesh. The tank is also equipped with damper baffles that prevent fuel from splashing when the truck is moving.

- Fuel Pressure Pump: Also called low pressure fuel pump, it is used to transport fuel directly from the fuel tank to the injection pump.

- Filters: are represented by coarse and fine filters, which alternately clean the fuel before entering the injection pump.

- Injection pump: the high-pressure fuel pump delivers fuel from the tanks to the cylinders in measured portions at certain times.

- Injectors: inject fuel into the combustion chamber.

- Fuel Lines: Metal tubes that are used to transport fuel to the combustion chamber and drain excess fuel to the tank.

- Flare spark plugs: are part of an electric torch device that facilitates starting an internal combustion engine at subzero temperatures.

The fuel system of the KamAZ 740 engine is equipped with a manual pump for pumping diesel fuel when the engine is turned off.

Maintenance and repair of the KAMAZ engine lubrication system

The engine lubrication system shown in Fig.

37, combined, with a “wet” sump. A two-section oil pump is installed in the crankcase. There is a plug screwed into the bottom of the crankcase to drain the oil. There is an air-oil radiator to cool the oil. A fine filter is installed to clean the oil from contaminants. Additional oil purification is carried out in a centrifugal filter. The oil level in the crankcase is measured with a measuring stick (dipstick). To ensure normal operation of the lubrication system, valves are installed in it, and it is monitored using instruments.

The main defects of the lubrication system are: – clogged filters; – damage to the air-oil radiator; – reduction in oil pump performance; – breakage of the gear teeth of the oil pump drive.

Promotional offers based on your interests:

To replace the filter elements, you need to unscrew the drain plugs on the caps and drain the oil from the filter into a container.

Then you should loosen the bolt securing the filter cap and remove the cap along with the filter element, after which it can be removed from the cap.

In the same order, remove the second cap and remove the second filter element. After this, it is necessary to wash the filter caps in diesel fuel, replace the filter elements and reassemble the filter.

After assembly, the full-flow oil purification filter is supplied to the engine assembly, installed on the right side of the cylinder block, and when assembling the car, the signaling device terminal is connected by a wire to the red warning light on the instrument panel. The light comes on when the filter is clogged and the filter bypass valve is opened.

The centrifugal oil filter is disassembled and washed; The drain and bypass valves are adjusted, if necessary, after washing on the bench, after which the filter is assembled.

Reducing, bypass and drain valves are washed in diesel fuel without disassembly. The technical requirements for valves installed in the filter housing are as follows: the drain valve must be adjusted to a pressure of 0.05-0.07 MPa, the bypass valve - to a pressure of 0.6-0.65 MPa.

The filter is assembled in the reverse order of its disassembly, after which it goes to engine assembly. The filter is installed on the front cover of the cylinder block on the right side of the engine.

During major engine overhauls, the oil pump is checked at an oil pump inspection and testing stand. The stand tests pump performance, opening pressure of safety and limit valves. Safety valves should open at a pressure of 0.85-0.95 MPa. The limiting valve, designed to limit the pressure in the main line, should operate at a pressure of 0.40-0.45 MPa. If the oil pump does not meet the technical requirements, then the gears are replaced and the covers are ground.

Rice. 37. KamAZ-740 engine lubrication system

Source

Cooling system

KamAZ 740 engines use a closed liquid cooling system with forced circulation of coolant. This approach makes it possible to increase the boiling point of the liquid and prevent its evaporation.

The main task of this system is to create a high-quality thermal regime when the motor is turned on, and it consists of the following components:

- Radiator: its primary purpose is emergency cooling of liquid and its storage. The radiator is a structure of two tanks and a core. The upper tank is connected to the engine cooling cavity, the lower one is connected to the water pump, and it is also equipped with an outlet valve. The KamAZ engine cooling radiator is filled through an expansion tank, which at the same time acts as a compensator for the volume of heated liquid.

- Louvers: Installed on the radiator grille, they regulate the flow of air that passes through the cooling system. In winter, when warming up the internal combustion engine, the blinds are closed.

- Fan: used to control air flows that are directed to the radiator core - it works automatically using a fluid coupling, which transmits torque from the crankshaft to the KamAZ engine cooling fan. In addition, the fluid coupling can operate with the fan turned off or constantly running, when the coolant temperature is not taken into account.

- Centrifugal pump: used to force coolant to the cylinder block and other components of the internal combustion engine.

- Thermostat: a copper cylinder with copper powder, used to automatically control the temperature of the KamAZ engine and its heating after starting. The liquid heated by the cylinders is also sent here.

The cooling system provides the KamAZ 740 engine with an optimal operating temperature in any season, and therefore requires regular maintenance and maintenance.

The KamRemCenter company offers qualified service and repair of KamAZ engines.

You can also buy new and used engines from us with a quality guarantee and delivery throughout Russia. WE HAVE WHAT YOU NEED! +7